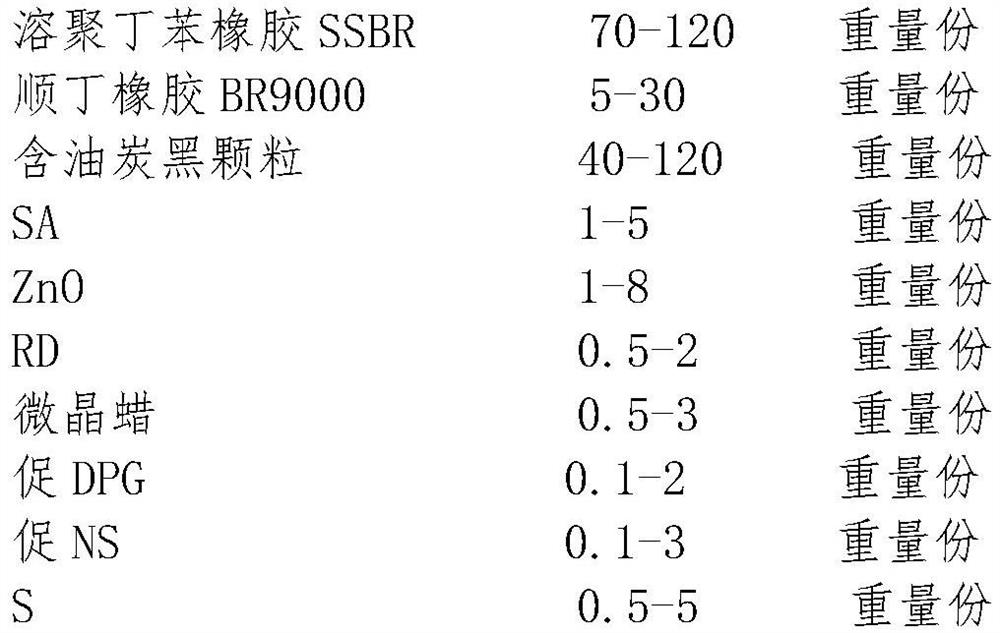

A kind of method for preparing oily carbon black particles, oily carbon black and application thereof

A technology of carbon black and granules, which is applied in the field of preparing oil-containing carbon black granules, can solve the problems of rubber processing performance deterioration, and achieve the effects of facilitating processing performance, simplifying the process, and reducing energy consumption for mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

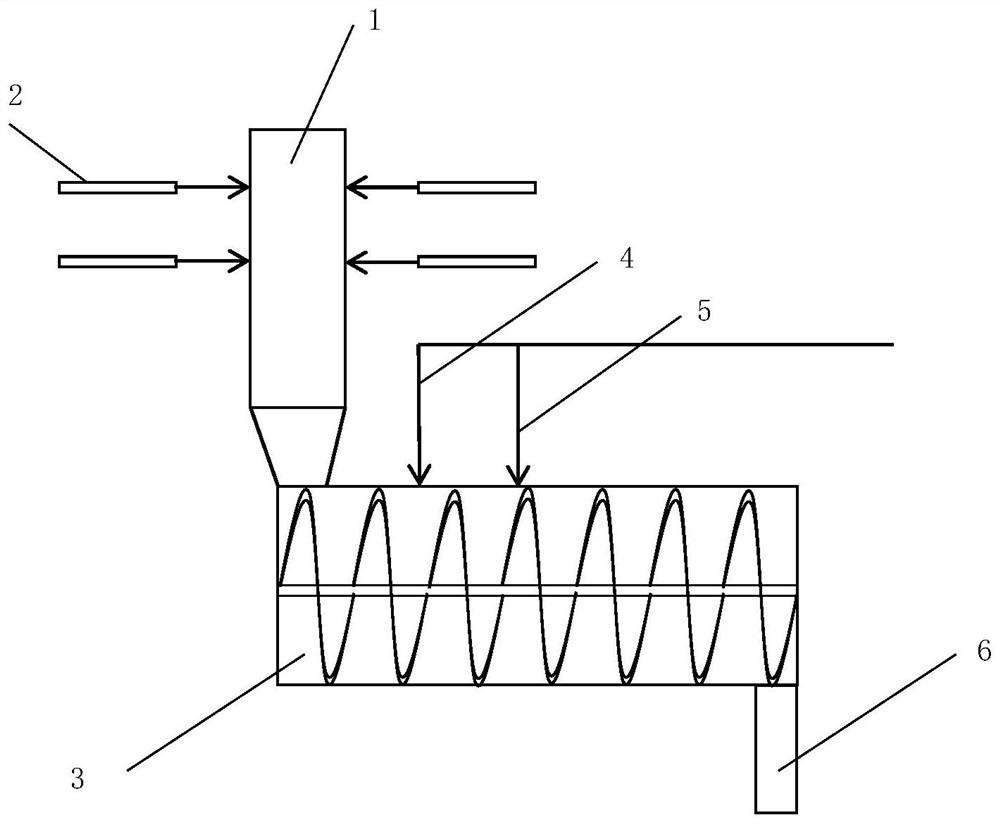

Method used

Image

Examples

Embodiment 5

[0046] The powdered carbon black before granulation is metered and fed into the upper channel of the granulator, and the feeding speed is controlled to be 400g / min. The oil temperature was controlled at 60°C and the flow rate was 40 g / min. When the carbon black enters the granulation section, the granulation water pump is turned on, and the flow rate of the granulation water is controlled at 600g / min. After the granulated carbon black is obtained, it is dried by a drum dryer until the moisture content is qualified.

Embodiment 6

[0048] The powdered carbon black before granulation is metered and fed into the upper channel of the granulator, and the feeding speed is controlled to be 200g / min. The oil temperature was controlled at 60°C and the flow rate was 40 g / min. When the carbon black enters the granulation section, the granulation water pump is turned on, and the flow rate of the granulation water is controlled at 600g / min. After the granulated carbon black is obtained, it is dried by a drum dryer until the moisture content is qualified.

Embodiment 7

[0050] The powdered carbon black before granulation is metered and fed into the upper channel of the granulator, and the feeding speed is controlled to be 100g / min. The metering pump is used to meter and atomize the operating oil or mixed oil, which accounts for 40% of the carbon black mass. The oil temperature was controlled at 60°C and the flow rate was 40 g / min. When the carbon black enters the granulation section, the granulation water pump is turned on, and the flow rate of the granulation water is controlled at 600g / min. After the granulated carbon black is obtained, it is dried by a drum dryer until the moisture content is qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com