Plug valve

A plug valve and spool technology, applied in the field of plug valves, can solve problems such as unfavorable long-term use of products, loose plug valves, short service life, etc., and achieve the effects of avoiding errors, reducing processing errors, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

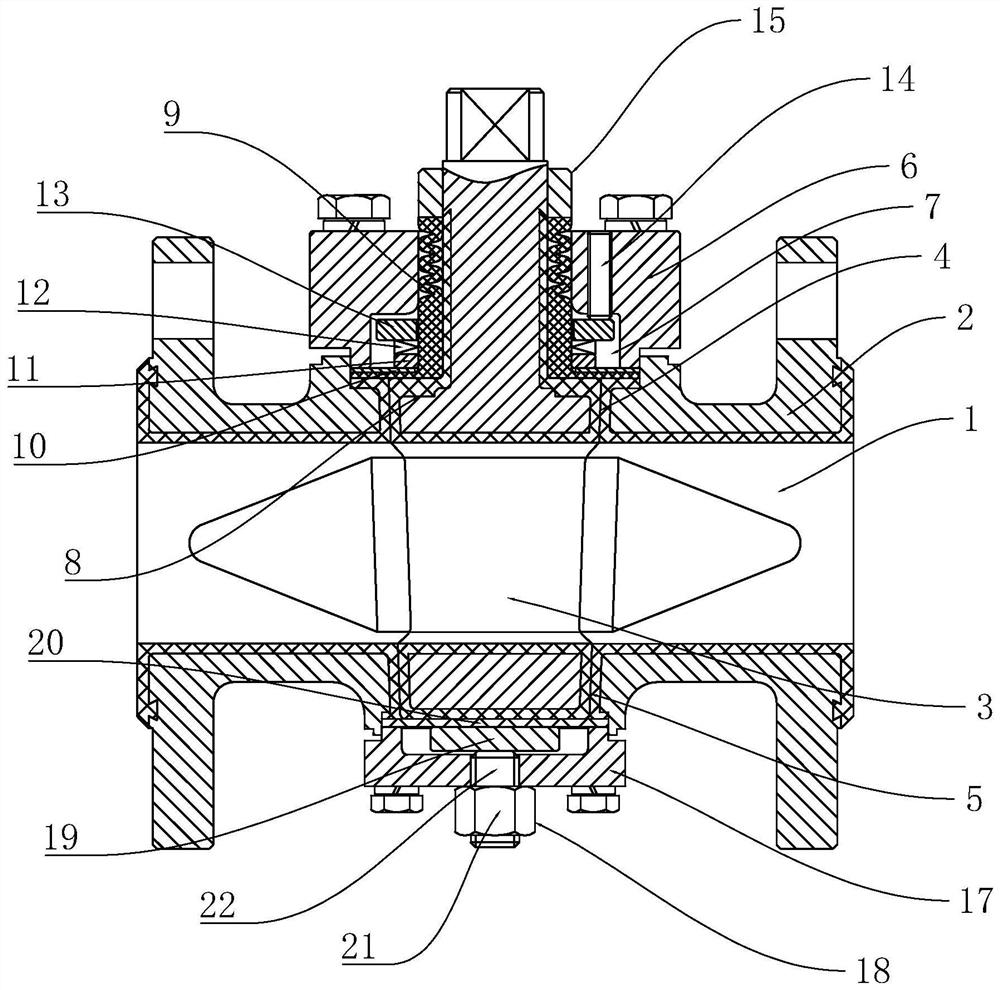

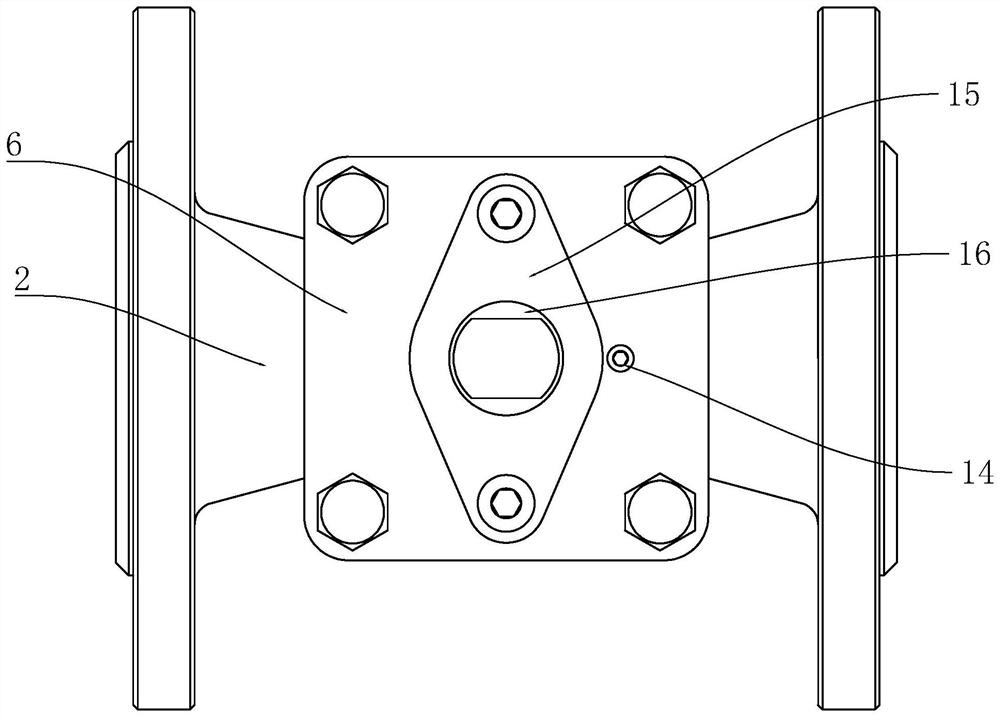

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] This embodiment discloses a plug valve, such as figure 1 , figure 2 As shown, it has the beneficial effects of facilitating processing, avoiding assembly and processing, damage caused during transportation, and multi-stage sealing. It includes a valve body 2 with a cavity 1, the cavity 1 runs through both sides of the valve body 2, and also includes a valve core 3 rotatably arranged in the valve body 2, and the valve body 2 is provided with a first installation channel 4 and a second The installation channel 5; the valve core 3 is set in the cavity 1 through the first installation channel 4; the valve body 2 is also provided with a first sealing part and a second sealing part; the first sealing part and the second sealing part An installation channel 4 cooperates to seal the upper end of the spool 3; the second sealing part cooperates with the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com