Patents

Literature

34results about How to "Reduce mixing energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

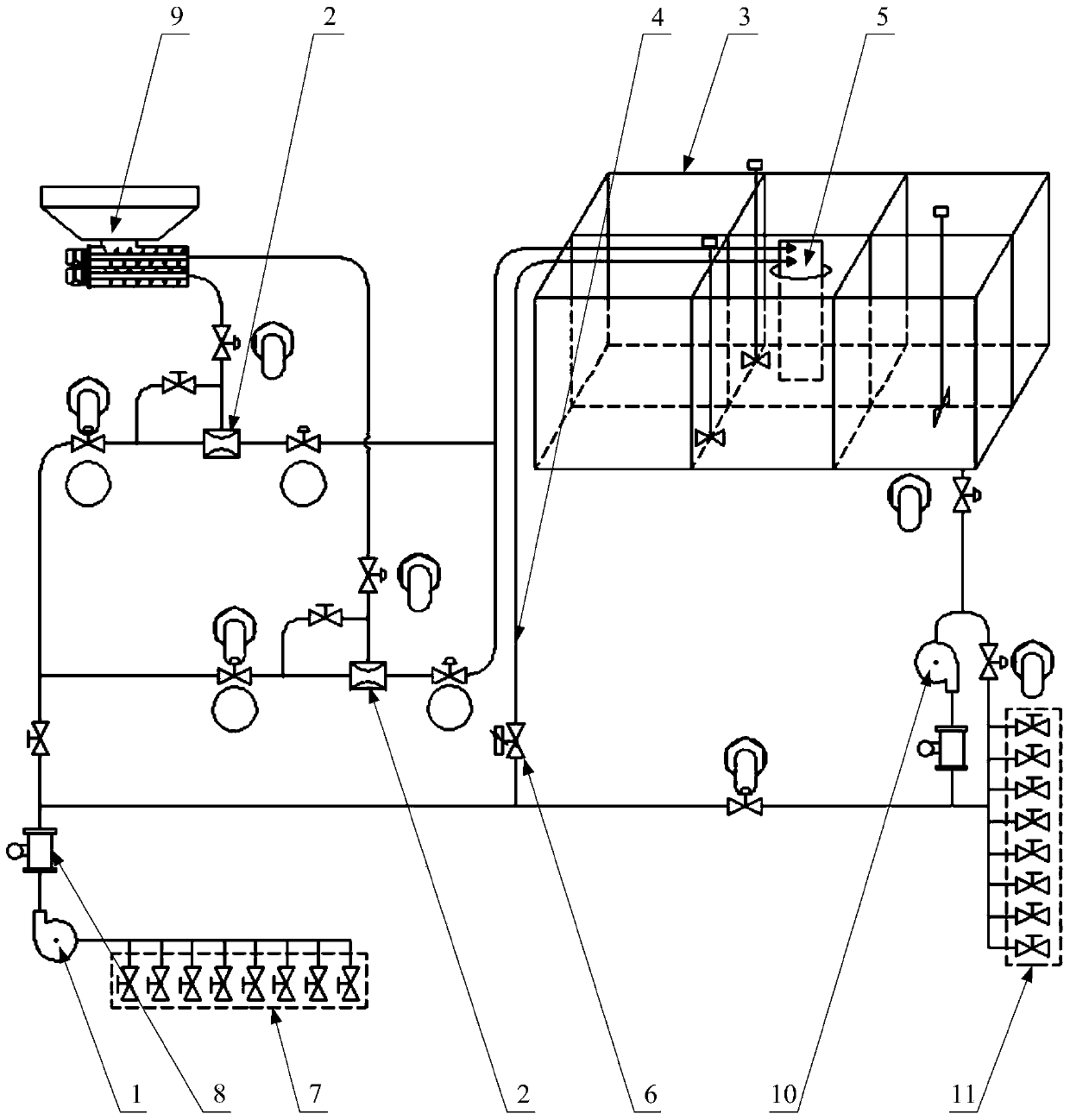

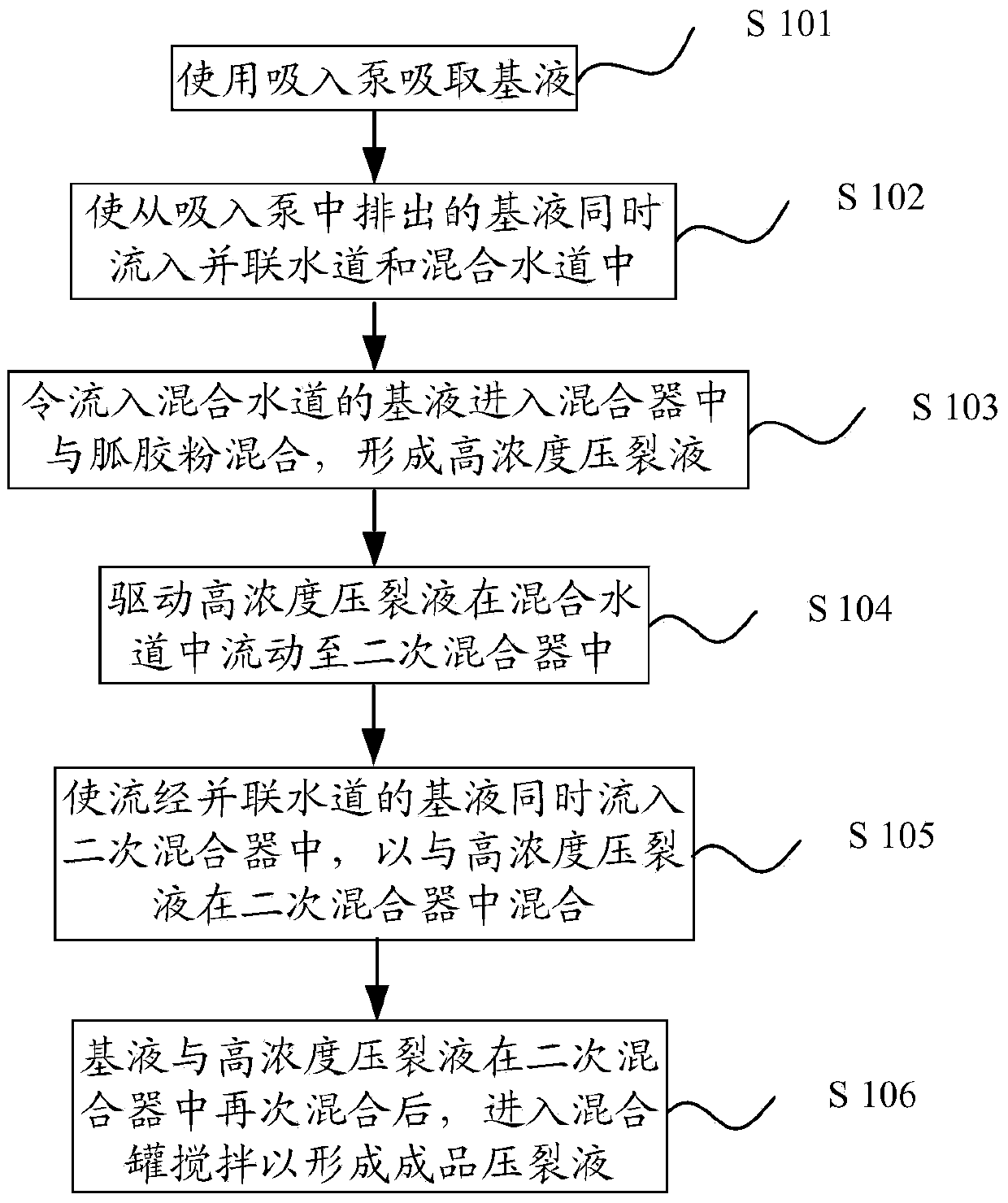

Blending system of fracturing fluid and blending technology of system

InactiveCN103990410AReduce concentrationImprove mixing efficiencyMixing methodsMixersFracturing fluidEngineering

The invention provides a blending system of a fracturing fluid. The blending system comprises a suction pump, a mixer, a mixing tank, a secondary mixer which is arranged between the mixer and the nixing tank and is used for mixing the fracturing fluid again, and a parallel-connection water channel, wherein one end of the parallel-connection water channel is communicated with the suction pump, the parallel-connection water channel and a mixing water channel of the mixer are connected in parallel, and the other end of the parallel-connection water channel is communicated with the secondary mixer. The blending system provided by the invention has the advantages that the parallel water channel is additionally arranged and is connected with the mixing water channel in parallel, a base solution is capable of simultaneously entering two routes, namely the mixing water channel and the parallel-connection water channel, not all of the base solution enters the mixing water channel, a condition that the limitation on blending efficiency is caused by the relatively small flow of the mixing water channel is avoided, the blending time is shortened, the blending energy consumption is reduced, the fracturing fluid is formed through multi-time blending in a double-route manner, the mixing uniformity is improved, and the quality of the fracturing fluid is further optimized. The invention also provides a fracturing fluid blending technology suitable for the blending system of the fracturing fluid.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

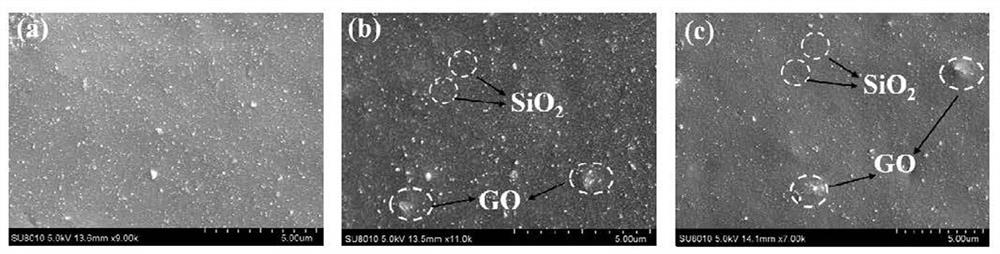

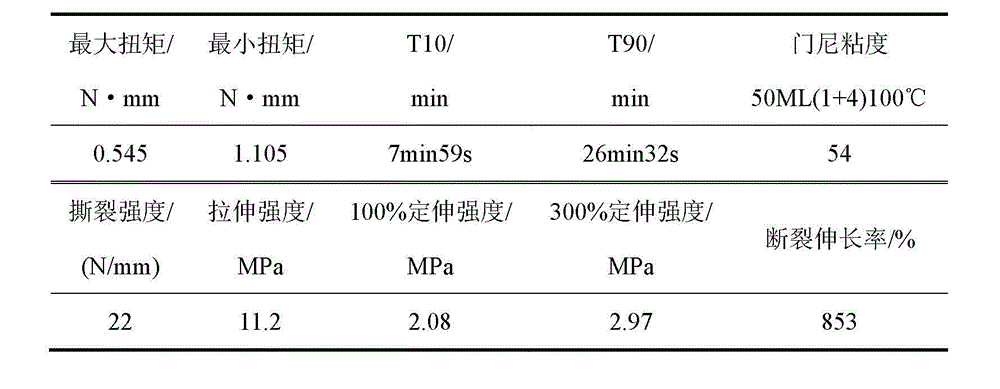

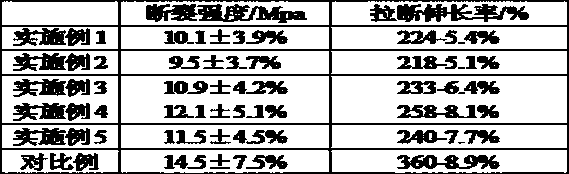

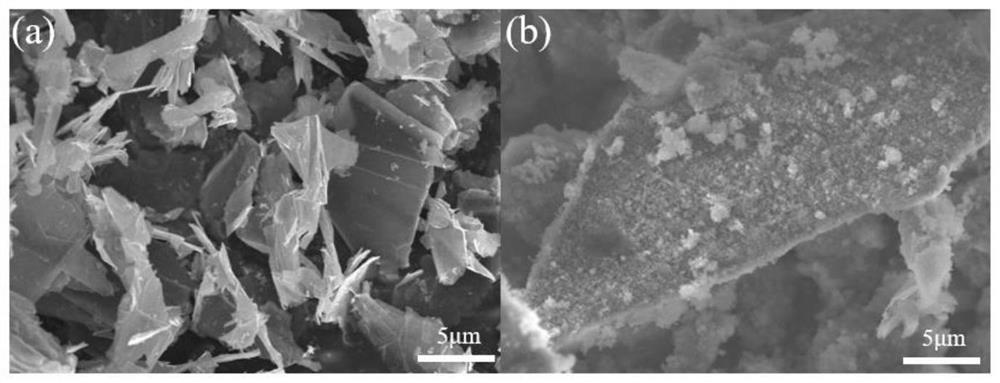

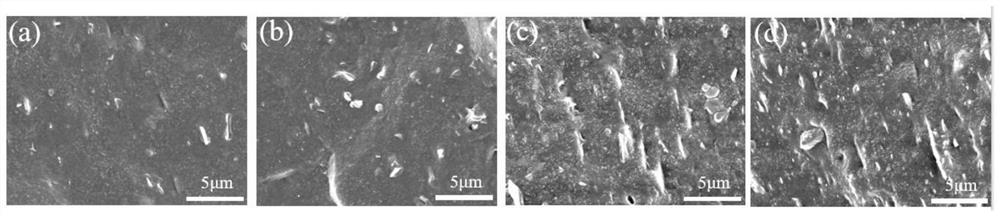

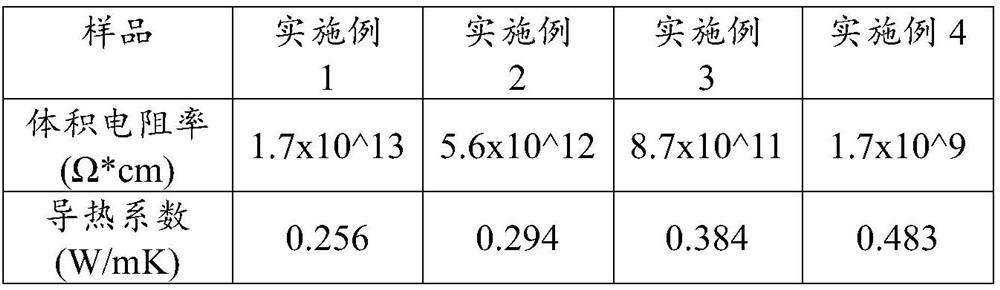

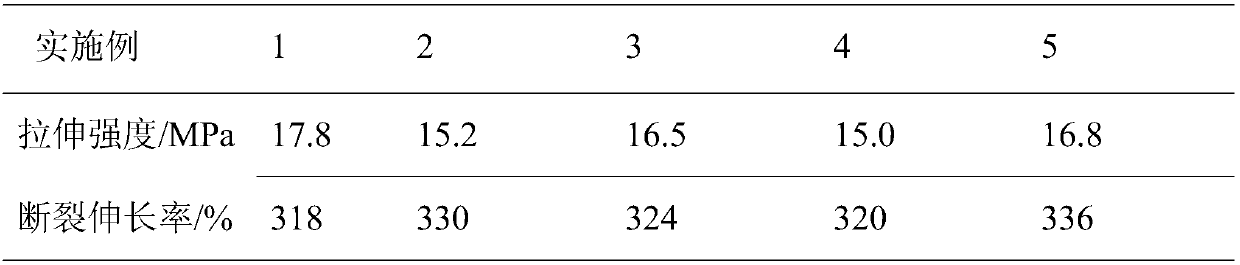

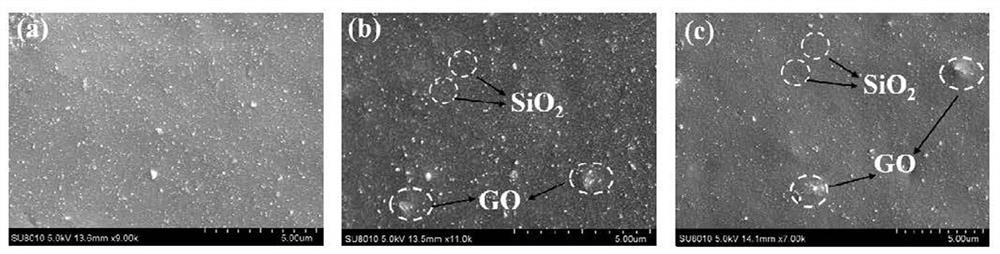

Preparation method of graphene-silicon dioxide modified natural rubber composite material with high thermal conductivity, low thermodynamic property and excellent mechanical property for tires

ActiveCN113462040AGood dispersionImprove thermal conductivitySpecial tyresRolling resistance optimizationSimple Organic CompoundsGraphene

The invention relates to the field of functional natural rubber composite materials, in particular to a preparation method of a graphene-silicon dioxide modified natural rubber composite material with high thermal conductivity, low thermodynamic property and excellent mechanical property for tires. GO aqueous dispersion liquid, SiO2 particles and natural rubber (NR) latex are used as raw materials, SiO2 is modified twice by adopting an organic compound and GO, and the GO-SiO2 modified NR composite material is prepared in a co-aqueous phase by utilizing a latex co-precipitation method. The preparation method has the advantages that the mixing section number, the mixing time, the mixing energy consumption and the dust pollution in the rubber preparation process can be reduced, the dispersity of GO-SiO2 in a rubber matrix can be improved, the interface interaction between GO-SiO2 and the rubber matrix is improved, and the mechanical property of the finally prepared rubber composite material is obviously improved; and meanwhile, friction heat generated between a filler and a matrix and interface thermal resistance between the filler and the matrix can be reduced, and temperature rise of the tire in the driving process is reduced, so that the thermal aging speed of the rubber tire in the dynamic use process is slowed down, and the service life of the rubber tire is prolonged.

Owner:ZHONGBEI UNIV +1

Anti-aging modified natural rubber composite material

The invention discloses an anti-aging modified natural rubber composite material. The anti-aging modified natural rubber composite material is prepared from natural rubber, butadiene rubber, butadiene styrene rubber, butadiene-acrylonitrile rubber, epoxidized natural rubber, nano-zinc oxide, stearic acid, sulfur, dicumyl peroxide, triallyl trimellitate, p-tert-butyl-phenolic resin, nano calcium carbonate, precipitated silica, carbon black purple, nano-microcrystalline cellulose, nano-silicon dioxide, an anti-aging agent, potassium iso-propyl xanthate, dibenzylamine, tetrahydrofurfurylamine, isopropyl trioleoyl titanate, vinyltris(beta-methoxyethoxy)silane, diethylene glycol distearate and polyethyl dialcohol adipate. The anti-aging modified natural rubber composite material is high in strength, good in heat resistance and aging resistance and capable of meeting the usage requirements of multiple fields of cables, rubber pipes and the like.

Owner:苏州技佳橡塑有限公司

Clay powder for improving vulcanization processability of rubber and preparation method for same

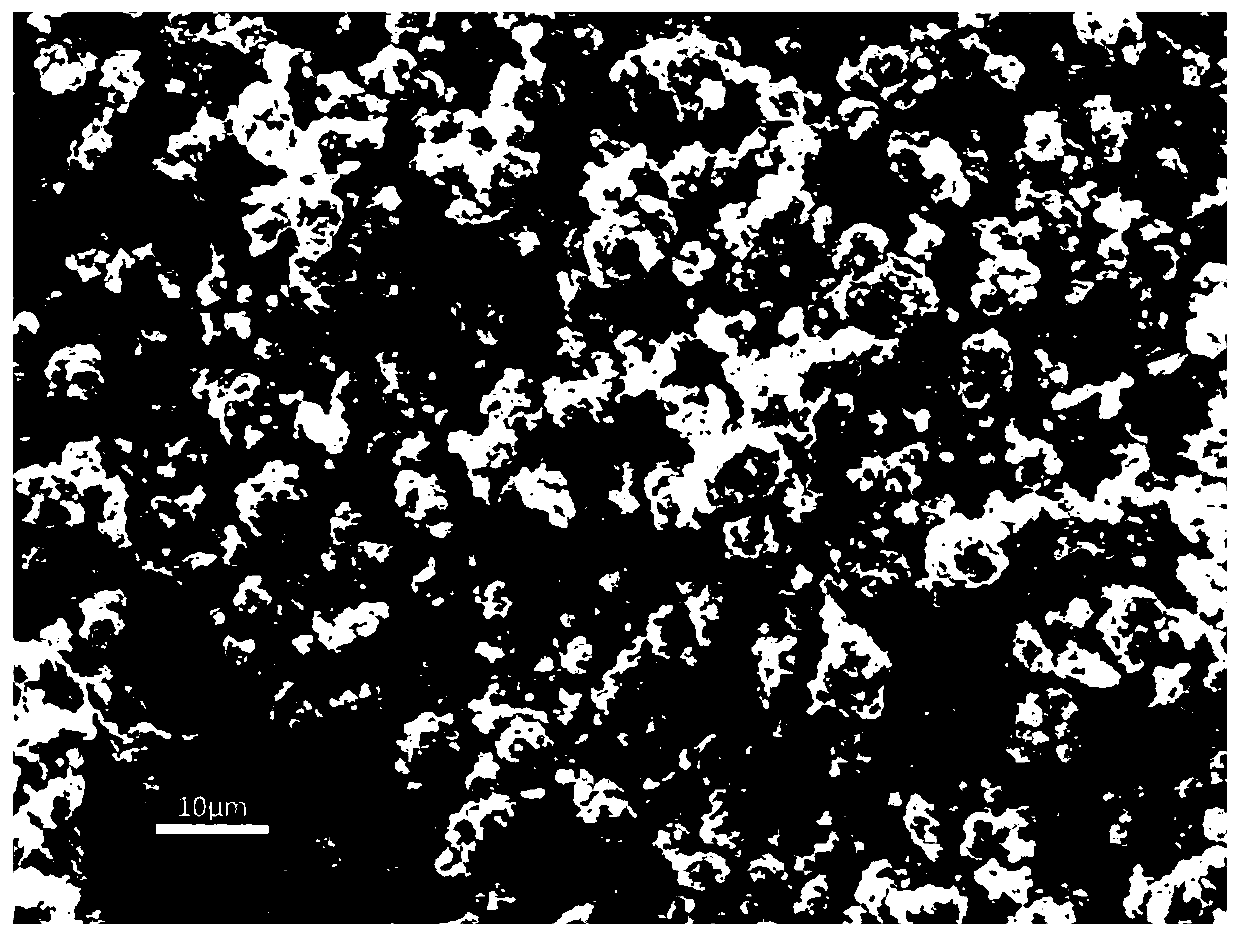

ActiveCN103146026AEasy to dissociateReduce energy consumptionPigment treatment with organosilicon compoundsPigment physical treatmentSodium polyacrylateSodium silicate

The invention relates to a clay powder for improving the vulcanization processability of rubber and a preparation method for the same, wherein the average diameter of the grains of the clay powder disclosed by the invention is 1.5-2.0 mum, the average diameter of the grain lamellar structure of the powder is 600-800 nm, and the average thickness of the lamellar structure is 50-200 nm. The clay powder is composed of the following components in parts by weight: 50-80 parts of kaolin, 20-50 parts of bentonite, 0.5-2.0% of dispersant and 0.5-2.0% of surface modifier, wherein the dispersant is one or more in sodium polyacrylate, sodium hexametaphosphate and sodium silicate, and the surface modifier is one or more in a titanate coupling agent, a silane coupling agent and fatty acid salt. The preparation method is the traditional stirring and grinding method. With the clay powder, the vulcanization time of rubber can be shortened, the vulcanization time is increased, and the processability of rubber is improved; simultaneously, the good mechanical performances of tensile strength, stretching strength and the like of rubber materials can be contributed.

Owner:ZAOZHUANG SANXING ADVANCED MATERIALS

Rubber hose inner rubber layer for ethanol resistant gasoline oiling machine and preparation method of rubber hose inner rubber layer

The invention relates to the field of rubber hose preparation, in particular to a rubber hose inner rubber layer for ethanol resistant gasoline oiling machine and a preparation method of the rubber hose inner rubber layer. The rubber hose inner rubber layer is prepared from the following raw materials in parts by weight: 60-76 parts of nitrile rubber, 24-35 parts of chlorosulfonated polyethylene rubber, 8-13 parts of a homogenizer, 2.7-4.2 parts of zinc oxide, 1.1-1.8 parts of stearic acid, and 2-4 parts of an anti-aging agent, 8.9-10 parts of carbon black, 7-12 parts of white carbon black, 17-25 parts of silica micro powder, 8-13 parts of light calcium carbonate, 7-12 parts of dioctyl ester, 1.2-1.7 parts of sulfur, 0.6-1.1 parts of an accelerant, 0.8-1.3 parts of a vulcanization accelerant and 4.6-7.3 parts of an adhesive. The rubber hose inner rubber layer has good vapor oil resistance and ethanol resistance.

Owner:漯河市久隆液压科技有限公司

An electromagnetic induction type thermally dispersed PAN-PE composite modified stone mastic asphalt material, a preparing method thereof and a constructing method of the material

ActiveCN105906235AAuxiliary heat efficiency improvementImprove construction efficiencyIn situ pavingsSolid waste managementStone mastic asphaltChipseal

The invention relates to an electromagnetic induction type thermally dispersed PAN-PE composite modified stone mastic asphalt material, a preparing method thereof and a constructing method of the material. The material is prepared by mixing and stirring polyoxyethylene alkyl ether, silicone oil and water to prepare a dispersing agent, mixing polyaniline and polyethylene to prepare an electromagnetic induction type PAN-PE compound polymer modifying agent, adding the modifying agent into matrix asphalt, stirring, mixing, shearing, blending weighed aggregate and lignin fibres, blending the PAN-PE compound modified asphalt, the aggregate and the lignin fibres, adding the dispersing agent and a warm-mix agent, adding ore powder, blending, and discharging from a kettle to obtain the material. The material can be used for local damage repair of SMA pavements of bridge floors, tunnels, airports and highways of various grades, is capable of pre-mixing, free of blocking and capable of long-term storage, is a high-performance hot-repair material that can be heated when the material is to be used for pits and slots, is suitable for repairing SMA type pavements and fully matches original pavements.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH

Preparation method of silicon dioxide/graphene modified rubber composite material

ActiveCN114716737AGood dispersionImprove mechanical propertiesSpecial tyresRolling resistance optimizationEmulsionSpray dried

The preparation method of the silicon dioxide / graphene modified rubber composite material comprises the following steps: dispersing graphene in a solvent to obtain a graphene dispersion liquid, and adding an amphiphilic polymer into the graphene dispersion liquid to react to obtain a hydrophilic graphene dispersion liquid; carrying out spray drying to obtain powdery hydrophilic graphene of which the surface is modified with an amphiphilic polymer; the preparation method comprises the following steps: dispersing powdery hydrophilic graphene in a silicon source compound aqueous solution to obtain a graphene-silicon source compound solution, and adjusting the pH value of the graphene-silicon source compound solution until a silicon source compound is hydrolyzed to obtain a mixed filter cake of silicon dioxide graphene-based binary particles; diluting the mixed filter cake into an emulsion as a filler, adding the emulsion into latex to obtain a mixed system, adding a flocculant into the mixed system to induce demulsification of the latex to obtain flocculate, and adding a processing aid into the flocculate to obtain the silicon dioxide / graphene modified rubber composite material. The mechanical property, wear resistance and thermal conductivity of the rubber composite material are improved.

Owner:HENAN UNIVERSITY

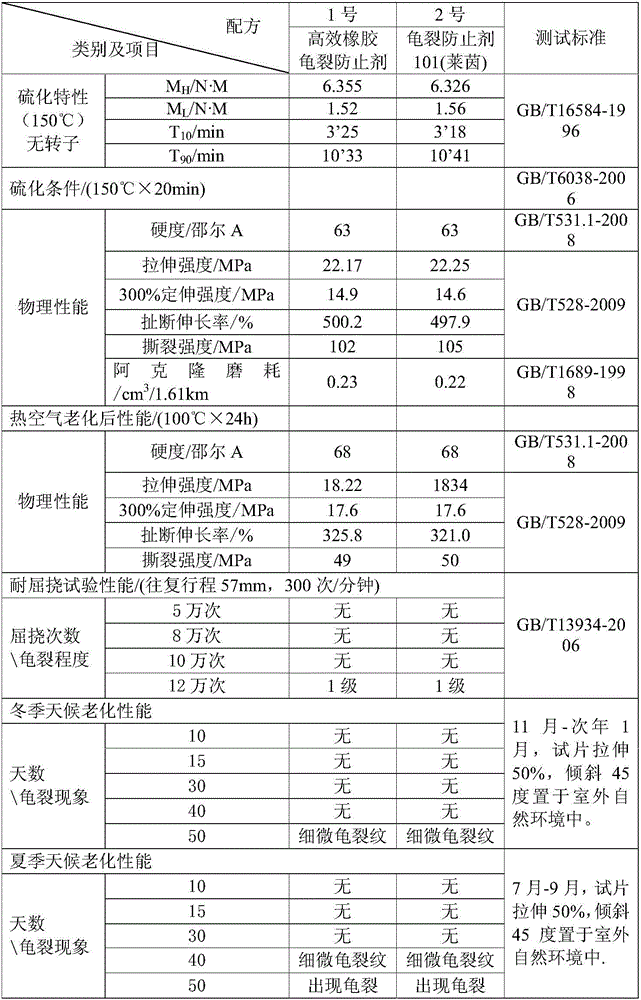

High-performance rubber cracking preventing agent

InactiveCN106751940AImprove crack resistanceImprove inner qualityMicrocrystalline waxHeat resistance

The invention discloses a high-performance rubber cracking preventing agent. The preventing agent is prepared from the following components in parts by weight: 20 to 30 parts of Number-58 completely-refined paraffin, 15 to 25 parts of number-58 semi-refined paraffin; 22 to 34 parts of number-70 microcrystalline wax, 18 to 30 parts of number-85 microcrystalline wax, 4 to 8 parts of oxidized polyethylene wax, and 2 to 5 parts of polyethylene wax. The preventing agent is smooth in surface, uniform in thickness, good in leakproofness, compact in structure, high in flexibility, heat resistance, elasticity and adhesive force, uneasy to drop, capable of playing a barrier role in preventing rubber from contacting ozone gas, and capable of effectively delaying the oxidization effect, delaying the cracking and prolonging the service life.

Owner:JIANGSU KAOU CHEM

Preparation method of cottonseed meal protein compound slurry

The invention discloses a preparation method of cottonseed meal protein compound slurry. The preparation method comprises the following steps: mixing cottonseed meal, which is treated by detoxification by using gossypol, with starch according to a dry basis mass ratio of (20 to 1) to (10 to 1) to obtain mixed dry powder; putting the mixed dry powder into an alkaline solution, wherein the mass of the alkaline solution is 5-20 times that of the mixed dry powder, and the hydroxyl ion concentration of the alkaline solution is 1-5%; carrying out ultrasonic treatment on the obtained mixture for 5-60min; then, stirring and heating for 30-90min at the constant temperature of 50-95 DEG C, adding a hydrophilic plasticizer in the process of stirring and heating, wherein the mass of the hydrophilic plasticizer accounts for 10-30% of that of the mixed dry powder, using diluted hydrochloric acid to adjust the pH value of a reaction system to a neutral or weak alkaline condition, and removing precipitate to obtain the slurry which is the cottonseed meal protein compound liquid slurry directly used for sizing. After the technical scheme is adopted, the completely unshelled cottonseed meal is prepared into the slurry for warp sizing so as to replace polyvinyl alcohol (PVA), so that the problem that the biodegradation of desizing wastewater is difficult to implement is effectively solved, and the bottleneck that the desizing wastewater is difficult to treat is broken through.

Owner:JIANGNAN UNIV +1

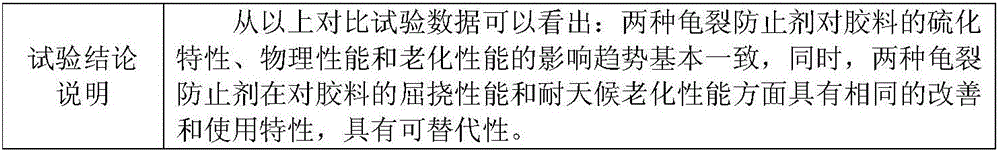

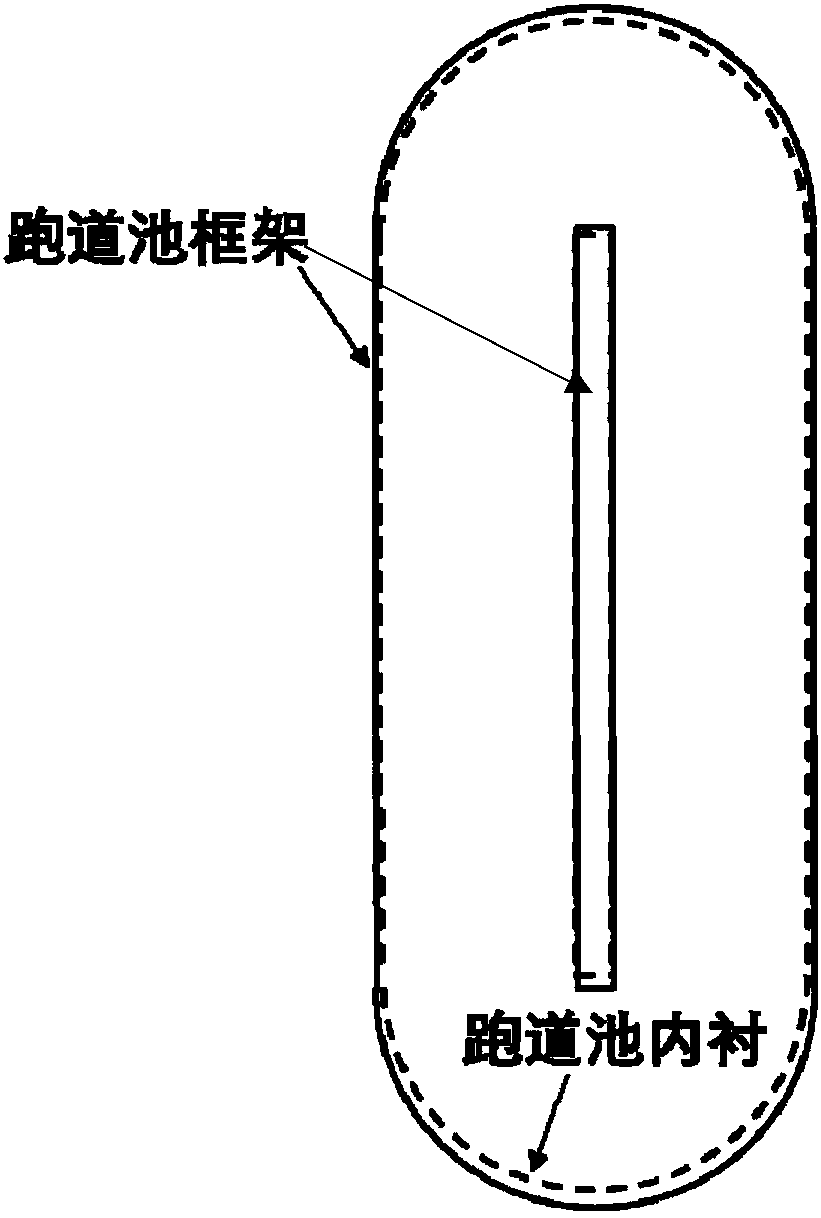

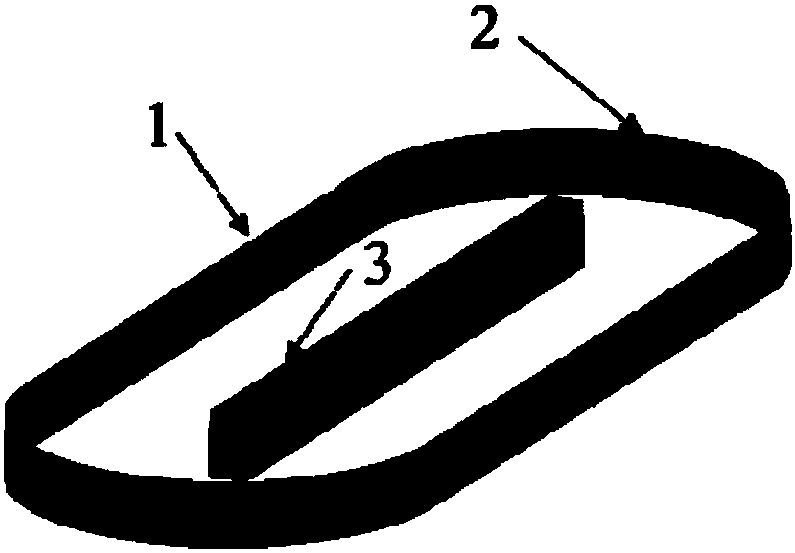

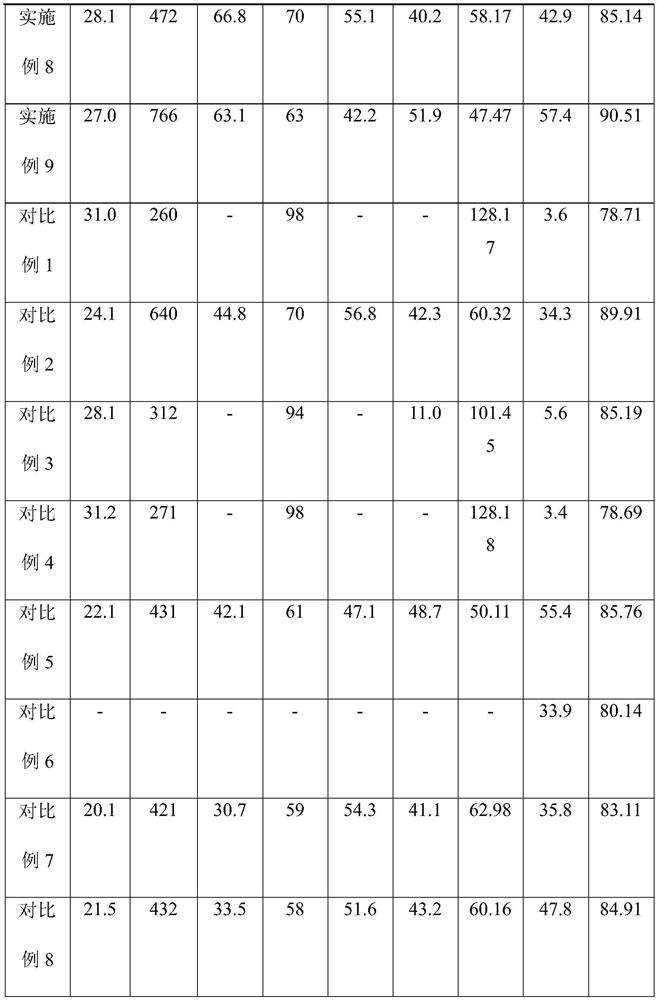

Simple raceway pond used for microalgae cultivation and use method thereof

PendingCN107723214AEasy to buildBuild strongBioreactor/fermenter combinationsBiological substance pretreatmentsBiologyMechanical engineering

The invention belongs to the field of photobioreactors, and particularly relates to a simple raceway pond used for microalgae cultivation and a use method thereof. The simple raceway pond comprises araceway pond lining and a raceway pond frame, wherein the raceway pond frame comprises a straight runner wall, a bent runner wall, a flow separating wall, stirring paddles, a variable speed motor, a support rod and a liquid propeller, wherein the straight runner wall, the bent runner wall and the flow separating wall form a circular water pond frame of the raceway pond. The raceway pond frame is easy to construct and is firm, is convenient to disassemble, and can be enlarged easily, and the corresponding size can be determined according to actual site. The raceway pond lining is of a completesleeve structure, cannot wrinkle during use, does not need to be splice, can effectively avoid liquid leakage, and is made of food-grade materials, so that the risk of heavy metal pollution caused byadopting cement or a geomembrane can be avoided. The liquid propeller can be matched with the stirring paddles to be used, has the characteristics of obviously reducing the liquid mixing energy consumption, and meanwhile can avoid algae cell settlement, so that the area yield can be increased.

Owner:湖南瑞藻生物科技有限公司

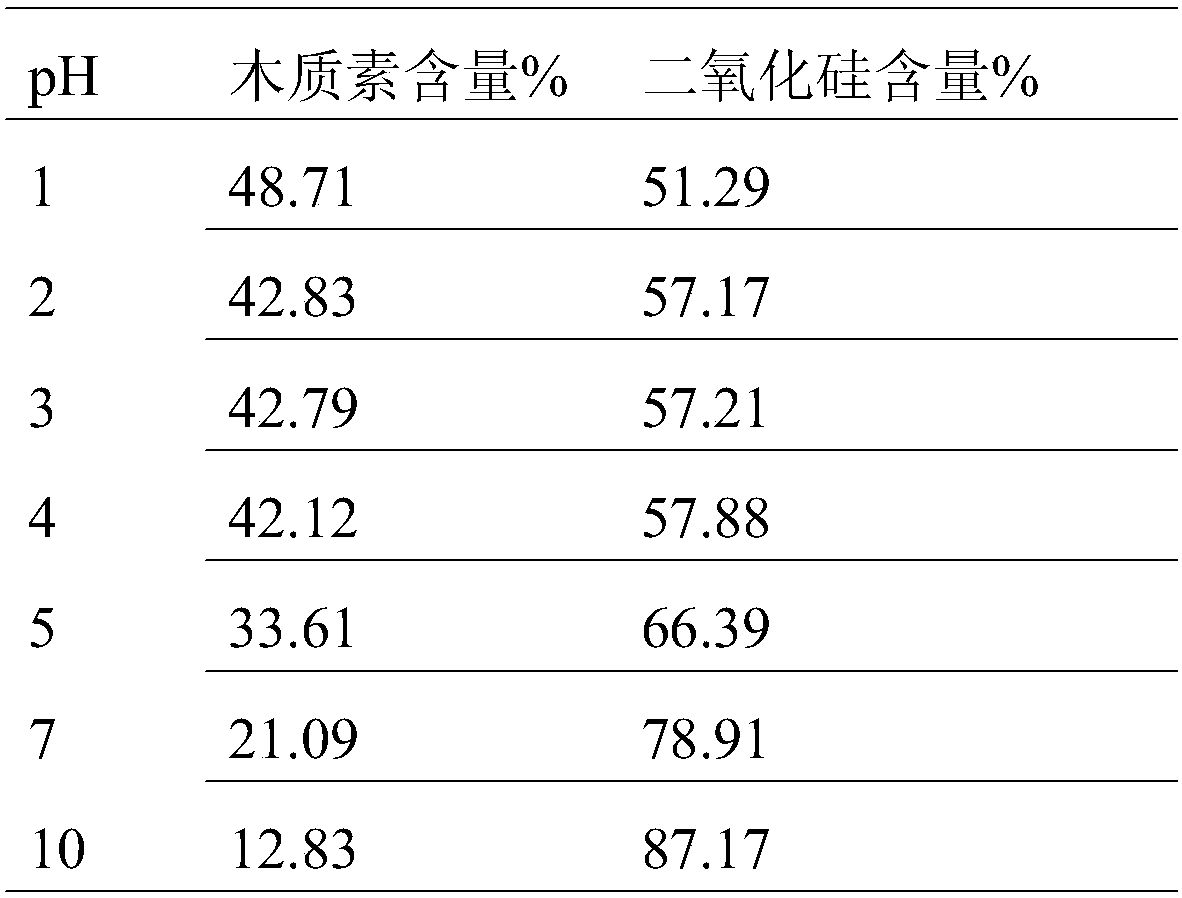

A kind of method of lignin silicon dioxide composite modified natural rubber masterbatch

The invention relates to a method of lignin and silicon dioxide composite modified natural rubber master batch, and belongs to the field of biomass energy chemical engineering, which solves the technical problems of low utilization rate of rice husk, difficulty in dispersing of inorganic nanometer particles in the rubber, easiness in agglomeration, and influence to the physical and mechanical properties of rubber in the prior art. The method comprises the following steps of using the rice husk as raw material, performing dilute-acid hydrolysis pretreatment, dissolving the silicon dioxide and the lignin by alkaline, adding acid to adjust the pH (potential of hydrogen) value of an end point, and then preparing the lignin and silicon dioxide composite filler with different components; blending the composite filler, a dispersant and a modifier, so as to obtain a modifying liquid; finally, uniformly mixing and emulsifying the modifying liquid and natural latex, flocculating and settling, so as to prepare the lignin and silicon dioxide composite modified rubber master batch. The method has the advantages that the rice husk resource is utilized, the physical and chemical properties of the rubber product are improved, the technology is simple, the cost is low, and the important application and development prospect is realized.

Owner:JILIN UNIV

Fiber/TPI rubber master batch, preparing method thereof and application of the rubber master batch in rubber compositions

The invention relates to fiber / TPI rubber master batch, a preparing method thereof and application of the rubber master batch in rubber compositions. The method includes following steps of: (1) mixing trans-isoprene rubber and fibers, stirring, mixing to obtain a premix material, with the stirring being performed at 30-50 DEG C for 5-9 min at a stirring speed of 900-1500 r / min; and (2) mixing the premix material in an internal mixer at 70-120 DEG C for 5-10 min, with the rotation speed of the internal mixer being 50-90 r / min, and discharging rubber to obtain the fiber / TPI rubber master batch. The prepared fiber / TPI rubber master batch is liable to mix with natural rubber or other synthetic rubber to form fiber / rubber compositions with good performance, and can improve performance of the rubber compositions.

Owner:QINGDAO TPI NEW MATERIAL

A kind of anti-aging modified natural rubber composite material

Owner:苏州技佳橡塑有限公司

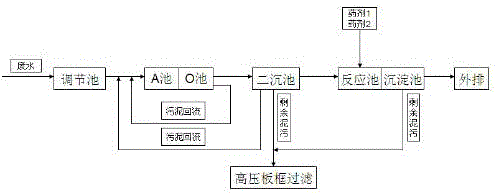

7-aminocephalosporanic acid production wastewater treatment method

InactiveCN106007186AImprove processing efficiencyStable waterTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFlocculationSludge

The invention discloses a method for treating waste water produced by 7-aminocephalosporanic acid. The waste water is injected into a regulating tank to adjust pH, and then undergoes A / O process biochemical treatment and mud-water separation, and then conducts solid-liquid treatment after flocculation reaction and precipitation. Separation, the separated water is discharged after testing up to the standard, and the remaining sludge enters the automatic high-pressure plate frame for dehydration treatment. The beneficial effects of the present invention are: the present invention has simple process, small engineering quantity, short construction period, small project investment, and the treatment efficiency of total nitrogen and ammonia nitrogen can be as high as 95%, stable water output, simple operation and convenient maintenance. Greatly improved the economic benefits of the enterprise.

Owner:焦作健康元生物制品有限公司

Rubber mixing method, rubber compound and application

InactiveCN114425823AEvenly dispersedReduce mixing energy consumptionPolymer scienceRolling resistance

The invention relates to the technical field of rubber mixing, in particular to a rubber mixing method, mixed rubber and application. According to the invention, the mixing uniformity of the rubber compound is improved, the physical and mechanical properties of the rubber compound are improved, the dynamic properties of the rubber compound can be improved, heat generation and rolling resistance are reduced, the fatigue resistance and crack resistance of the rubber compound are improved, and the service life of a tire is prolonged; the composite material has enough rigidity, and also has enough flex resistance, tear resistance and low heat generation performance.

Owner:山东万达宝通轮胎有限公司 +1

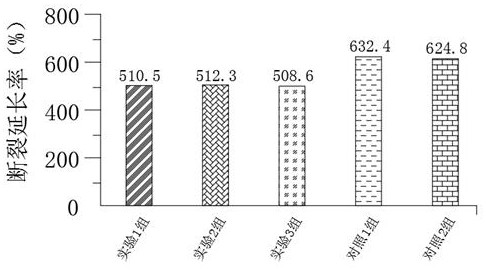

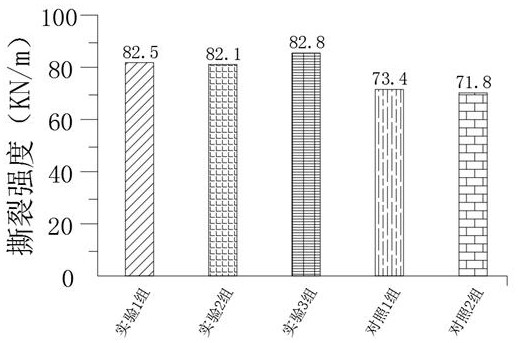

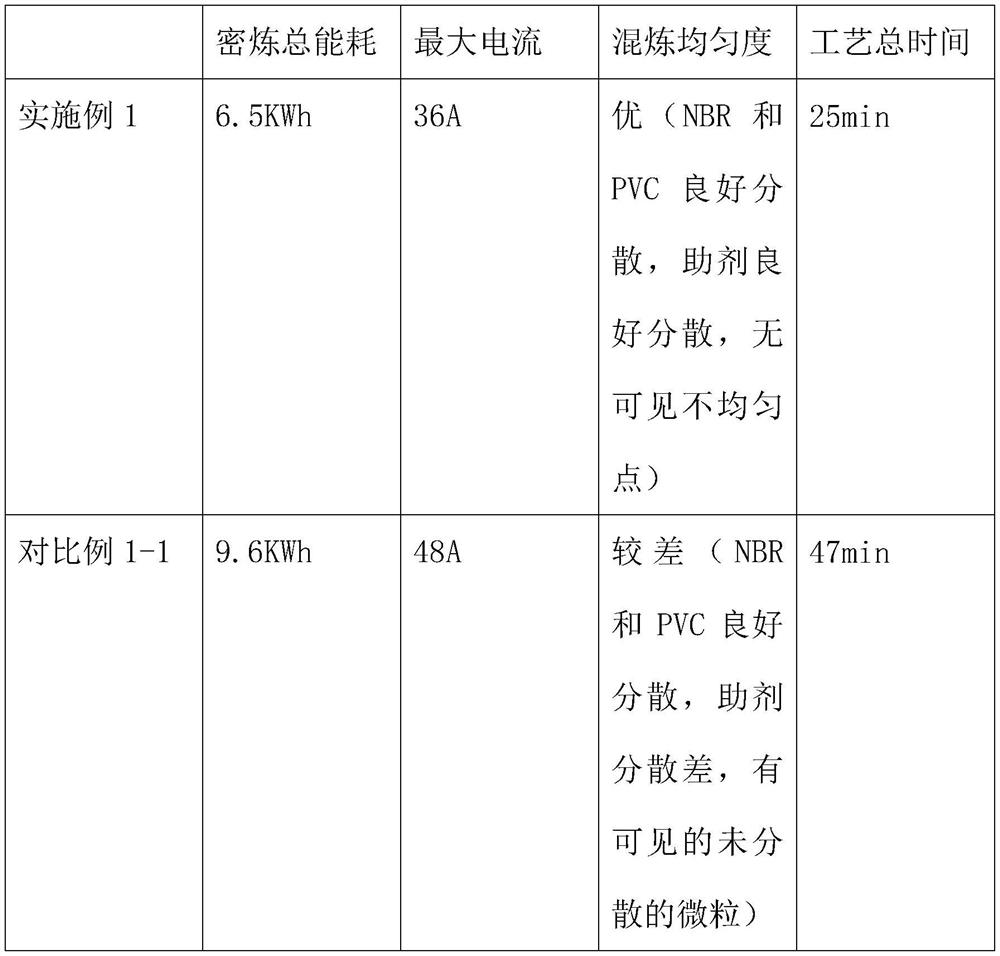

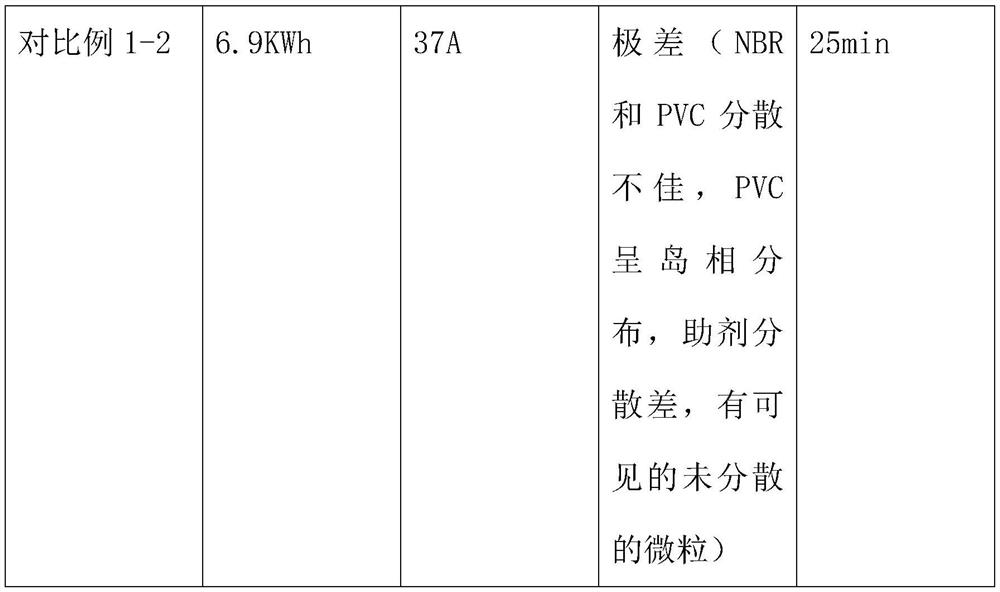

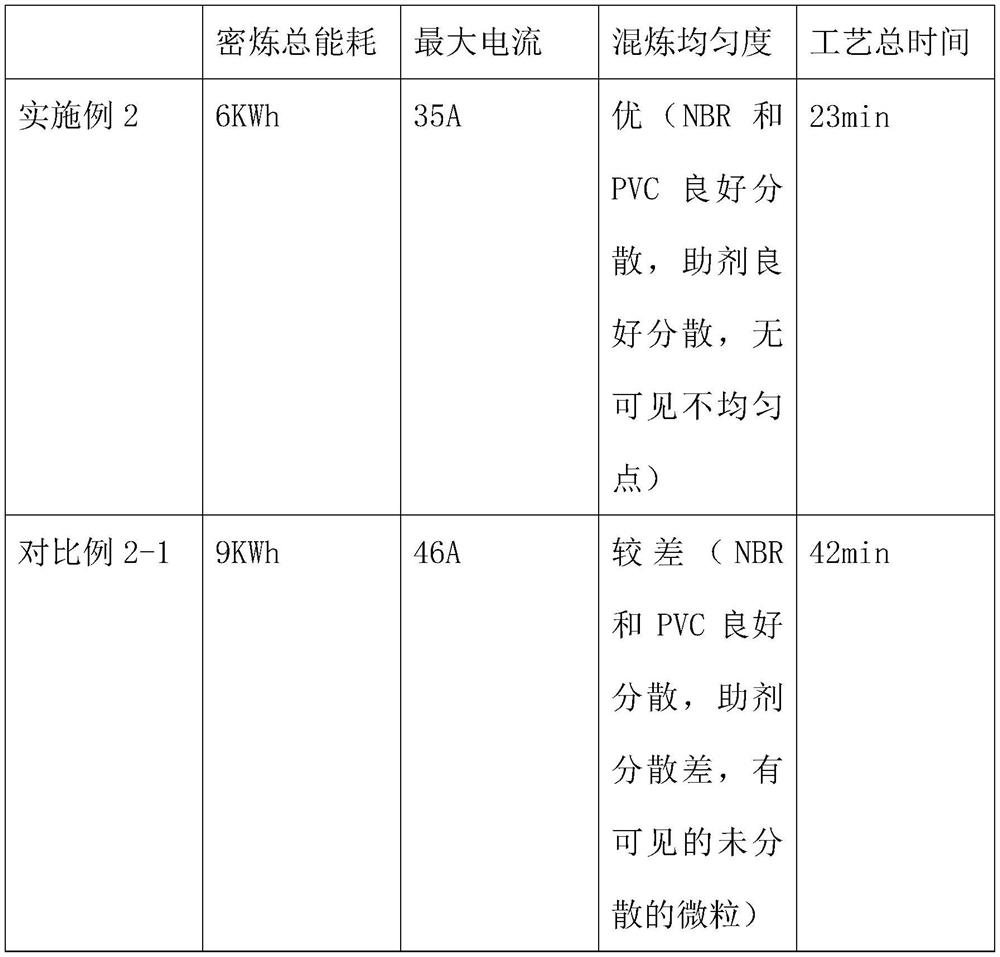

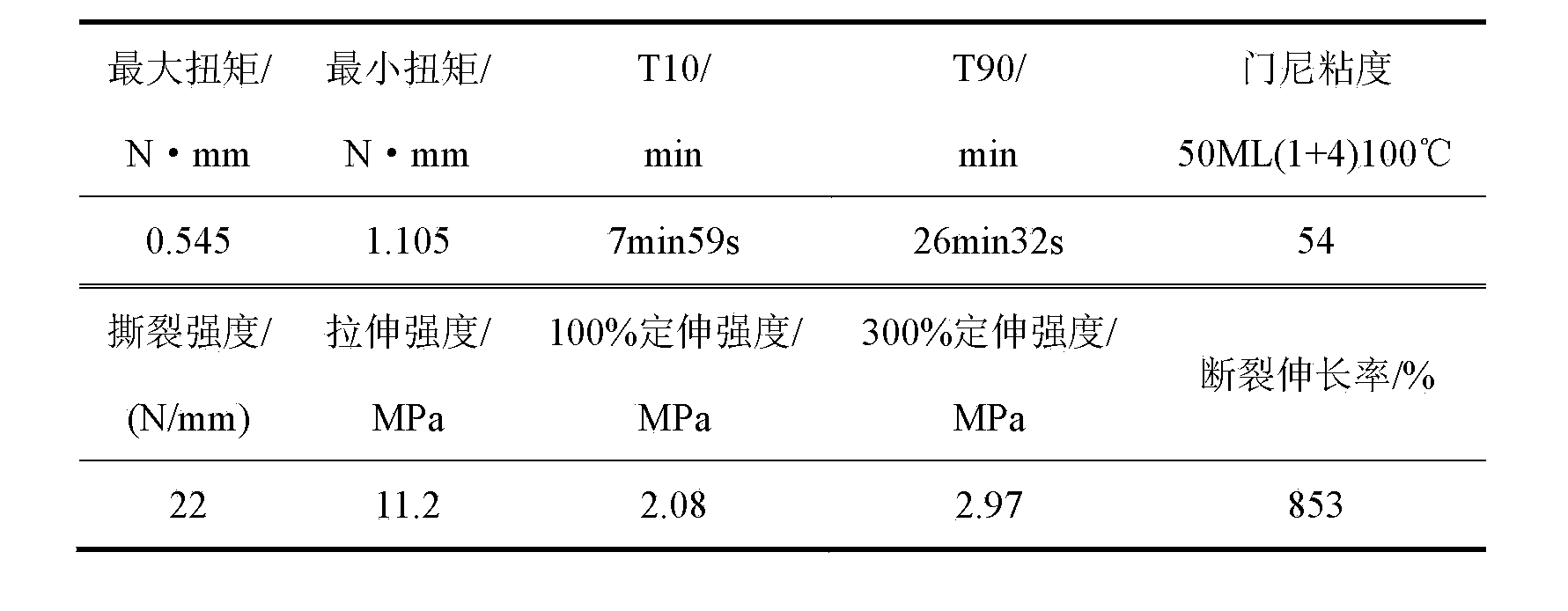

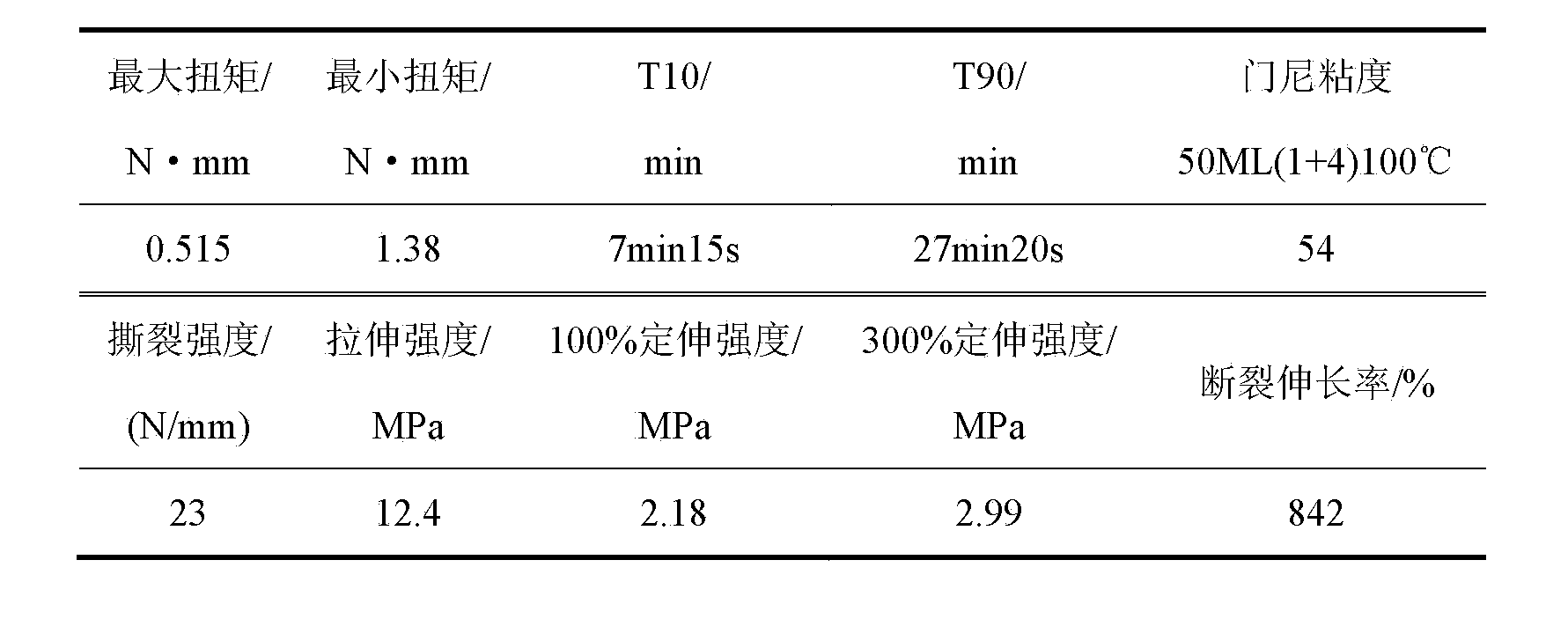

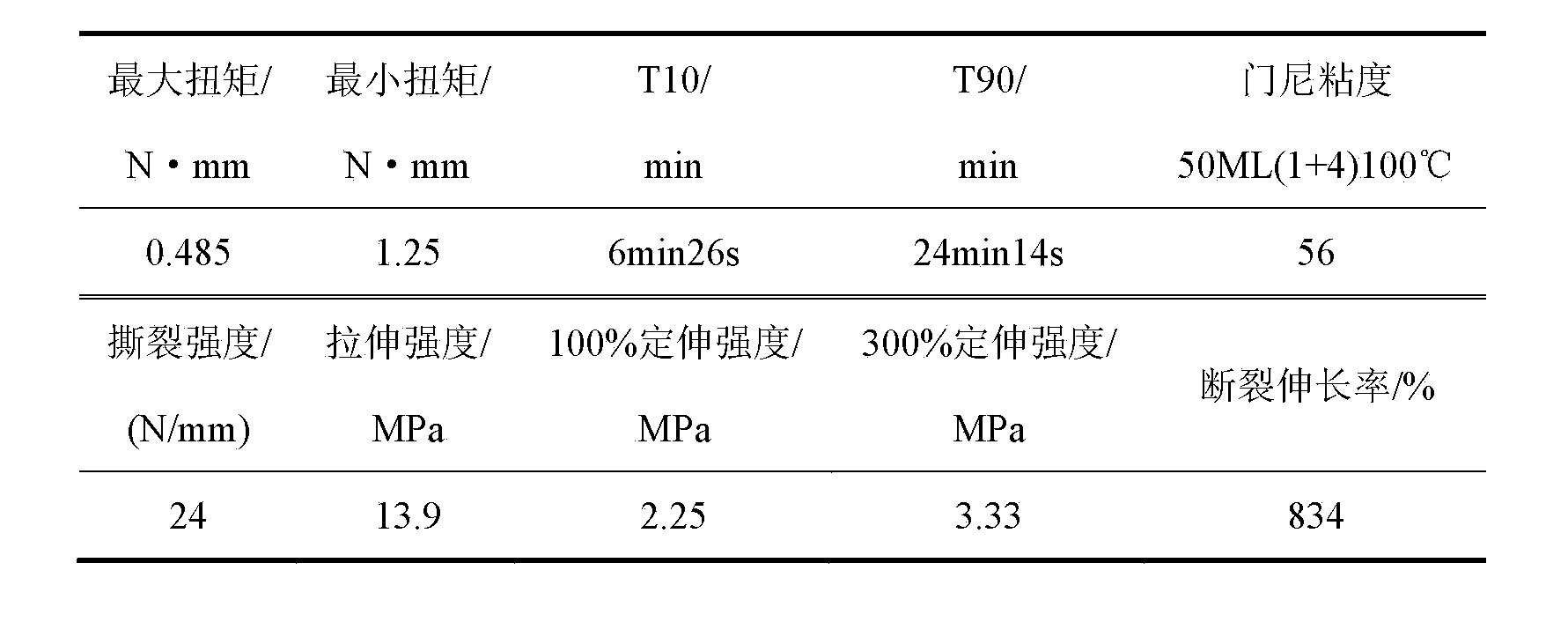

Mixing method for preparing nitrile rubber/polyvinyl chloride alloy rubber compound through two-stage mixing

The invention discloses a mixing method for preparing nitrile rubber / polyvinyl chloride alloy mixed rubber by two-stage mixing. The method is characterized in that the method comprises two-stage mixing, two internal mixers are used for mixing respectively, the first stage is heating mixing, and the second stage is cooling mixing; the method specifically comprises the following steps: adding nitrile rubber, polyvinyl chloride, a PVC stabilizer and a high-temperature rubber additive into the first-stage internal mixer, controlling the rotating speed in the mixing process to be that the shear heat generation is greater than the heat dissipation, heat is generated while mixing, and discharging after the mixing temperature reaches the first-stage discharging temperature; the discharged materials are not cooled and are directly fed into the second-stage internal mixer; and a final mixing aid is added into the second-stage internal mixer at the same time, the rotating speed and the cooling condition are controlled so that the materials are cooled at a certain cooling speed while internal mixing; when the temperature of the material mixture reaches a certain temperature, the material mixture is discharged, thus completing mixing; the material mixture is added into an open mill for thinning and sheet discharging.

Owner:王律杨 +1

Preparation method of graphene-silica modified natural rubber composite material with high thermal conductivity, low thermogenesis and excellent mechanical properties for tires

ActiveCN113462040BGood dispersionImprove thermal conductivitySpecial tyresRolling resistance optimizationSimple Organic CompoundsPhysical chemistry

The invention relates to the field of functional natural rubber composite materials, in particular to a method for preparing a graphene-silica modified natural rubber composite material with high thermal conductivity and low thermogenesis for tires; 2 Particles and natural rubber (NR) latex are used as raw materials, and SiO is modified twice with organic compounds and GO 2 , using the latex co-precipitation method to prepare GO‑SiO in the co-aqueous phase 2 Modified NR composites. It can not only reduce the number of mixing stages and mixing time in the rubber preparation process, reduce mixing energy consumption, reduce dust pollution, but also improve the GO‑SiO 2 Dispersion in rubber matrix to improve GO‑SiO 2 The interface interaction with the rubber matrix can significantly improve the mechanical properties of the final prepared rubber composite; at the same time, it can reduce the frictional heat generation between the filler-matrix and the interfacial thermal resistance between the filler-matrix, and reduce the tire during driving. temperature rise, thereby slowing down the thermal aging rate of rubber tires during dynamic use and prolonging the service life of rubber tires.

Owner:ZHONGBEI UNIV +1

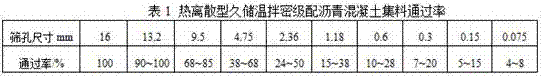

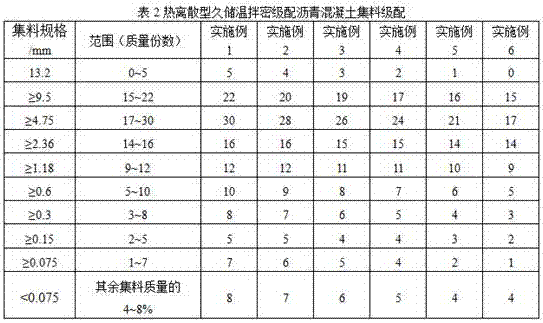

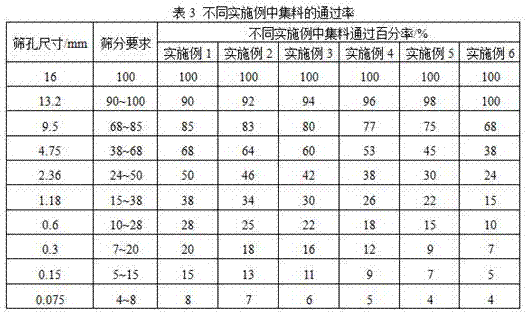

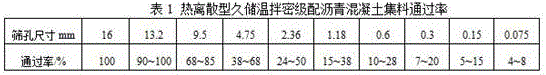

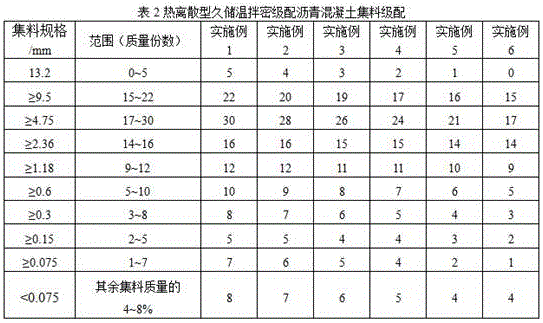

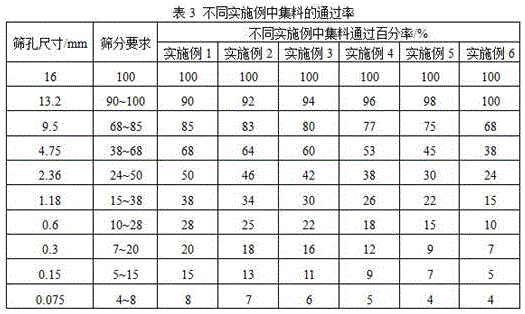

Thermal discrete long-storage temperature-mixed dense grading asphalt concrete and preparation method thereof

ActiveCN105693142BWill not stickReduce mixing energy consumptionClimate change adaptationPorosityRepair material

The invention relates to thermal dissociation type long-time storage warm mixing densely-graded asphalt concrete and a preparation method thereof.The thermal dissociation type long-time storage warm mixing densely-graded asphalt concrete is prepared from, by mass, 100 parts of aggregate, 4-8 parts of mineral powder, 4-6 parts of asphalt, 1-1.5 parts of Spro warm mixing disassociation agent and 1-5 parts of warm mixing agent.The maximum nominal grain diameter of the aggregate is 13 mm, and the design porosity of a mixture is 3.5%-4.5%.The Spro warm mixing discrete agent mainly achieves the effects of heat disassociation and reduction of the viscosity of an asphalt binding material on the mixture.The asphalt concrete can be applied to repairing of local damage such as pit slots, slurry spurting, check crack and fracturing of asphalt pavements, bridge floor asphalt pavement layers and tunnel asphalt concrete runway pavements, it is guaranteed that the pavement performance of the mixture completely meets the requirements for the performance of the hot mixing mixture, the problem that an existing diluted asphalt or emulsified asphalt cold repair material is insufficient in performance is solved, and the problem that a material source is hardly found hot material hot repairing can be solved.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH

Thermal dissociation type long-time storage warm mixing densely-graded asphalt concrete and preparation method thereof

ActiveCN105693142AReduce mixing energy consumptionImprove construction efficiencyClimate change adaptationRepair materialPorosity

The invention relates to thermal dissociation type long-time storage warm mixing densely-graded asphalt concrete and a preparation method thereof.The thermal dissociation type long-time storage warm mixing densely-graded asphalt concrete is prepared from, by mass, 100 parts of aggregate, 4-8 parts of mineral powder, 4-6 parts of asphalt, 1-1.5 parts of Spro warm mixing disassociation agent and 1-5 parts of warm mixing agent.The maximum nominal grain diameter of the aggregate is 13 mm, and the design porosity of a mixture is 3.5%-4.5%.The Spro warm mixing discrete agent mainly achieves the effects of heat disassociation and reduction of the viscosity of an asphalt binding material on the mixture.The asphalt concrete can be applied to repairing of local damage such as pit slots, slurry spurting, check crack and fracturing of asphalt pavements, bridge floor asphalt pavement layers and tunnel asphalt concrete runway pavements, it is guaranteed that the pavement performance of the mixture completely meets the requirements for the performance of the hot mixing mixture, the problem that an existing diluted asphalt or emulsified asphalt cold repair material is insufficient in performance is solved, and the problem that a material source is hardly found hot material hot repairing can be solved.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH

Clay powder for improving vulcanization processability of rubber and preparation method for same

ActiveCN103146026BGood dispersionIncrease layer spacingPigment treatment with organosilicon compoundsPigment physical treatmentRubber materialVulcanization

The invention relates to a clay powder for improving the vulcanization processability of rubber and a preparation method for the same, wherein the average diameter of the grains of the clay powder disclosed by the invention is 1.5-2.0 mum, the average diameter of the grain lamellar structure of the powder is 600-800 nm, and the average thickness of the lamellar structure is 50-200 nm. The clay powder is composed of the following components in parts by weight: 50-80 parts of kaolin, 20-50 parts of bentonite, 0.5-2.0% of dispersant and 0.5-2.0% of surface modifier, wherein the dispersant is one or more in sodium polyacrylate, sodium hexametaphosphate and sodium silicate, and the surface modifier is one or more in a titanate coupling agent, a silane coupling agent and fatty acid salt. The preparation method is the traditional stirring and grinding method. With the clay powder, the vulcanization time of rubber can be shortened, the vulcanization time is increased, and the processability of rubber is improved; simultaneously, the good mechanical performances of tensile strength, stretching strength and the like of rubber materials can be contributed.

Owner:ZAOZHUANG SANXING ADVANCED MATERIALS

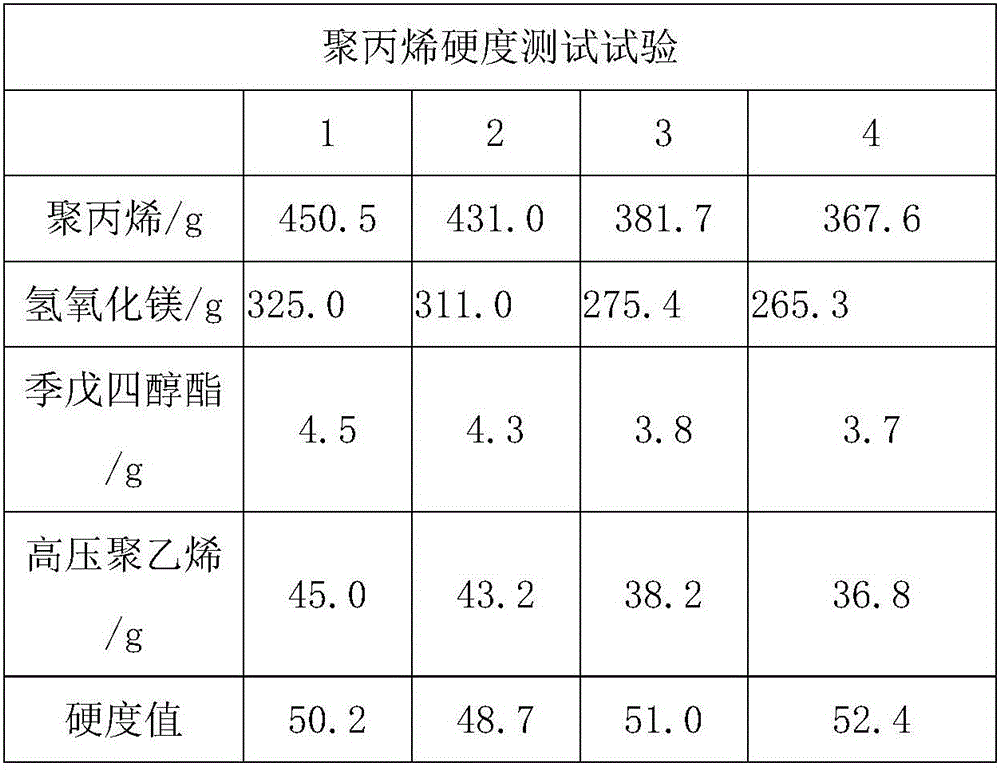

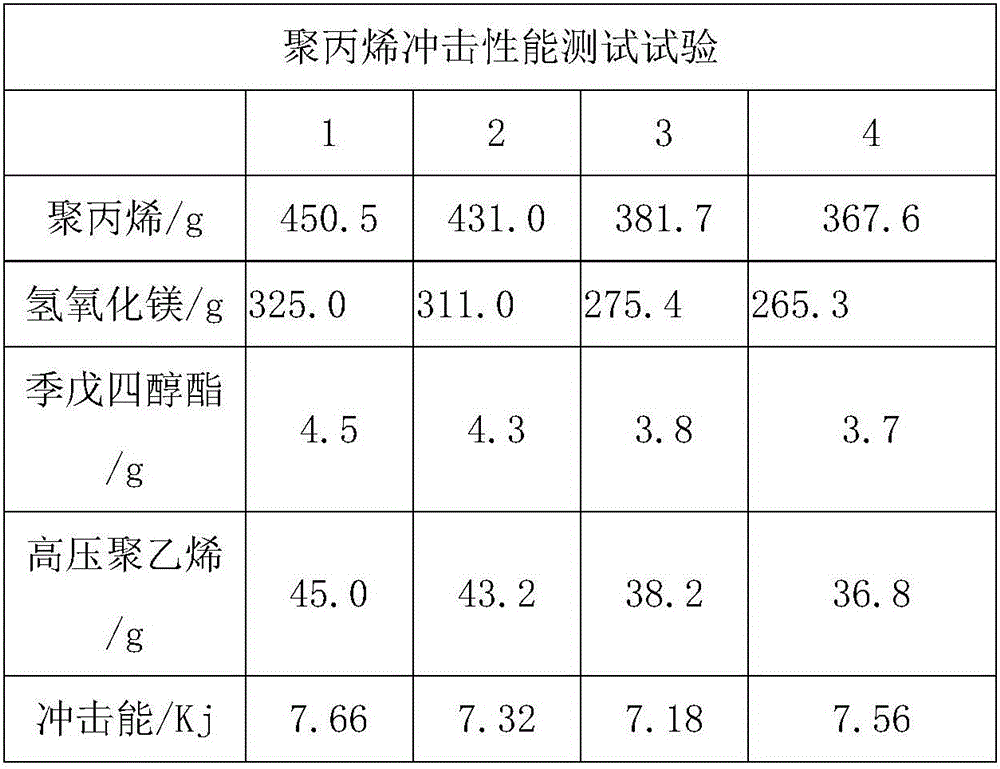

Process for efficiently modifying waste polypropylene in green manner

InactiveCN106519441AEnhancement effect is goodImprove mechanical propertiesPolymer sciencePentaerythritol

Owner:界首市华腾塑业有限公司

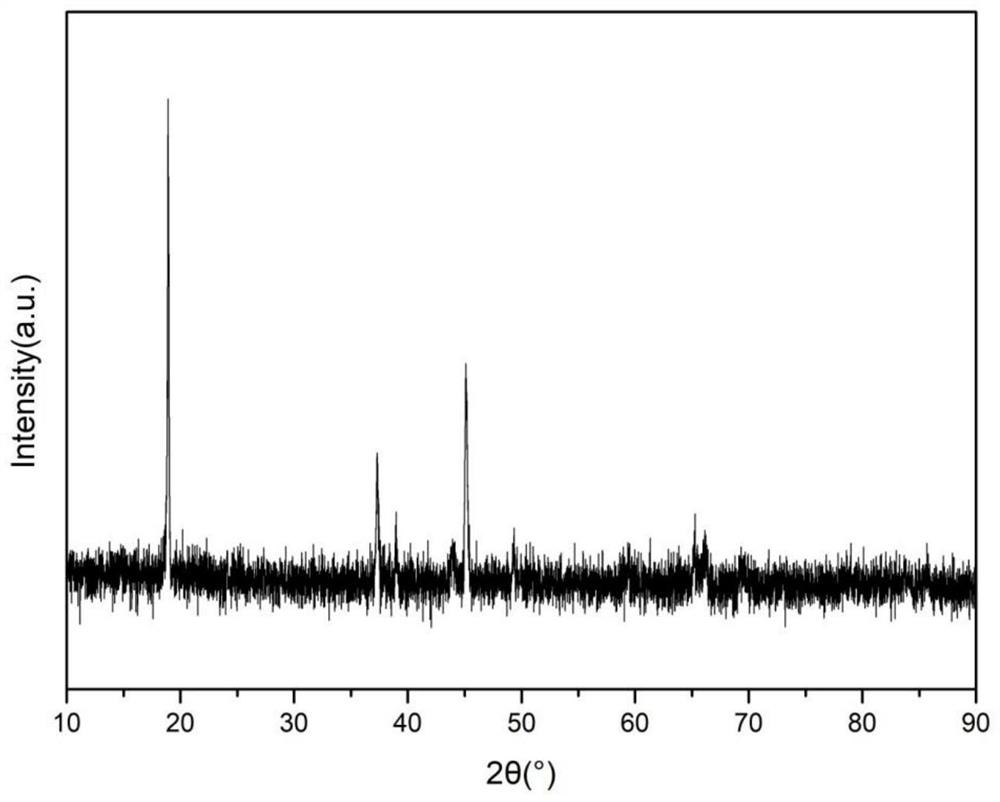

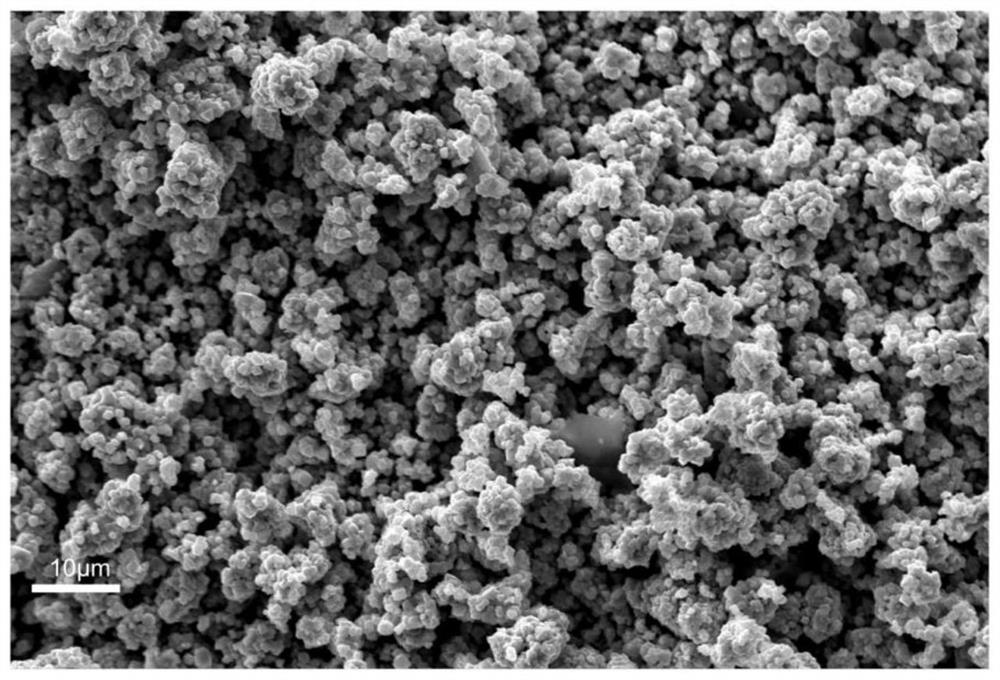

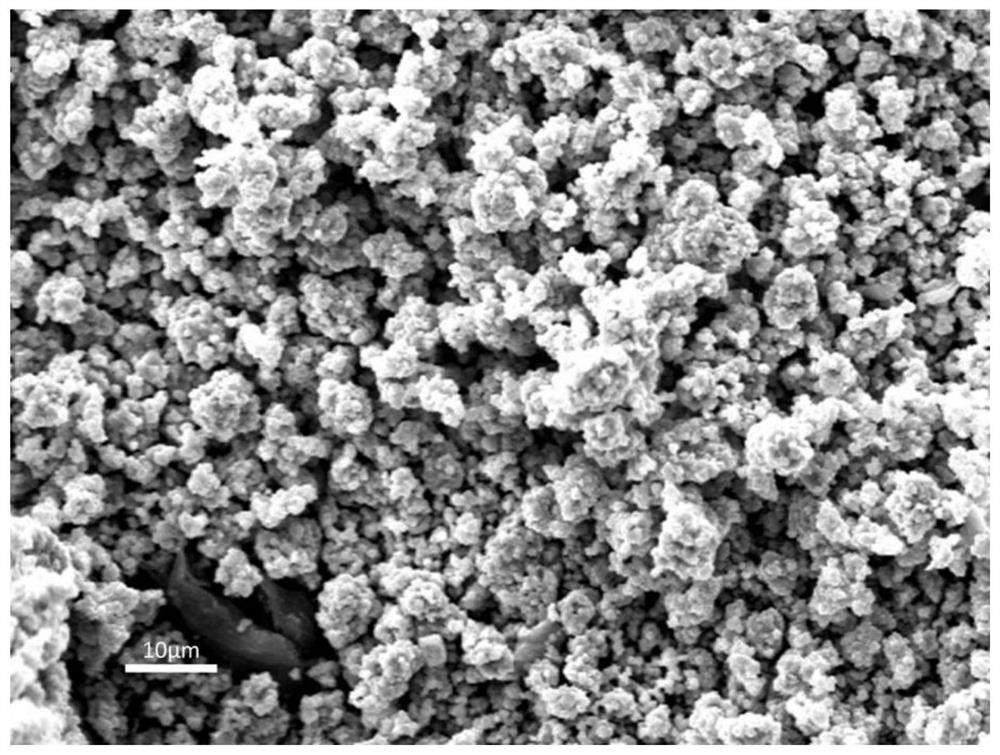

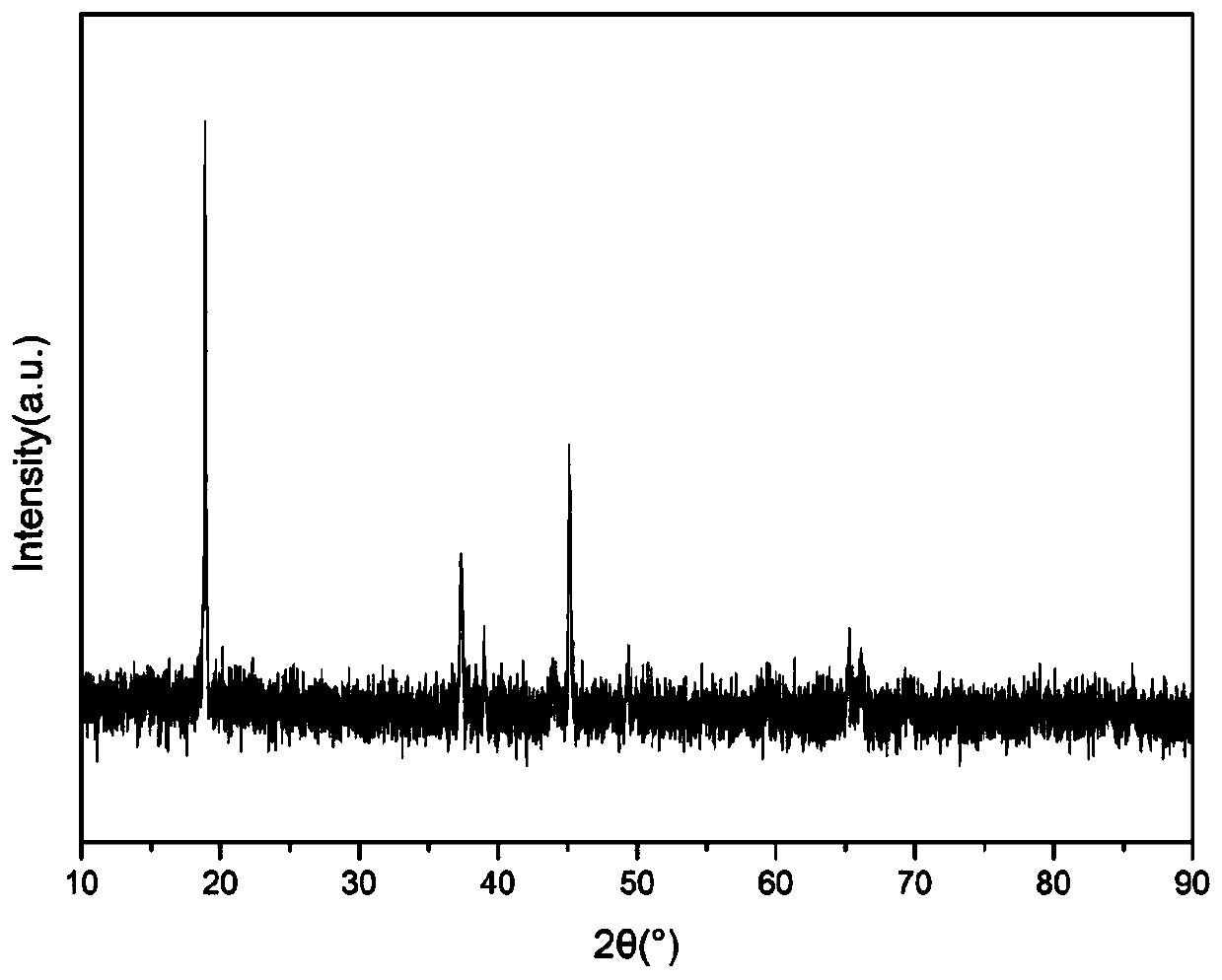

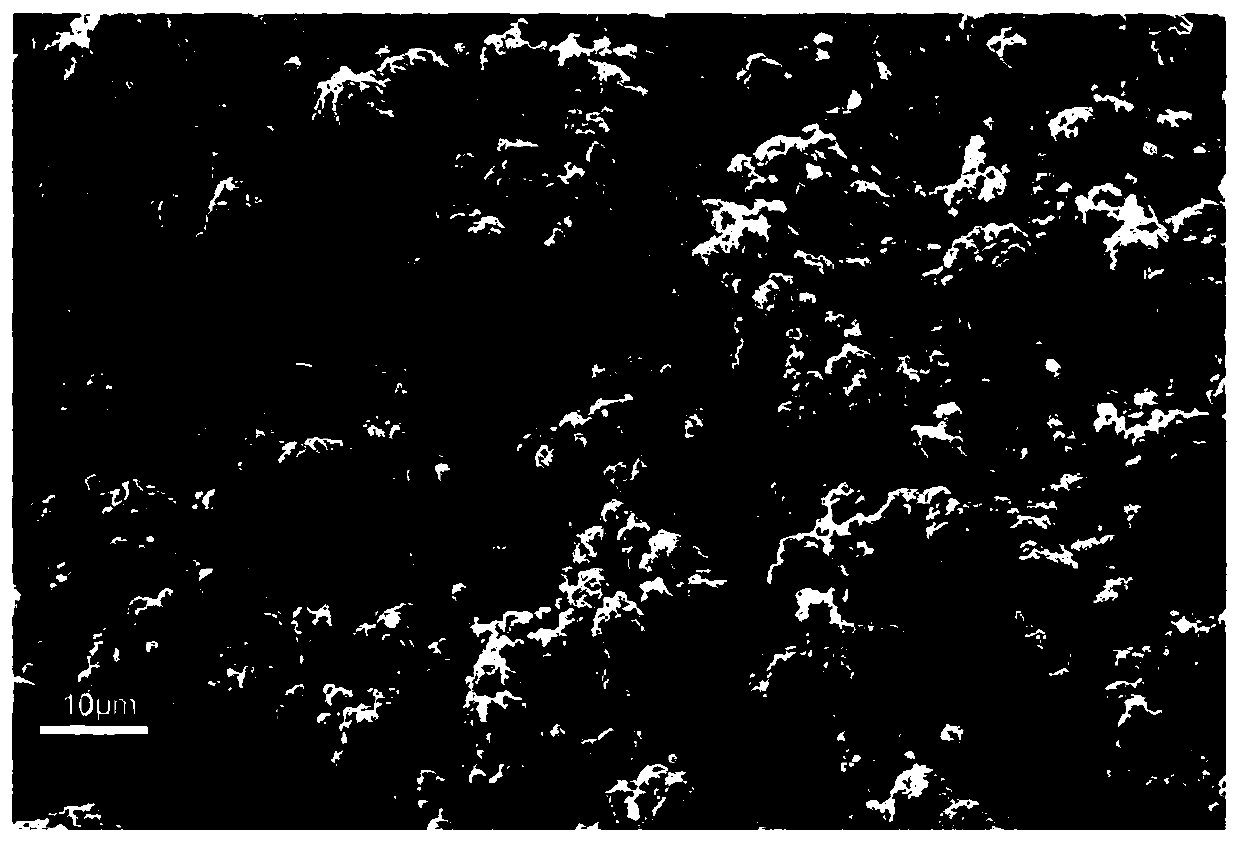

A kind of preparation method and application of hierarchical structure cathode material for lithium ion battery

ActiveCN110380041BEasy to embedImprove mechanical propertiesSecondary cellsPositive electrodesElectrical batteryMolten salt

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a hierarchical structure positive electrode material for lithium ion batteries and a preparation method thereof. The chemical formula of the hierarchical structure positive electrode material is specifically LiNi x co y Al 1‑x‑y o z Cl 2‑z ; 0.1≤x≤0.9, 0.1≤y≤0.9, 1.5≤z≤1.95, made by water mixing, molten salt mixing, sintering and crushing, by adding Cl element to replace the O element in the original NCA material, forming a different Compared with the NCA-like positive electrode of the traditional NCA material, the hierarchical structure positive electrode material has a regular and uniform microscopic morphology and has three characteristics of high potential, high specific energy, and high rate output.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

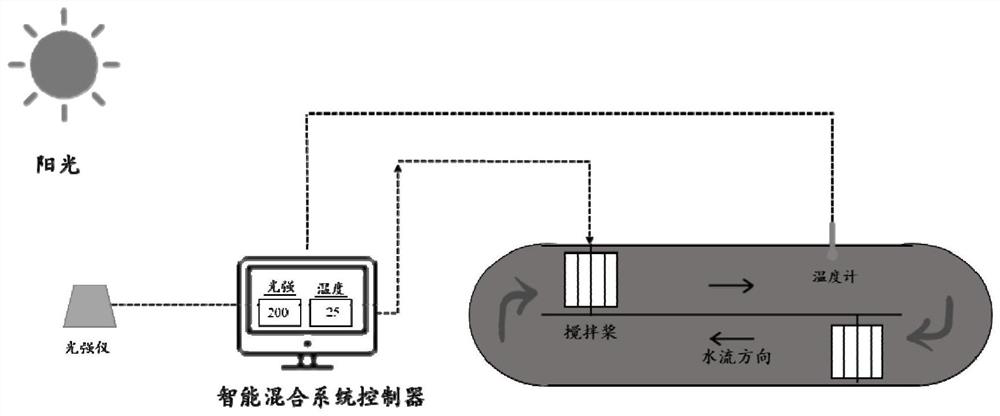

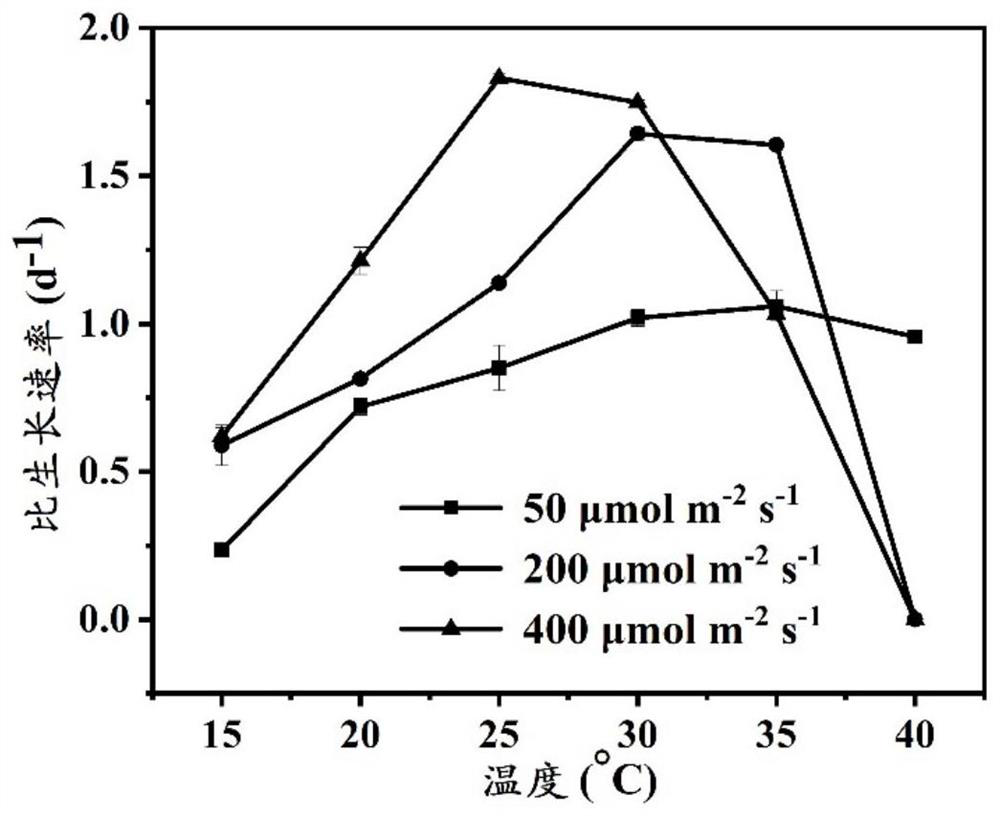

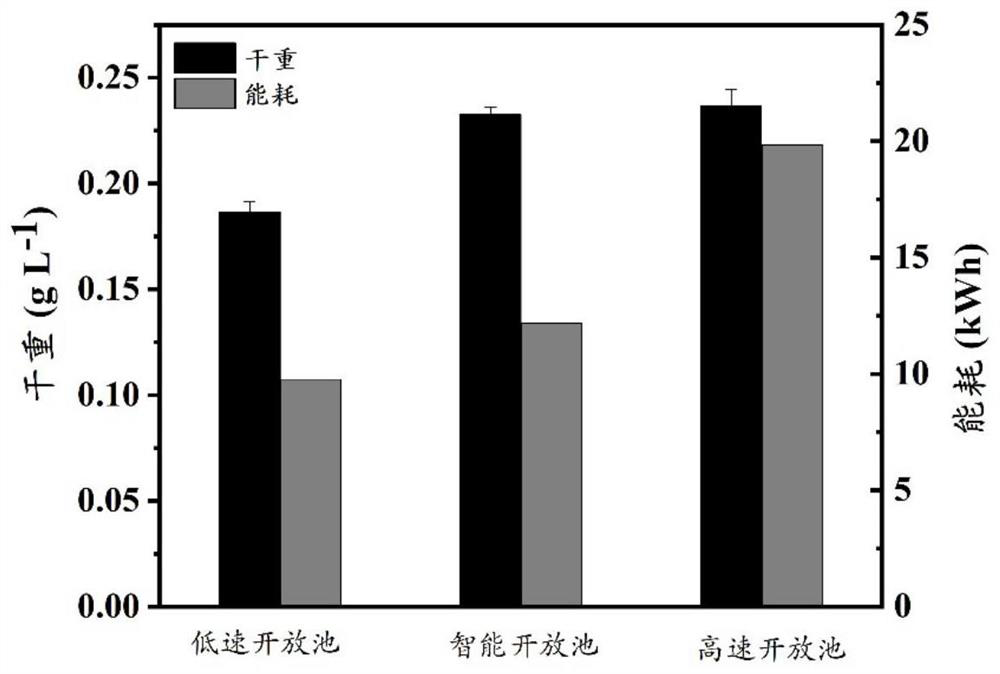

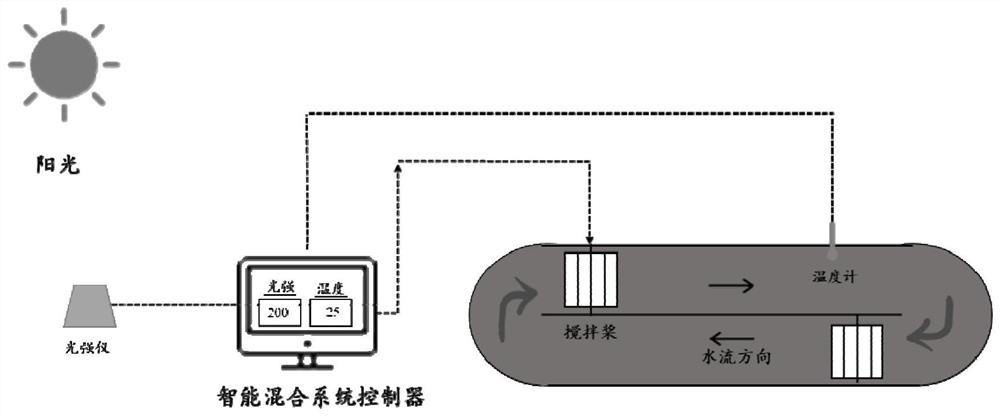

A method for cultivating microalgae based on artificial intelligence microalgae mixing system

ActiveCN112239727BEffective trainingEfficient growth processBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyBiochemical engineering

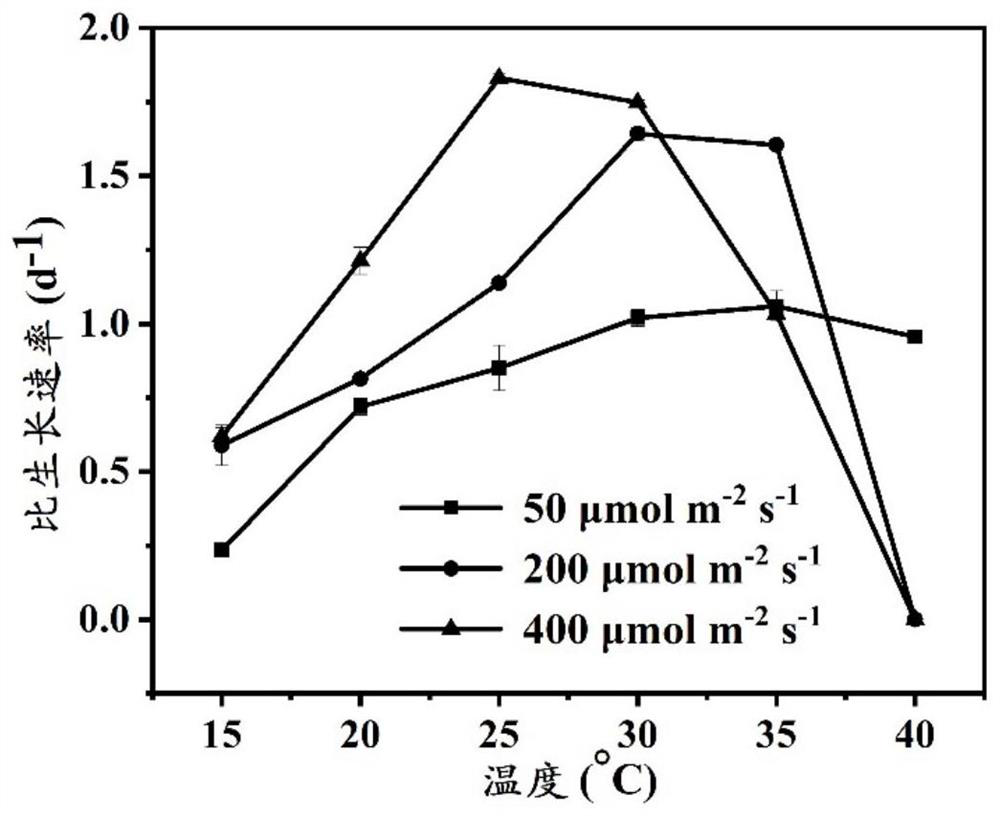

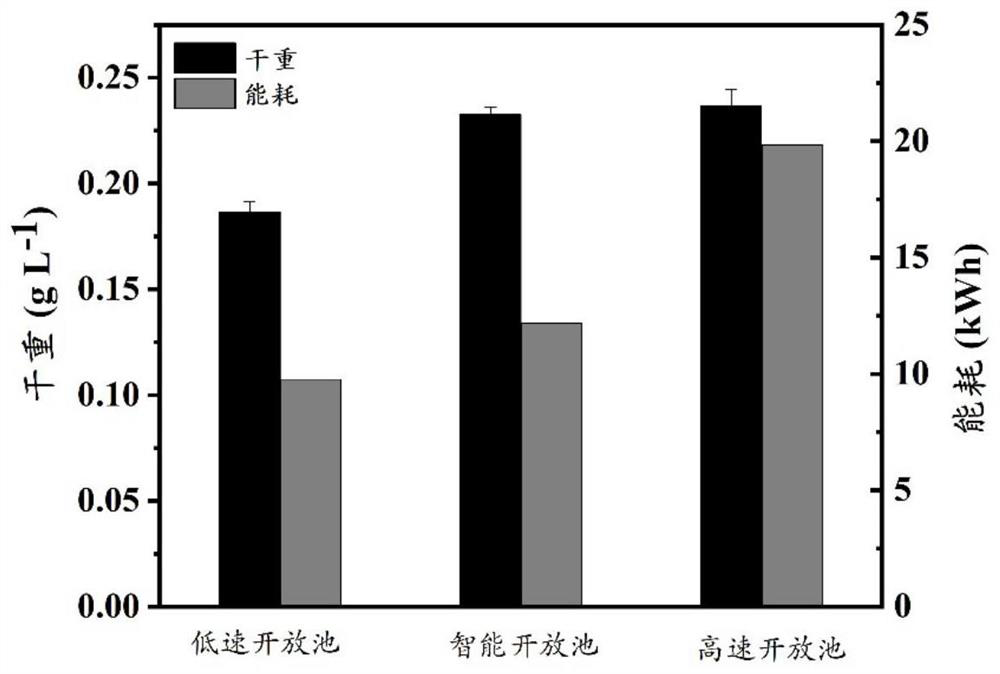

The invention discloses a method for cultivating microalgae based on an artificial intelligence microalgae mixing system, and relates to the technical field of microalgae cultivation. The method realizes balanced management of mixing energy by measuring temperature and light intensity in real time to adjust mixing intensity. More importantly, the method can enhance the mixing efficiency at the optimum growth time with the saved energy, thereby further improving the production efficiency of microalgae. Therefore, the present invention can also ensure efficient growth of microalgae while reducing mixing energy consumption, and has great application potential.

Owner:DALIAN UNIV OF TECH

Method for culturing microalgae based on artificial intelligence microalgae mixing system

ActiveCN112239727AEffective trainingEfficient growth processBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyBiochemical engineering

The invention discloses a method for culturing microalgae based on an artificial intelligence microalgae mixing system, and relates to the technical field of microalgae culture. According to the method, mixing intensity is adjusted by measuring the temperature and the light intensity in real time to realize balanced management of the mixing energy. More importantly, the method can enhance the mixing efficiency of the saved energy in the optimal growth time, so that the production efficiency of the microalgae is expected to be further improved. Therefore, the method provided by the invention can ensure the efficient growth of microalgae while reducing mixing energy consumption, and has great potential for application.

Owner:DALIAN UNIV OF TECH

Method for preparing hierarchical structure positive pole material for lithium ion battery and application

ActiveCN110380041AEasy to embedImprove mechanical propertiesSecondary cellsPositive electrodesPhysical chemistryMolten salt

The invention belongs to the technical field of a lithium ion battery and particularly relates to a hierarchical structure positive pole material for the lithium ion battery and a method for preparingthe hierarchical structure positive pole material for the lithium ion battery. A chemical formula of the hierarchical structure positive pole material is specifically LiNixCoyAl1-x-yOzCl2-z, whereinthe x is not smaller than 0.1 and is not greater than 0.9, the y is not smaller than 0.1 and is not greater than 0.9, the z is not smaller than 1.5 and is not greater than 1.95, the hierarchical structure positive pole material is prepared through water mixing, molten salt mixing, sintering and pulverization, by replacing O elements in an original NCA material by adding Cl elements, an NCA-type positive pole different from a conventional NCA material is formed, and the hierarchical positive pole material has the regular uniform microscopic morphology and further has high potential, high specific energy and high magnification output.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

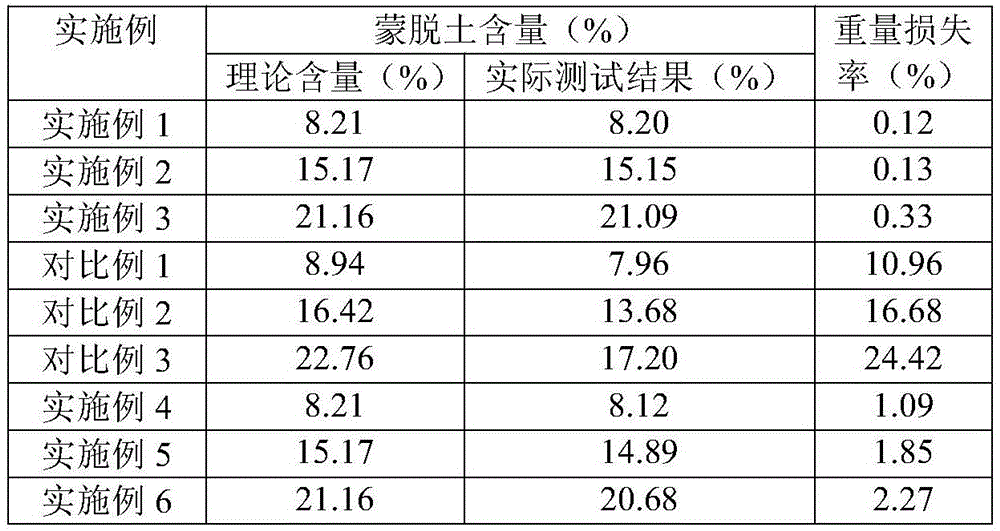

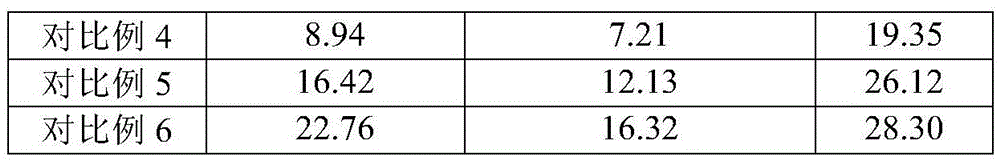

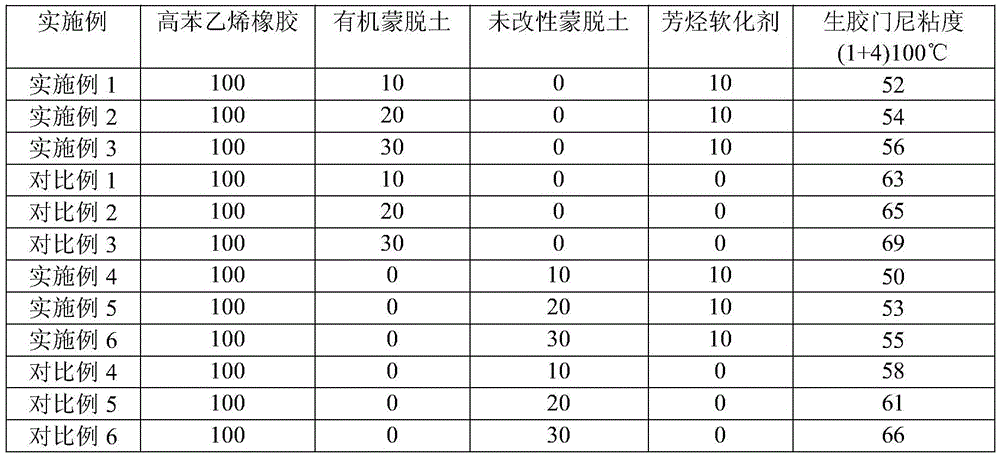

Preparation method of high styrene emulsion coprecipitation rubber filled with softening agent and montmorillonite

The invention discloses a preparation method of high styrene emulsion coprecipitation rubber filled with a softening agent and montmorillonite. The preparation method comprises the steps that 1, raw materials are prepared according to a formula; 2, a montmorillonite suspension, a coupling agent and an anti-aging agent are added into high styrene rubber emulsion; 3, the emulsification softening agent is added; 4, an emulsification mixture, a flocculating agent and protonic acid are slowly and simultaneously added into an aqueous solution of inorganic salt and a flocculating agent; 5, inorganic base is added to regulate the pH to be 7, flocculate is formed while stirring is performed, and the flocculate is dewatered and dried to obtain the high styrene emulsion coprecipitation rubber filled with the softening agent and the montmorillonite. According to the preparation method, the montmorillonite is firstly soaked and intercalated through the low-molecular softening agent in the coprecipitation process, and the low-molecular softening agent carries the montmorillonite to together permeate among rubber particle molecular chains to form an integral body, so that the montmorillonite cannot be separated into a water phase alone any more during massive filling of the montmorillonite; meanwhile, montmorillonite layers are dispersed more uniformly, the more effective filling and reinforcing effects are achieved, and the performance of the coprecipitation rubber is excellent.

Owner:QINGDAO UNIV +1

A kind of preparation method of cottonseed meal protein compound slurry

The invention discloses a preparation method of cottonseed meal protein compound slurry. The preparation method comprises the following steps: mixing cottonseed meal, which is treated by detoxification by using gossypol, with starch according to a dry basis mass ratio of (20 to 1) to (10 to 1) to obtain mixed dry powder; putting the mixed dry powder into an alkaline solution, wherein the mass of the alkaline solution is 5-20 times that of the mixed dry powder, and the hydroxyl ion concentration of the alkaline solution is 1-5%; carrying out ultrasonic treatment on the obtained mixture for 5-60min; then, stirring and heating for 30-90min at the constant temperature of 50-95 DEG C, adding a hydrophilic plasticizer in the process of stirring and heating, wherein the mass of the hydrophilic plasticizer accounts for 10-30% of that of the mixed dry powder, using diluted hydrochloric acid to adjust the pH value of a reaction system to a neutral or weak alkaline condition, and removing precipitate to obtain the slurry which is the cottonseed meal protein compound liquid slurry directly used for sizing. After the technical scheme is adopted, the completely unshelled cottonseed meal is prepared into the slurry for warp sizing so as to replace polyvinyl alcohol (PVA), so that the problem that the biodegradation of desizing wastewater is difficult to implement is effectively solved, and the bottleneck that the desizing wastewater is difficult to treat is broken through.

Owner:JIANGNAN UNIV +1

A kind of PBS thermoplastic elastomer and preparation method thereof

The invention belongs to the technical field of high molecular material processing and preparation and in particular relates to a full biodegradable PBS thermoplastic elastomer and a preparation method thereof. The full biodegradable PBS thermoplastic elastomer is prepared from the following components in parts by weight: a, organic salt microspheres, b, PBS, c, a softening agent and d, a hydrolysis resistant, wherein the weight ratio of the components a and b is 50: 50 to 75: 25; the component c accounts for 5-20 parts by weight based on total weight of the components a and b, totaling 100 parts; and the component d accounts for 2 parts by weight based on weight of the components a, totaling 100 parts. The PBS thermoplastic elastomer prepared by the preparation method has excellent mechanical properties, biodegradability and cell compatibility and the maximum torque in the processing course can be reduced obviously, so that the mixing energy consumption is reduced greatly and the costis saved.

Owner:QINGDAO UNIV OF SCI & TECH

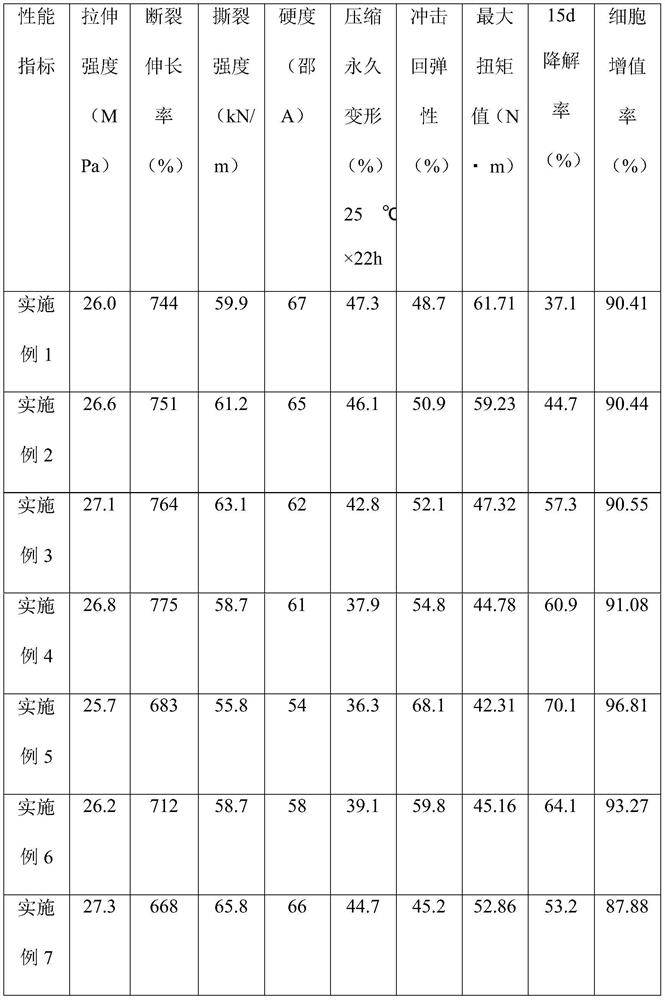

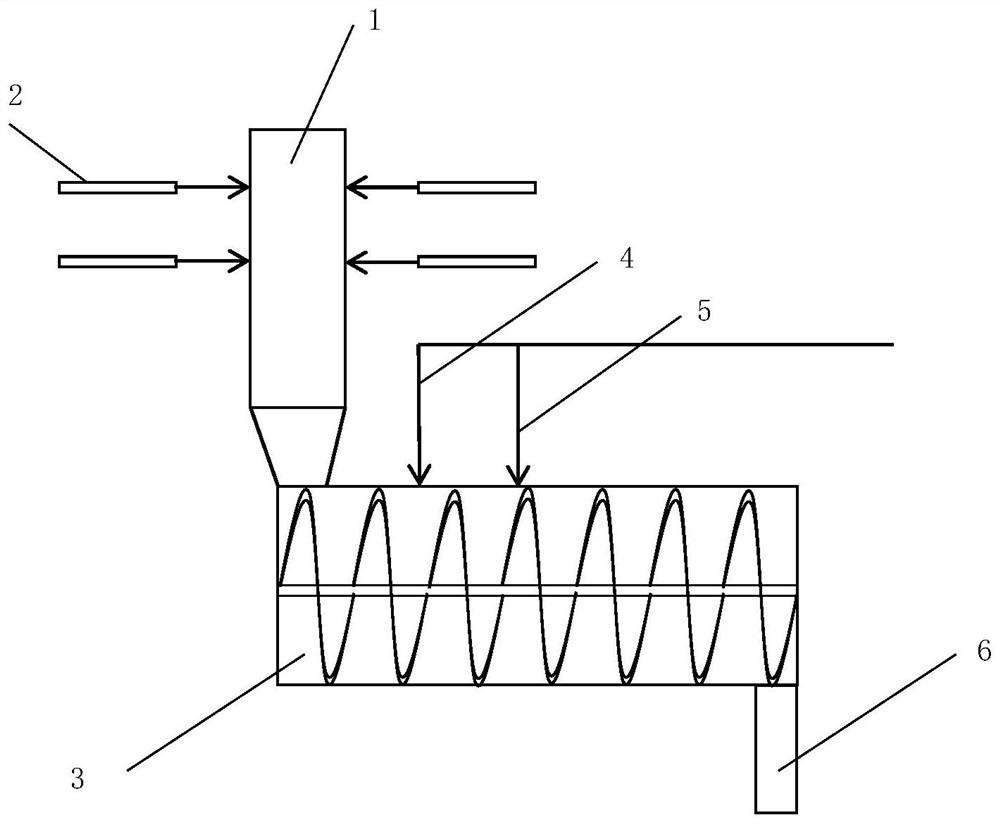

A kind of method for preparing oily carbon black particles, oily carbon black and application thereof

ActiveCN113563742BEasy to processReduce mixing energy consumptionPigment physical treatmentPigment treatment with non-polymer organic compoundsPolymer scienceOrganic chemistry

Owner:青岛黑猫新材料研究院有限公司

A kind of grouting slurry for preparing high-strength quartz crucible and its preparation method

Owner:YICHANG KENNSUN SOLAR ENERGY MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com