A kind of PBS thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and aliphatic technology, which is applied in the field of polymer material processing and preparation, can solve the problems of bio-based thermoplastic elastomers such as non-biodegradability, environmental pollution, and non-biocompatibility, etc., to reduce the mixing energy consumption, excellent mechanical properties, and good cell compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

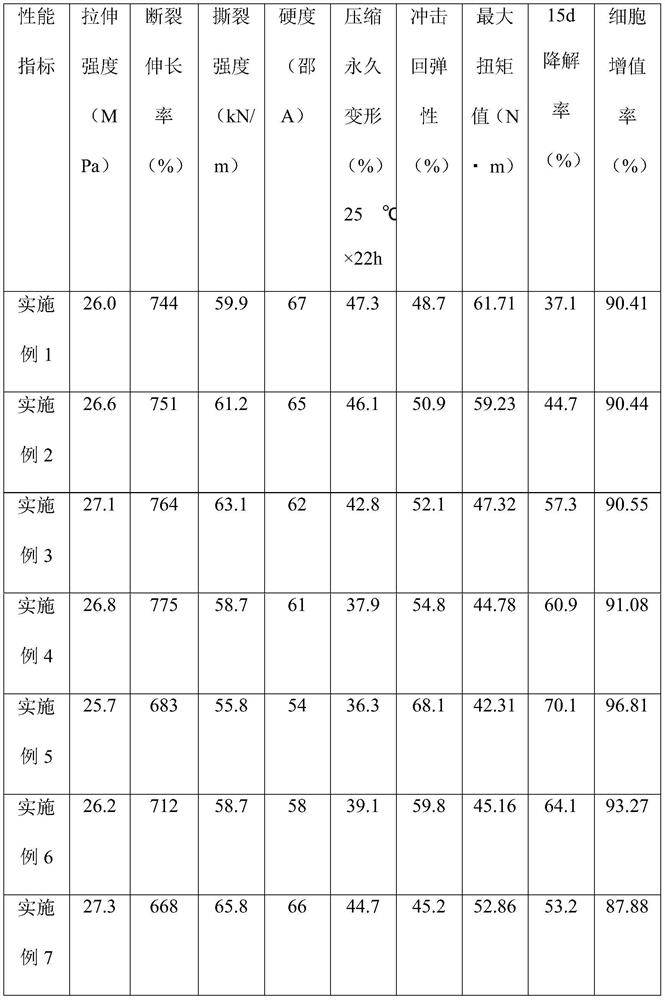

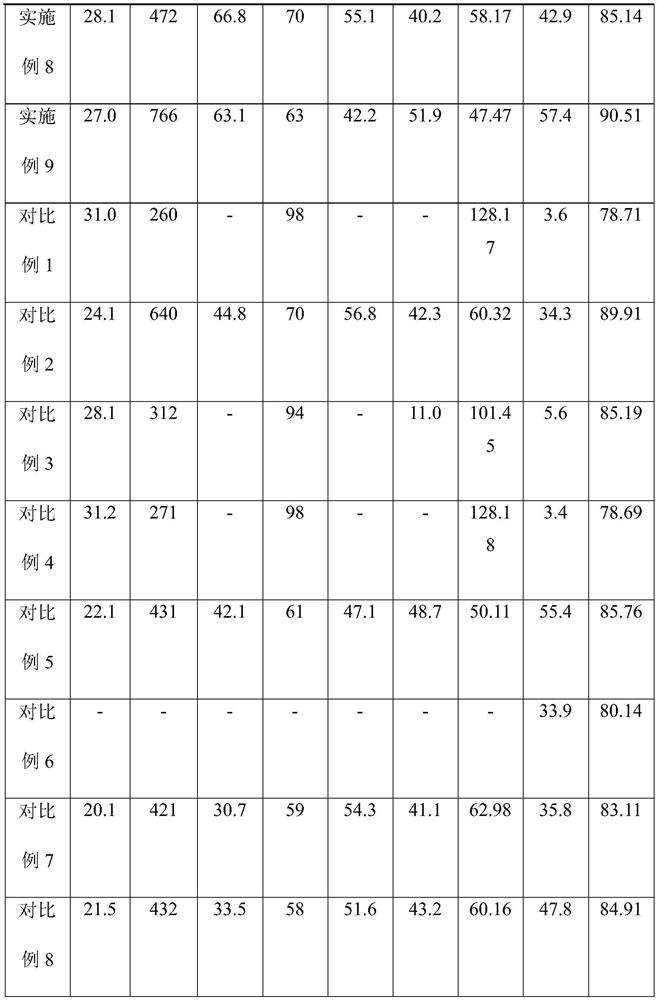

Examples

Embodiment 1

[0048] Add 5 parts (parts by mass, the same below) of acetyl tri-n-butyl citrate to 65 parts of dried organic salt microspheres for oil extension to obtain oil-extended organic salt microspheres;

[0049] Mix 70 parts of the above-mentioned oil-extended organic salt microspheres, 35 parts of PBS, and 1.3 parts of carbodiimide anti-hydrolysis agent UN-150 in a high-speed mixer, and then put the premix in the Hacker Torque Rheology The fully biodegradable PBS thermoplastic elastomer was prepared by high temperature melt blending in the instrument.

[0050] Haake torque rheometer processing conditions: working temperature is 150°C, rotating speed is 70rpm, mixing for 10min until the mixing torque is balanced.

[0051] Wherein, the preparation method of the organic salt microspheres is as follows:

[0052] 1. Add 18.27g (0.240mol) 1,3-propanediol, 21.18g (0.235mol) 1,4-butanediol, 3.00g ( 0.015mol) PEG-200, 4.00g (0.010mol) PPG-400 and 28.60g (0.2422mol) succinic acid, 49.01g (0...

Embodiment 2

[0058] Add 10 parts (parts by mass, the same below) of acetyl tri-n-butyl citrate to 65 parts of dried organic salt microspheres for oil extension to obtain oil-extended organic salt microspheres;

[0059] Mix 75 parts of the above-mentioned oil-extended organic salt microspheres, 35 parts of PBS, and 1.3 parts of carbodiimide anti-hydrolysis agent UN-150 in a high-speed mixer, and then put the premix in the Hacker Torque Rheology The fully biodegradable PBS thermoplastic elastomer was prepared by high temperature melt blending in the instrument.

[0060] Haake torque rheometer processing conditions: working temperature is 150°C, rotating speed is 70rpm, mixing for 10min until the mixing torque is balanced.

Embodiment 3

[0062] Add 15 parts (parts by mass, the same below) of acetyl tri-n-butyl citrate to 65 parts of dried organic salt microspheres for oil extension to obtain oil-extended organic salt microspheres;

[0063] Mix 80 parts of the above-mentioned oil-extended organic salt microspheres, 35 parts of PBS, and 1.3 parts of carbodiimide anti-hydrolysis agent UN-150 in a high-speed mixer, and then put the premix in the Hacker Torque Rheology The fully biodegradable PBS thermoplastic elastomer was prepared by high temperature melt blending in the instrument.

[0064] Haake torque rheometer processing conditions: working temperature is 150°C, rotating speed is 70rpm, mixing for 10min until the mixing torque is balanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com