A construction technique of h-shaped water-stop curtain

A construction process and technology for water-stop curtains, which are applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems that the curtain construction effect cannot achieve the expected purpose, affect the tunnel construction progress, and the tunnel operation environment is poor, etc., and achieve enhanced safety. The effect of stability, reducing construction disturbance and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Technical solutions

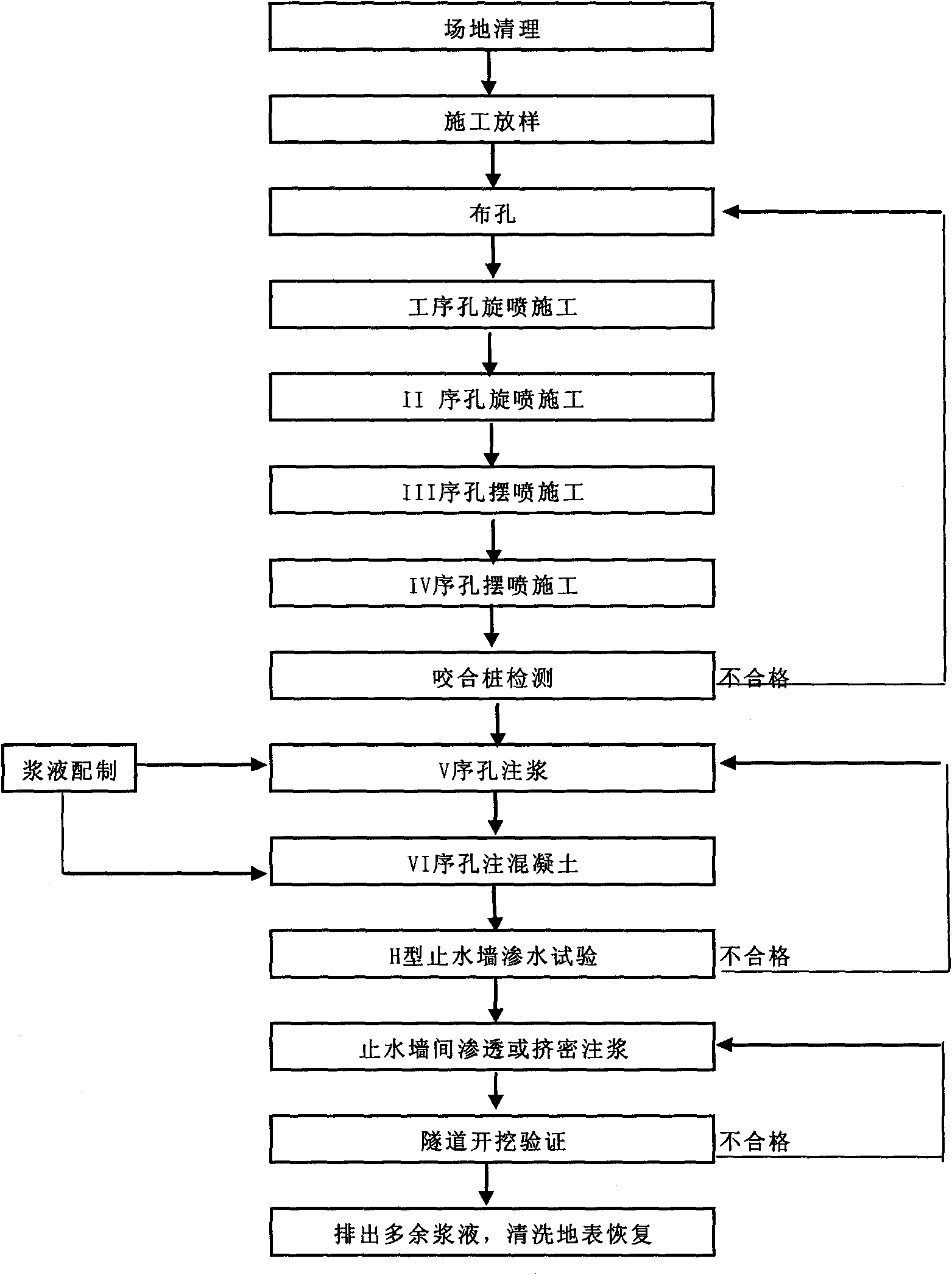

[0035] 1. Process method:

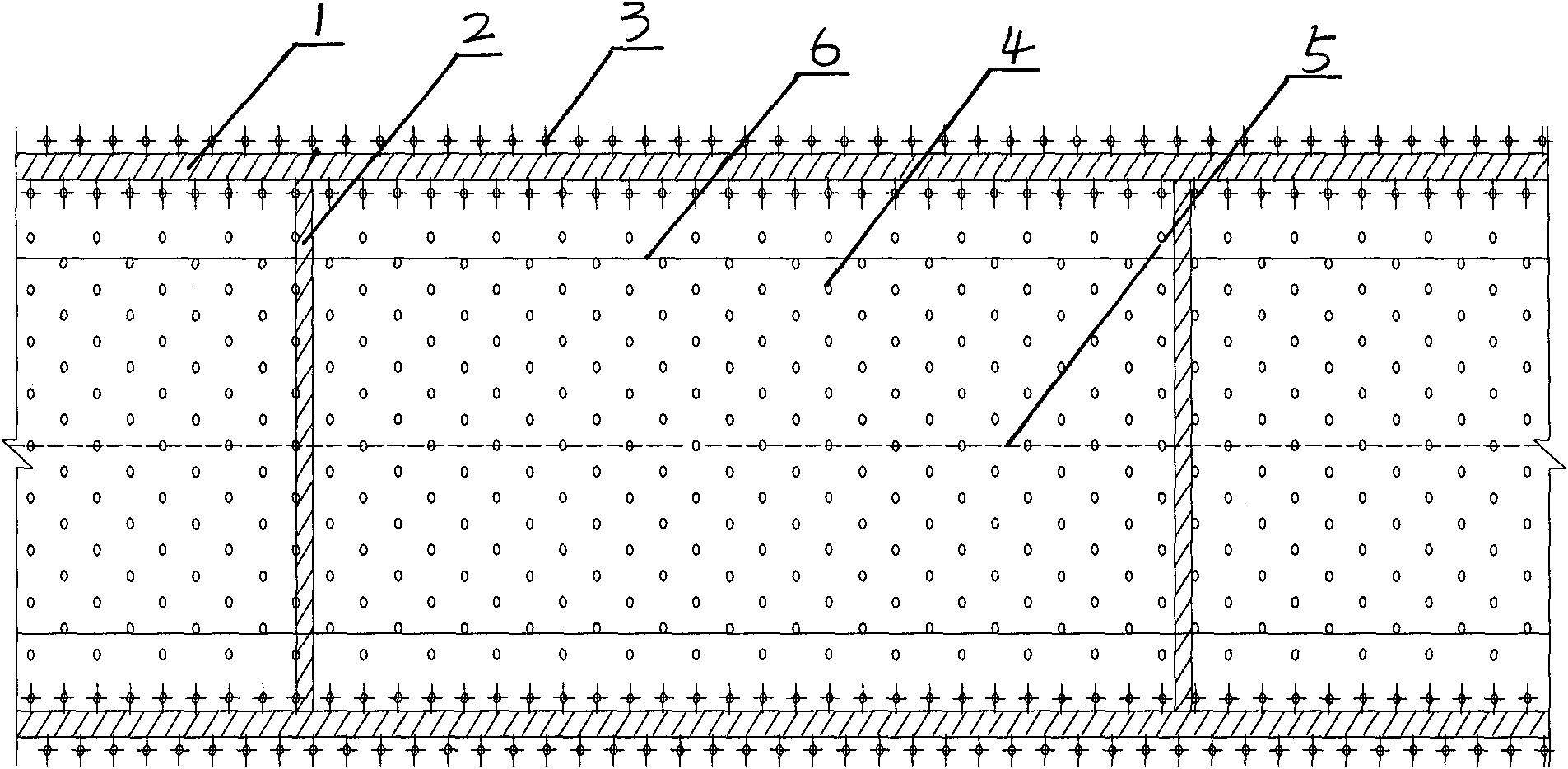

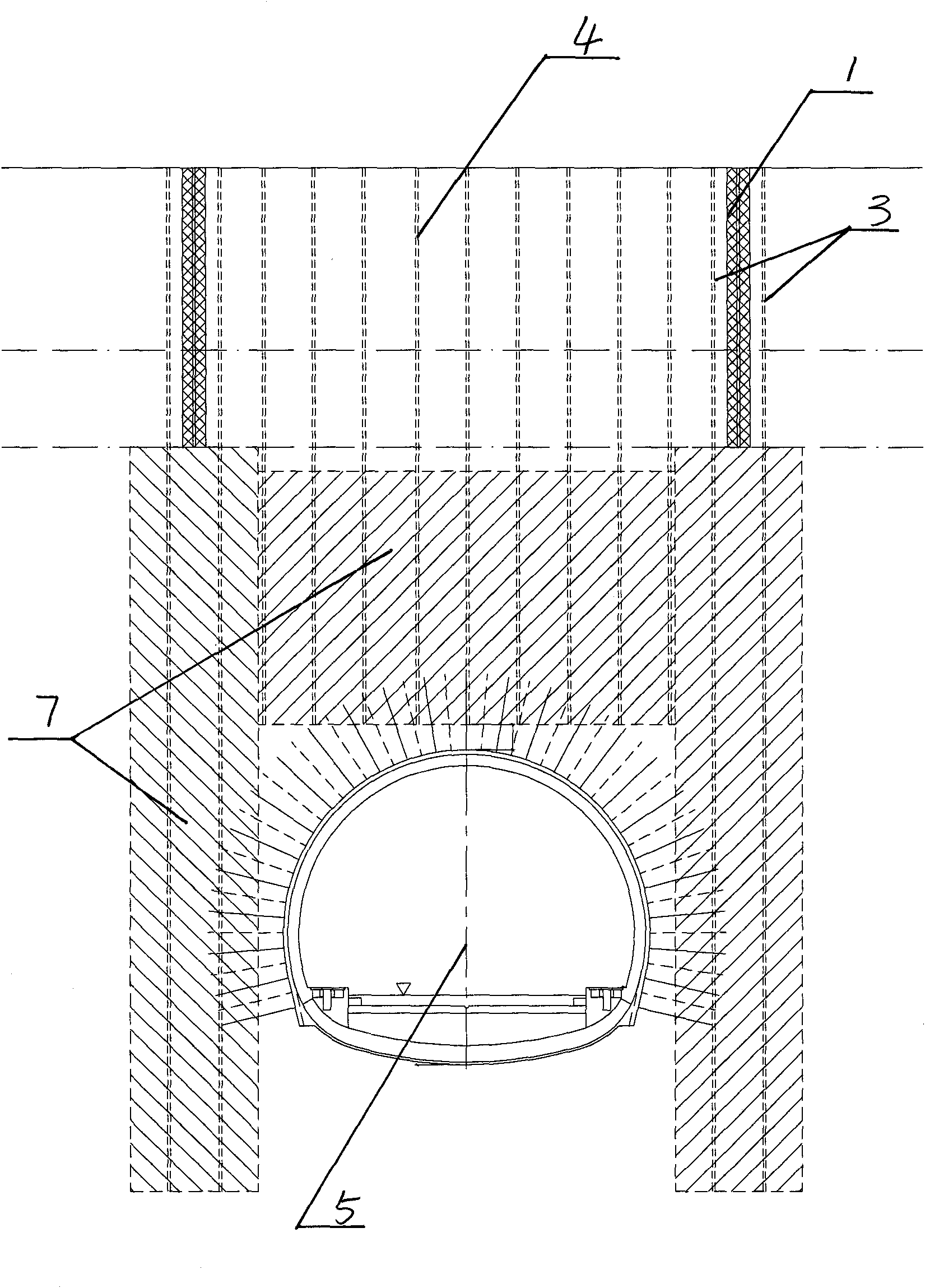

[0036] (1) Set up two cut-off walls 2.5m away from both sides of the outer side wall of the tunnel, and set up two rows of occlusal rotary grouting piles or mixing piles for water cut-off on the upper soil layer or sand layer (i. In the section where the rock is directly in contact with the rock, double rows of Φ500mm cement mixing piles are used for the soft soil layer, and the spacing is arranged at a distance of 400mm; The spacing is arranged according to 500mm), and a horizontal double-row occlusal rotary grouting pile or mixing pile is installed between the two cut-off walls at intervals of 100m to 150m along the longitudinal direction of the tunnel (the longitudinal spacing can be adjusted appropriately according to the conditions of the construction site and the geological and hydrological conditions) , to form a closed water cut-off curtain wall, which separates the influence area of the tunnel from the surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com