Preparation method of graphene-silica modified natural rubber composite material with high thermal conductivity, low thermogenesis and excellent mechanical properties for tires

A thermodynamic performance, silica technology, applied in the direction of rolling resistance optimization, special tires, tire parts, etc., can solve problems such as accelerated rubber aging, tire thermal damage, bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

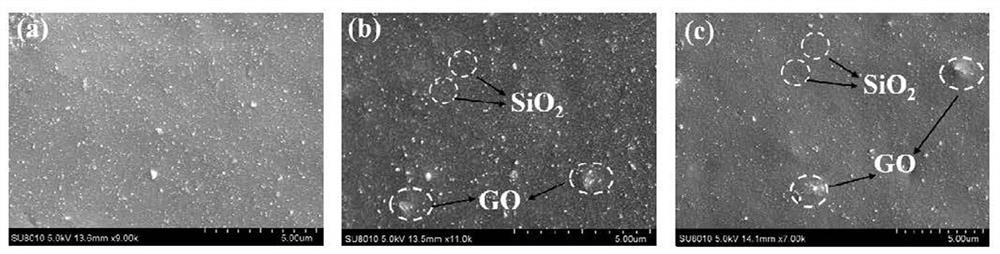

[0031] Graphene oxide-silica modified natural rubber

[0032] ①Preparation of surface aminated silica: Mix ethanol and water at a mass ratio of 7:1 at room temperature, then add 3g to 5g of silane coupling agent KH550 dropwise to 100ml of ethanol and water mixture Fully hydrolyzed in the middle, the hydrolysis time is 2h. Then the raw material SiO 2 The powder was added to the aqueous ethanol solution of KH550 and stirred at 70°C for 8 h to obtain KH550-modified SiO 2 . Finally, after filtering and washing three times with absolute ethanol and water, to remove unreacted KH550, the obtained modified SiO 2 Treat in a vacuum oven at 60°C for 24 hours to obtain aminated silicon dioxide.

[0033] ②Preparation of graphene oxide-silica composite particles: 100g of 0.5wt.% GO (graphene oxide) aqueous solution was mixed with deionized water, and the graphene oxide was fully dispersed in the aqueous solution by ultrasonication for 30 minutes. The GO aqueous solution was cooled to 0...

Embodiment 2

[0038] 3-Mercaptopropyltriethoxysilane Modified Graphene Oxide-Silica Modified Natural Rubber

[0039] ①Preparation of surface aminated silica: Mix ethanol and water at a mass ratio of 7:1 at room temperature, then add 3g to 5g of silane coupling agent KH550 dropwise to 100ml of ethanol and water mixture Fully hydrolyzed in the middle, the hydrolysis time is 2h. Then the raw material SiO 2 The powder was added to the aqueous ethanol solution of KH550 and stirred at 70°C for 8 h to obtain KH550-modified SiO 2 . Finally, after filtering and washing three times with absolute ethanol and water, to remove unreacted KH550, the obtained modified SiO 2 Treat in a vacuum oven at 60°C for 24 hours to obtain aminated silicon dioxide.

[0040] ②Preparation of graphene oxide-silica composite particles: Mix 100g of 0.5wt.% GO aqueous solution with deionized water, and ultrasonically 30min to fully disperse graphene oxide in the aqueous solution. The GO aqueous solution was cooled to 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com