Block for constructing retaining wall, prefabricated reinforced retaining wall constructed using the block and construction method of the prefabricated reinforced retaining wall

A block and retaining wall technology, applied in excavation, construction, water conservancy projects, etc., can solve problems such as difficulties in using equipment to build, labor-intensive difficulties, and inconvenient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

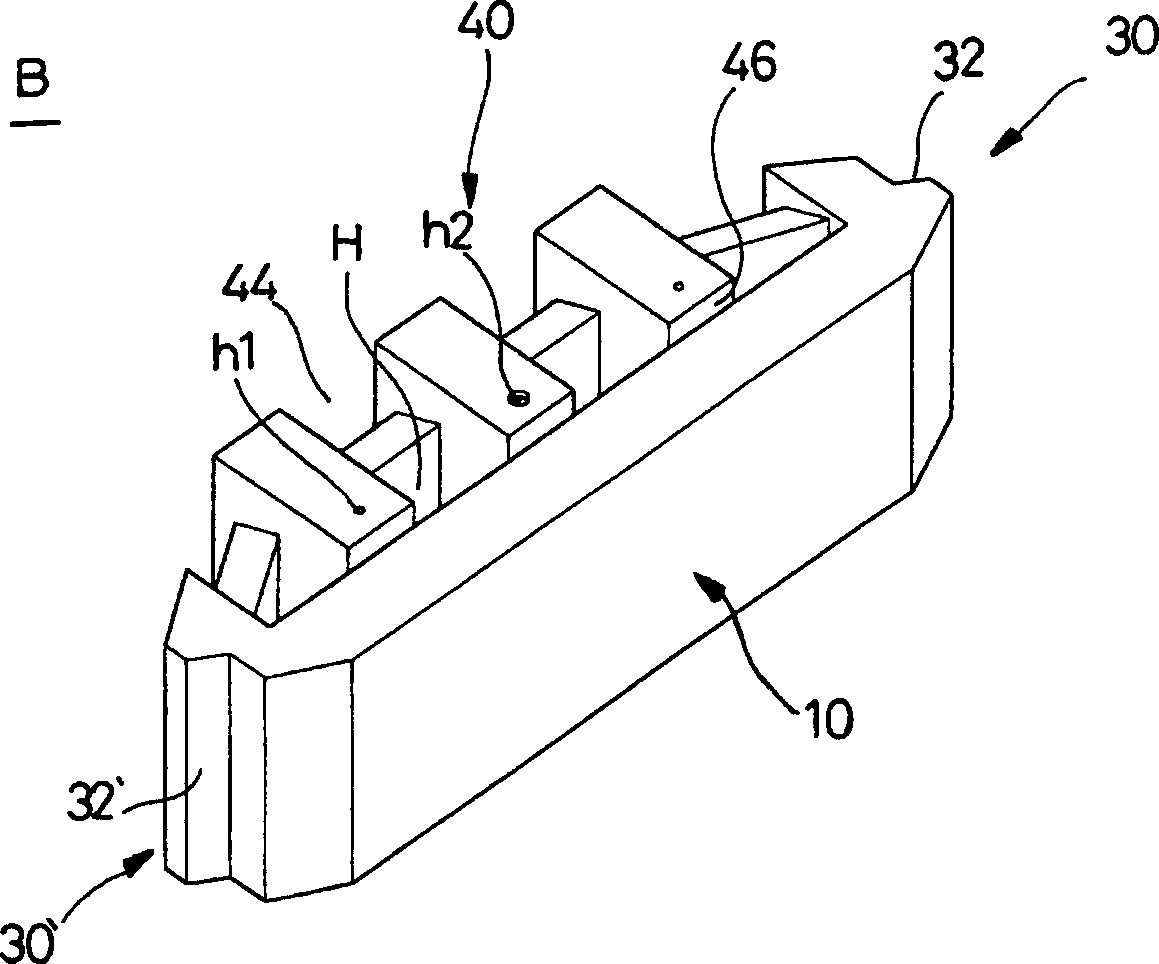

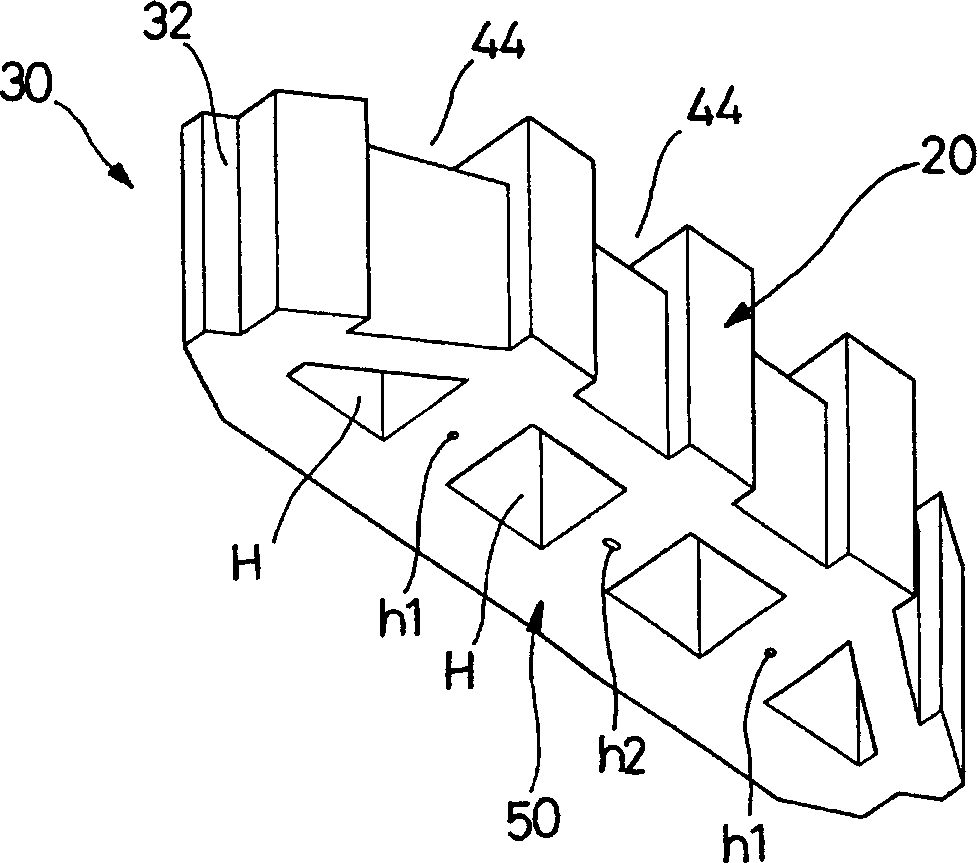

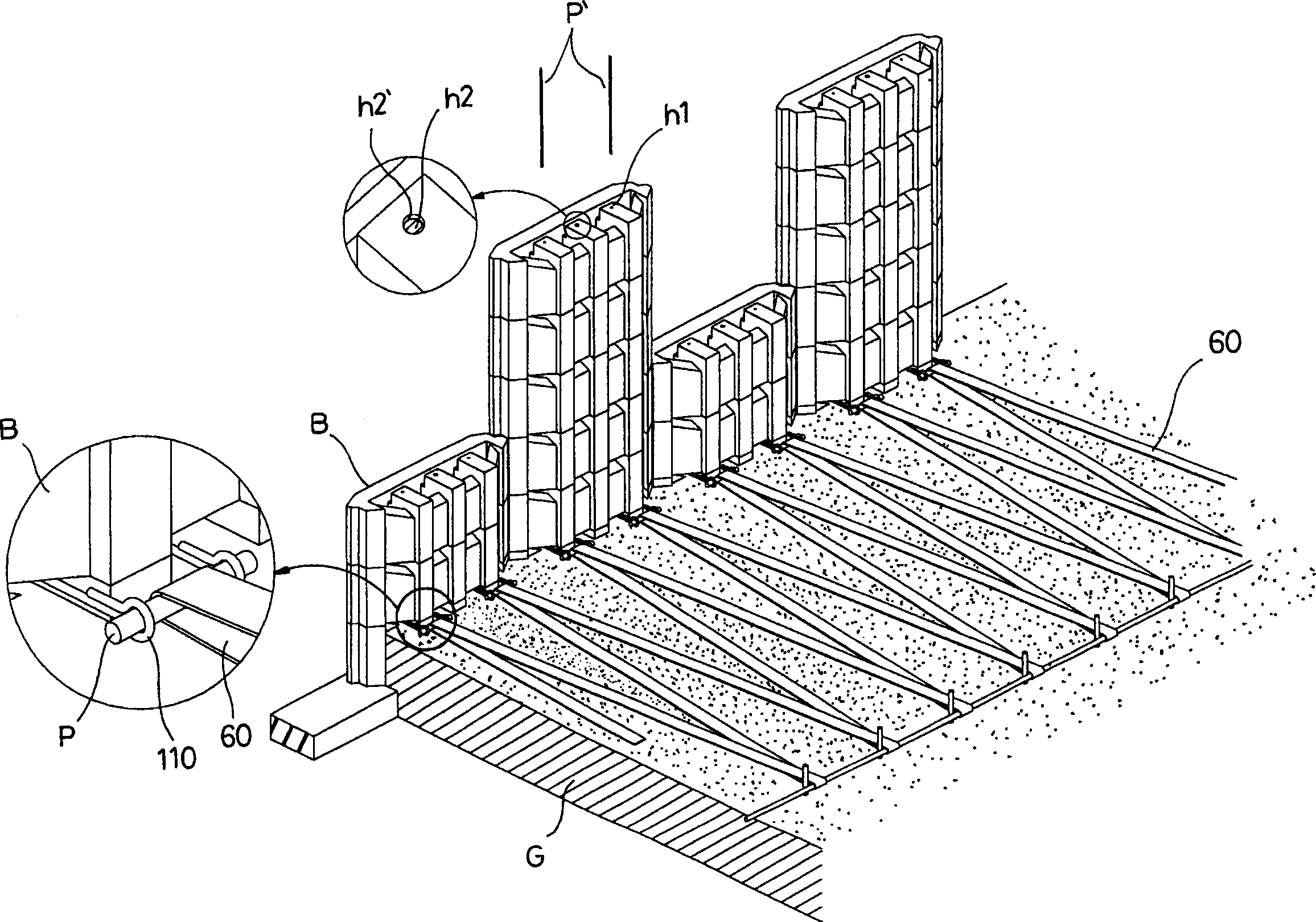

[0070] Figure 1-8 A block, a retaining wall constructed using the blocks, a method of constructing the retaining wall, and a method of repairing the retaining wall when damaged according to the first embodiment of the present invention are explained. Such as figure 1 and 2 As shown, a block B for building a retaining wall according to the first embodiment of the present invention includes: a front face 10 forming a face of the retaining wall, and a rear face 20 contacting a reinforced soil structure; a left side 30 and a right side 30', with The corresponding interfitting parts 32 and 32' on it are respectively used for interfitting and connecting between adjacent blocks; the top surface 40 has a reinforcing member insertion groove 44 formed along the front and rear direction, and the reinforcing member or is used for connecting The holder of the reinforcement is fitted into the groove, and has a fixing groove 46 formed on either side in front of the reinforcement insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com