Gravity balance structure of crane

A gravity balance, crane technology, applied in cranes, mechanical equipment, springs/shock absorbers, etc., can solve problems such as tipping, inclination of gondolas, inconvenient assembly of balancing devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

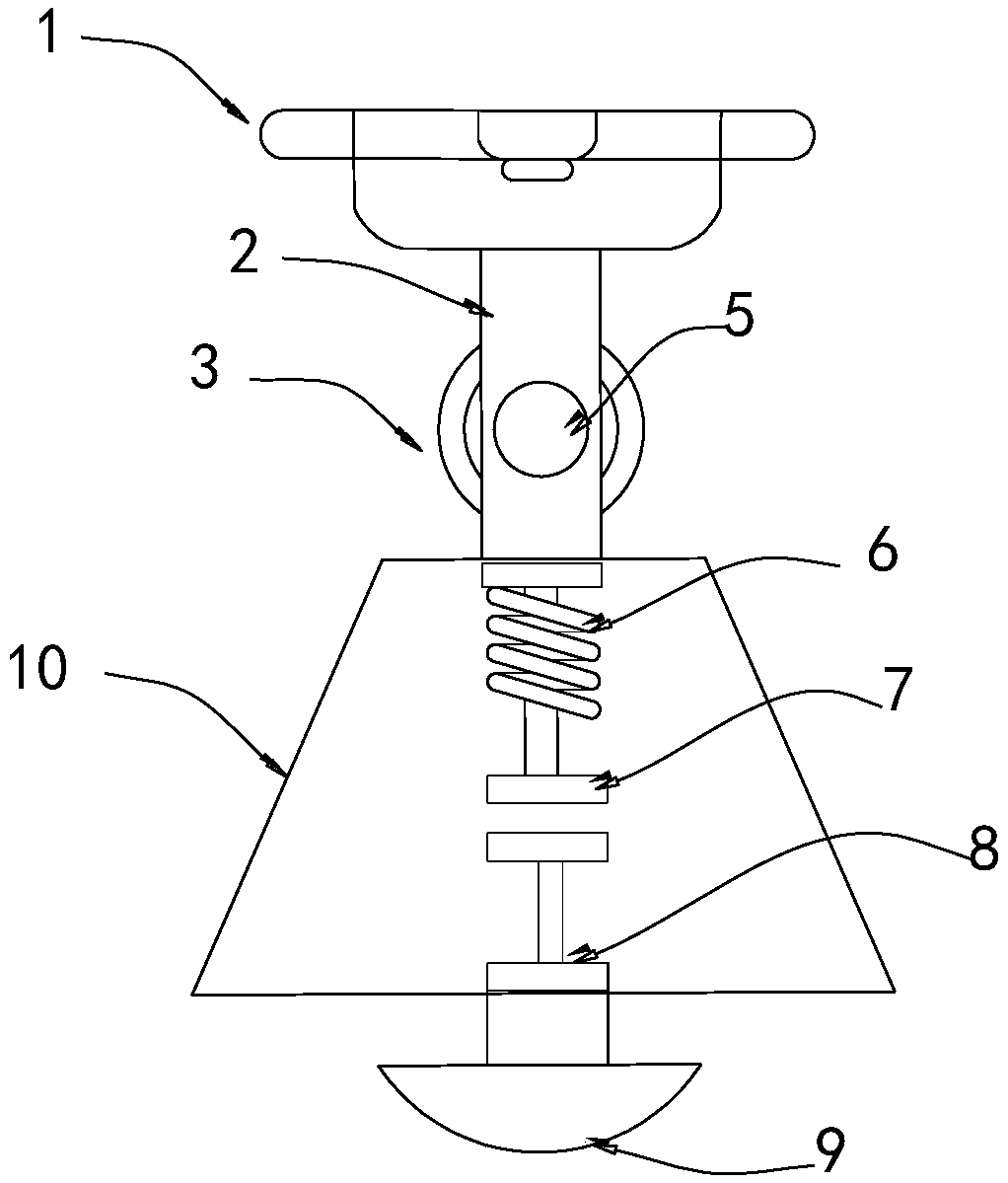

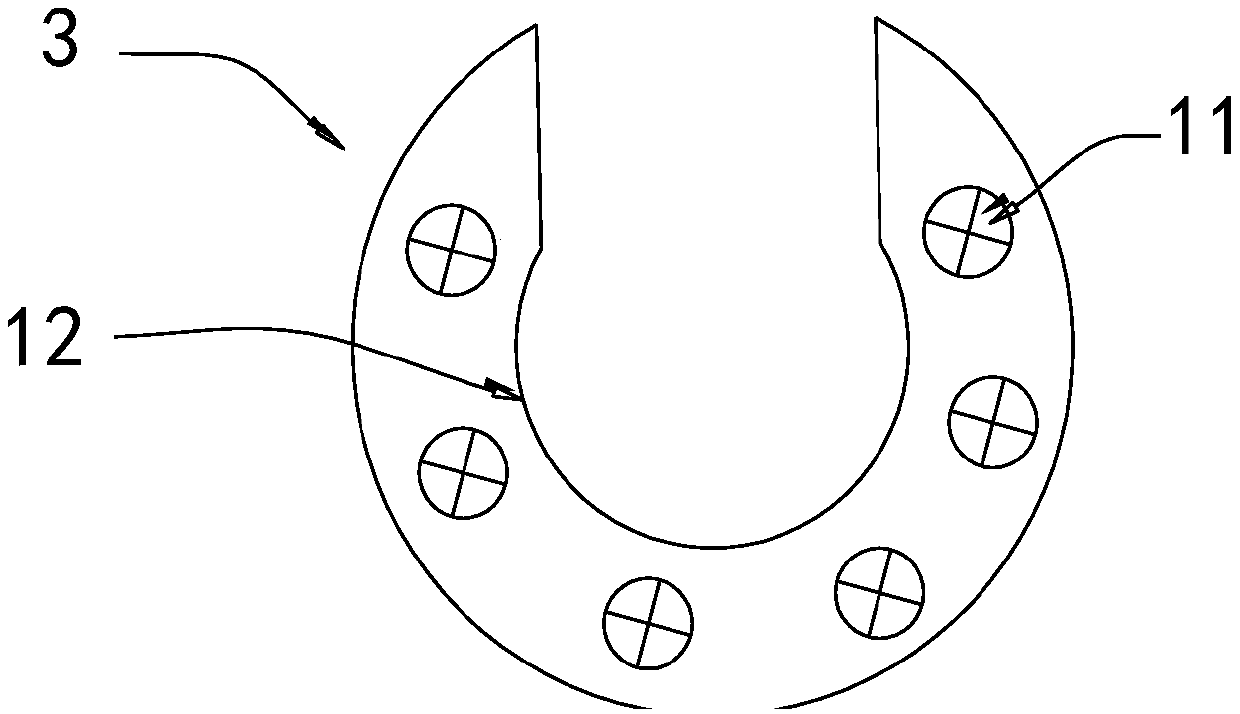

[0020] see Figures 1 to 2 , in an embodiment of the present invention, a crane gravity balance structure includes a boom ring 1, a connecting plate 2 is movably connected to the bottom of the boom ring 1, the boom ring 1 is arranged under the boom of the crane, and a connecting plate 2 is connected below the boom ring 1. The mounting base 10 is fixedly connected, the middle part of the connecting plate 2 is provided with an assembly plate 3, the connecting plate 2 is arranged at the opening of the assembly plate 3, and the connection plate 2 and the assembly plate 3 are connected with a fixed shaft 6 through the assembly plate 3. The inner end of the opening extends the limit section 12, the diameter of the limit section 12 is greater than the width of the joint between the assembly plate 3 and the connecting plate 2, and the limit section 12 is arc-shaped, passing through the limit section 12 of the arc, and the limit The diameter of the bit section 12 is greater than the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com