Assembly type variable steel girder platform, distribution method and assembly method thereof

A steel truss and assembled technology, which is applied in the direction of scaffolding, house structure support, house structure support, etc., can solve the problems of high construction cost, long construction period, and non-returnable use, so as to achieve simple erection and reduce construction costs. Difficulty and the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

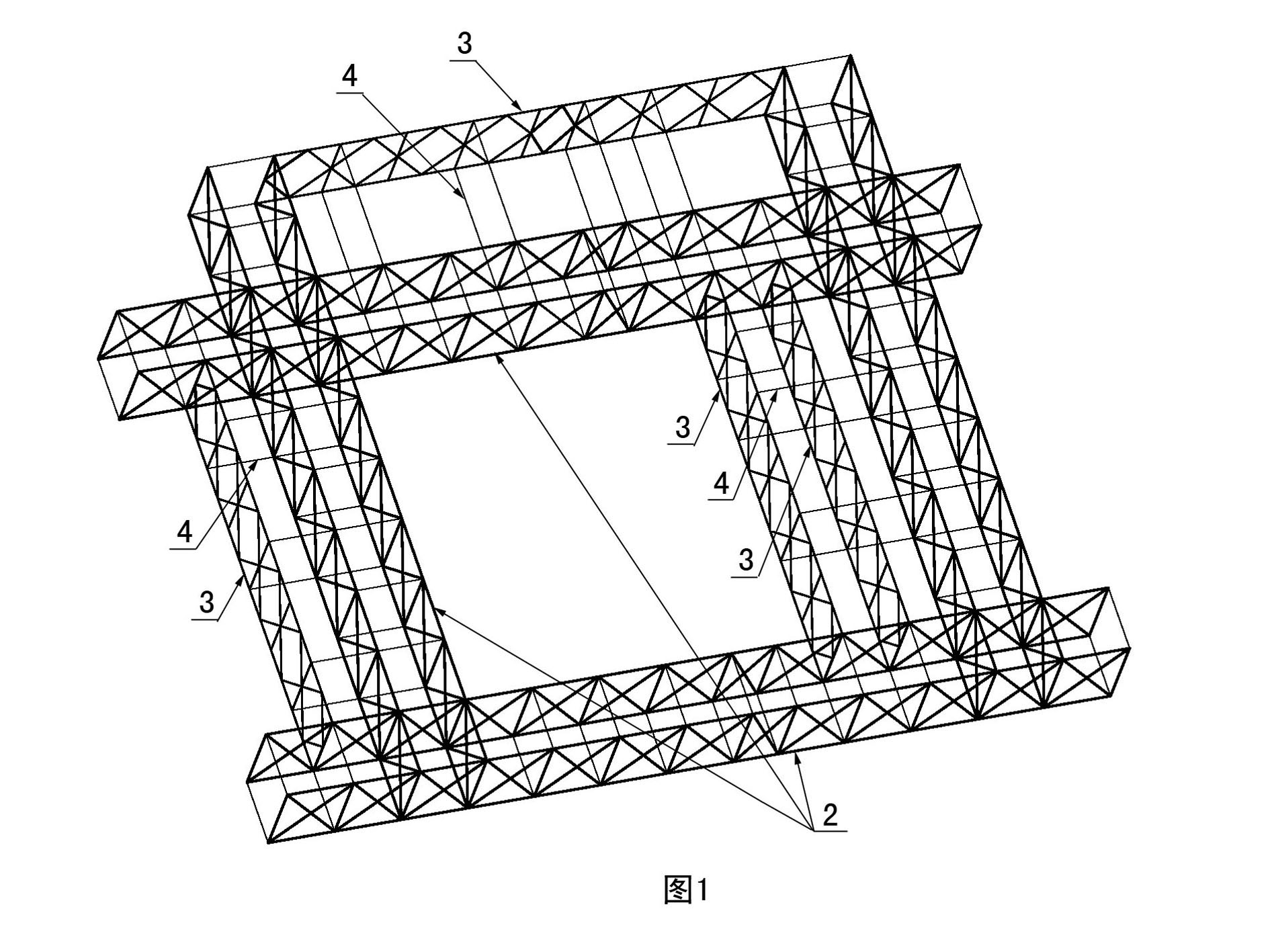

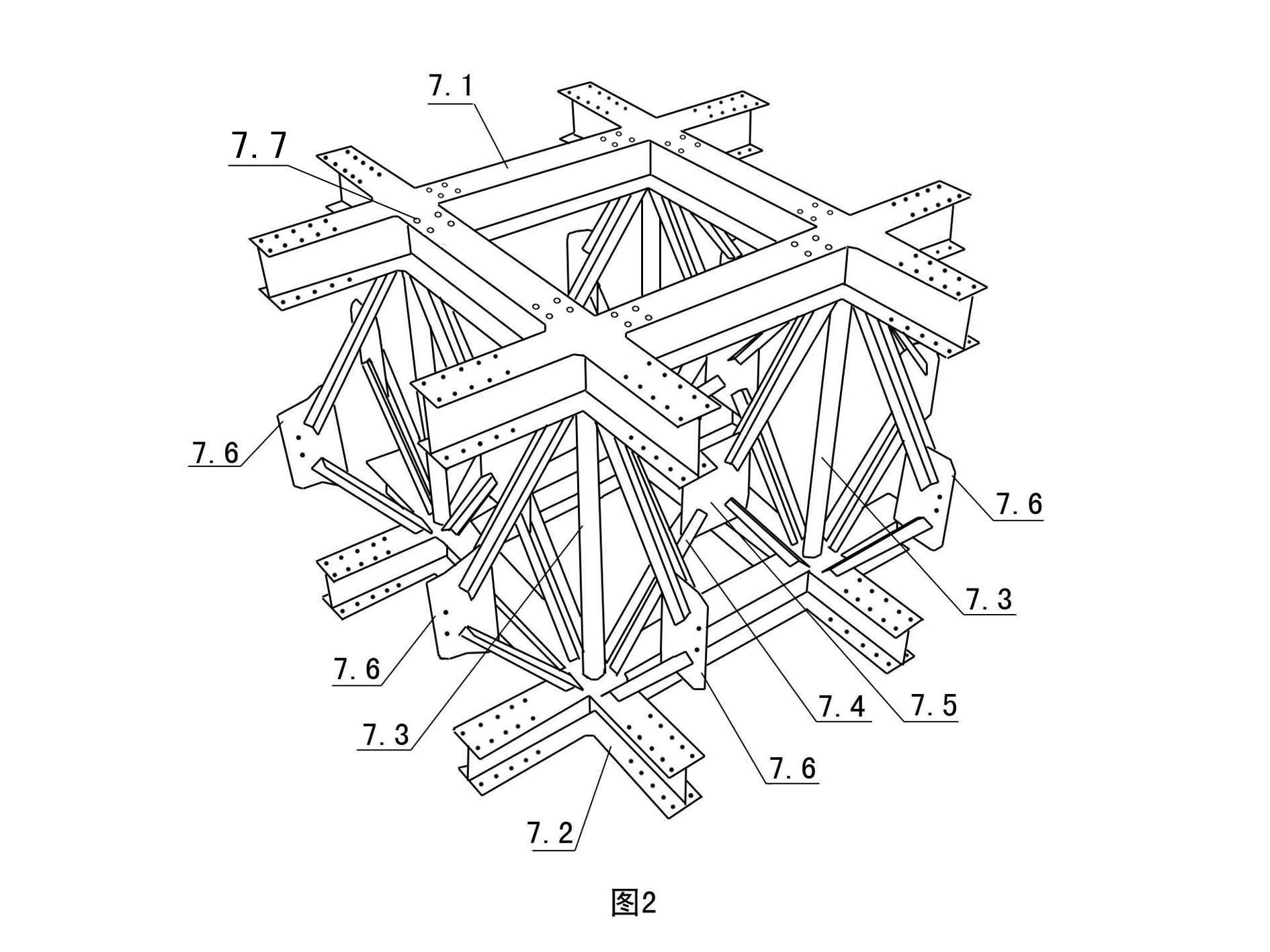

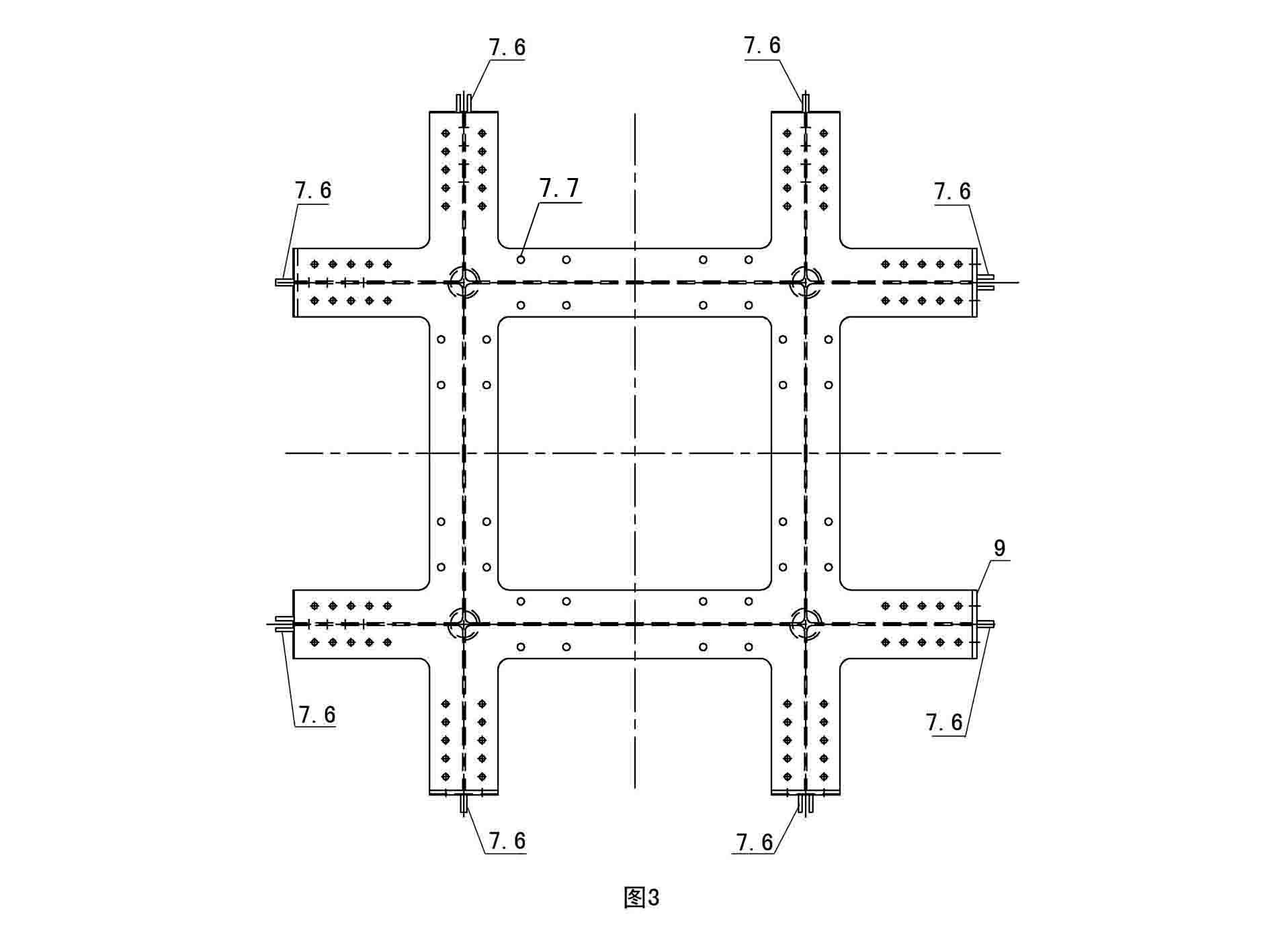

[0045] Examples see Figure 1-10As shown, this prefabricated variable steel truss platform is supported on the core tube 1 and is formed by fixed connection of steel trusses. The main truss 2 is composed of the main truss standard section 5 and the main truss shaft node standard section 7 through the gusset plate 6 with screw holes and bolts. The secondary truss 3 It is formed by detachable connection of the sub-truss standard sections 8 one by one, and the sub-stress truss 3 is detachably connected between two main stress trusses, and the struts 4 between the trusses are detachably connected in parallel Between two main truss standard sections, between two parallel secondary truss standard sections, and between parallel main truss standard sections and secondary truss standard sections.

[0046] see Figure 4-6 , the main truss standard section 5 includes a main truss upper chord 5.1 with a screw hole at the end, a main truss lower chord 5.2 with a screw hole at the end and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com