A kind of mixing method for preparing nitrile rubber/polyvinyl chloride alloy compound rubber by two-stage mixing

The technology of polyvinyl chloride and nitrile rubber is applied in the preparation technology of rubber-plastic alloy compound rubber, and the preparation technology field of NBR/PVC alloy compound rubber, which can solve the problem of high hardness of the blended rubber, high operation difficulty and large equipment loss. and other problems, to achieve the effect of less decomposition of the foaming agent, avoiding high torque and high production efficiency

Active Publication Date: 2022-06-10

王律杨 +1

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

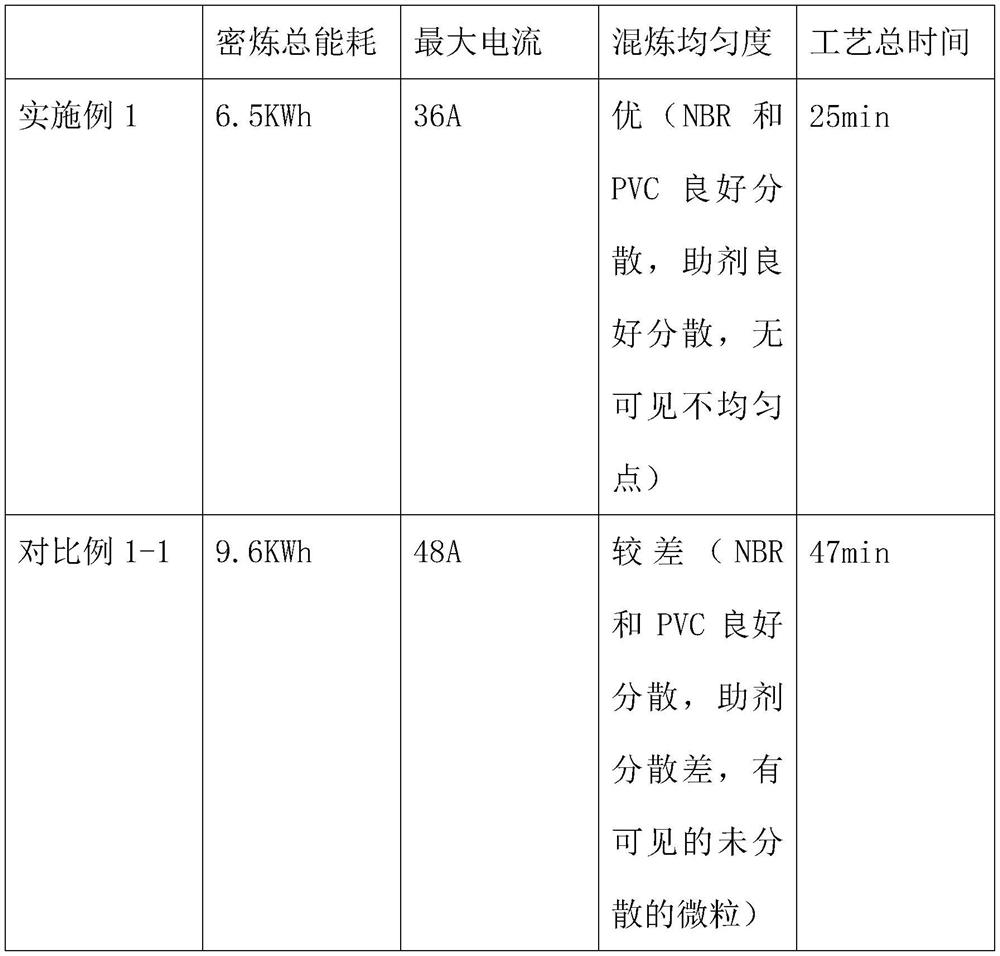

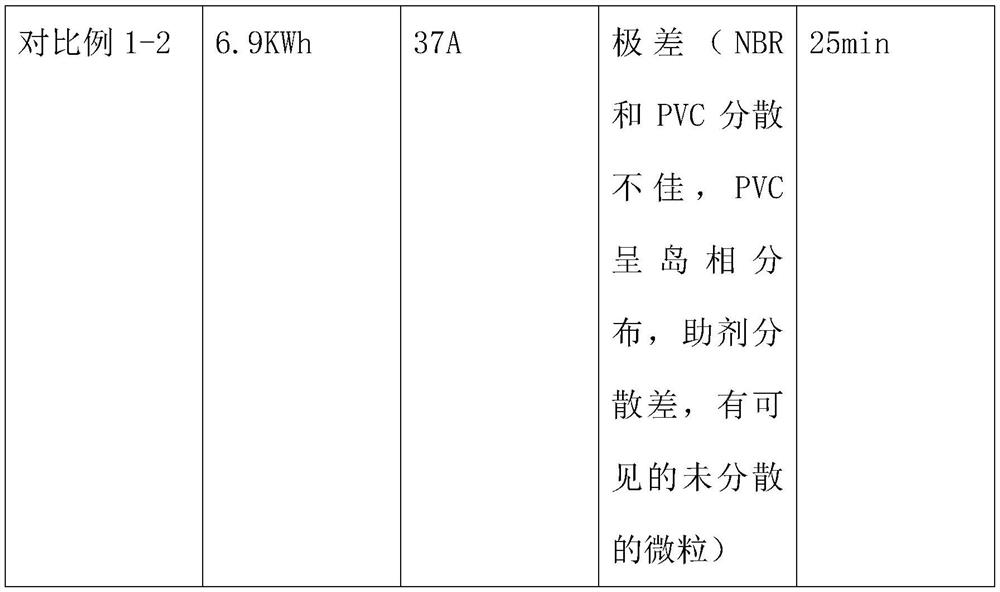

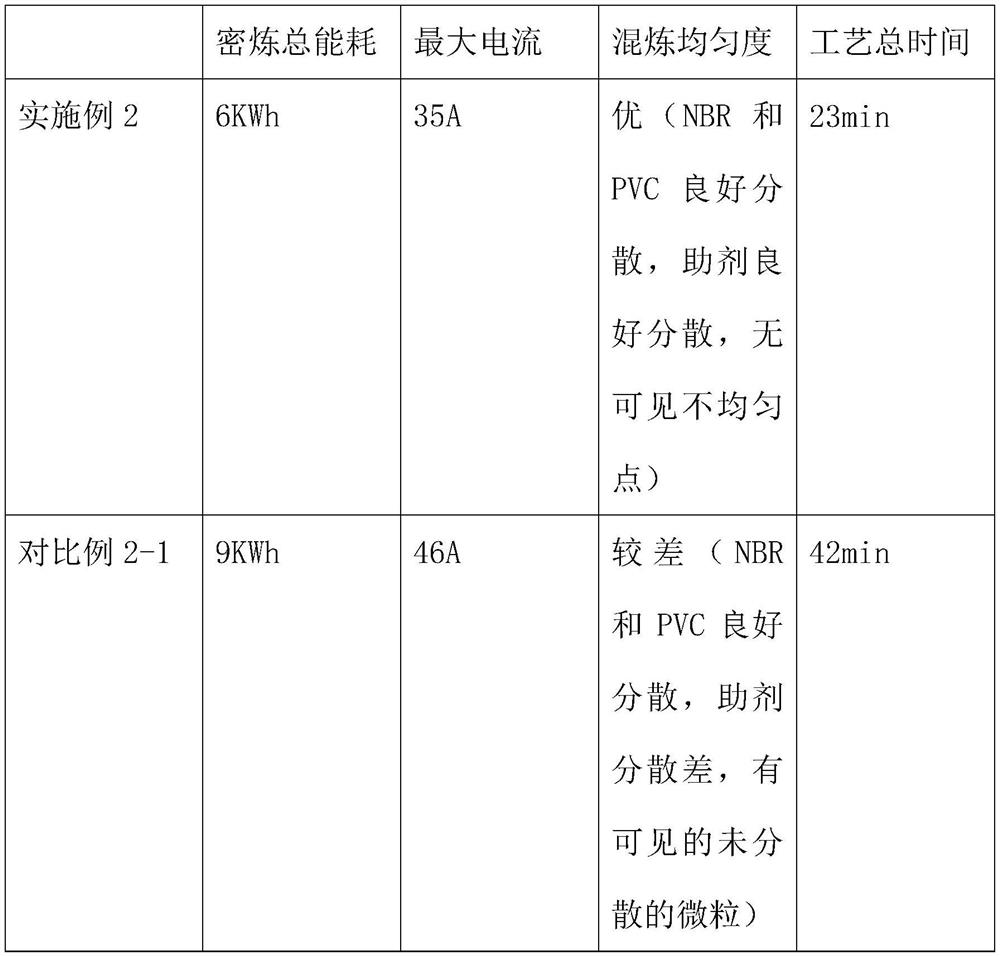

[0008] In the prior art, NBR / PVC compound rubber is generally mixed by two-step method, that is, NBR and PVC are mixed at high temperature first, and after being prepared into a blended rubber, other rubber additives are added after cooling, and then mixed. Discharge after reaching a certain temperature. This method has several obvious disadvantages. First, the energy consumption of mixing is very high. The preparation of the blend requires heating up. Adding rubber additives needs to be cooled before adding, and then heating up after adding. The two heating processes consume a lot of electric energy. The second is that the cooled NBR / PVC blend rubber has a high hardness, and re-mixing will cause a large loss of equipment, especially when the PVC content in the blend rubber is high. When the ratio of PVC and NBR exceeds 1:1, the operation of this method is more difficult and the loss of equipment is greater

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a mixing method for preparing acrylonitrile-butadiene rubber / polyvinyl chloride alloy compound rubber by two-stage mixing. The first stage is temperature-rising mixing, and the second stage is cooling mixing, which specifically includes the following steps: Add nitrile rubber, polyvinyl chloride, PVC stabilizer and high-temperature adhesive additives to the first-stage internal mixer, and during the mixing process The rotational speed is controlled so that the shear heat generation is greater than the heat dissipation, and the heat is generated at the same time during mixing. After mixing until the temperature reaches the first-stage discharge temperature, the material is discharged; after discharge, the material is directly put into the second-stage internal mixer without cooling; The final refining aid is added to the second-stage internal mixer at the same time, and the rotating speed and cooling conditions are controlled so that the material is cooled at a certain cooling rate while mixing. When the material temperature reaches a certain temperature after mixing, the material is discharged, and the mixing is completed. Thin the flakes in the mill.

Description

A kind of mixing of two-stage mixing to prepare nitrile rubber / polyvinyl chloride alloy mixed rubber method technical field The present invention relates to the technical field of mixing rubber preparation technology of rubber-plastic alloy, particularly relate to a kind of NBR / PVC alloy The field of compound rubber preparation technology. Background technique [0002] NBR / PVC blends are widely used in the preparation of foamed products, such as thermal insulation boards, cushions for sporting goods, handles, etc. Wait. In this system, NBR can provide good elasticity and feel, while PVC can play the role of skeleton in the system, The whole foaming system has good operability and stable product quality; in addition, NBR and PVC are both polar high molecular polymers, which have Good compatibility, so its application is more and more widely. On the other hand, the melting point of PVC is higher, and when it is blended with NBR, it needs to have enough when PVC is m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L9/02C08L27/06C08K13/04C08K13/02C08K7/26C08K3/04B29B7/74

CPCC08L9/02C08L27/06B29B7/7461C08K13/04C08K13/02C08K7/26C08K3/04

Inventor 王律杨张建其他发明人请求不公开姓名

Owner 王律杨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com