Pressing and rotating mechanism for gasket on cosmetic bottle body

A technology of gasket pressing and rotating mechanism, used in screw caps, liquid handling, bottle filling, etc., can solve the problems of affecting normal rotation, low efficiency, poor effect, etc., and achieve the effect of ensuring normal rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

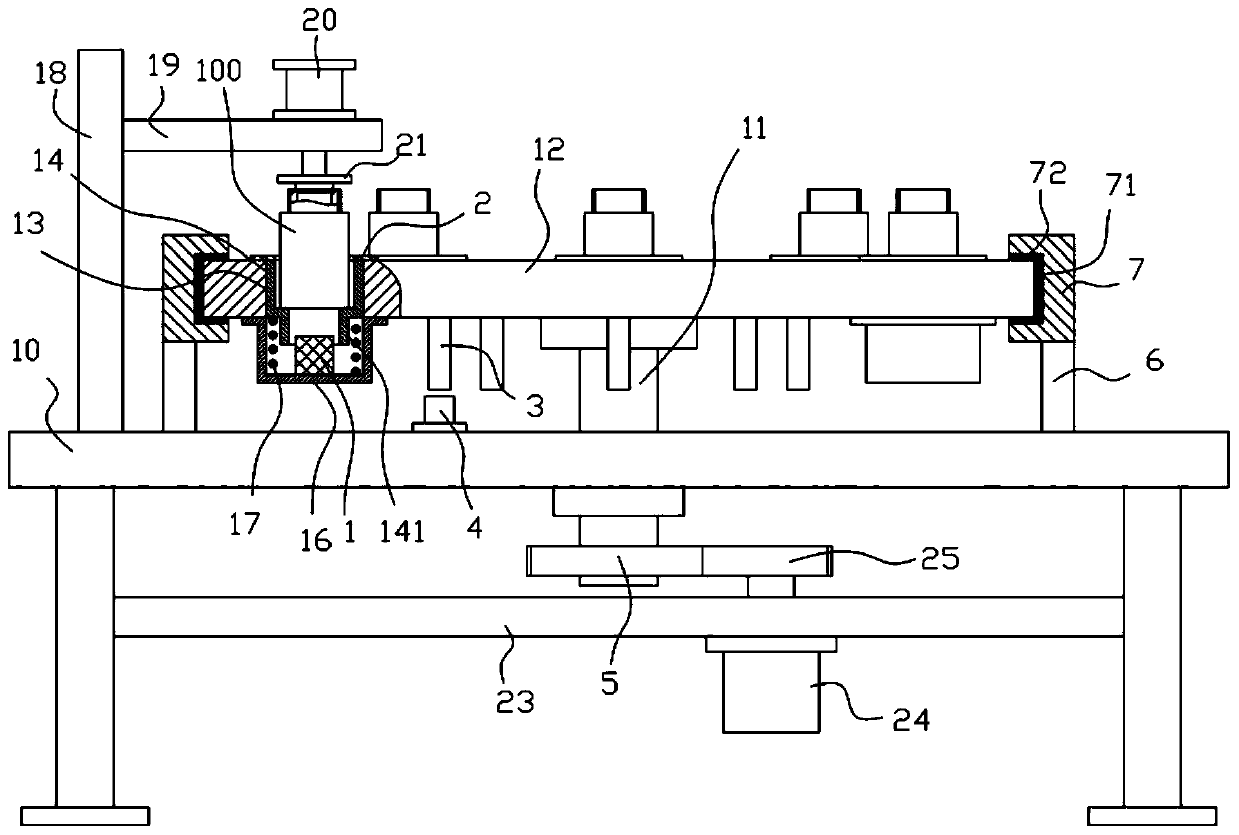

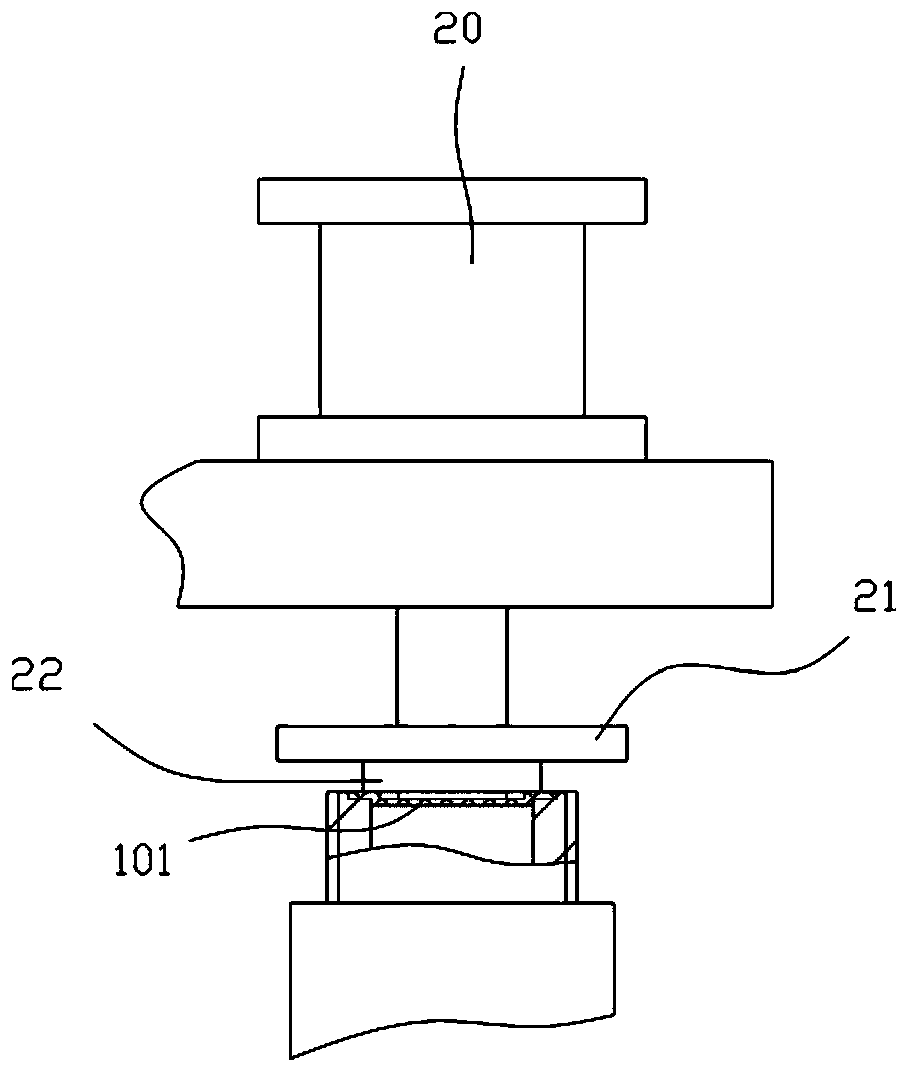

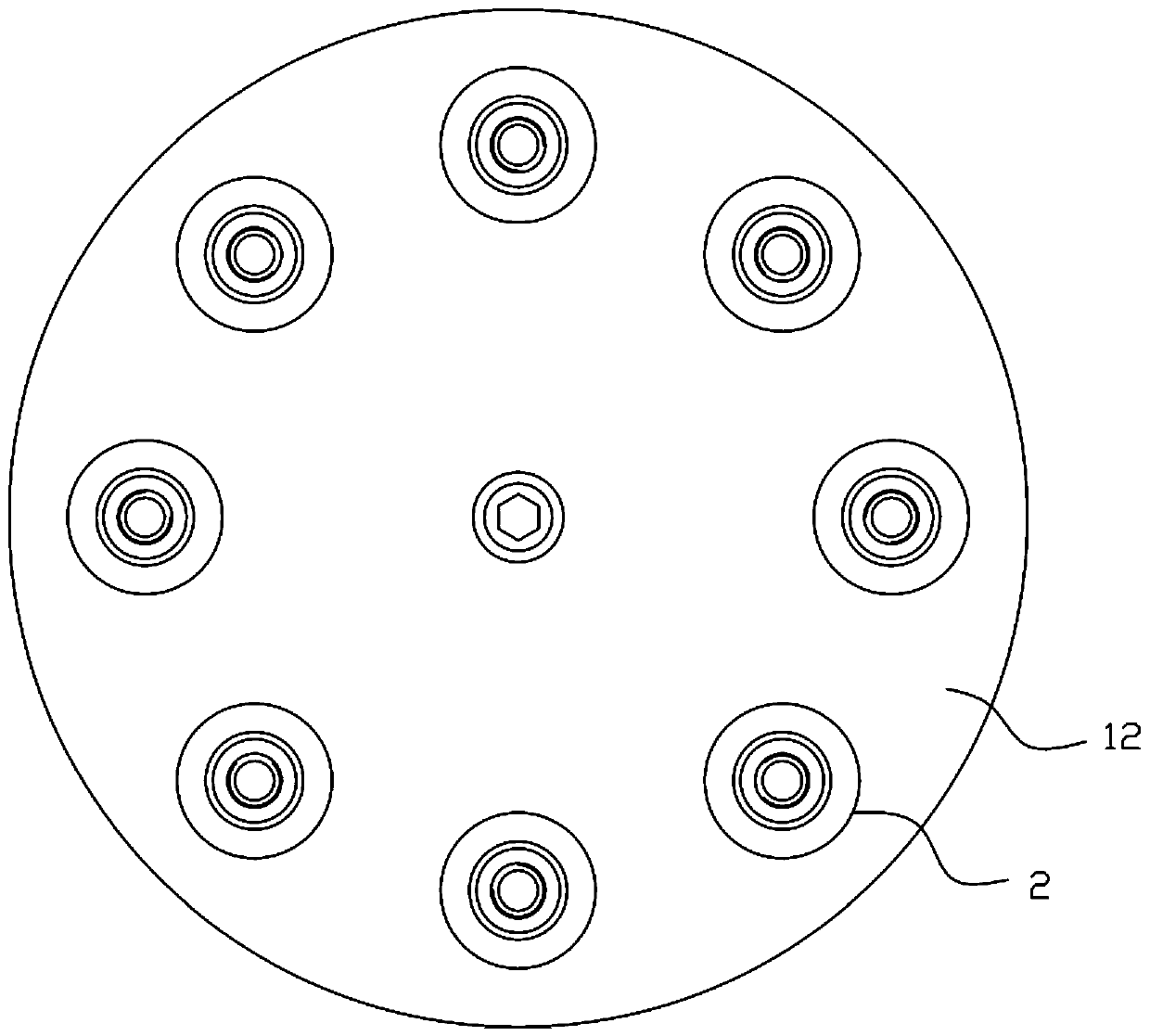

[0019] Example: see Figure 1 to Figure 3 As shown, a gasket compression rotation mechanism on a cosmetic bottle includes a frame 10, the middle part of the top plate of the frame 10 is hinged with a vertical main shaft 11, and the bottom end of the vertical main shaft 11 extends out of the top plate of the frame 10 The top of the vertical spindle 11 protrudes from the top of the top plate of the frame 10 and is fixed with a rotating disk 12. The edge of the rotating disk 12 is formed with a plurality of vertical through holes 13, and the guide sleeve 14 is inserted in the vertical In the through hole 13, the outer side wall of the guide sleeve 14 is close to the inner side wall of the vertical through hole 13, and the lower support sleeve 16 is fixed on the bottom surface of the edge portion of the rotating disk 12, and the lower support sleeve 16 is positioned at the front of the vertical through hole 13. Below, the top surface of the bottom plate of the lower supporting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com