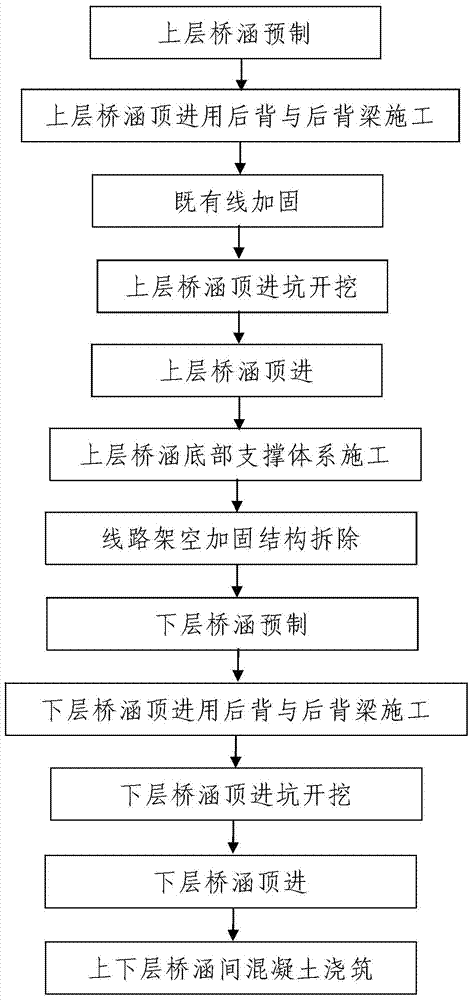

Construction process of double-layer jacking culvert penetrating through existing railway lines

A construction technology and a technology of existing lines, applied in the field of double-layer jacking culvert construction technology, can solve problems such as influence and inability to solve the problem of structure jacking construction, and achieve simple methods and steps, simple and easy construction quality, and enhanced safety. and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

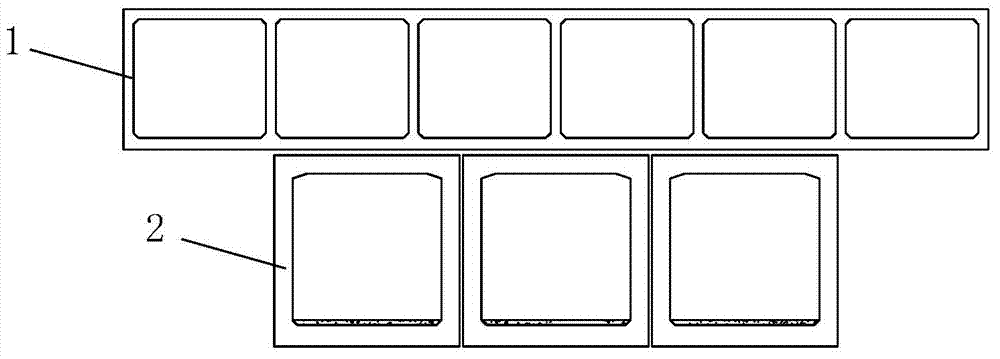

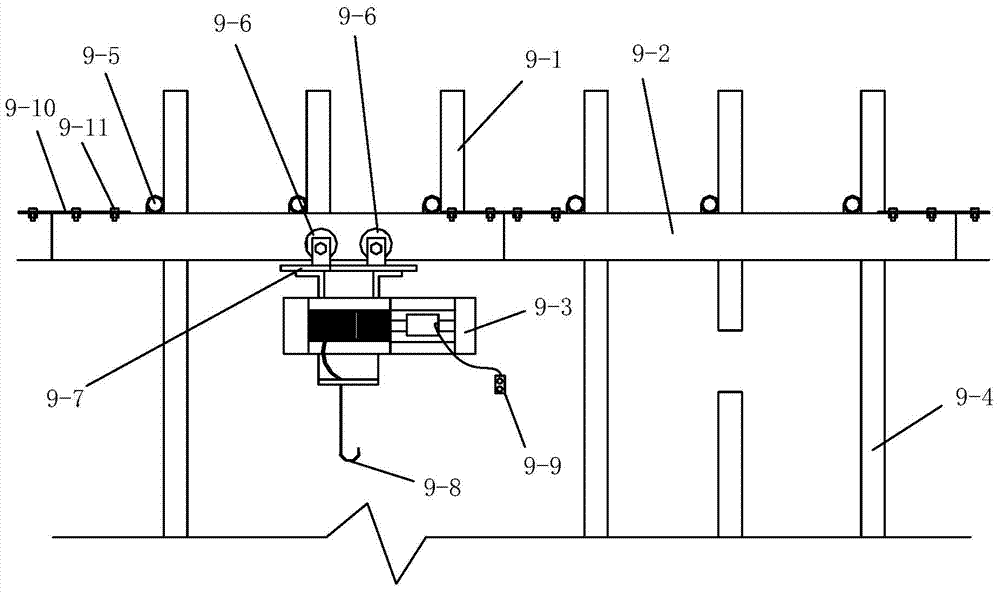

[0056] like figure 1 Shown is a double-layer jacking culvert construction process crossing the existing line. The double-layer jacking culvert constructed is a double-layer bridge culvert crossing the existing line. The double-layer bridge culvert includes the upper bridge culvert 1 and the The lower bridge culvert 2, the upper bridge culvert 1 is located below the existing line crossed, the upper bridge culvert 1 and the lower bridge culvert 2 are reinforced concrete structures and the two are integrated by concrete pouring, the left and right length of the upper bridge culvert 1 greater than the left-right length of the lower bridge and culvert 2, see figure 2 ; The double-deck jacking culvert construction technique comprises the following steps:

[0057] Step 1. Prefabrication of the upper bridge and culvert: After the prefabricated pit 1 for prefabricating the upper bridge culvert 1 is excavated, the upper bridge culvert 1 is prefabricated in the prefabricated pit 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com