Patents

Literature

201results about How to "Improve construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-side-wall-pilot-hole subsection bench cut method construction method

InactiveCN102720504AImprove Convergent Deformation Constraint AbilityImprove performanceUnderground chambersTunnel liningPilot holeStructural engineering

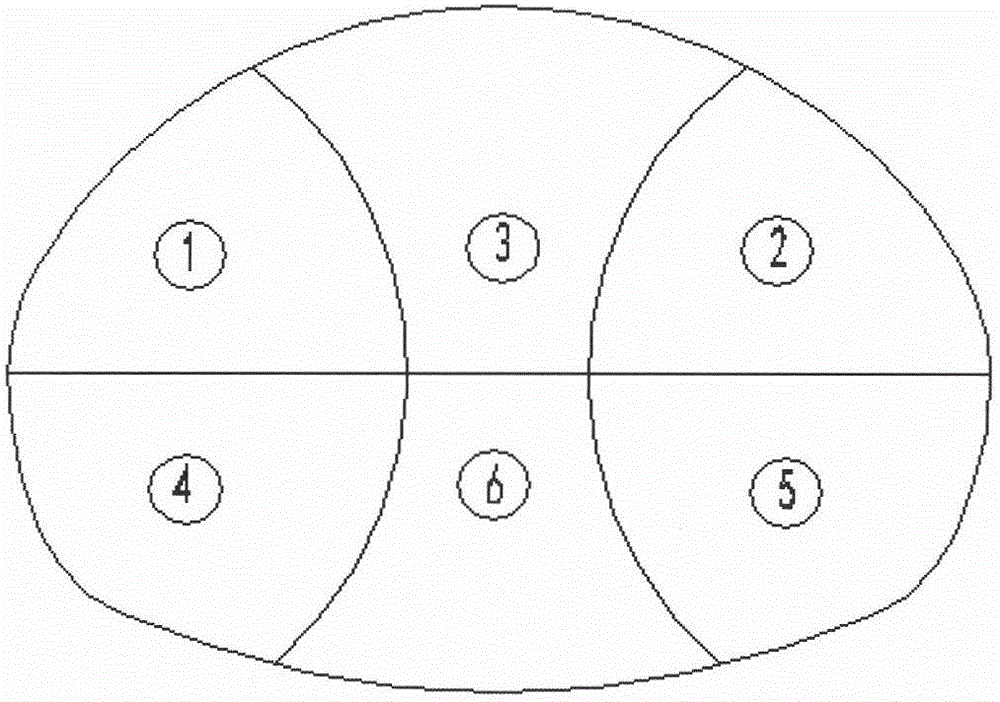

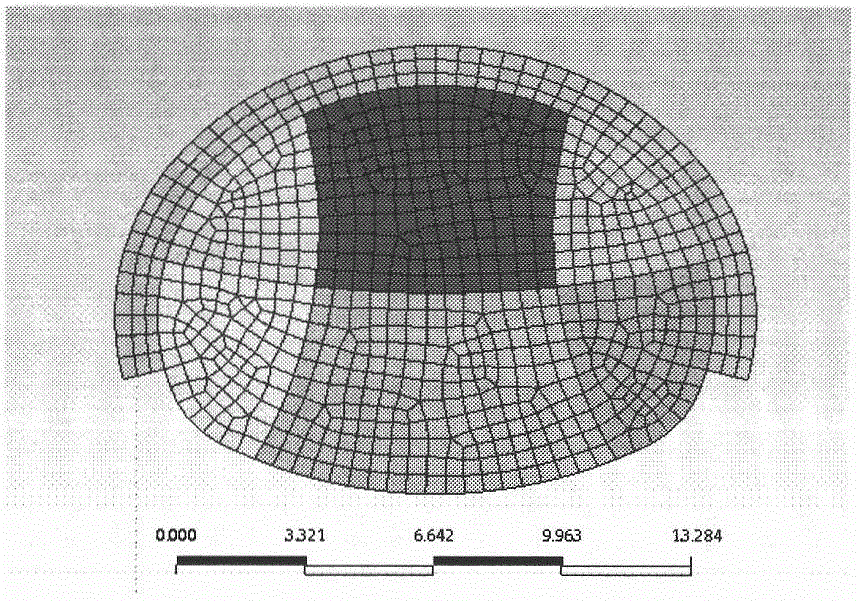

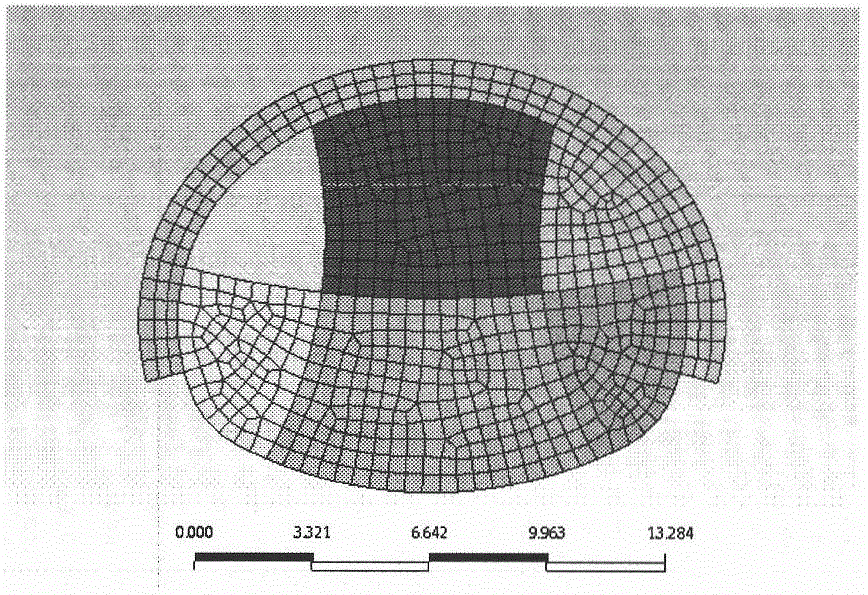

The invention relates to a double-side-wall-pilot-hole subsection bench cut method construction method, which comprises the steps that 1, upper bench two-side pilot holes are dug, and temporary support and preliminary bracing are carried out; 2, an upper bench middle pilot hole is dug, and the temporary support and the preliminary bracing are carried out; 3, lower bench two-side pilot holes are dug, and the temporary support and the preliminary bracing are carried out; and 4, a lower bench middle pilot hole is dug, and the temporary support and the preliminary bracing are carried out. The construction method has the advantages that the disturbing influence on surrounding rock bodies caused by the large cross-section tunnel six-part digging is smaller than that in the prior art, the work surface is increased, the work efficiency is improved, the surrounding rock convergence deformation restricting capability is improved, the integral performance of the preliminary bracing is improved, the operation efficiency is improved through reducing the work procedure alternation, and the disturbance on the surrounding rock is reduced through reducing the temporary support.

Owner:BEIJING ROAD & BRIDGE CONSTR GROUP

Construction method of deep foundation pit close to building and adopting underground structure as internal support

ActiveCN102966108AIncrease construction costsImprove construction periodExcavationsBasementEngineering

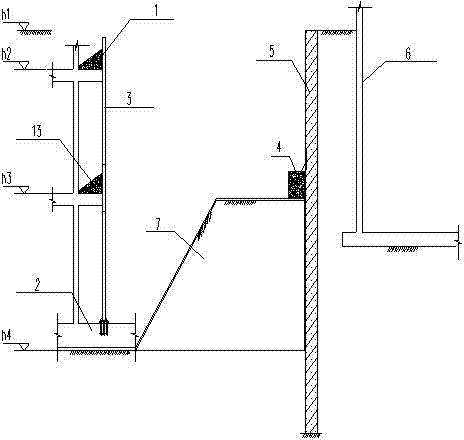

The invention relates to a construction method of a deep foundation pit close to a building and adopting an underground structure as an internal support. The construction method comprises the following specific steps of: (1) constructing a drilling and filling pile; (2) excavating a negative-layer earthwork; (3) constructing a main body structure outside the a back-pressure earth area; (4) constructing a waist beam and installing horizontal steel supports; (5) excavating back-pressure earth and constructing a main body structure in a the back-pressure earth area; (6) removing the horizontal steel support at the -4.000m position; (7) constructing a negative-layer basement structure; (8) backfilling the back-pressure earth between a negative layer and a rotary-excavating drilling pile; and (9) removing the horizontal steel support at the -0.400m position. The construction method has the beneficial effects that the construction cost and the construction period can be reduced to a great extent; the construction difficulty is reduced and the potential hazard for water seepage of a basement is reduced; and the disturbance influence of an anchor rod on the surrounding building base is eliminated.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

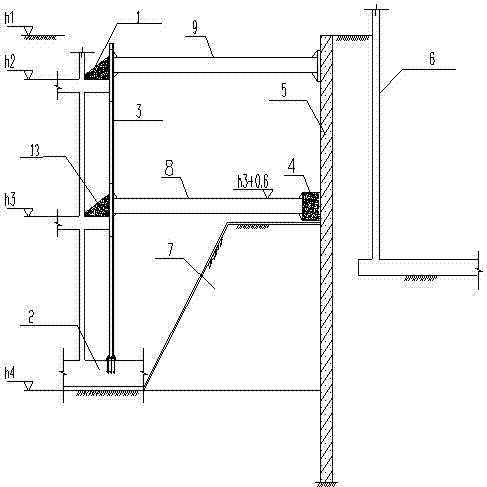

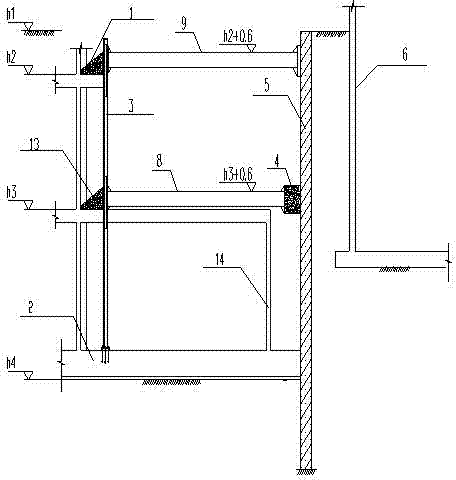

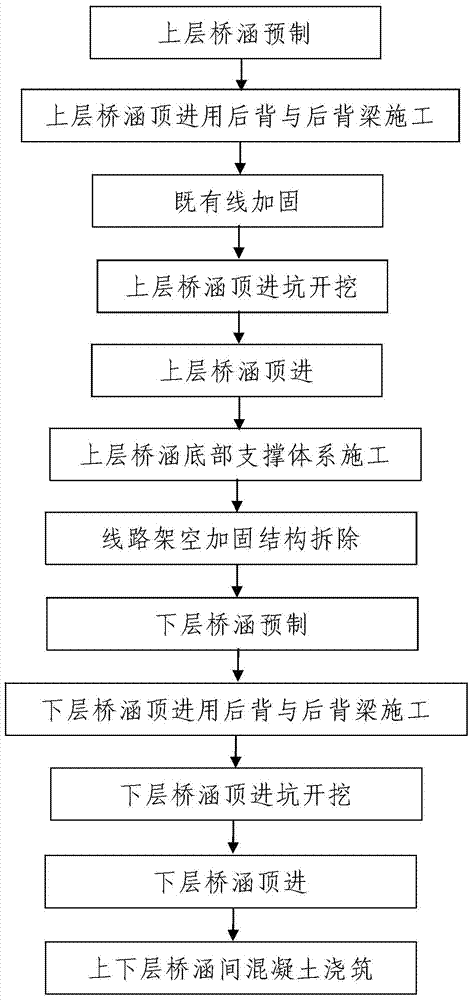

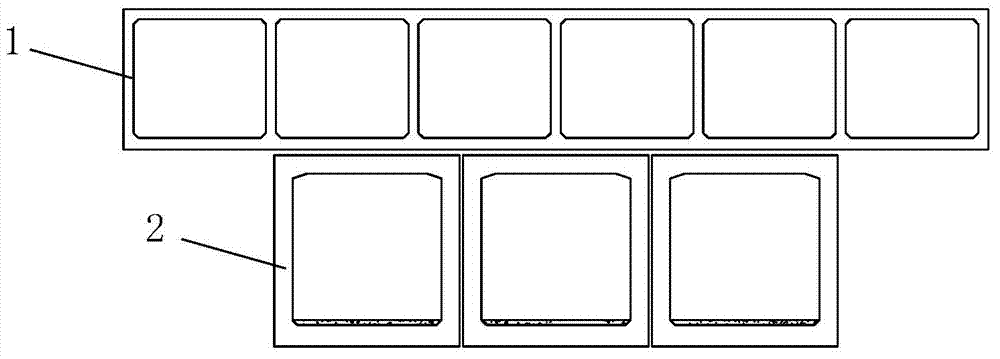

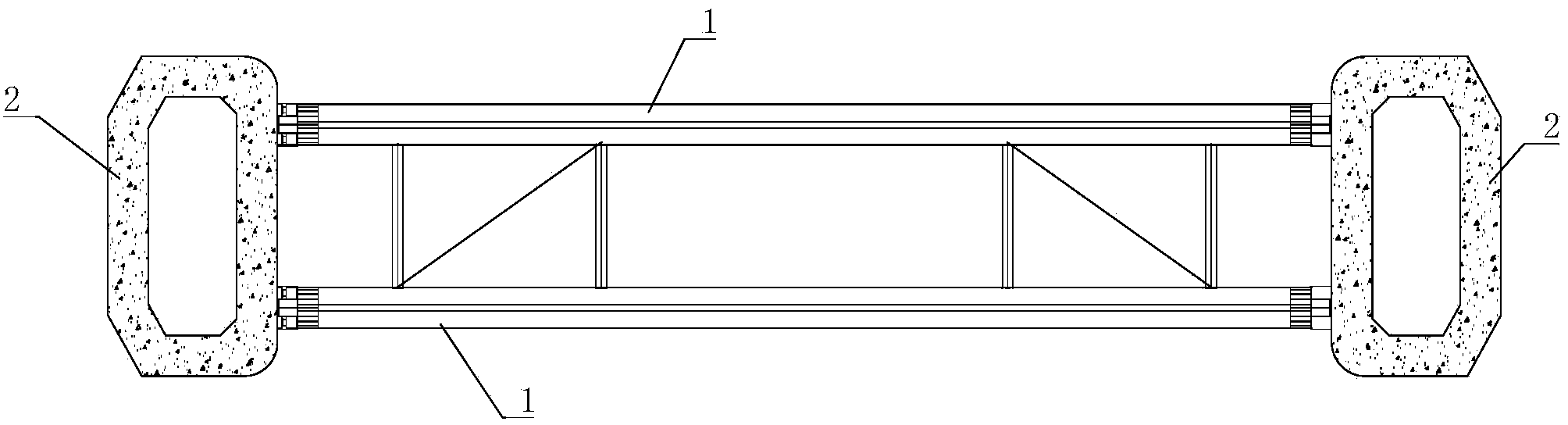

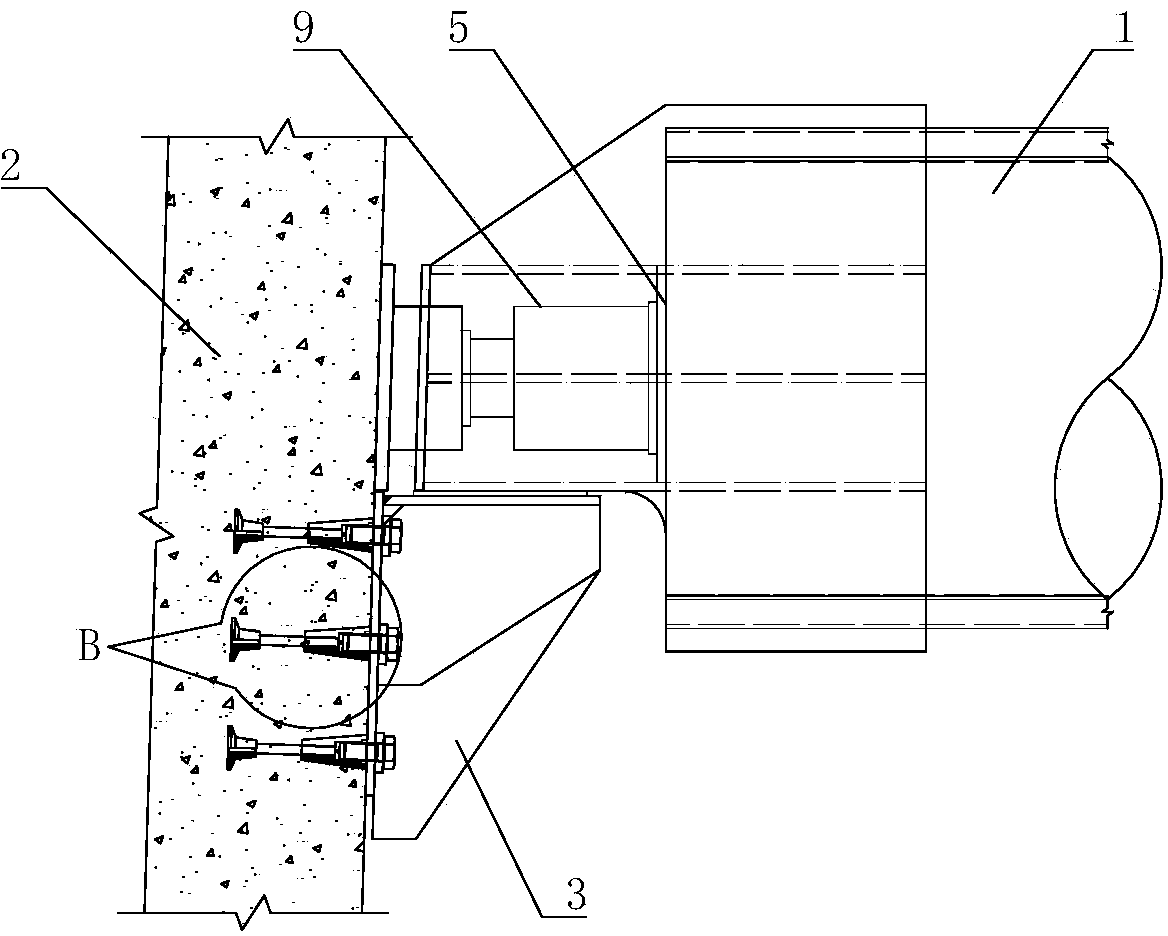

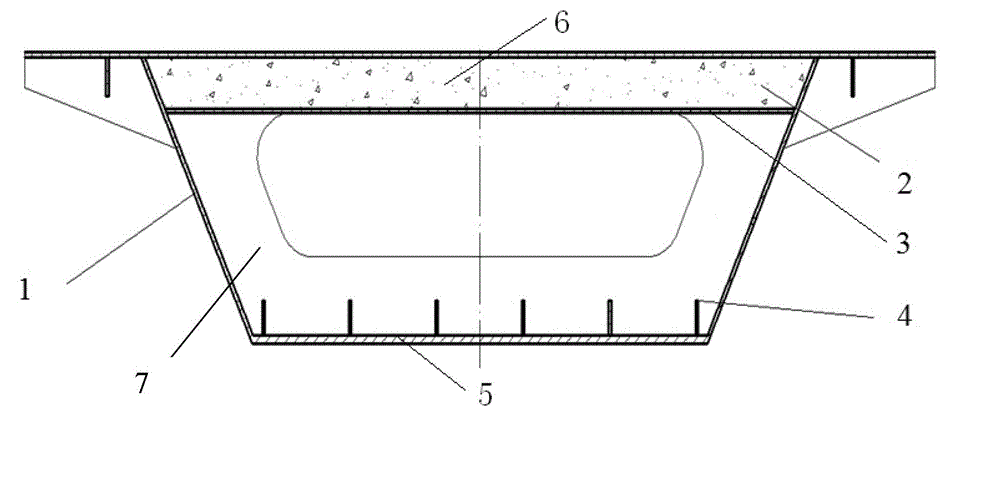

Construction process of double-layer jacking culvert penetrating through existing railway lines

ActiveCN103485288AThe method steps are simpleReasonable designGround-workTunnelsSupporting systemCulvert

The invention discloses a construction process of a double-layer jacking culvert penetrating through existing railway lines. The construction process includes the following steps: (1) precasting of an upper-layer bridge culvert body, (2) construction of a back and a back beam used for jacking of the upper-layer bridge culvert body, (3) reinforcement of the existing railway lines, wherein the existing railway lines are reinforced through a line overhead reinforcing structure, (4) digging of a jacking pit of the upper-layer bridge culvert body, (5) jacking of the upper-layer bridge culvert body, (6) construction of a bottom supporting system of the upper-layer bridge culvert body, (7) detachment of the line overhead reinforcing structure, (8) precasting of a lower-layer bridge culvert body, (9) construction of a back and a back beam used for jacking of the lower-layer bridge culvert body, (10) digging of a jacking pit of the lower-layer bridge culver body, (11) jacking of the lower-layer bridge culvert body, and (12) concrete pouring, wherein after the lower-layer bridge culvert body is jacked properly, concrete is poured between the upper-layer bridge culvert body and the lower-layer bridge culvert body. The method is simple, reasonable in design, low in investment construction cost and good in using effect, the construction process of the double-layer jacking culvert can be easily, conveniently and quickly finished and is high in quality, and the construction process is safe and reliable.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

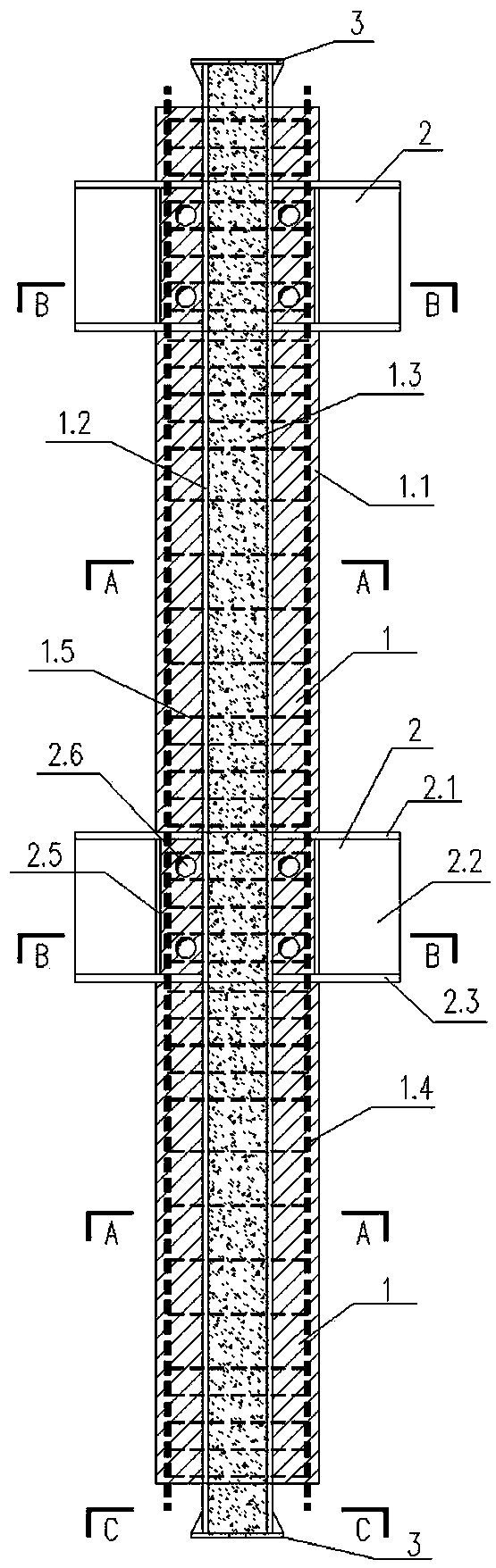

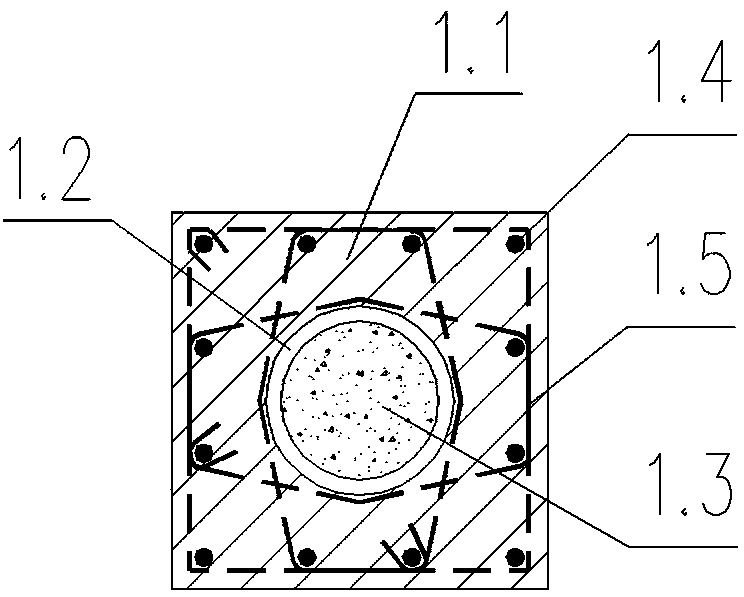

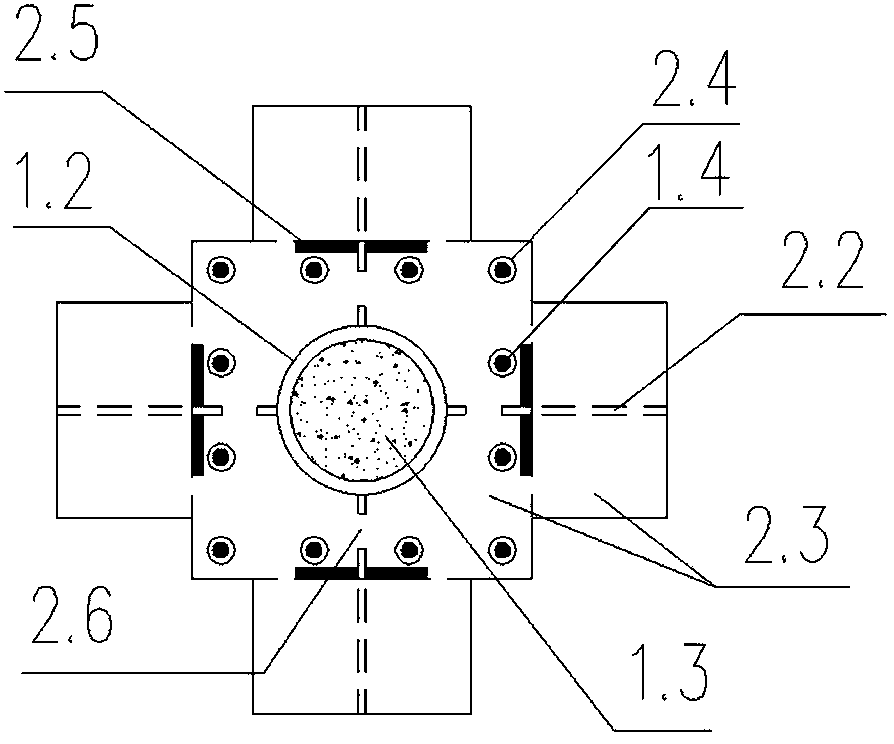

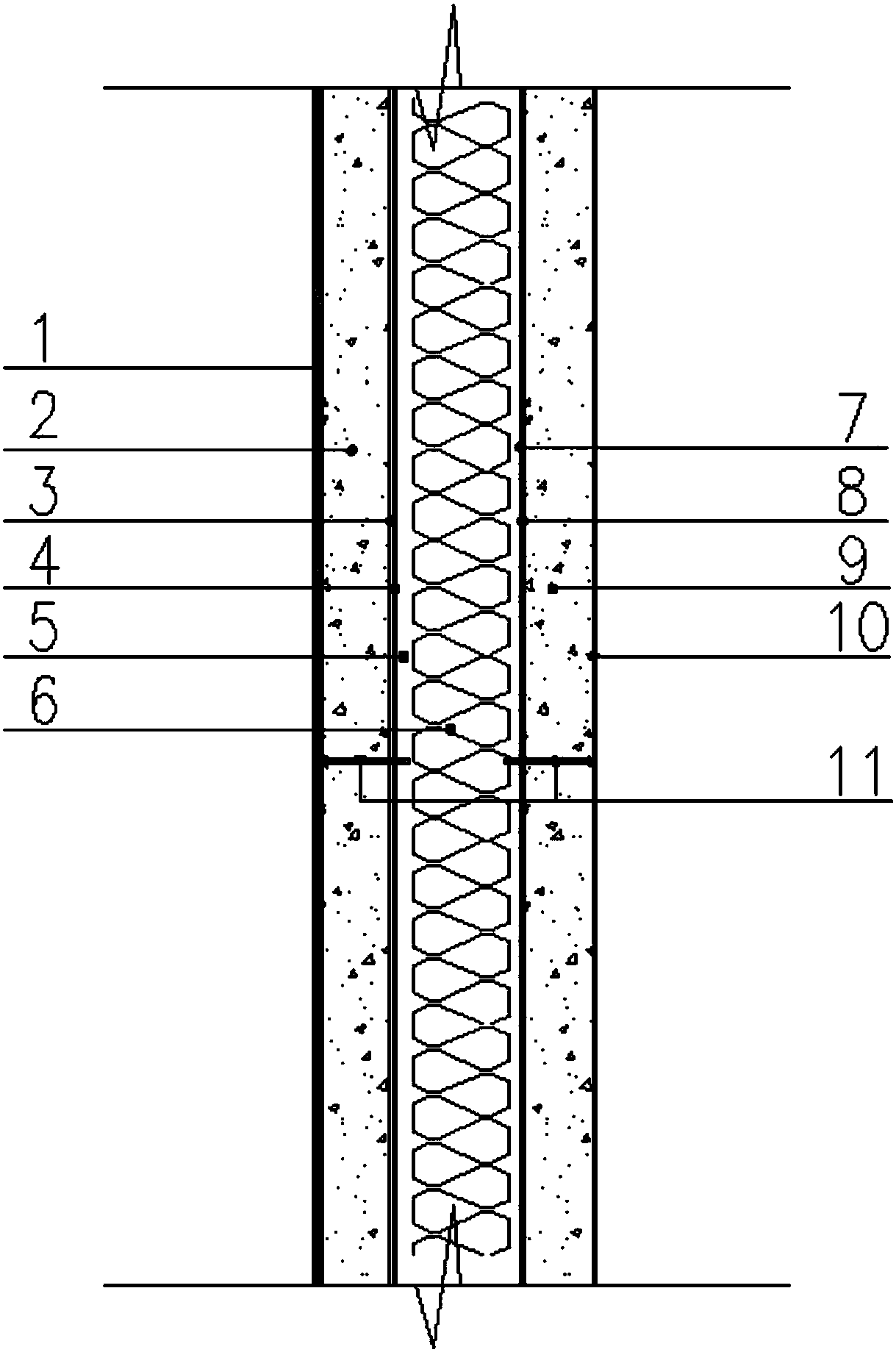

Fabricated frame strip steel bracket long column and construction method thereof

ActiveCN103556781AEasy to processEasy to installStrutsPillarsReinforced concrete columnEarthquake resistance

The invention discloses a fabricated frame strip steel bracket long column and a construction method of the fabricated frame strip steel bracket long column. The column body is a composite column consisting of three parts, namely steel pipe outer reinforced concrete, a steel pipe and steel pipe inner concrete; the steel pipe and the steel pipe inner concrete penetrate through the whole long column; the steel pipe inner concrete is subjected to primary prefabrication to form a steel pipe concrete column; concrete at a steel pipe outer joint or total concrete is poured in advance at the second time; a steel bracket is welded with the steel pipe. The long column has the advantages that 1, a multi-layer frame column is manufactured into a long column, the manufacture is simple, and the installation is convenient; 2, the column body is a composite column, the compression bearing capacity and shear capacity of the column are 2-4 times that of a reinforced concrete column with the same section, and the bearing capacity and anti-seismic property of the frame column are obviously improved; 3, the steel bracket is arranged and can be connected with a steel beam or a cast-in-place reinforcedconcrete beam, and the connection is convenient and reliable; and 4, high-strength concrete in the steel pipe is prefabricated in a factory, and the construction cost of the column is greatly reducedcompared with that of a conventional composite column. Therefore, the long column is suitable for various multi-story and high-rise prefabricated buildings and is wide in market prospects.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

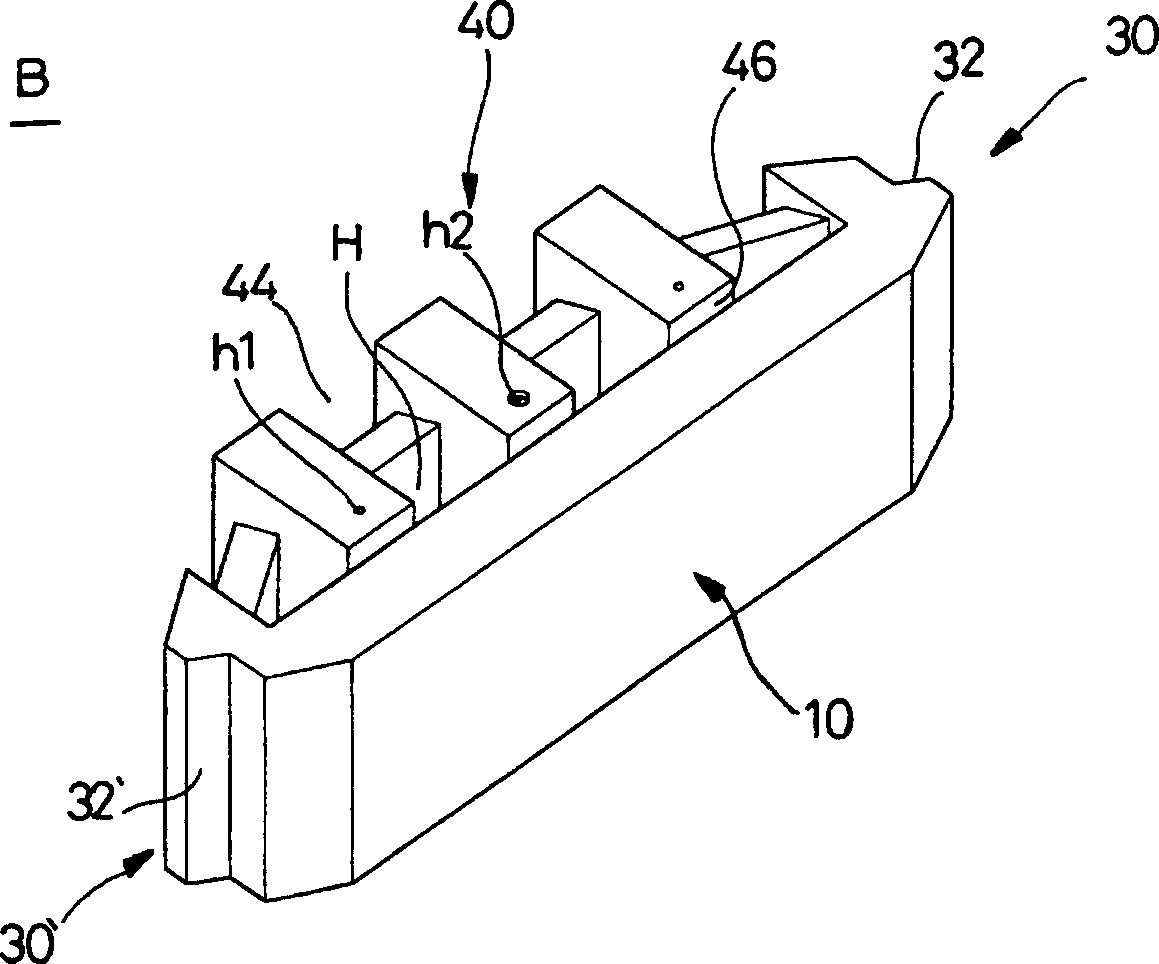

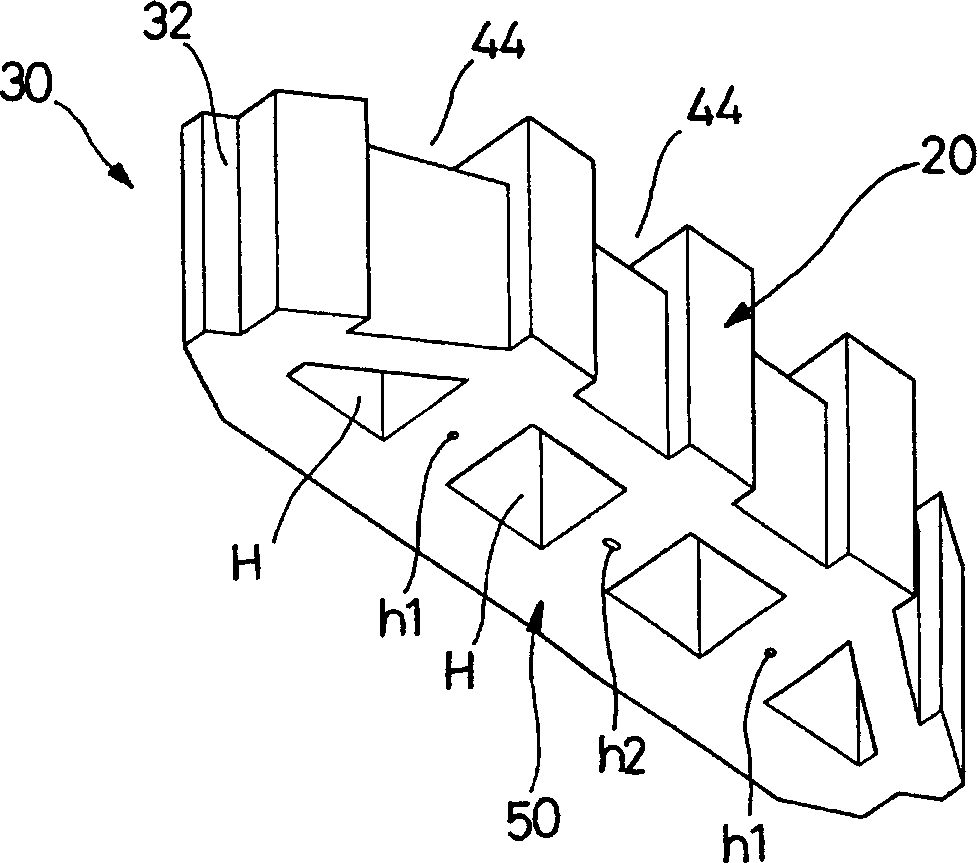

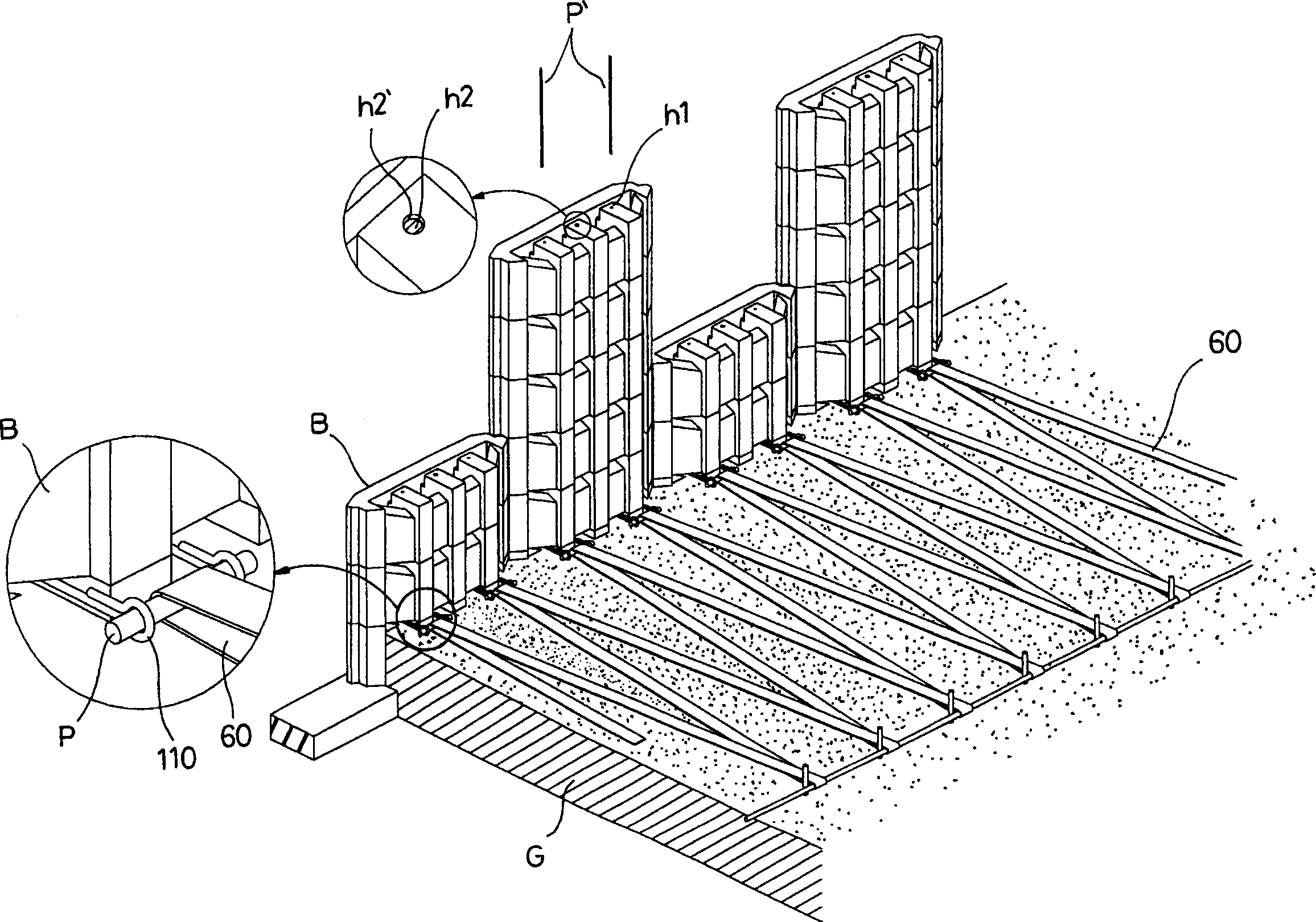

Block for constructing retaining wall, prefabricated reinforced retaining wall constructed using the block and construction method of the prefabricated reinforced retaining wall

InactiveCN1720375AReduce demandEasy to handleArtificial islandsCoastlines protectionRetaining wallBuilding construction

Provided are blocks for constructing a retaining wall, a prefabricated reinforced earth retaining wall constructed using the blocks, a method for constructing the prefabricated reinforced earth retaining wall. The block for constructing a retaining wall comprises a front surface 10 forming a surface of the retaining wall, and a rear surface 20; left and rights sides 30 and 30' having corresponding intermeshing portions 32 and 32' formed thereon; a top surface 40 having reinforcement member insertion grooves 44 formed in a front-to-rear direction, and fixture grooves 46 formed on either side of the front of the reinforcement member insertion grooves 44 for fixing the reinforcement member or anchor; and a bottom surface 50 corresponding to the top surface 40, wherein a connecting pin insertion hole h1 for pinning upper and lower blocks with a connecting pin and a lifting pin insertion hole h2 for simultaneously lifting the upper and blocks, penetrate through the top and bottom surfaces 40 and 50.

Owner:李廷洙 +1

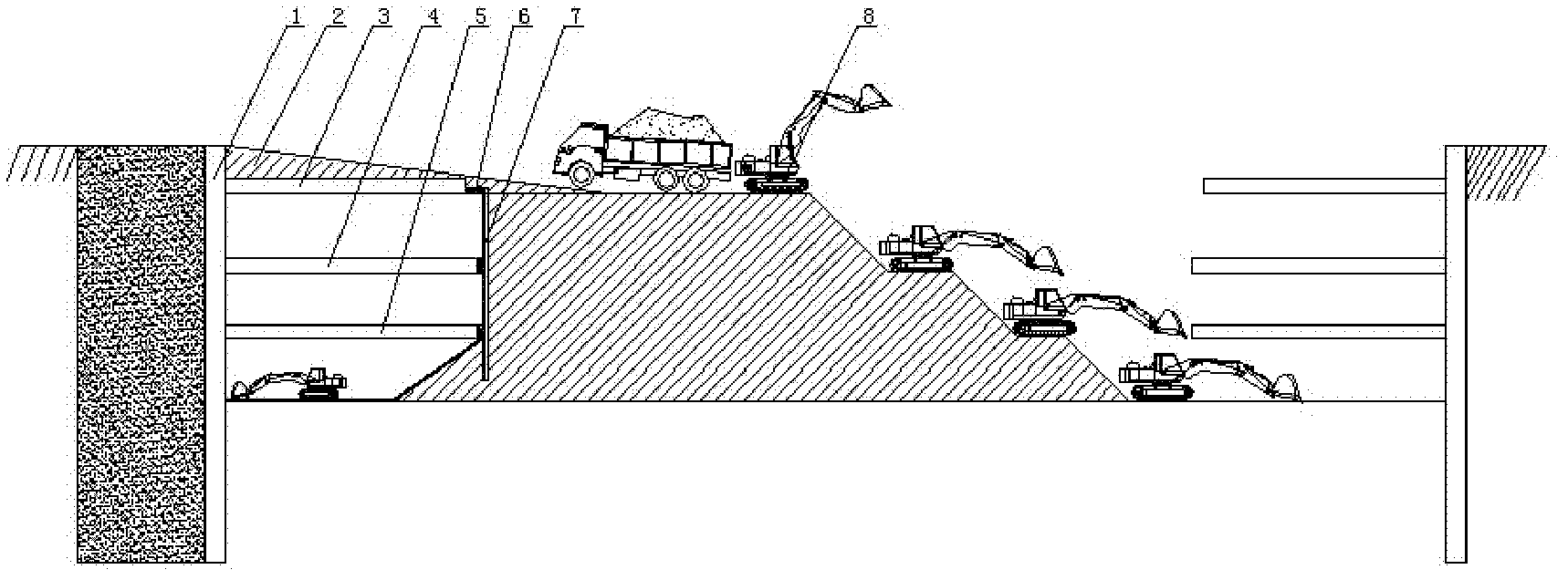

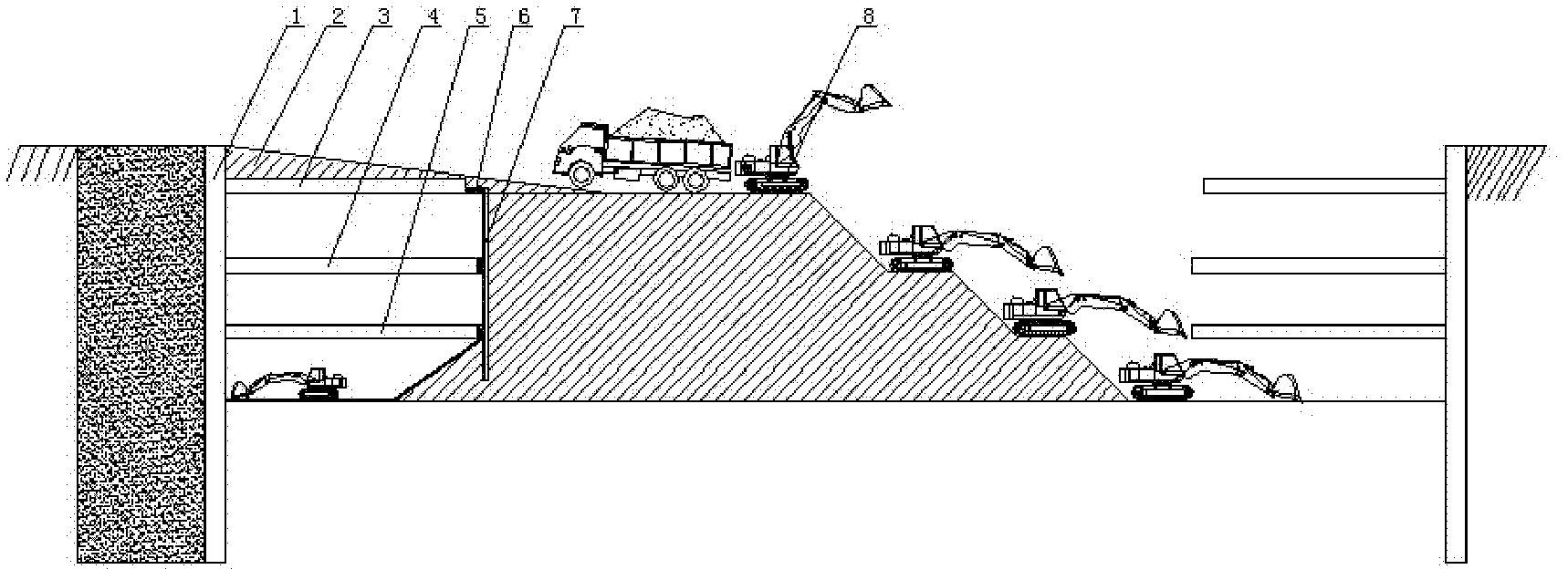

Deep foundation pit earthwork digging method

ActiveCN102425173AEnsure safetyAvoid repeated digging and fillingExcavationsBulkheads/pilesBuilding constructionSteel plates

The invention relates to a deep foundation pit earthwork digging method. The method comprises the following steps of: (1) after paying-off measurement of a deep foundation pit is finished, designing N layers of horizontal supporting steel plates according to the deep foundation pit engineering conditions in the deep foundation pit from top to bottom, and digging the foundation pit earthwork layerby layer by adopting an island type digging method, wherein N is more than or equal to 1 and less than or equal to 20; (2) downwards driving an outside steel plate pile along the wall of the deep foundation pit; and (3) digging the earthwork above the first layer of horizontal supporting steel plate, welding one end of the first layer of horizontal supporting steel plate to the outside steel plate pile, downwards driving an inside steel plate pile at the other end of first layer of the horizontal supporting steel plate and the like, constructing the Nth layer of horizontal supporting steel plate, building a ramp, digging the earthwork below the Nth layer of horizontal supporting steel plate, regressing, digging the ramp, removing the inside steel plate pile, digging the rest earthwork, and thus finishing digging the earthwork of the deep foundation pit. The construction method is simple and feasible; a trestle is not required, the construction period is effectively quickened, and the digging cost of the earthwork of the deep foundation pit is reduced; and the deep foundation pit earthwork digging method is safe and reliable.

Owner:MCC TIANGONG GROUP

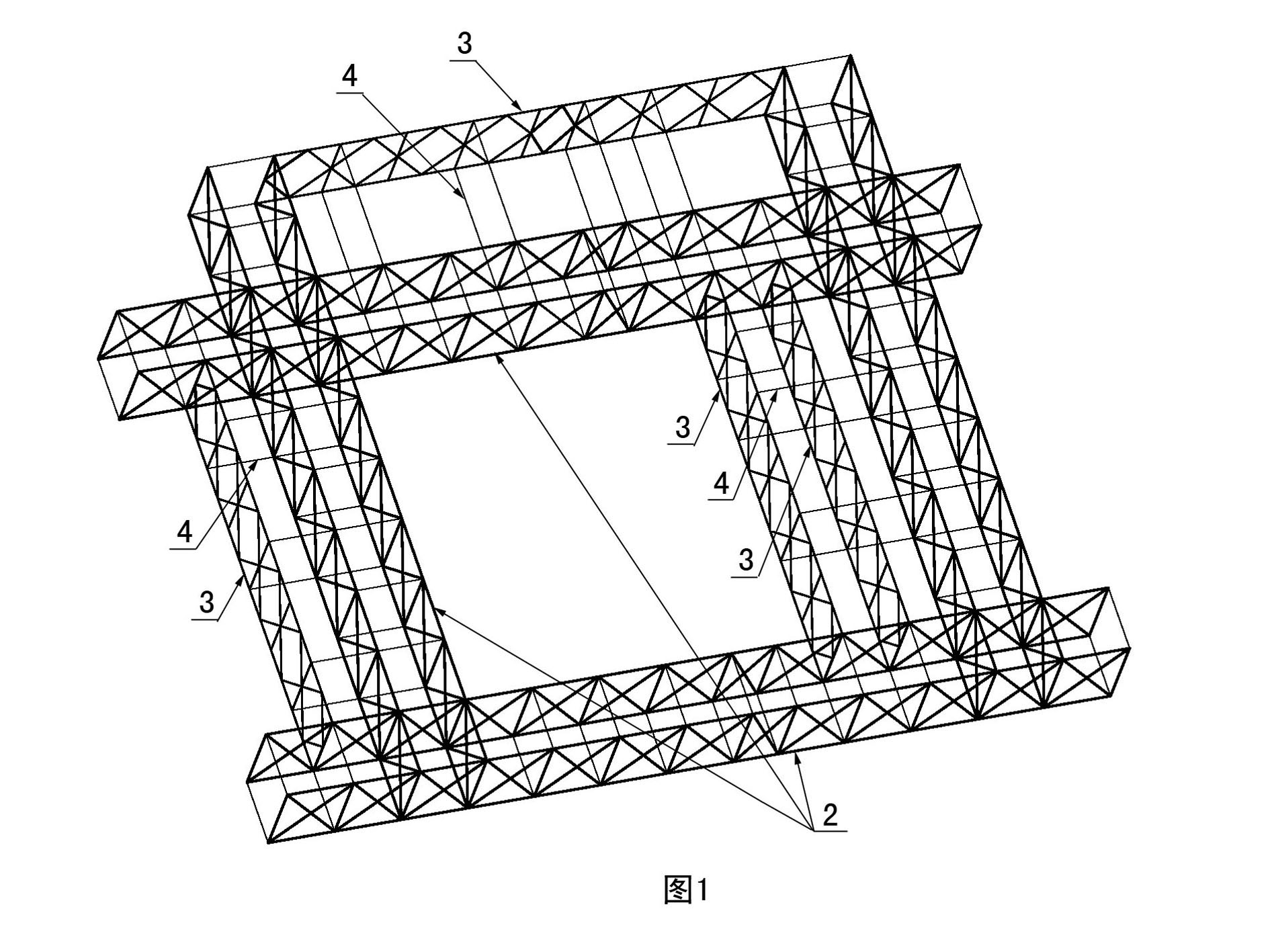

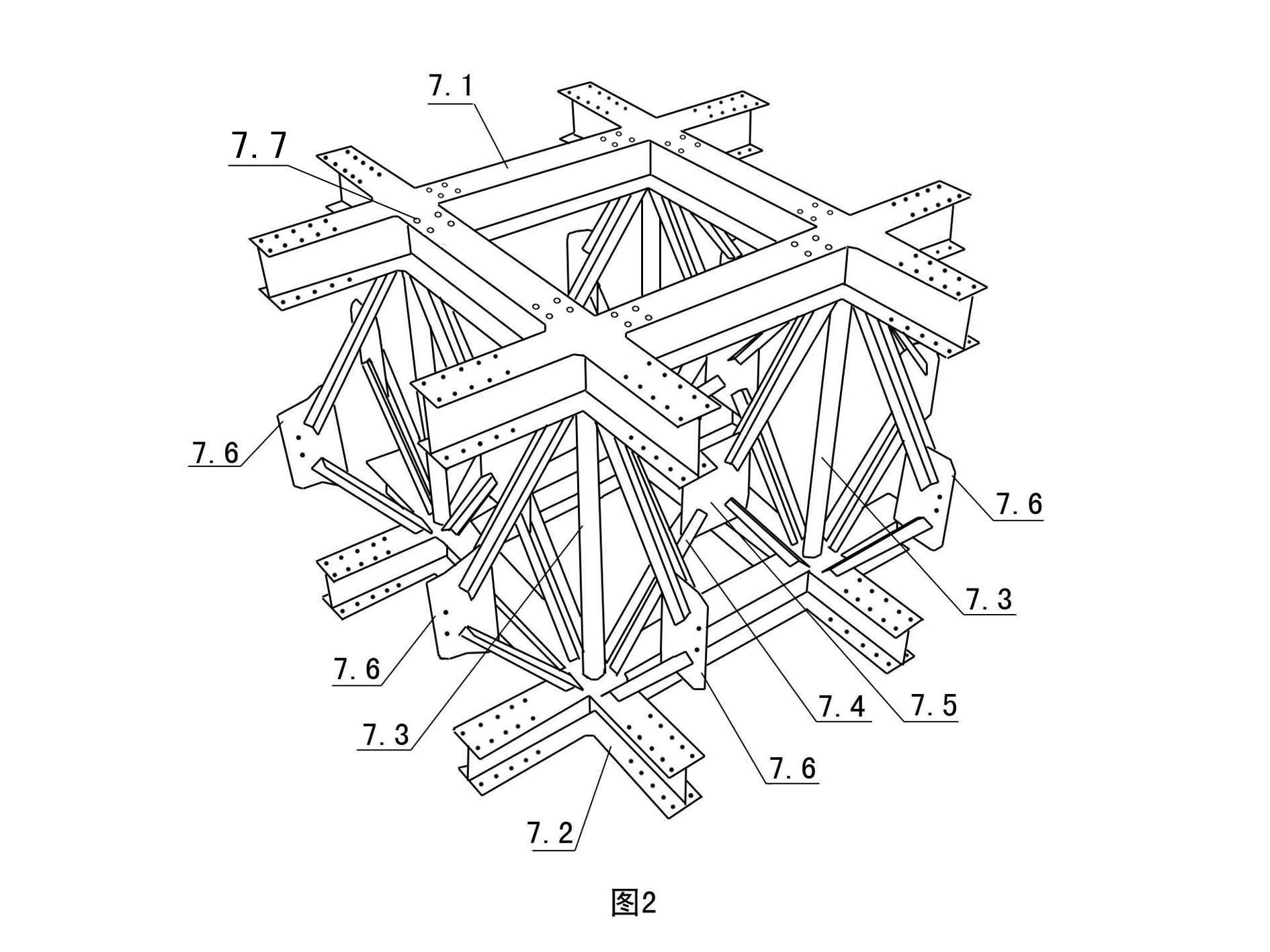

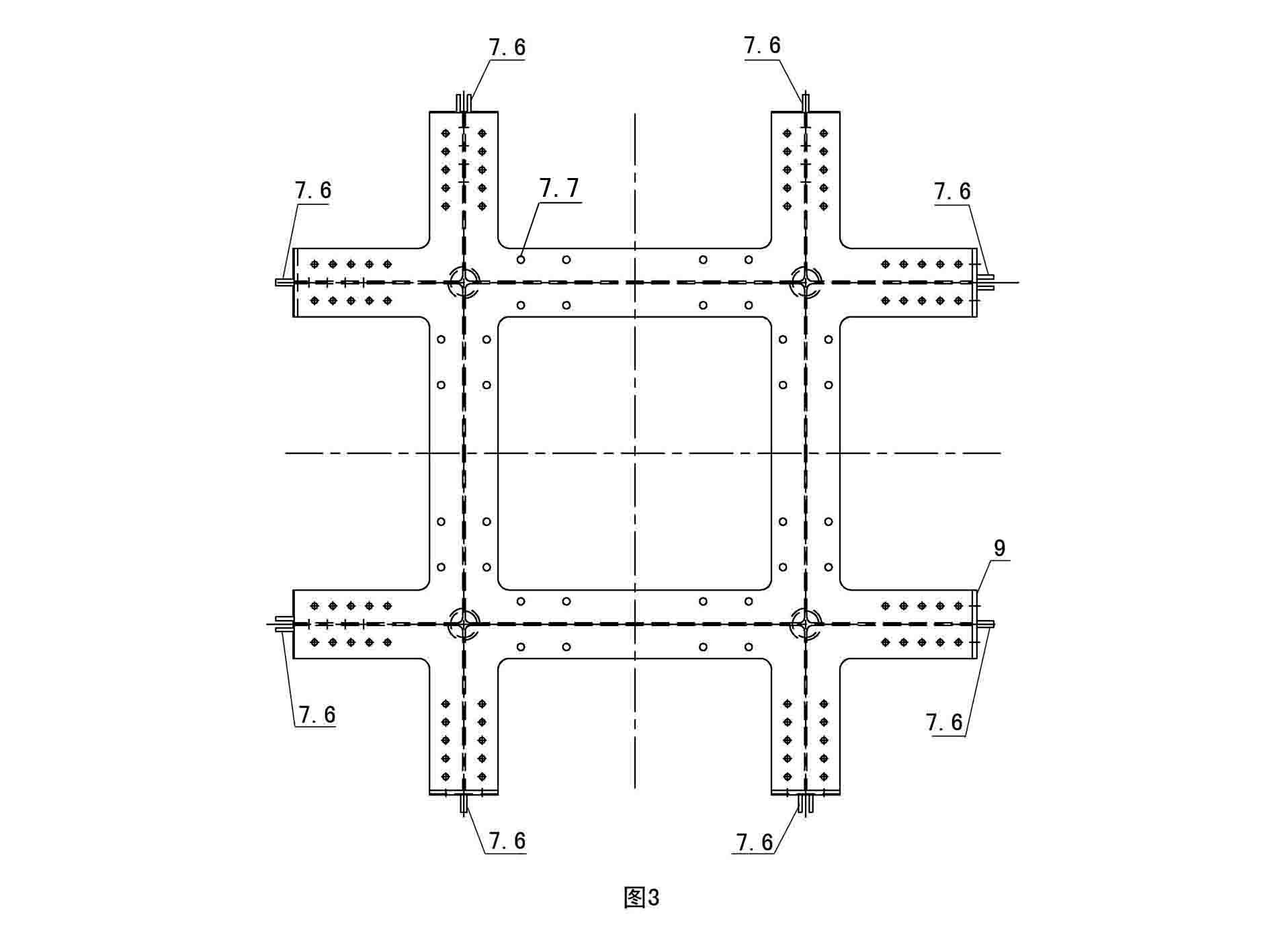

Assembly type variable steel girder platform, distribution method and assembly method thereof

ActiveCN101824905AEasy to set upSpeed up the construction periodBuilding support scaffoldsWork periodDistribution method

The invention relates to an assembly type variable steel girder platform, a distribution method and an assembly method thereof. The platform is supported on a core tube, and is formed by sectional steel grinders through being fixedly connected, and the sectional steel grinders mainly consist of main stress grinders, sub stress grinders and support rods between grinders, wherein the main stress grinders are formed by main grinder standard nodes and main grinder groined node standard nodes through being dismountably connected via node plates with bolt holes, end sealing plates with bolt holes and screw bolts, the sub stress grinders are formed by sections of sub grinder standard sections through being dismountably connected end to end, and in addition, the sub stress grinders are dismountably connected between two main stress grinders. The platform can be applied to template lifting construction of high and superhigh building core tube steel platforms, and can also be used as platforms for large-area spanning construction operation and construction machine pile carrying and placement, the construction is very easy, the work period of the construction is greatly accelerated, and the construction cost is reduced.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

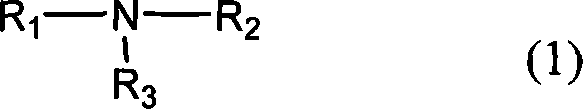

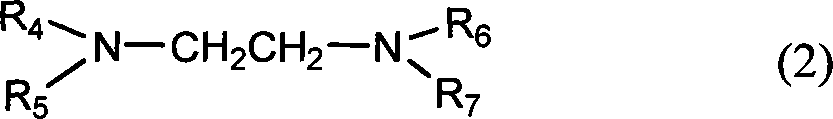

Composite liquid for increasing early strength of concrete mixed with polycarboxylate additive

The invention relates to a compound liquid for improving the early strength of the concrete mixed with polycarboxylate additive and a preparation method thereof. The compound liquid is prepared with the following components in weight proportion: 25-40percent of water soluble sulphate, 3-6 percent of organic alkoxyl amine and the rest is water. The preparation method is: 1) water is put into a reaction vessel and heated to 40DEG C- 60DEG C, and organic alkoxyl amine is added and well stirred; 2) water soluble sulphate is added and stirred to form a homogenous solution. The preparing process of the invention is simple and easy to apply; the invention does not corrode steel, and does not affect the condensation of concrete and reduce the later strength of concrete. The addition of the compound liquid is 0.5-1.5 percent of cementing material content and can improve the compressive strength of the concrete by 30-60 percent in 16h, by 25-40percent in 1d and by 15-25 percent in 3d, and the compressive strength of the concrete does not fall in 28d, which greatly shortens maintenance period, expedites construction progress, advances turnover rate of template, shortens construction period and lowers cost.

Owner:JIANGSU SUBOTE MATERIAL

Composite material for consolidated soil pavement base course and construction method thereof

InactiveCN1566533AHigh compressive strengthAvoid damageRoadwaysOrganic fertilisersRoad surfaceMaterials science

Disclosed is a material for composite consolidating earthen road surface and construction method thereof, wherein the said material comprises: sandy soil ranging from 92-98% by wt, 2-8% by wt of cement, ZL-1 liquid curing agent or EN-1 liquid curing agent ranging from 0.1-0.3 permillage of by gross weight of gray soil mixture; or silty soil or clayey soil ranging from 90-96% by wt, 4-10% by wt of lime, ZL-1 liquid curing agent or EN-1 liquid curing agent ranging from 0.1-0.3 permillage by gross weight of gray soil mixture. The material for composite consolidating earthen road surface and its construction method takes extensively distributed soil as main material, reduces 20-50% construction costs, shortens construction time limit, resists freeze, and prolongs available construction time in northern area with early freezing time.

Owner:王涌

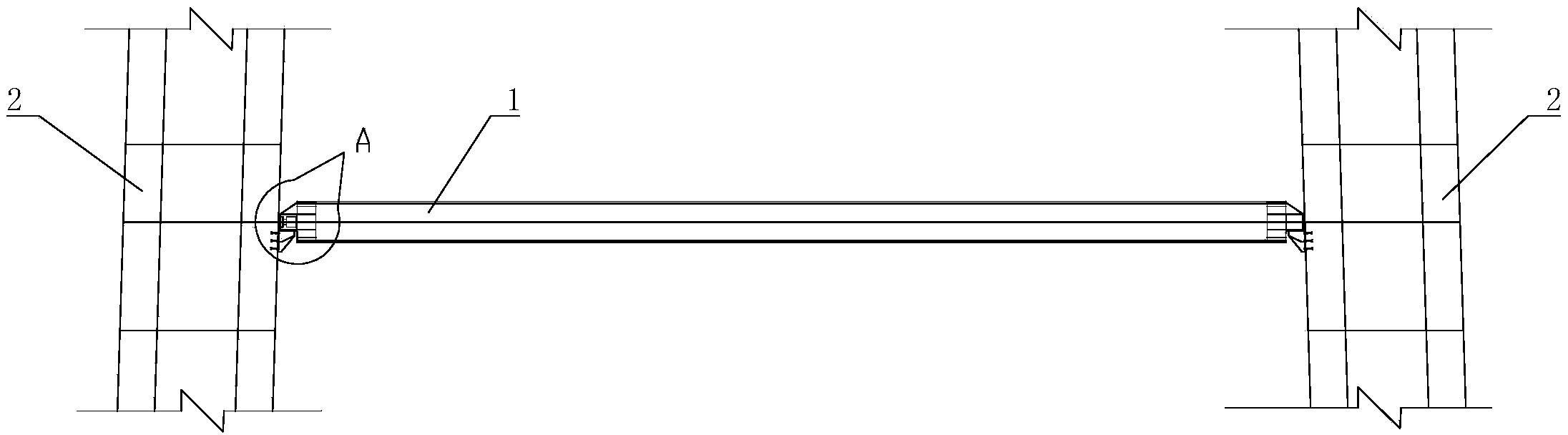

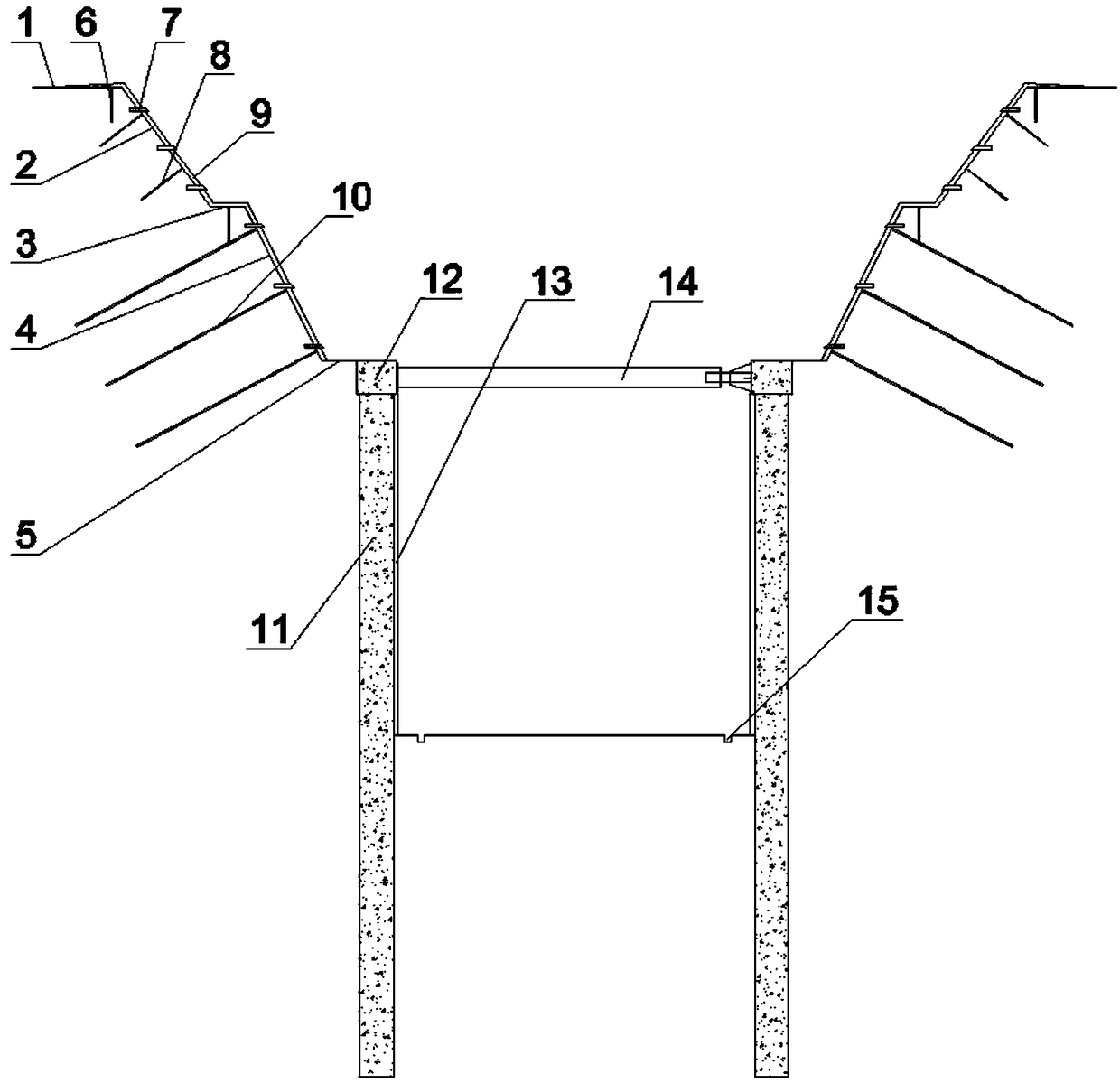

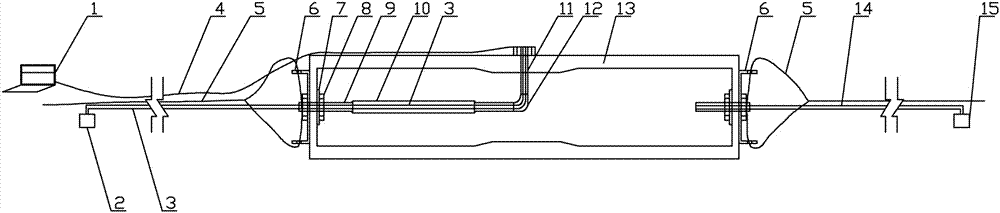

H-shaped tower column inner force adjustable temporary cross supporting structure and construction method thereof

The invention relates to an H-shaped tower column inner force adjustable temporary cross supporting structure which comprises a cross supporting part and brackets fixed on tower columns on the two sides respectively. The cross supporting part is arranged on the brackets in a carrying mode. The cross supporting part comprises an abutting-connecting end in abutting connection with the tower column on one side and a pushing end opposite to the abutting-connecting end. A lifting-underlay object is inserted at the movable portion between the pushing end and the tower column on the other side. The pushing end is provided with a pushing part which enables the horizontal supporting part to move to the abutting-connecting end after being stressed. The invention further relates to a construction method of the temporary cross supporting structure. Time occupied by a tower crane during temporary cross supporting part mounting is saved, adjusting on pushing force during construction is convenient, cable bend tower construction is accelerated, temporary cross supporting part high-altitude welding workload is lowered, temporary cross supporting part disassembling difficulty is lowered, and high-altitude working safety risks are reduced. The H-shaped tower column inner force adjustable temporary cross supporting structure and the construction method thereof can be used in horizontal temporary cross supporting part construction in bridge construction.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

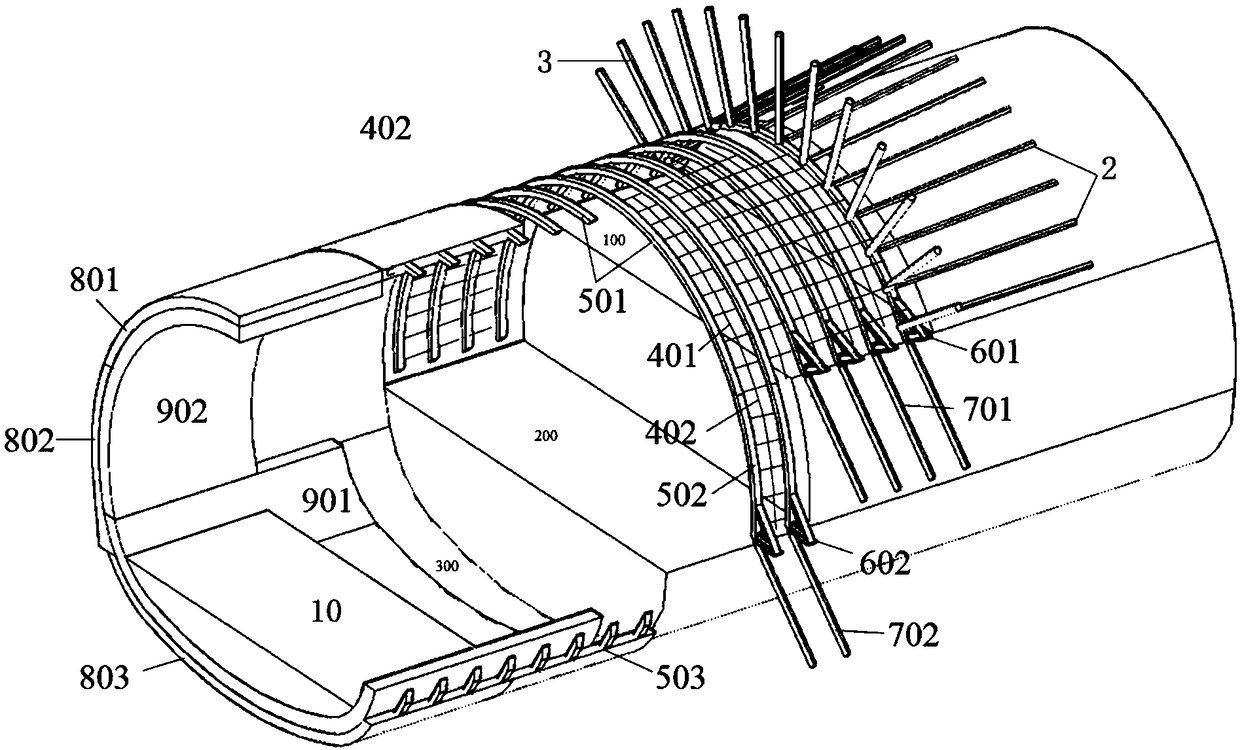

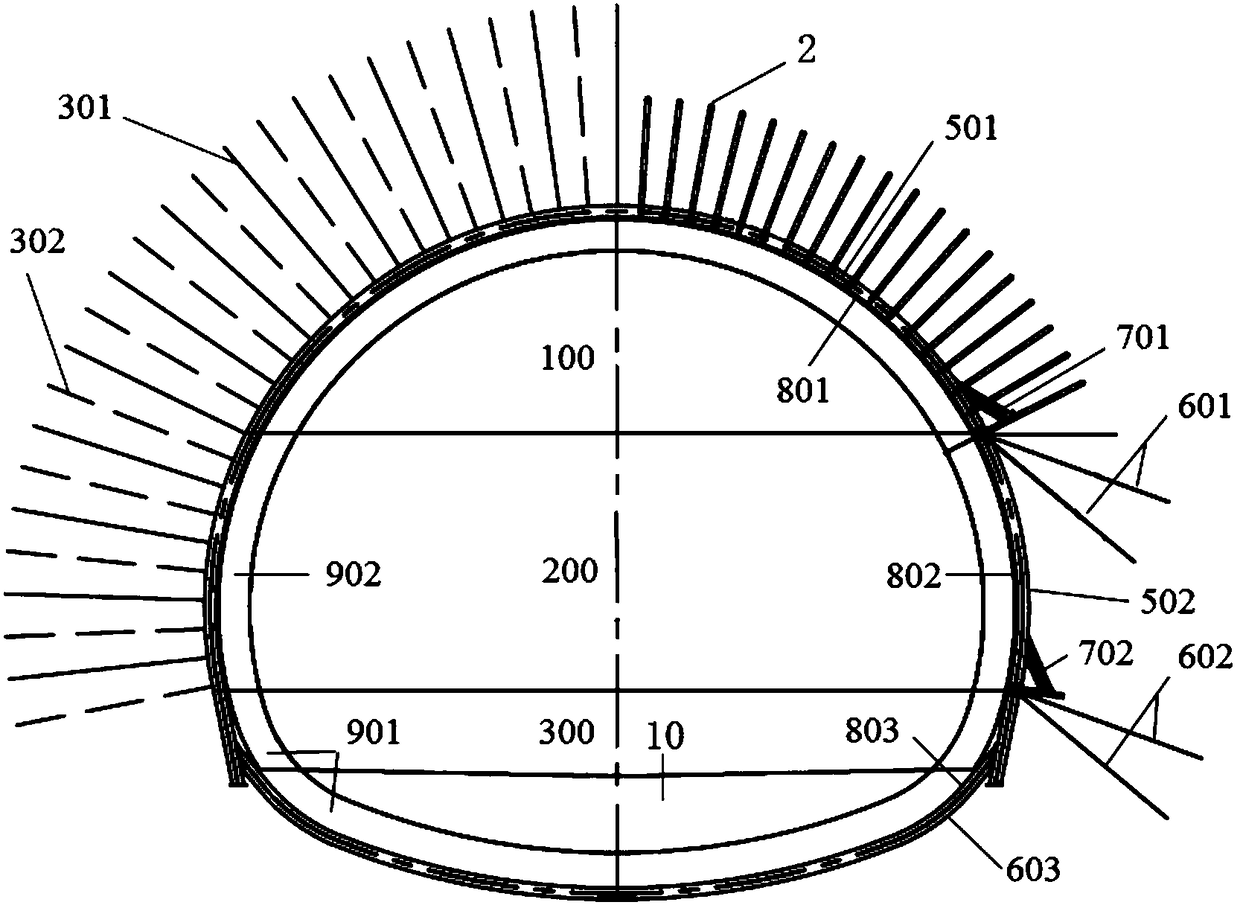

Large-arch-foot three-step tunnel rapid construction method and structure based on pipe shed pre-supports

PendingCN108278115AConstruction safetyLarge amount of workUnderground chambersTunnel liningDeformation controlFoot type

The invention discloses a large-arch-foot three-step tunnel rapid construction method and structure based on pipe shed pre-supports. Short pipe sheds are constructed through a hole interior non-work-room pipe shed construction technology to reinforce and support surrounding rock in front of a tunnel face in advance; large arch feet are arranged at bases all stages of steps; and under dual controlmeasures, the tunnel cross section is sequentially excavated by three steps, according to the specific processes, firstly, short pipe shed advance supports are constructed within a certain range alongan arch part of a tunnel, the upper, middle and lower steps are sequentially excavated with alternate distances, after excavation of each step, the primary supports are constructed instantly, footings of the primary supports are designed to of a large-arch-foot type, and when the lower step is away from a secondary lining of a former cycle by the tunnel diameter, an inverted arch, side walls, a filled layer and a secondary lining are constructed. The problem that under the condition of the shallow-buried weak surrounding rock, deformation control over the tunnel is difficult is solved, and meanwhile the disadvantages that under the same condition, a traditional construction method is many in subsection, numerous in working procedure, slow in construction, many in temporary support and thelike are further overcome.

Owner:CENT SOUTH UNIV

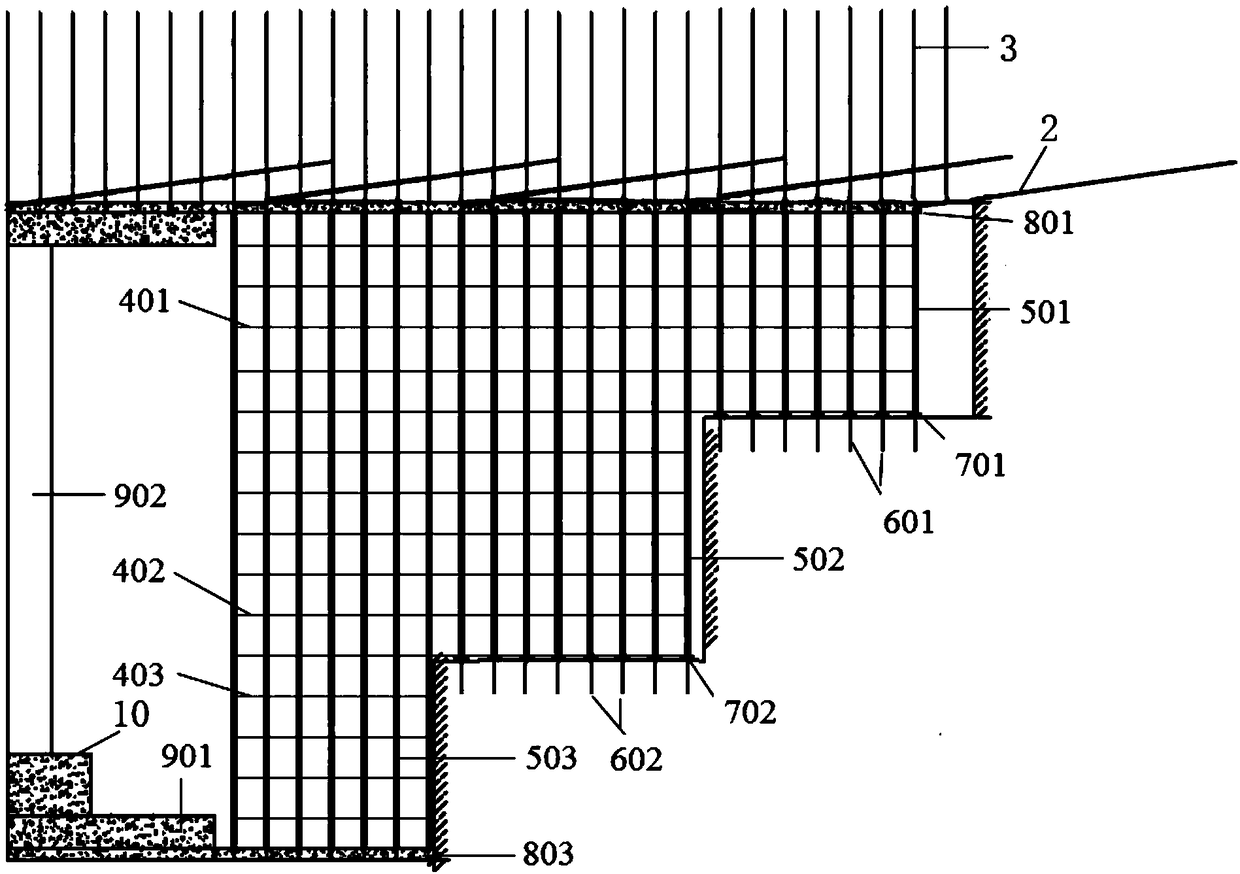

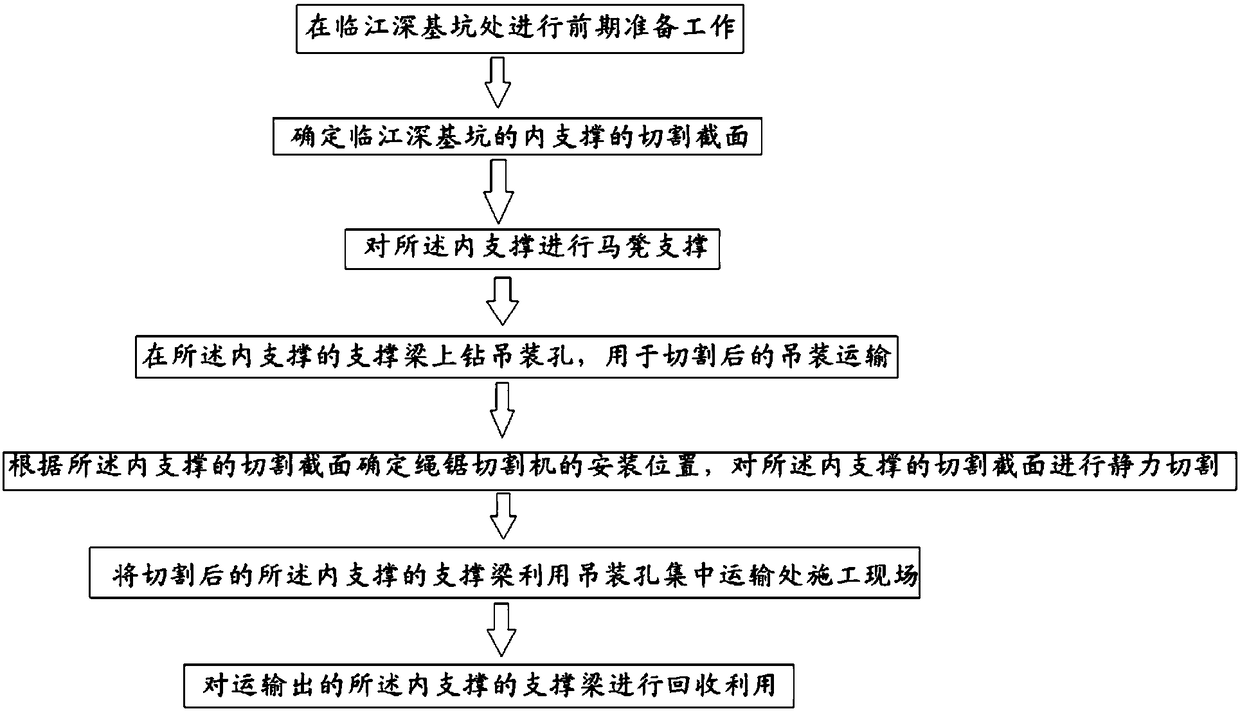

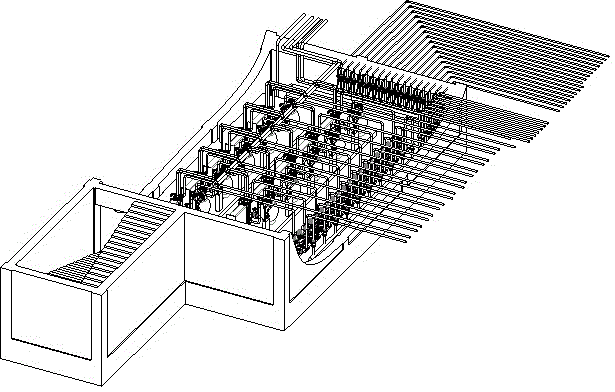

Method for cutting, removing and recycling deep foundation pit concrete near river

InactiveCN108166500AReduce the impactWill not affect normal lifeBuilding repairsExcavationsEnvironment effectEngineering

The invention discloses a method for cutting, removing and recycling deep foundation pit concrete near a river, and belongs to the technical field of building construction. The method for cutting, removing and recycling the deep foundation pit concrete near the river comprises the following steps that early-stage preparation work is carried out at a deep foundation pit near the river; the cuttingcross section of an inner support of the deep foundation pit is determined; supporting steel bars are used for supporting the inner support; hoisting holes are drilled in supporting beams of the innersupport, and are used for hoisting and transporting after cutting; the installation position of a rope saw cutting machine is determined according to the cutting cross section of the inner support, and static force cutting is carried out on the cutting cross section of the inner support; the supporting beams of the cut inner support are completely conveyed to a construction site through the hoisting holes; and the supporting beams, which are transported out, of the inner support are recycled. The method for cutting, removing and recycling the deep foundation pit concrete near the river is efficient, safe, environment-friendly, low in vibration, low in noise, free-dust, small in influence on surrounding environment, and low in environmental pollution, and can effectively reduce the construction waste.

Owner:WUHAN UNIV OF SCI & TECH

Environment-friendly building outer wall simulated tile coating and preparation method thereof

The invention relates to an environment-friendly building simulated tile coating and a preparation method thereof, and belongs to building materials. The environment-friendly building simulated tile coating is used for the decoration of surfaces of outer walls of buildings, and the defects of high possibility of dropping, large dead height of tiles and high cost in the conventional tile system are overcome. The environment-friendly building simulated tile coating consists of water, titanium dioxide, colorful sand and a dispersing agent, 2 weight percent of cellulose ether aqueous solution, a pure acrylic emulsion, ethanediol, a thickening agent, a film-forming aid, a defoamer, a preservative, a pH regulator and a multifunctional aid in a specific weight ratio. The preparation method comprises the following steps of: mixing liquid materials uniformly, mixing solid materials uniformly, adding the uniformly-mixed solid materials into the uniformly-mixed liquid materials slowly, and stirring uniformly to obtain the environment-friendly building simulated tile coating. The environment-friendly building simulated tile coating has a vivid tile visual effect and is diversified in colors, simple and tasteful, high in contractibility resistance, resistant to aging, long in service life, non-toxic and tasteless, and environmental protection is facilitated; and the environment-friendly building simulated tile coating can be constructed at the temperature of -5 DEG C, and compared with like products, the environment-friendly building simulated tile coating has the advantage that the construction period can be prolonged by one month.

Owner:JILIN KELONG BUILDING ENERGY SAVING TECH

Steel-concrete combined box beam

InactiveCN102720120AImprove bearing capacityIncrease stiffnessBridgesStructural stabilityEngineering

The invention discloses a steel-concrete combined box beam which comprises two steel webs, a steel bottom plate, a diaphragm plate, a concrete layer, multiple stiffening ribs and a steel top plate, wherein the two steel webs and the steel bottom plate form a box chamber; the diaphragm plate is horizontally arranged at the upper part in the box chamber to divide the box chamber into an upper box chamber and a lower box chamber; the concrete layer is filled in the upper box chamber; the multiple stiffening ribs are arranged on the bottom plate in the lower box chamber; and the steel top plate is horizontally arranged on the top surface of the upper box chamber. In the steel-concrete combined box beam disclosed by the invention, the concrete combined top plate composed of the steel top plate, the steel webs, the diaphragm plate and the concrete layer bears pressure, and the lower bottom plate and multiple stiffening ribs bear the tension; and the steel-concrete combined box beam has the characteristics of high bearing capacity, high rigidity, good integrity and the like, greatly improves the structural stability, can give full play to the performance of the materials, is convenient to transport and hoist, and has short construction period, high efficiency and obvious economic benefits. Moreover, through the box beam, the height of the cross section of the box beam can be reduced, and the bridge appears more concise and beautiful.

Owner:TIANJIN URBAN CONSTR COLLEGE

Integrated pipeline distribution modeling method of pipeline

ActiveCN105260491AImprove construction periodQuality improvementSpecial data processing applicationsTechnical specificationsSelf-Examination

The invention discloses an integrated pipeline distribution modeling method of a pipeline. The integrated pipeline distribution modeling method uses SolidWorks mechanical design software and is characterized by comprising the following steps: a) collating an electronic edition construction drawing; b) carrying out unified labeling and basic modeling; c) when the professional drawing is revised and optimized by each specialty, making pipeline schematic movement directions and dimensions in an original drawing clear; d) after each electromechanical installation specialty revises the drawing, carrying out self-examination on a finished first draft from the aspects of the requirements of a professional technical specification, a design idea, an executing unit and a supervisor; e) before an integrated plane graph is drawn, determining an elevation and a plane position; and f) checking the dimensions of the girders, the plates and the columns of each professional electromechanical installation drawing and architectural structure drawing. The integrated pipeline distribution modeling method has the advantages that large pipelines which occupy top space and include ventilation air conditioner air hoses, air conditioner water pipes and the like in a building can be reasonably distributed, the requirements of aspects including construction periods, quality, cost, impressions and the like are improved, and various requirements of interested parties including the executing unit, the supervisor, design parties and the like can be reasonably coordinated and met to a largest extent.

Owner:MCC5 GROUP CORP SHANGHAI

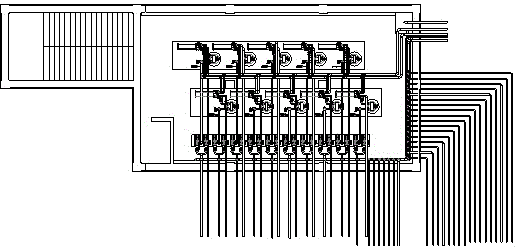

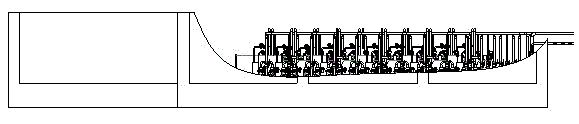

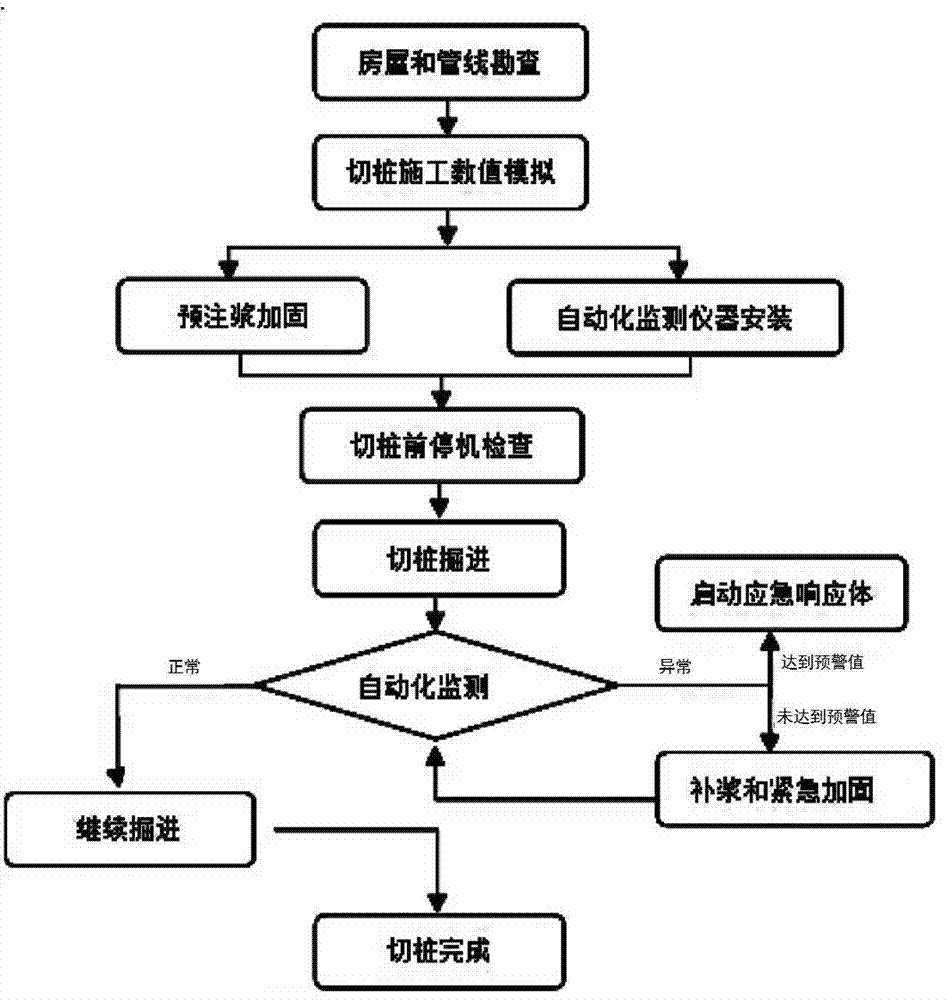

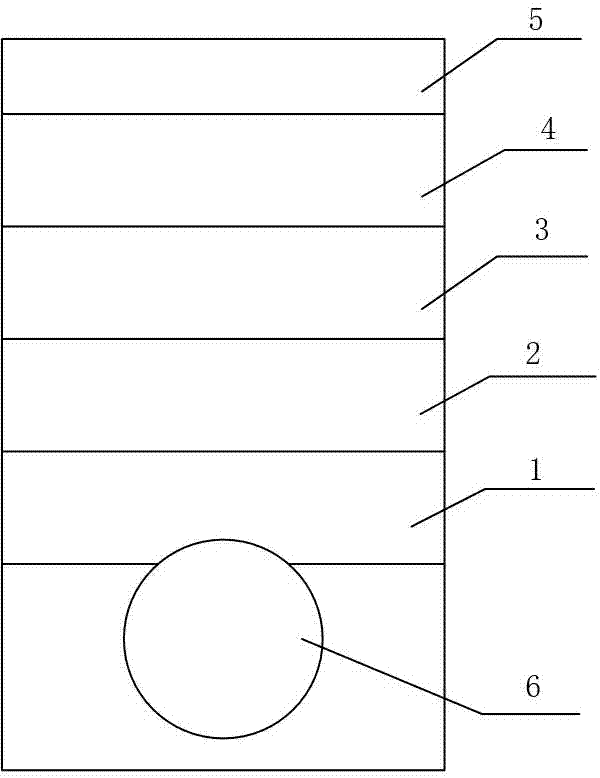

Construction method of shield and continuous cutting pile foundation for penetrating through residential building group

ActiveCN104847364AFew constraintsImprove applicabilityTunnelsArchitectural engineeringConstruction management

The invention relates to a construction method of a shield and continuous cutting pile foundation for penetrating through a residential building group. The construction method comprises the following steps that the first step, house investigation and investigation of pipelines around houses are conducted; the second step, pile cutting construction numerical simulation is conducted; the third step, an automatic monitoring instrument is installed; the fourth step, pre-grouting reinforcement is conducted, wherein the reinforcement range includes buildings, the pipelines and planning tool changing points, and the reinforcement mode is a retrograde grouting mode; the fifth step, shutdown and inspection of a shield machine are conducted before pile cutting is conducted; the sixth step, pile cutting tunneling and pipe sheet splicing are conducted; the seventh step, grout supplement and emergent reinforcement are conducted. According to the construction method, pile cutting and penetration can be directly conducted without the operation that the existing buildings are demolished, the idea of energy conservation and environmental protection is met, the investment cost can be substantially reduced, the negative influence caused by demolition is reduced, and the number of the constraint factors of metro line selection is reduced; in addition, shield construction parameters and grouting parameters can be guided according to data which are fed back in real time through automatic monitoring, a comprehensive dynamic construction management system is implemented, the engineering risk is controllable, and the construction cost can be substantially reduced.

Owner:CHINA CONSTR COMM ENG GRP UNITED

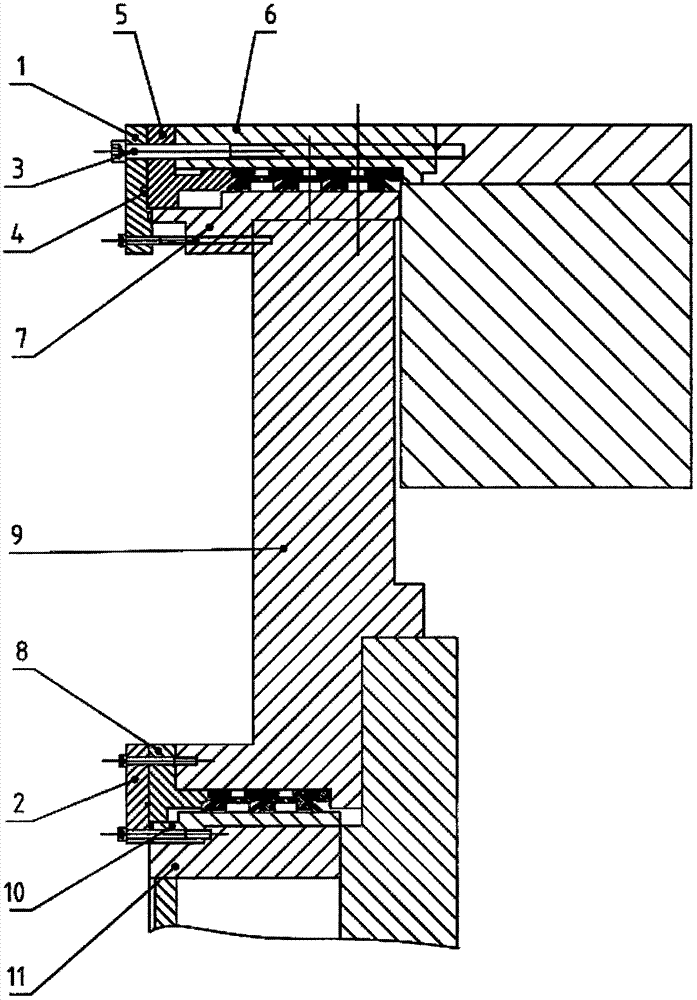

Earth pressure balance shield machine main drive seal test device and method

PendingCN107132008AAvoid breakdown repairs and replacement operationsImprove construction periodMeasurement of fluid loss/gain rateEarth pressure balanceStructural engineering

Owner:济南中铁重工轨道装备有限公司

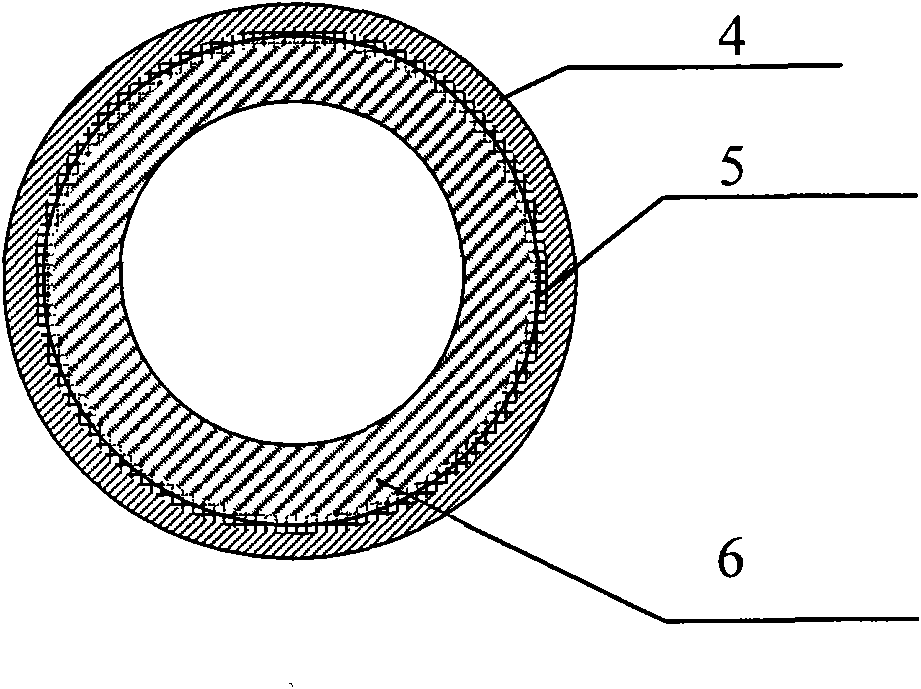

Foamed hollow plastic fender product and production method and equipment

InactiveCN101638887ASolve the problem of seawater corrosionSolving Corrosion ProblemsLoad-supporting elementsShipping equipmentReinforced concreteEngineering

The invention provides a foamed hollow plastic fender product and a production method and equipment. The product comprises outer skin of the fender body and a filling layer, and is characterized in that a center hole is arranged in the fender body; an outer layer of an inner core, an enhancement layer and an inner layer of the inner core are sequentially arranged between the filling layer and thecenter hole, and a high-strength extrusion-tension rod is arranged in the filling layer. The invention has the following advantages: the product is suitable for the quay fenders, crash barriers, girders, columns and other building structures, saves the timber, rubbers and steel, is easy for construction, shortens the construction period and saves the building cost; besides, the product has excellent chemical stability and oxidation resistance, substantially enhances the impact resistance and flexibility, increases the elastic modulus and rigidity, thoroughly solves the problem that the steel reinforced concrete is corroded by seawater and doubles the service life; the application range of the product is expanded and waste polyethylene is used as the main material, thus obviously lighteningthe pressure of pollution.

Owner:沈阳新永成塑胶有限公司

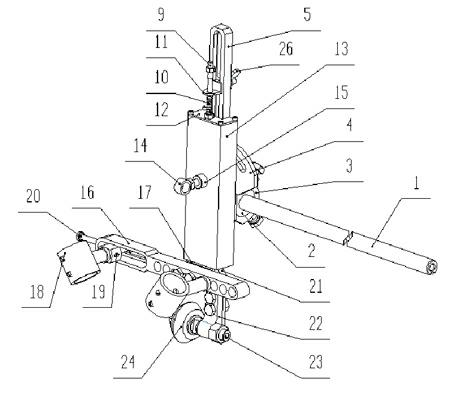

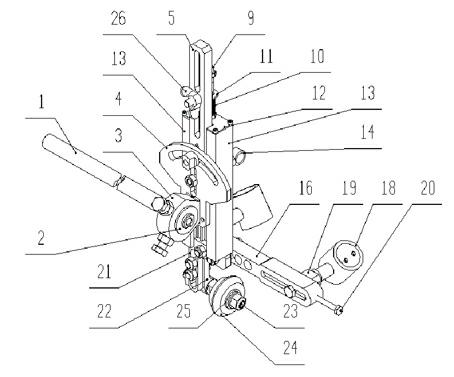

Spring pressure-assisted cutting fixing device with double cutting torches and application method of spring pressure-assisted cutting fixing device

ActiveCN102581534AStrong structural rigiditySmall frictional resistanceWelding/cutting auxillary devicesAuxillary welding devicesSheet steelMechanical engineering

The invention discloses a spring pressure-assisted cutting fixing device with double cutting torches and an application method of the spring pressure-assisted cutting fixing device, which are quite suitable for cutting grooves of petals of spherical tanks and can simultaneously carry out one-step groove forming cutting for two groove surfaces. The fixing device comprises a transverse adjusting rod, a cutting torch fixing sleeve and a supporting guide wheel, the transverse adjusting rod is connected with an arc seam cutting adjusting mechanism, the cutting torch fixing sleeve is mounted on a cutting torch positioning mechanism, the supporting guide wheel is mounted in a supporting guide wheel mounting mechanism, the arc seam cutting adjusting mechanism is fixed onto a spring pressure assisting mechanism by a bolt, and the cutting torch positioning mechanism and the supporting guide wheel mounting mechanism are mounted on the lower portion of the spring pressure assisting mechanism. The application method includes cutting an upper groove angle beta 1 by the aid of a positioning cutting torch; and cutting a lower groove angle beta 2 by the aid of an adjustable cutting torch in the movable cutting torch fixing sleeve, leading the positioning cutting torch and the adjustable cutting torch to realize cutting simultaneously, and forming an X-shaped cutting line on a spherical shell plate. Owing to spring pressure assistance, the supporting guide wheel always contacts with the steel spherical shell plate along with change of the shape of a cutting plate.

Owner:中石化胜利油建工程有限公司

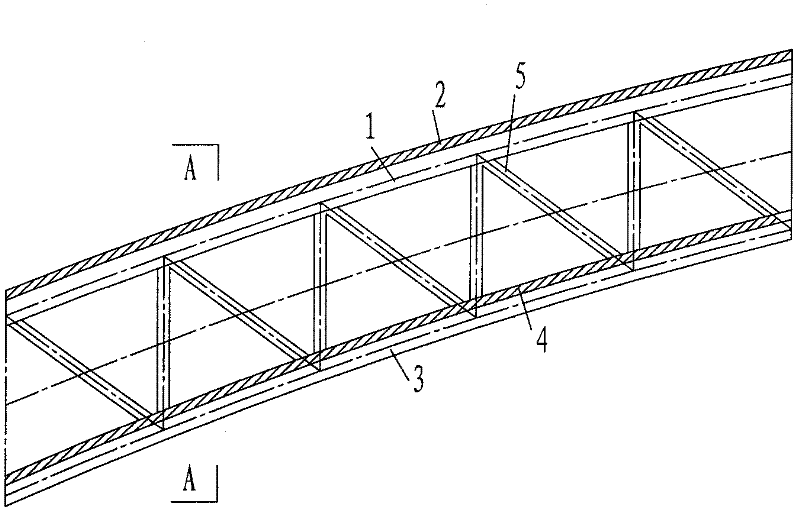

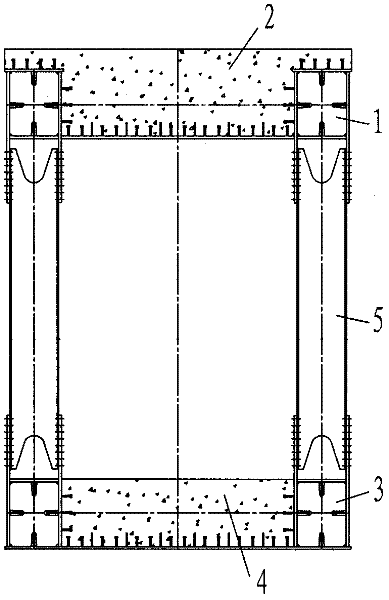

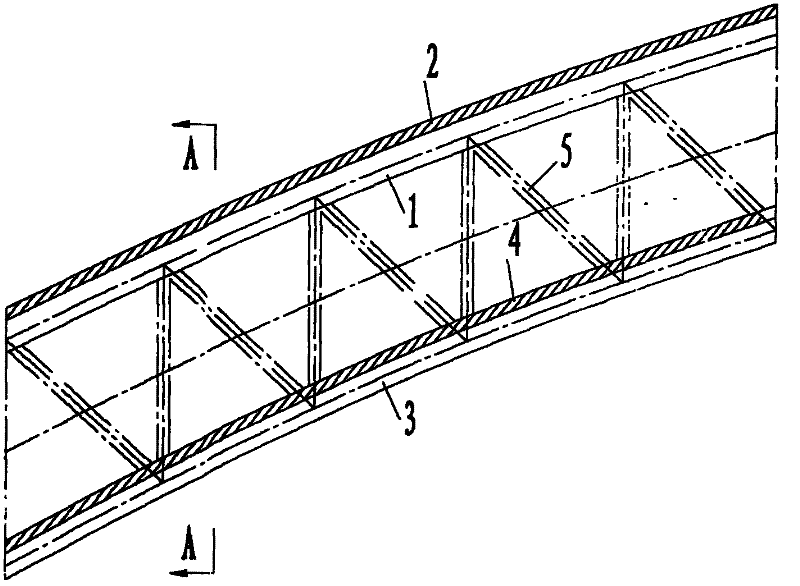

Double-layer steel-truss concrete laminated arch structure and construction method thereof

InactiveCN102409603AImprove material propertiesSimple structureBridge structural detailsBridge erection/assemblyMaterials scienceArch bridge

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST +1

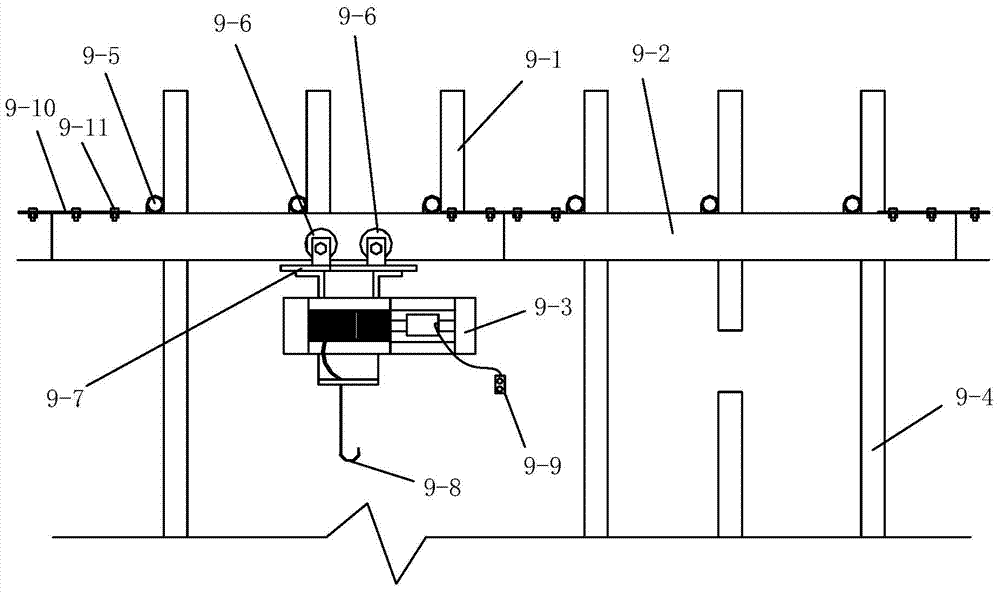

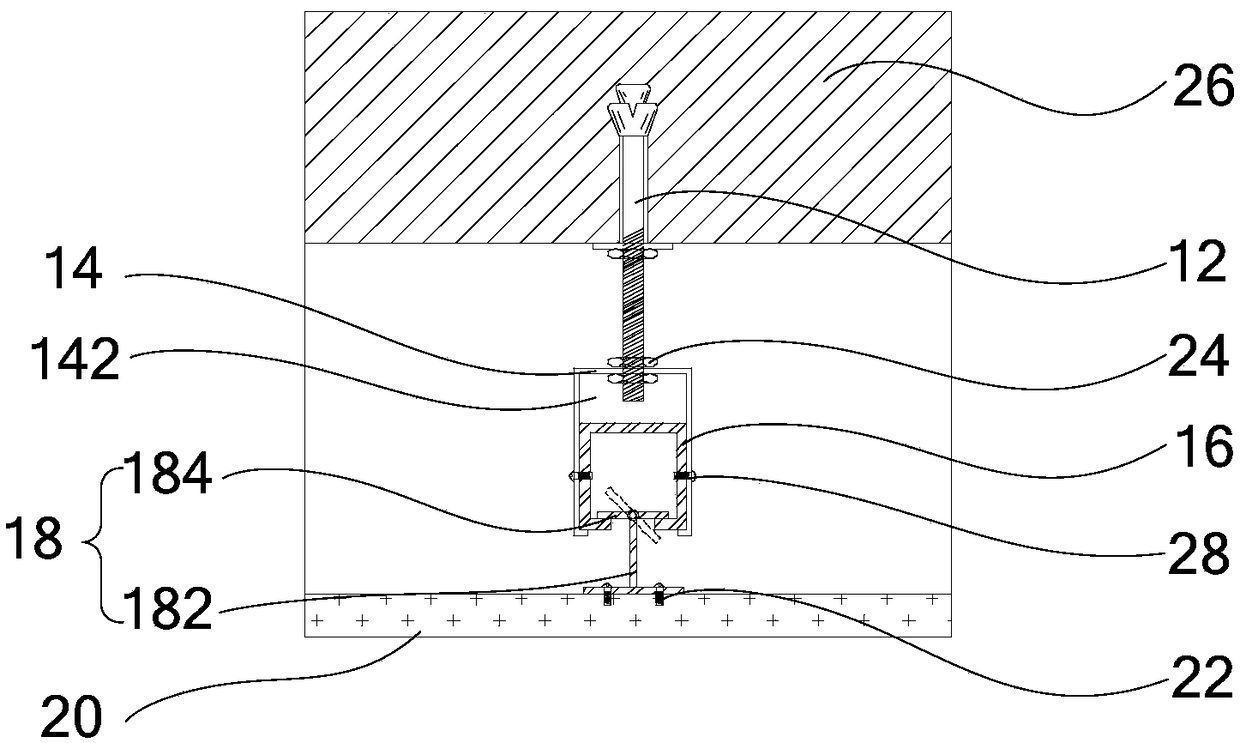

Ceiling keel system and method for installing ceiling keel system

InactiveCN109235737ASimple manufacturing processReduce manufacturing difficultyCeilingsEngineeringBuilding construction

The invention provides a ceiling keel system and a method for installing the ceiling keel system; the ceiling keel system is fixed on the wall surface and comprises a hanging piece, a connecting piece, a main keel, an auxiliary keel, a panel and a screw; one end of the hanging piece is fixed on the wall surface; the connecting piece is provided with a first fixing groove, and one end of the connecting piece is connected with the other end of the hanging piece; the main keel is provided with a second fixing groove, and the main keel is embedded in the first fixing groove; the auxiliary keel comprises a first auxiliary keel body and a connecting part, the connecting part is rotationally connected with the first auxiliary keel body, and the connecting part is embedded in the second fixing groove to make the main keel connected with the auxiliary keel; the panel is fitted to the lower surface of the first auxiliary keel body; at least two screws pass through the first auxiliary keel body and the panel to connect the auxiliary keel to the panel. As the ceiling keel system is of a split type structure, the industrialization and batch installation of all components can be achieved, thereby reducing production cost and shortening construction period.

Owner:周建武

Supporting structure of ultra-deep pipe gallery foundation pit and construction method thereof

The invention discloses a supporting structure of an ultra-deep pipe gallery foundation pit and a construction method thereof, and relates to the field of pipe gallery foundation pit construction. According to the supporting structure, a slope support and a cast-in-place pile support are combined and applied to the ultra-deep pipe gallery foundation pit, the support structure is divided into a slope-laying support section and a concrete cast-in-place pile support section from top to bottom, so that the problem that the earth excavation amount is large when a side slope support is adopted singleness is avoided, and the problem that safety cannot be guaranteed when a cast-in-place pile support is adopted singleness is avoided. The supporting structure of the ultra-deep pipe gallery foundation pit and the construction method of the supporting structure of the ultra-deep pipe gallery foundation pit are high in operability, the supporting cost of the ultra-deep foundation pit is reduced, and the construction period is remarkably shortened.

Owner:CHINA MCC17 GRP

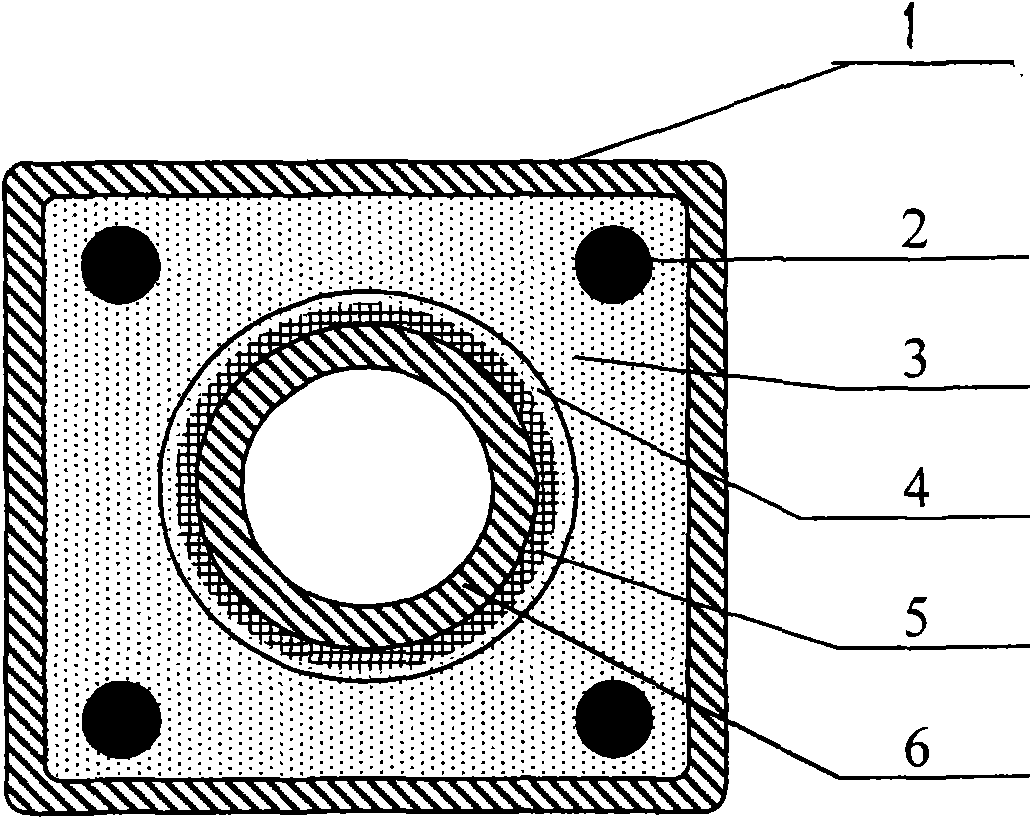

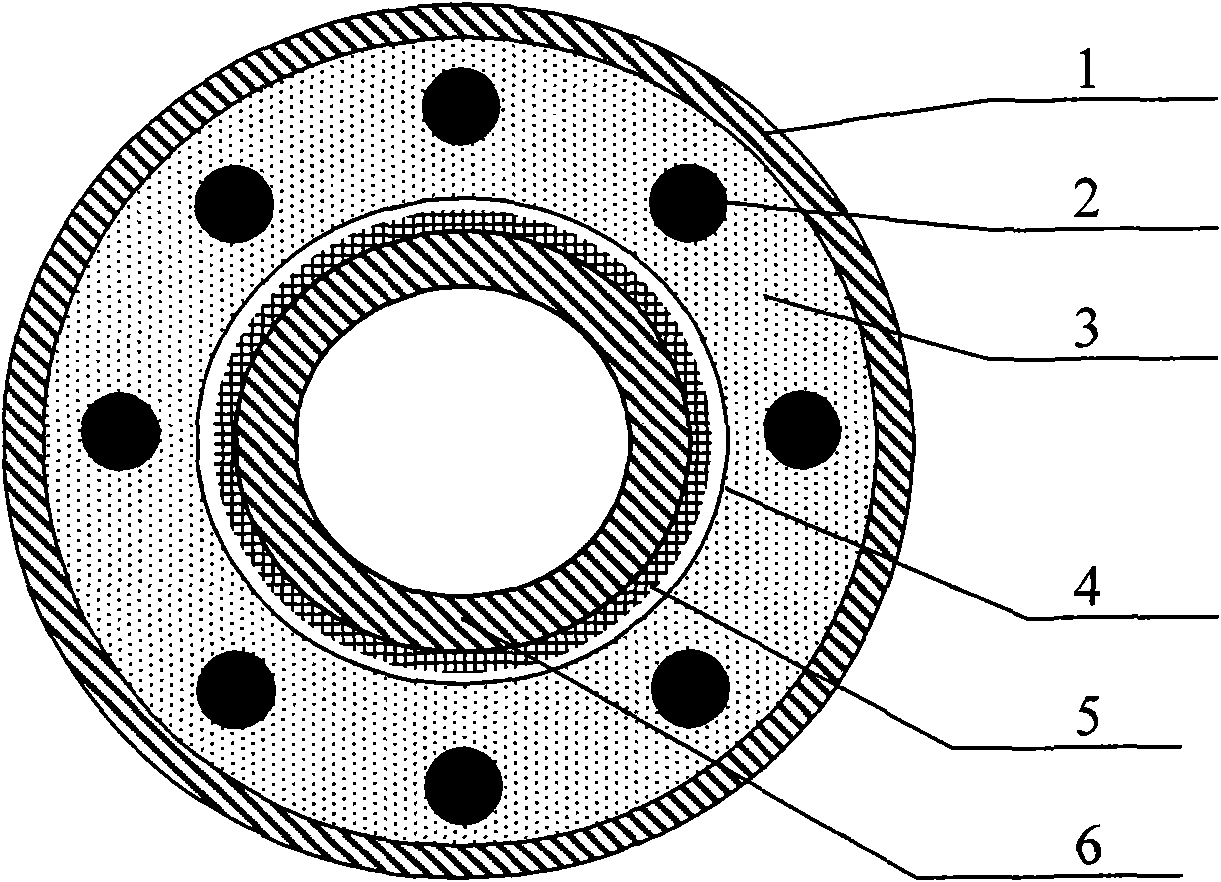

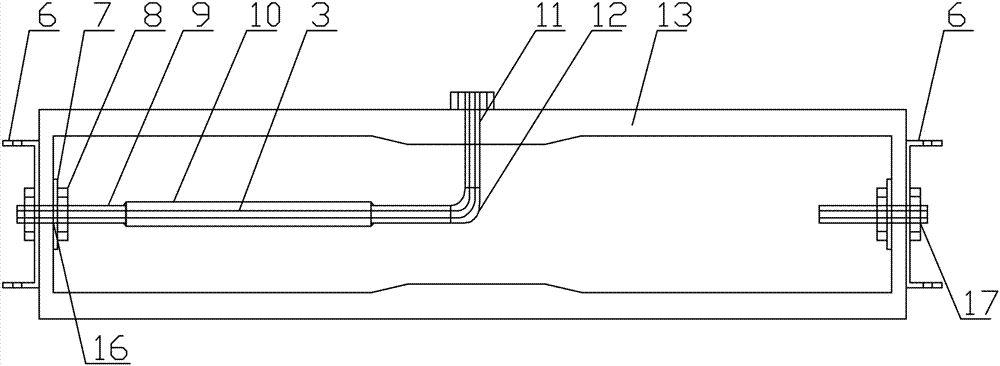

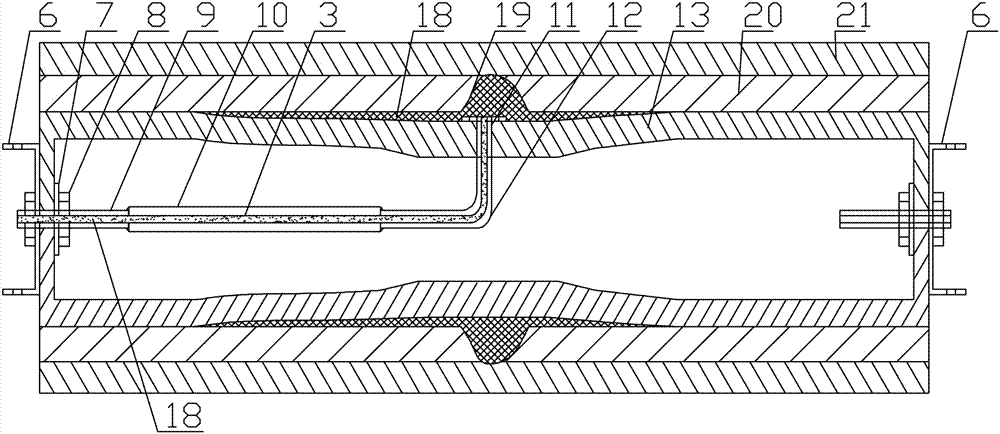

Pipeline internal water seepage plugging device and construction method thereof

The invention discloses a pipeline internal water seepage plugging device and a construction method of the pipeline internal water seepage plugging device. The pipeline internal water seepage plugging device comprises an air bag. The air bag is provided with an air inlet, a feeding opening and a discharging opening. The air inlet is connected with an inflation device. The feeding opening is connected with a pressure grouting device. The discharging opening is connected with the feeding opening through a grouting pipeline. The discharging opening is arranged on the side wall of the air bag. The two ends of the air bag are provided with traction devices. The air bag is made of high-temperature-resistant rubber pipe materials. The thicknesses of the air bag are not identical. The wall thickness at the discharging opening is larger than that at other positions. The two ends of the air bag are fixedly provided with gaskets through nuts. The outer walls of the two ends of the inflated air bag can be attached to a pipeline to be repaired in a sealed manner so that a sealed cavity can be formed in the middle of the air bag. By the adoption of the pipeline internal water seepage plugging device, grouting can be conducted inside the pipeline of any diameter, and therefore the problem that water seepage inside the pipeline cannot be plugged is solved.

Owner:CHINA NUCLEAR IND 22ND CONSTR

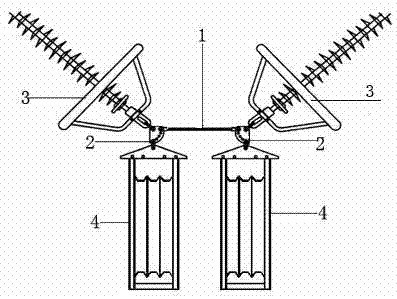

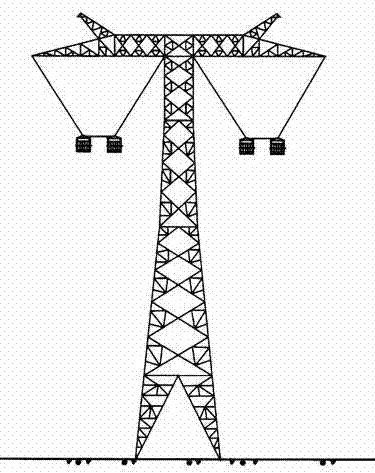

Construction method for parallel suspension of lead trolleys by using V-shaped strings

InactiveCN102208777APrevent tackle from steppingPrevent irregular swinging back and forthApparatus for overhead lines/cablesComposite insulatorsPower engineering

The invention relates to a method for construction, maintenance and repairing of transmission and transformation lines in power engineering, in particular to a construction method for parallel suspension of lead trolleys by using V-shaped strings, which is characterized in that the V-shaped strings of composite insulators and two three-wheel lead wire releasing trolleys are connected into a whole by a Phi 22 circular steel connecting rod and two -20 three-hole linkage plates. A hanging tool for implementing the construction method for parallel suspension of lead trolleys by using V-shaped strings is characterized by mainly comprising the Phi 22 circular steel connecting rod for V-shaped strings, and two-twenty three-hole linkage plates. The construction method for parallel suspension of lead trolleys by using V-shaped strings, disclosed by the invention, can be widely applicable to the construction method of suspending lead trolleys by using V-shaped strings in the construction of 660 kv and above large-cross multi-split conductors with 2*' ONE Pulling Two', 2* 'One Pulling Two and One Pulling Four' and 2* 'One Pulling Four' tension wirings.

Owner:STATE GRID CORP OF CHINA +1

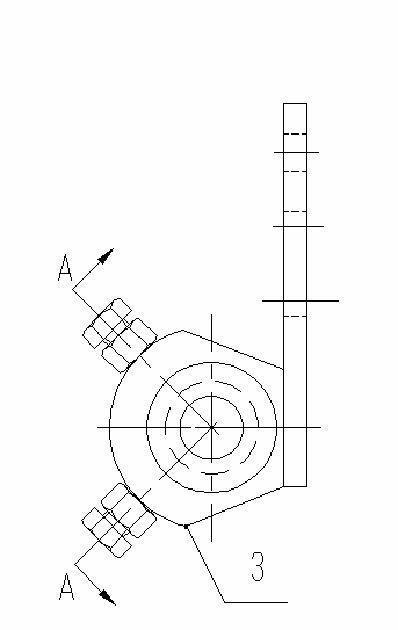

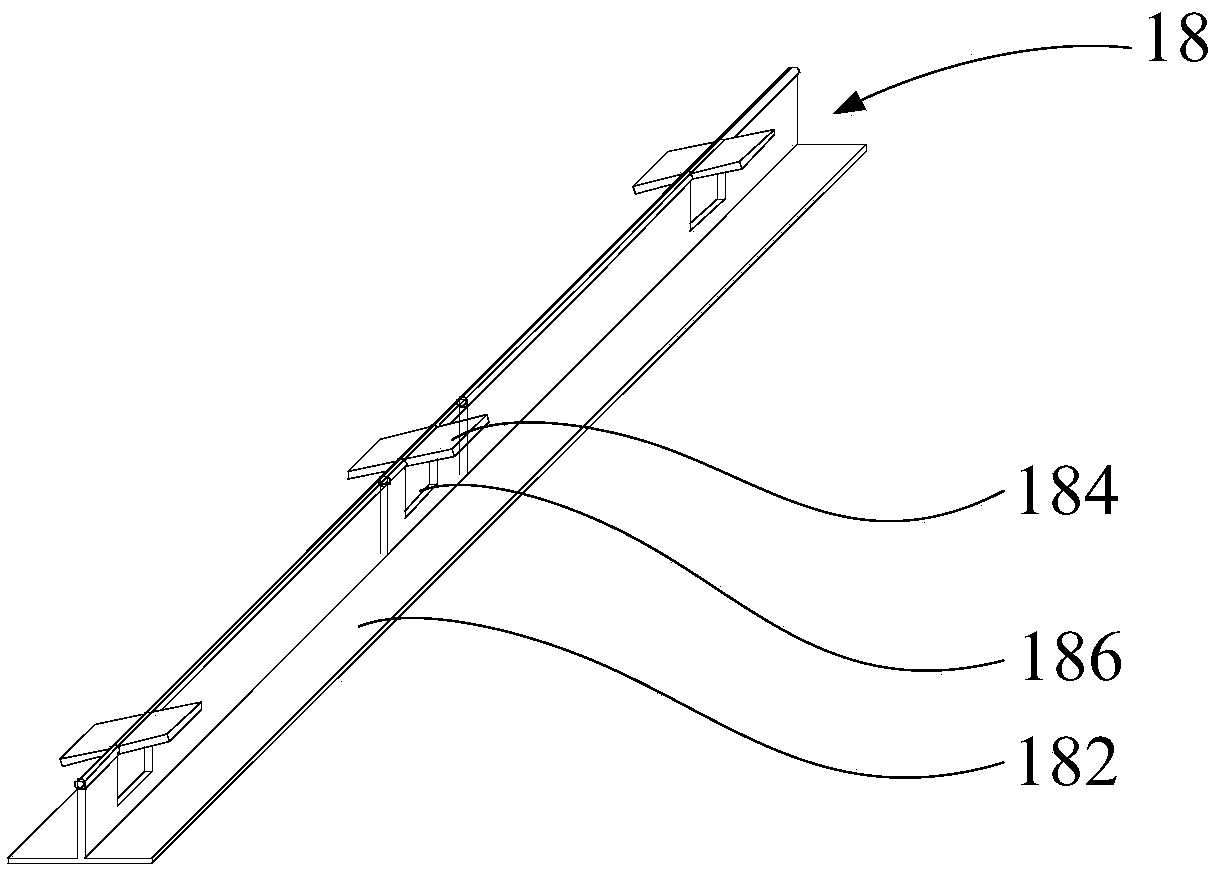

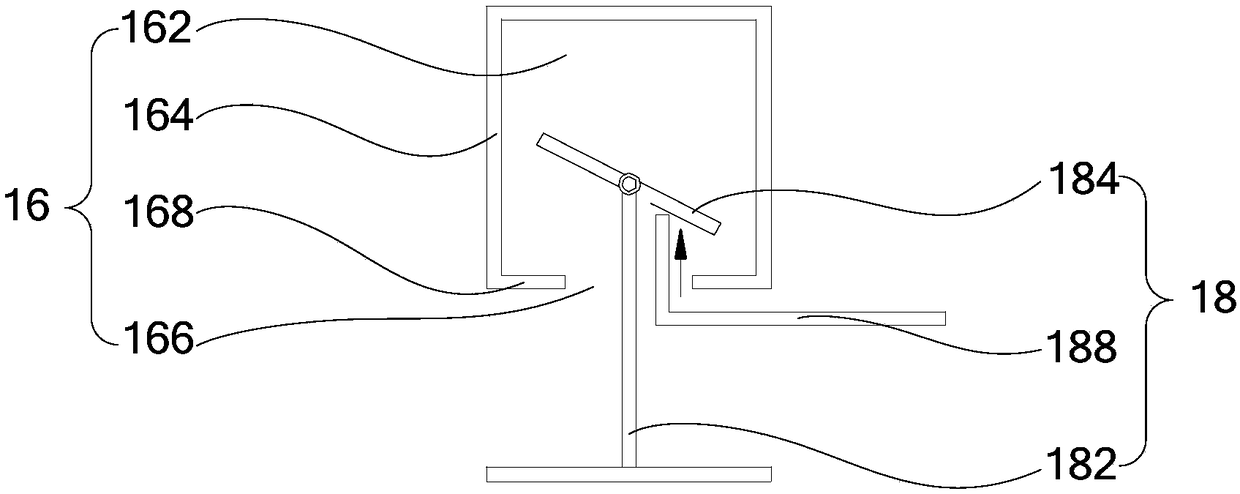

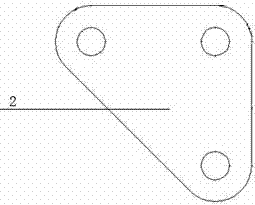

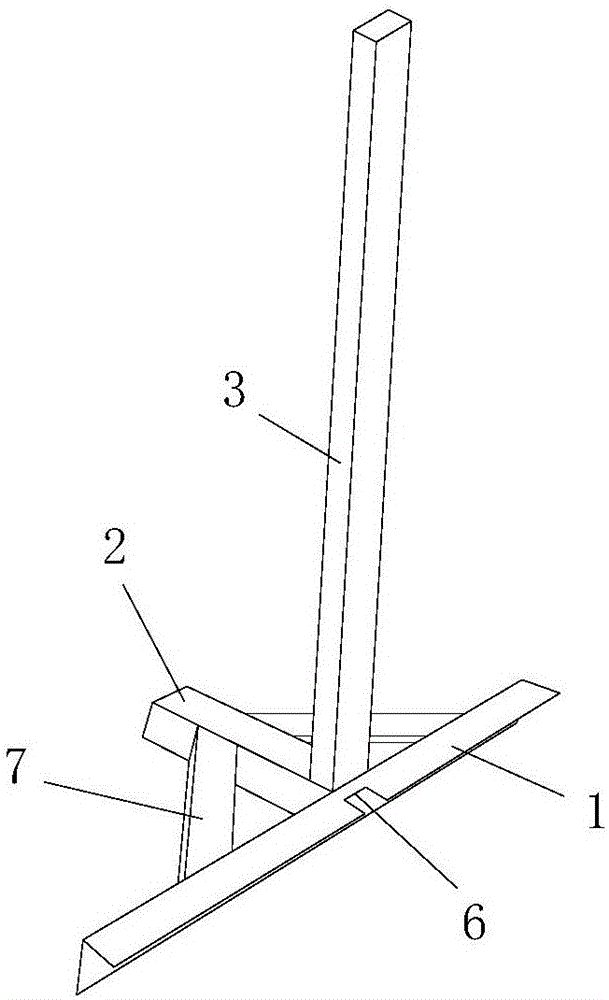

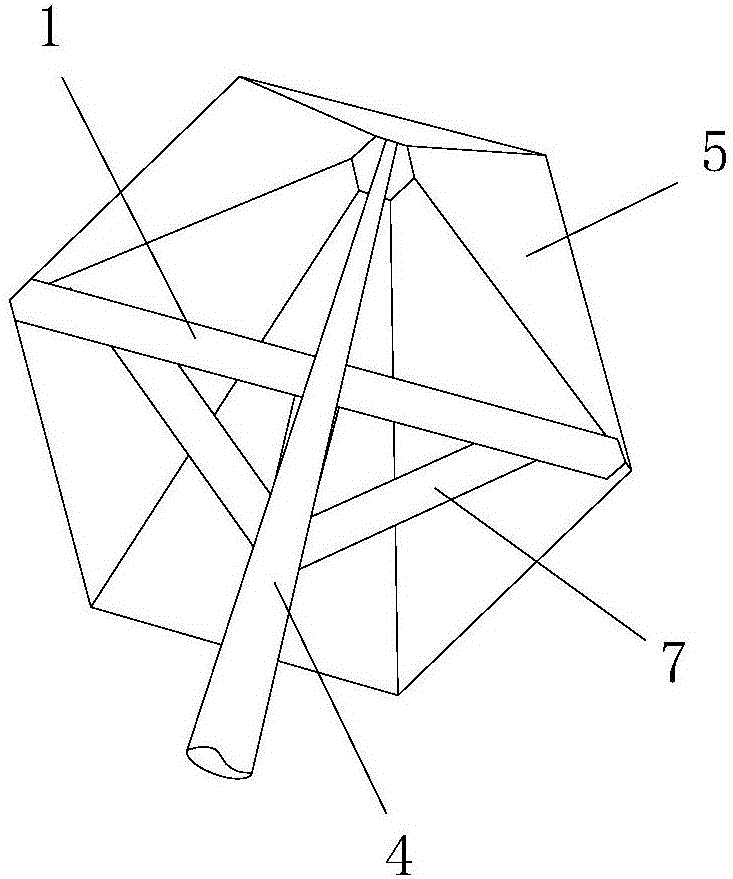

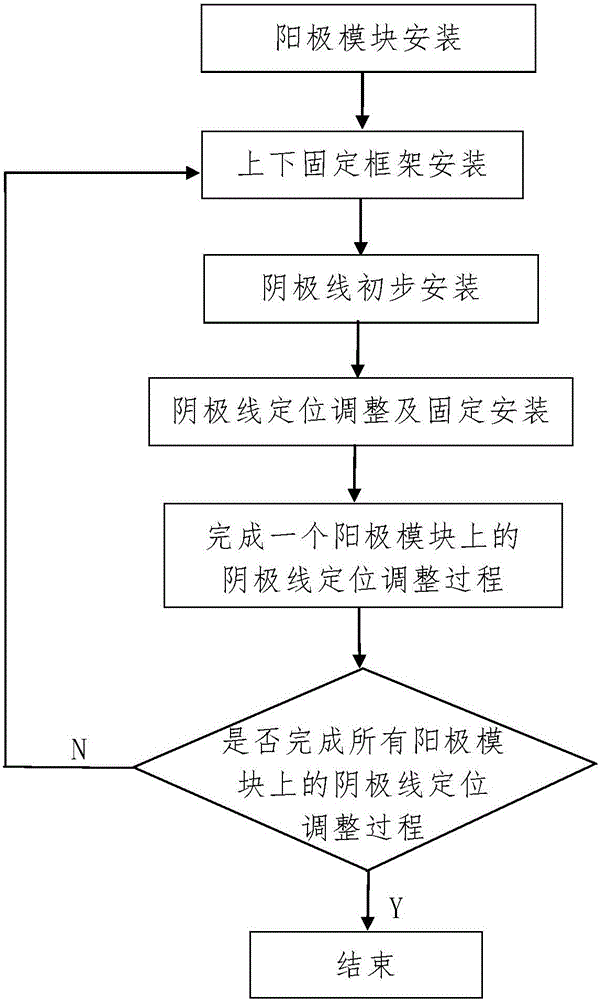

Cathode line positioning die and cathode lien positioning and adjustment construction method

ActiveCN106238212ASimple structureEasy to processElectrostatic separation detailsArchitectural engineeringAnode

The invention discloses a cathode line positioning die and a cathode lien positioning and adjustment construction method. The positioning die comprises a rear measuring rod, a front measuring rod arranged on the front side of the middle of the rear measuring rod and a vertical rod fixed behind the rear portion of the front measuring rod, wherein the front measuring rod and the vertical rod are located in front of the rear measuring rod, the rear measuring rod, the front measuring rod and the vertical rod are straight rods, the rear measuring rod and the front measuring rod are arranged in a perpendicular mode, the rear measuring rod and the front measuring rod form a horizontal positioning rack, and a clamping groove for positioning an adjusted cathode line is formed in the rear side of the middle of the rear measuring rod. The constriction method comprises the steps that 1, anode module installation is performed; 2, cathode line installation construction is performed: when the cathode line is installed on any group of anode modules, the process is that 201, upper and lower fixing frames are installed; 202, preliminary cathode line installation is performed; 203, cathode line positioning, adjustment and fixing installation are performed. The cathode line positioning die is reasonable in design, simple and convenient to use and operate, good in using effect and capable of simply, conveniently and rapidly perform accurate cathode line positioning and ensuring cathode line installing precision.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

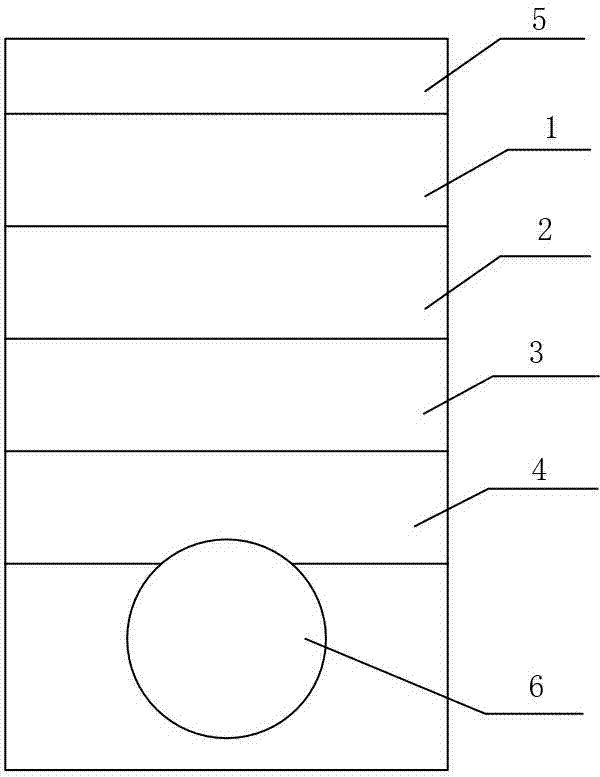

Fabricated light steel keel wall body suitable for building and construction technology

PendingCN107859213AImprove sound insulationImprove thermal insulation and energy savingWallsThick plateEngineering

The invention belongs to the technical field of fabricated light steel keel enclosure wall bodies of buildings and construction and discloses a fabricated light steel keel wall body suitable for a building and a construction technology. The fabricated light steel keel wall body suitable for the building comprises a wall surface anti-cracking and waterproof material composite layer and the like. AnALC board base layer with the thickness being 50-200 mm is arranged on the right side of the wall surface anti-cracking and waterproof material composite layer, and a damping and sound-insulating material layer with the thickness being 1.2-19 mm is arranged on the right side of the ALC board base layer with the thickness being 50-200 mm. A heat-insulating material layer with the thickness being 2-15 mm is arranged on the right side of the damping and sound-insulating material layer with the thickness being 1.2-19 mm, and a light steel keel wall frame is arranged on the right side of the heat-insulating material layer with the thickness being 2-15 mm. The light steel keel wall frame is filled with a heat-insulating material with the thickness being 30-140 mm, and a heat-insulating materialwith the thickness being 2-15 mm is arranged on the right side of the light steel keel wall frame. A sound-insulating material with the thickness being 1.2-19 mm is arranged on the right side of theheat-insulating material with the thickness being 2-15 mm, and an ALC board with the thickness being 50-200 mm is arranged on the right side of the sound-insulating material with the thickness being 1.2-19 mm. A facing layer is arranged on the right side of the ALC board with the thickness being 50-200 mm.

Owner:武汉麦特建筑科技有限公司

Construction method adopting guide positioning through guide hole and smooth blasting

The invention relates to a construction method adopting guide positioning through a guide hole and smooth blasting. The construction method includes the steps that S1, a hole drilling blasting method is adopted for excavating a vertical shaft, an inclined shaft or a groove to the design elevation; S2, the four corners of the vertical shaft are excavated to form guide positioning holes, the drilled hole depth of the guide positioning holes reaches the design elevation; S3, the four positioning holes are connected, positioning control pre-cracking holes are distributed on a peripheral excavation line, and drilling to the design elevation is achieved at a time; S4, based on field engineering geology and rock conditions, the number of the drilled holes is appropriately increased, and the charging amount is adjusted; and S5, after vertical footage by 5 m, blasting excavation is paused, pouring of concrete is used for locking, after a tunnel is through, the vertical shaft is blast to penetrate a safety layer, and parallel slag discharging from the tunnel is achieved. The construction method has the beneficial effects that the construction quality is improved, the back break amount is reduced, and the stability of surrounding rock is good; the temporary support lining work amount can be reduced, and the construction cost is reduced; and the construction period can be accelerated.

Owner:哈密新智源水利水电工程建设监理有限公司

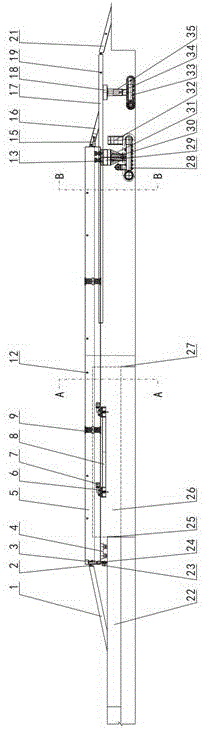

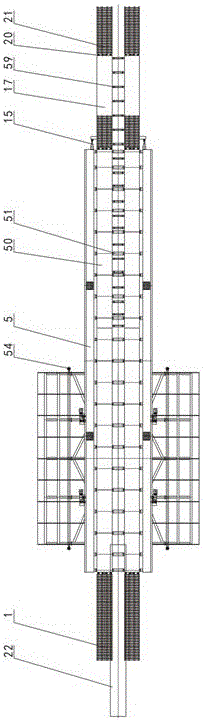

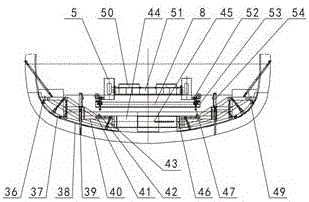

Multifunctional stretchable inverted-arch trestle

ActiveCN106640133AImplement resizingEasy to disassemble/assembleUnderground chambersTunnel liningHydraulic cylinderEngineering

The invention discloses a multifunctional stretchable inverted-arch trestle. The multifunctional stretchable inverted-arch trestle comprises a trestle girder, a front ladder stand, a back ladder stand, a walking cart, a stretchable trestle body, an inverted-arch formwork and a central furrow formwork; the walking cart is installed below the trestle girder, the stretchable trestle body is located at the front portion below the trestle girder, the front portion of the stretchable trestle body is arranged on a stretchable trestle body beam, the back portion of the stretchable trestle body is movably installed on the trestle girder through connecting plates, and the stretchable trestle body beam is installed on a walking auxiliary caterpillar band chassis through vertical auxiliary lifting hydraulic cylinders and auxiliary movable stand columns; the inverted-arch formwork and the central furrow formwork are sequentially installed in the middle and at the back portion below the trestle girder from front to back and move back and forth through the walking cart. According to the multifunctional stretchable inverted-arch trestle, the trestle girder, the stretchable trestle body, the inverted-arch formwork, the central furrow formwork and end sealing plates are designed into an integrated device, multiple working procedures can be carried out at the same time, the construction period is greatly saved, the construction efficiency is improved, the labor intensity of workers is reduced, the construction quality is guaranteed, and the construction cost is reduced.

Owner:四川省创力隧道机械设备有限公司

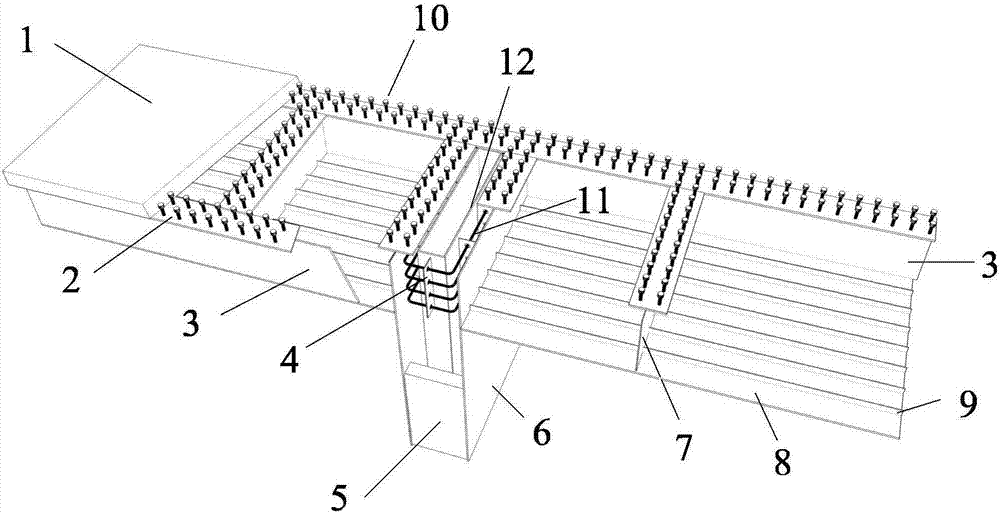

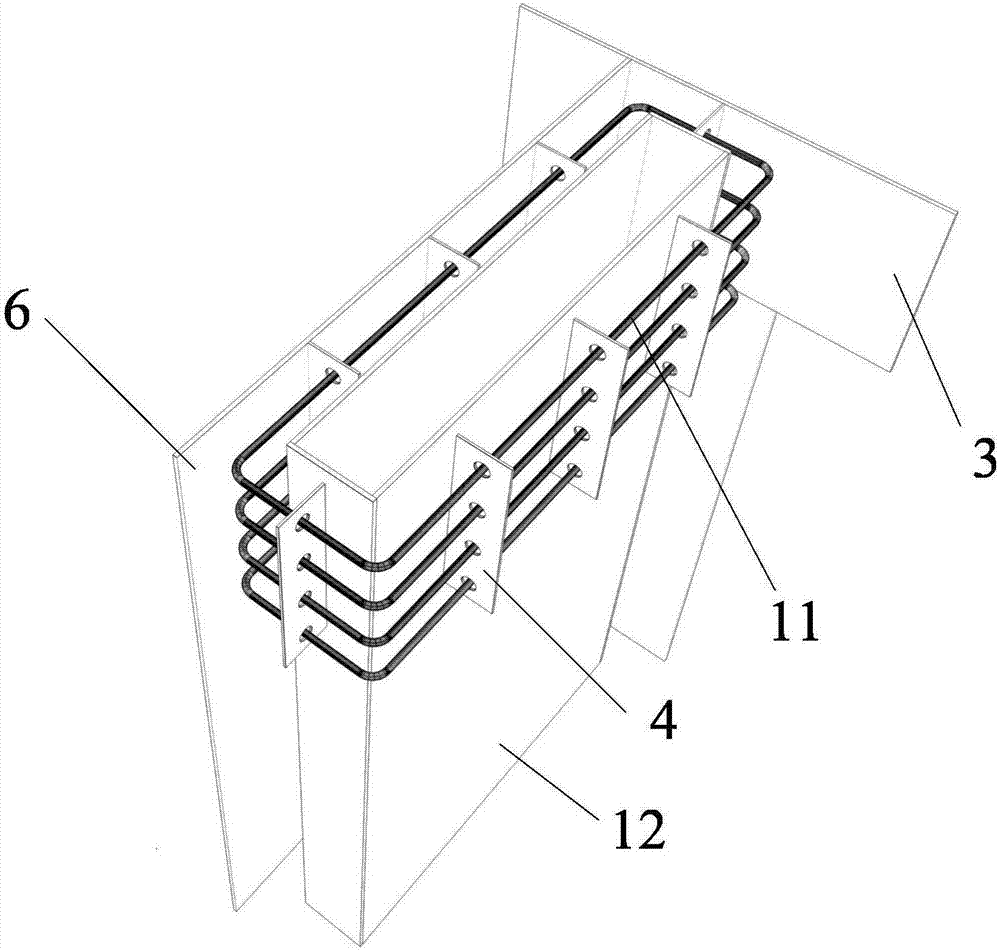

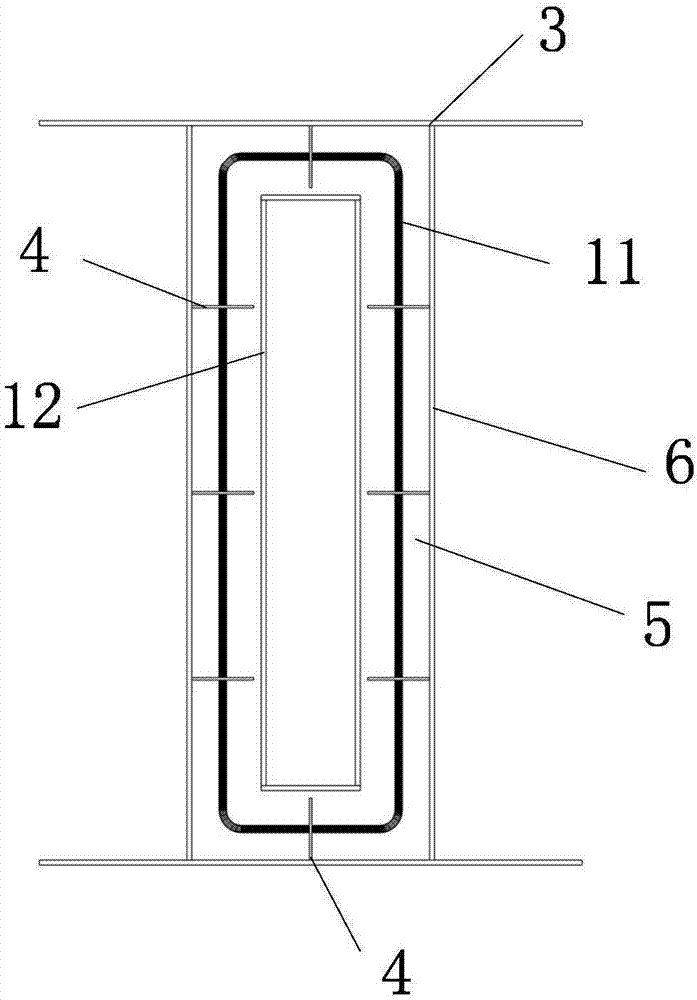

Rigid connection structure form of double-layered steel box concrete pier column and steel beam and construction method

ActiveCN106906736ATroubleshoot connection construction issuesSimple structureBridge structural detailsBridge erection/assemblySheet steelWhole body

The invention discloses a rigid connection structure form of a double-layered steel box concrete pier column and a steel beam and a construction method. The rigid connection structure form comprises the double-layered steel box concrete pier column and a steel box beam at the upper part or a steel-concrete combined beam; the steel box beam or a top flange plate of the steel-concrete combined beam, a bottom plate and web plates are welded to form a whole body; bottom plate reinforcing ribs are arranged on the bottom plate; a transverse separation plate is arranged between the web plates; cotters are further arranged on the top flange plate of the steel-concrete combined beam and a concrete roof is poured on the cotters; the bottom plate is disconnected at a node connecting part and the double-layered steel box concrete pier column is inserted; an outer steel plate of the double-layered steel box concrete pier column is welded with the bottom plate and the top flange plate; reinforcing ribs are welded among the outer steel plate of the double-layered steel box concrete pier column and an inner steel plate of the double-layered steel box concrete pier column, and the web plates; the reinforcing ribs are provided with holes and steel bars penetrate into the holes. The node rigid connection structure form disclosed by the invention is used for a continuous rigid-structure bridge or a steel-concrete combined continuous rigid-structure bridge.

Owner:SOUTHEAST UNIV

Two-component polyurethane adhesive and preparation method thereof

InactiveCN110484191AHigh bonding strengthHigh bond strengthPolyureas/polyurethane adhesivesEster polymer adhesivesPrepolymerPolyurethane adhesive

The invention discloses a two-component polyurethane adhesive which is formed by mixing a component A and a component B. The component A is a polyurethane prepolymer, the component B is a mixture of acrylic resin and polyether polyol, and the ratio of the component A to the component B is 1: 1. The mixing ratio of the component A to the component B is optimized; therefore, the prepared two-component polyurethane adhesive is high in bonding strength; the surface drying time of the two-component polyurethane adhesive is relatively suitable for construction operation; during construction of engineering, the construction in a relatively constant state can be maintained; the normal construction period of a project is not influenced; the engineering construction period cannot be prolonged; meanwhile, the prepared adhesive stone is high in strength, meets the test standard of concrete C20 and is good in water resistance test, the adhesive stone prepared from the two-component polyurethane adhesive is resistant to aging and high in hardness, the water permeability reaches 35% or above, the water permeation effect is improved, and the stability of the adhesive stone used in rainy days is improved.

Owner:无锡庄周新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com