Pipeline internal water seepage plugging device and construction method thereof

A plugging device and pipeline technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problem of water seepage in the pipe that cannot be blocked, and achieve the effect of saving costs and speeding up the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

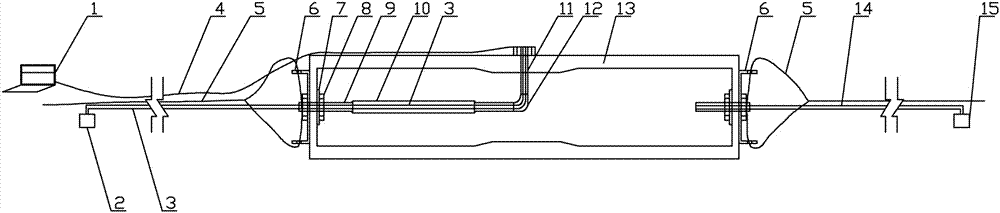

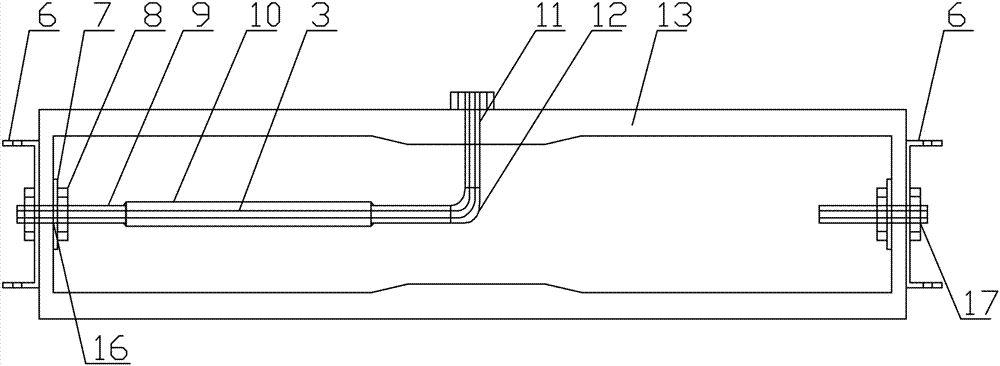

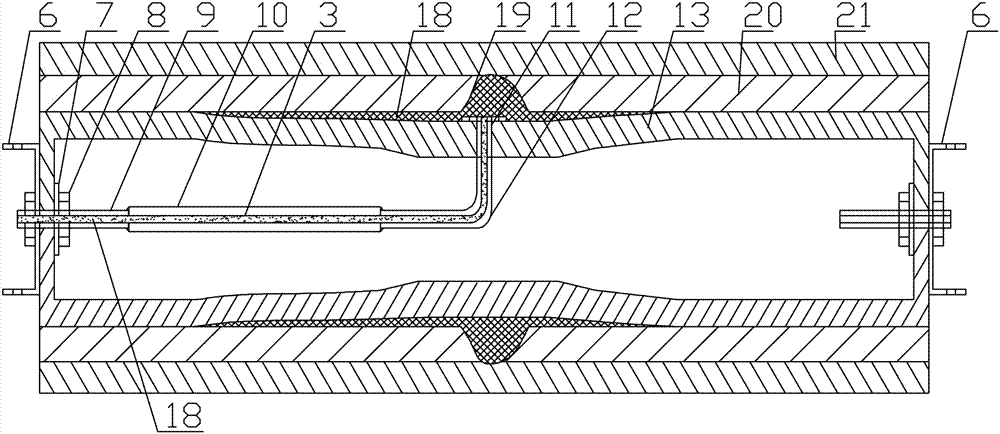

[0043] Such as Figure 1-2 , a pipe seepage plugging device, it includes an air bag 13, the air bag 13 is provided with an air inlet 17, an inlet 16 and an outlet 11.

[0044] Further, the air inlet 17 is connected to the inflation device; the feed port 16 is connected to the pressure tank slurry device; the discharge port 11 is connected to the feed port through a grouting pipeline; the discharge port 16 is set On the side wall of the airbag 13. The air inlet can fill the air bag with air, and the air bag is required to maintain a certain air pressure range, so a barometer is installed at the air inlet to replenish air in time when the air pressure does not meet the requirements.

[0045] Further, traction devices are provided at both ends of the airbag 13 .

[0046] Further, the airbag 13 is made of a high-temperature-resistant rubber tube material, and the wall thickness of the airbag 13 is inconsistent, and the wall thickness at the discharge port 11 is greater than that...

Embodiment 2

[0058] Such as image 3 , the construction method of water seepage sealing device in pipeline, it comprises the following steps:

[0059] Step1: use the endoscope 4 to go deep into the pipeline 20 to be blocked, and initially determine the position of the leakage point 19 through the image display device 1;

[0060] Step2: Extend the uninflated airbag 13 into the pipeline 20 to be blocked, and adjust its position inside the pipeline 20 to be blocked by pulling the steel wire rope 5 at both ends, so that the discharge port 11 is located at the position of the leakage point 19 Location;

[0061] Step3: Inflate the inside of the airbag 13 through the pressure gauge and the inflation device 15, so that the outer walls of both ends of the airbag 13 and the inner wall of the pipeline 20 to be blocked are bonded and sealed, and an airtight cavity is formed in the middle;

[0062] Step4: Use the pressure grouting machine 2 to inject the plugging material to the leakage point 19 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com