Preparation method of high styrene emulsion coprecipitation rubber filled with softening agent and montmorillonite

A high styrene and emulsion co-precipitation technology, applied in the field of polymer materials, can solve the problems of difficult industrial production, poor wettability, and difficult coating of montmorillonite, and achieve easy industrialization, low Mooney viscosity, effective filling and filling strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention relates to a preparation method of co-precipitation glue filled with montmorillonite high-styrene emulsion filled with softener. The required raw materials are 100 parts by weight of high-styrene latex for component A; 1-80 parts by weight of montmorillonite for component B Component C is 1-80 parts by weight of softening agent; Component D is 0.1-5 parts by weight of coupling agent; Component E is 0.1-5 parts by weight of anti-aging agent; Component F is flocculant; Component G is Mixed aqueous solution of inorganic salt and flocculant; component H is protonic acid; component I is inorganic base. Several other components (if necessary).

[0025] The high styrene latex of component A refers to the high styrene latex produced by the emulsion method, and the styrene content in the high styrene is 60-65%.

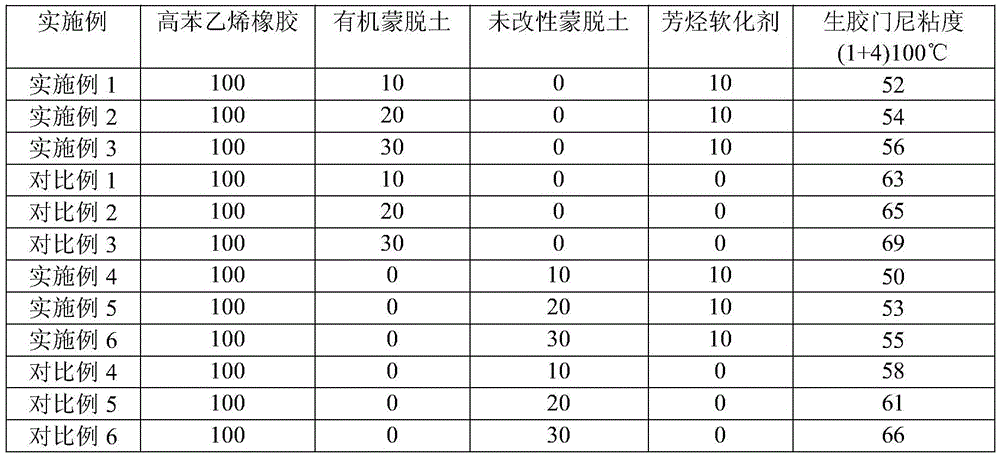

[0026] The component B montmorillonite can be organically modified montmorillonite or unmodified montmorillonite, and is prepared into organically modifi...

Embodiment 1-6

[0046] Taking aromatic hydrocarbon oil softener filled montmorillonite emulsion co-precipitated high-styrene rubber with 10 parts by weight as an example, the preparation method and performance of softener-filled montmorillonite high-styrene emulsion co-precipitated rubber of the present invention are illustrated.

[0047] The first step: raw material components and their preparation

[0048] 1. Raw material component (A) is high styrene rubber emulsion (solid content 24wt%), component (B) is organically modified montmorillonite (or unmodified montmorillonite) suspension (solid content is 11wt%) ); Component (C) is an emulsified aromatic oil softener (aromatic oil content 58wt%); Component (D) coupling agent silicon 69 (bis-[γ-(triethoxysilyl) propyl] tetrasulfide ); Component (E) antioxidant butyl (N-phenyl-2-naphthylamine); Component (F) is flocculant dinitrile diamine formaldehyde condensate (CA); Component (G) sodium chloride and Aqueous solution of dinitrile diamine form...

Embodiment 7

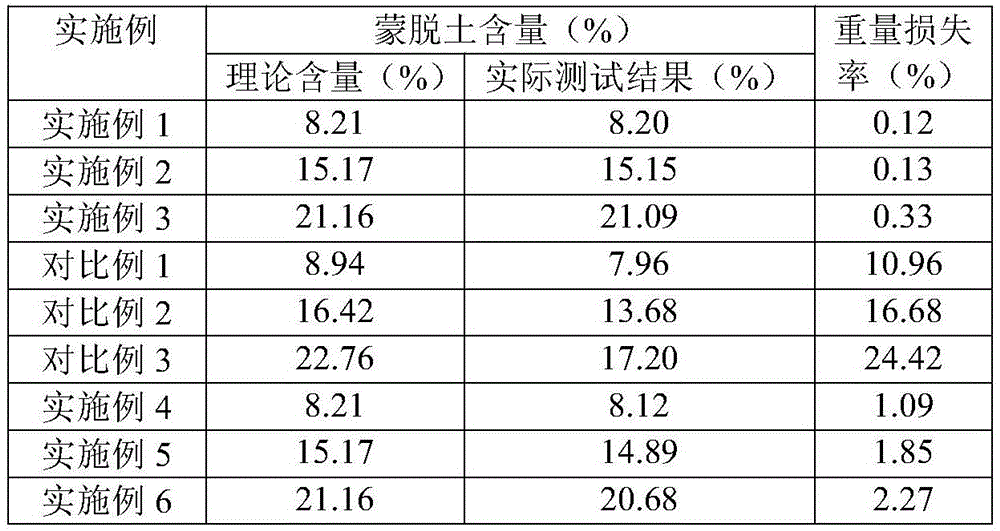

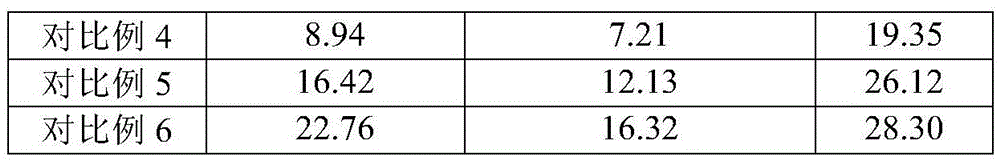

[0069] Carry out performance test to the softening agent filling montmorillonite high styrene emulsion coprecipitation glue prepared in embodiment 1-6:

[0070] 1. Raw rubber Mooney viscosity test: take softener-filled montmorillonite high-styrene emulsion co-precipitated rubber as pure rubber, and test its Mooney viscosity. The results are shown in Table 3.

[0071] Table 3 Embodiment 1-6 and comparative ratio raw rubber Mooney viscosity contrast

[0072]

[0073] From the results in Table 3, it can be seen that compared with the comparative example only filled with montmorillonite, the Mooney viscosity of co-sedimented rubber filled with montmorillonite and softener (only 10 parts by weight) is significantly reduced, indicating that the processing performance is greatly improved.

[0074] 2. Test of mechanical properties of vulcanized rubber: take softener-filled montmorillonite high-styrene emulsion co-precipitated rubber as pure rubber, add appropriate amount of compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com