A method for cultivating microalgae based on artificial intelligence microalgae mixing system

A technology of artificial intelligence and hybrid system, applied in the field of microalgae cultivation based on artificial intelligence, can solve problems such as waste of energy consumption, and achieve the effect of improving production efficiency, efficient cultivation, and large application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

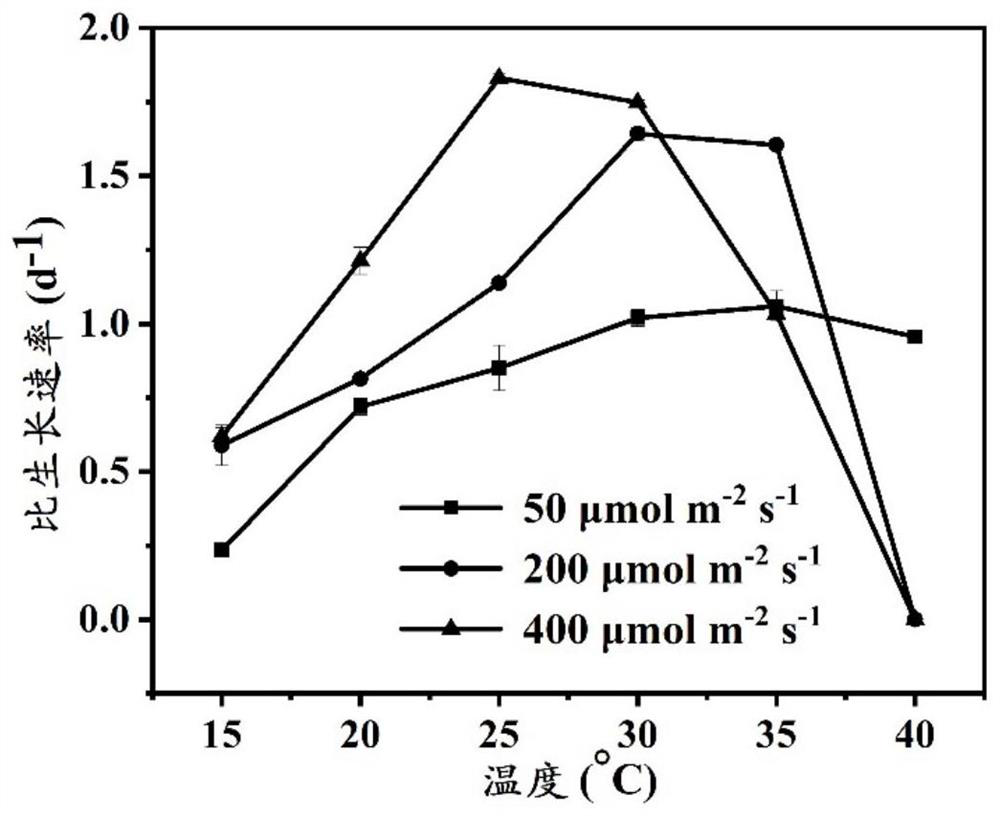

[0066] The influence of embodiment 1 temperature and light intensity on the growth of spirulina

[0067] First prepare the following medium: 25.2g L -1 NaHCO 3 , 2.5 g L -1 NaNO 3 , 0.04g L -1 CaCl 2 2H 2 O, 1.0g L -1 K 2 SO 4 ,0.5gL -1 K 2 HPO 4 ,0.2g L -1 MgSO 4 ·7H 2 O,0.01gL -1 FeSO 4 ·7H 2 O,1.979gL - 1 MoCl 2 4H 2 O, 3.092 g L -1 h 3 BO 3 , 0.484g L -1 NaMo 4 2H 2 O, 0.23 g L -1 ZnSO 4 ·7H 2 O, 0.183 g L - 1NaVO 3 , 0.048g L -1 CoCl 2 ·6H 2 O, 0.2 g L -1 CuSO 4 ·5H 2 O.

[0068] The above-mentioned medium was injected into a rectangular tubular photobioreactor with a height of 10 cm, a width of 5.0 cm, and a length of 20 cm. The mixing of the reaction was provided by a rocker shaker with a speed of 60 rpm, and the shaker was set to continuous working mode. Then in this reactor, insert fresh Spirulina FACHB-314, and control final inoculation volume and inoculation density to be 200ml and 0.1g L respectively -1 . Finally, at 50, 20...

Embodiment 2

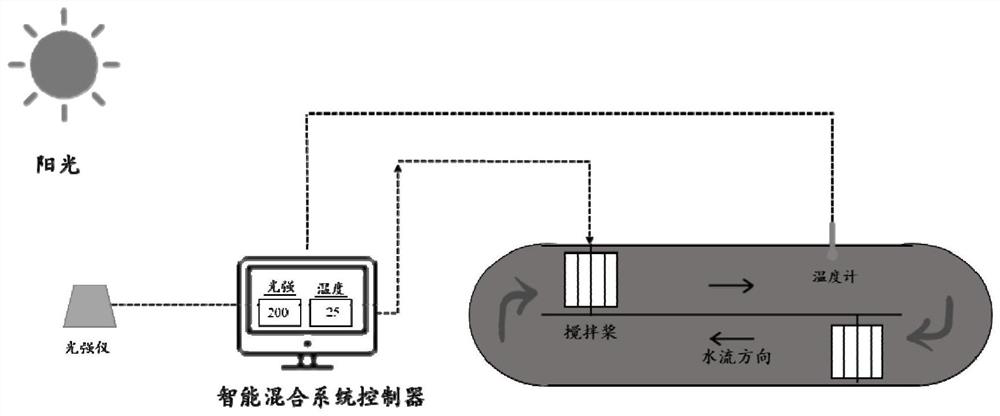

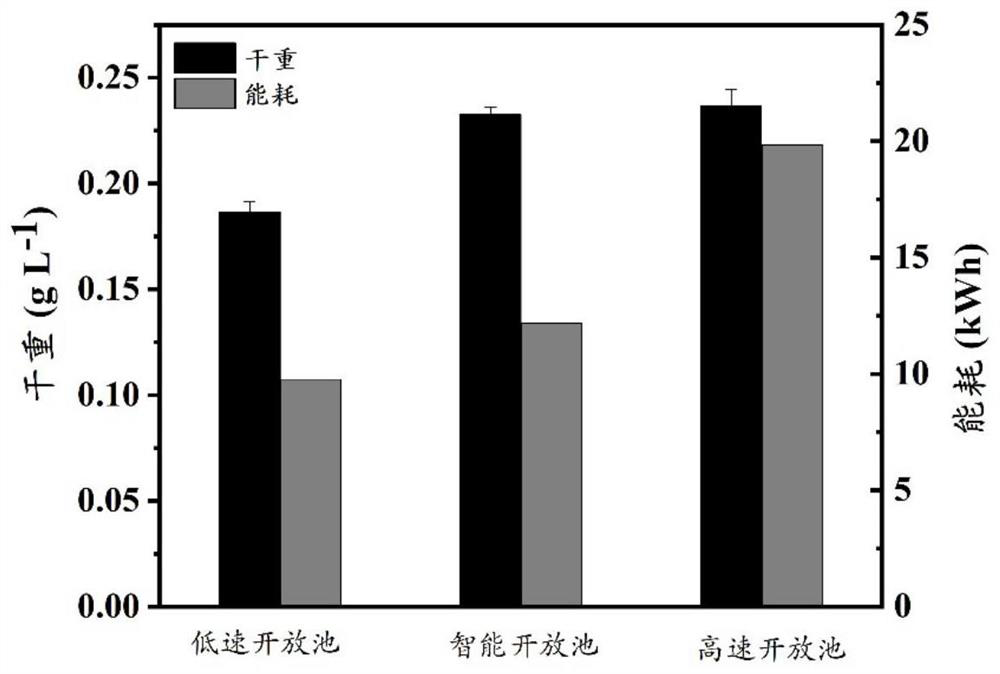

[0070] Embodiment 2 intelligent open pond cultivates spirulina

[0071] It is 2.0m2 that the 400L culture medium described in embodiment 1 is injected into the cultivation area 2 In the runway pool, the thickness of the liquid layer is 20.0cm after the culture medium is injected. The mixing of the culture solution in the open pool is driven by its stirring paddle, wherein the stirring paddle is connected with the controller of the intelligent mixing system through a data line, and operates under the instruction of the controller. In addition, the controller is also respectively connected with a light intensity meter and a thermometer for detection and acquisition of light intensity and temperature, wherein the measured temperature is the temperature of the culture solution. The controller will be used to control the rotation speed of the stirring paddle according to the data detected in real time and through a pre-programmed program. The control is based on the experimental r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com