Gravity-hydraulic balancing device and method for an upper cone roll of a ring rolling mill and its transmission system

A technology of transmission system and hydraulic balance, applied in fluid pressure actuation devices, fluid pressure actuation system components, metal rolling, etc., can solve large frictional resistance, increase guide plate wear, increase equipment maintenance workload and Cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

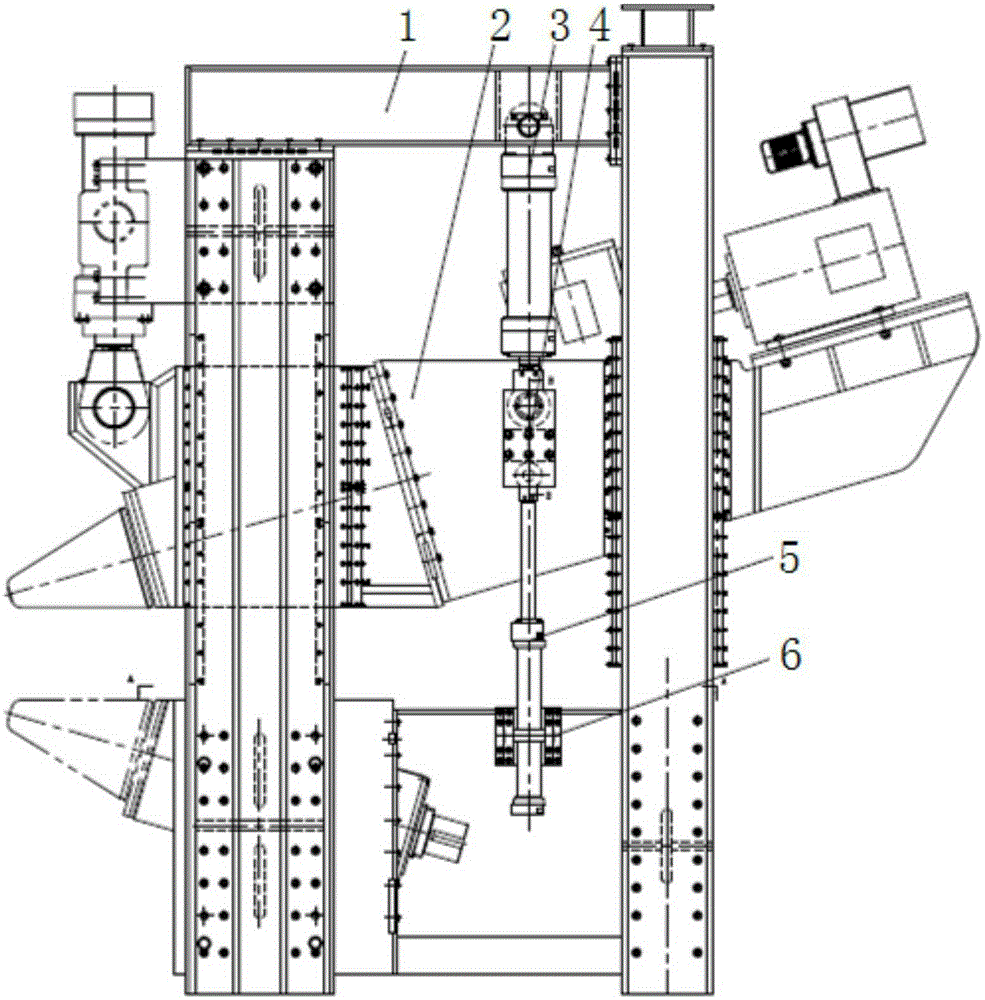

[0011] As shown in the attached figure, a gravity-hydraulic balancing device for the upper cone roll and its transmission system of a ring rolling machine, including the upper cone roll and its transmission system 2, and cylinders are installed at the positions of the gravity action lines on both sides of the upper cone roll and its transmission system 2 The head connection seat 4, the tail of the upper balance oil cylinder 3 is installed in the upper beam of the combined frame 1 through a hinge shaft, the head of the upper balance oil cylinder 3 and the upper end of the cylinder head connection seat 4 are connected together through a hinge shaft, and the lower balance oil cylinder The tail of 5 is connected with the lower beam of the combined frame 1 through the oil cylinder mounting seat 6, the head of the lower balance oil cylinder 5 and the upper end of the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com