Cathode line positioning die and cathode lien positioning and adjustment construction method

A technology for positioning molds and positioning adjustments, which is applied in the direction of electrostatic separation, etc., can solve the problems of not being able to complete the measurement of the distance between the cathode lines at one time, the inability to accurately position the cathode lines, and affecting the construction period, etc., achieving good economic and social benefits, simple structure, and low investment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

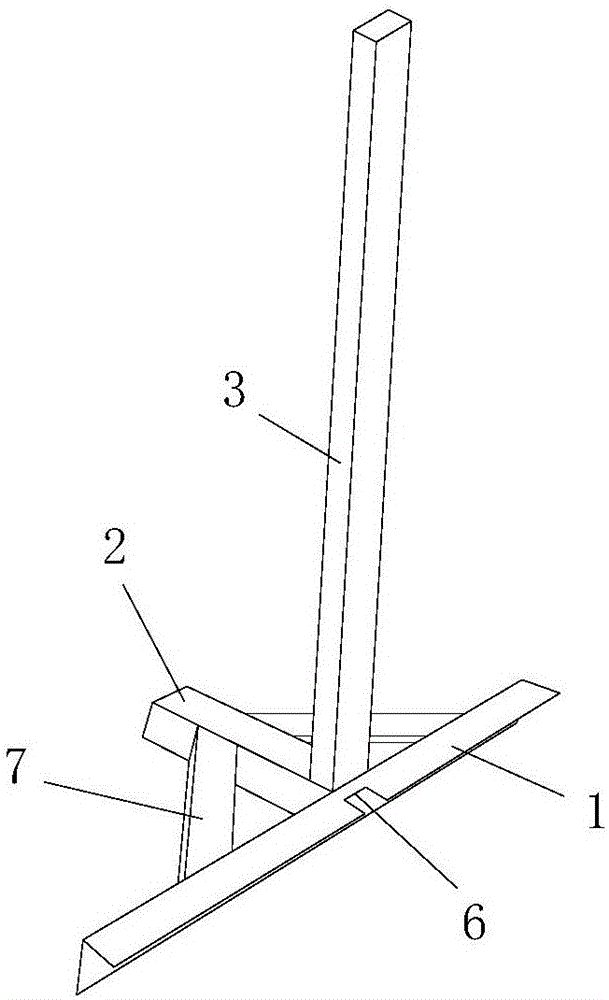

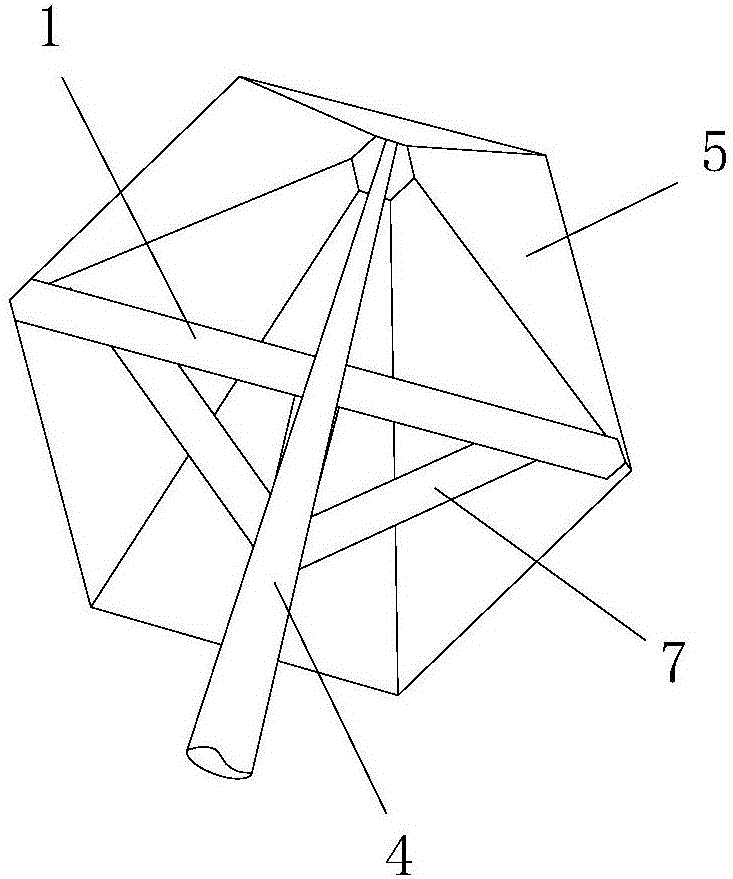

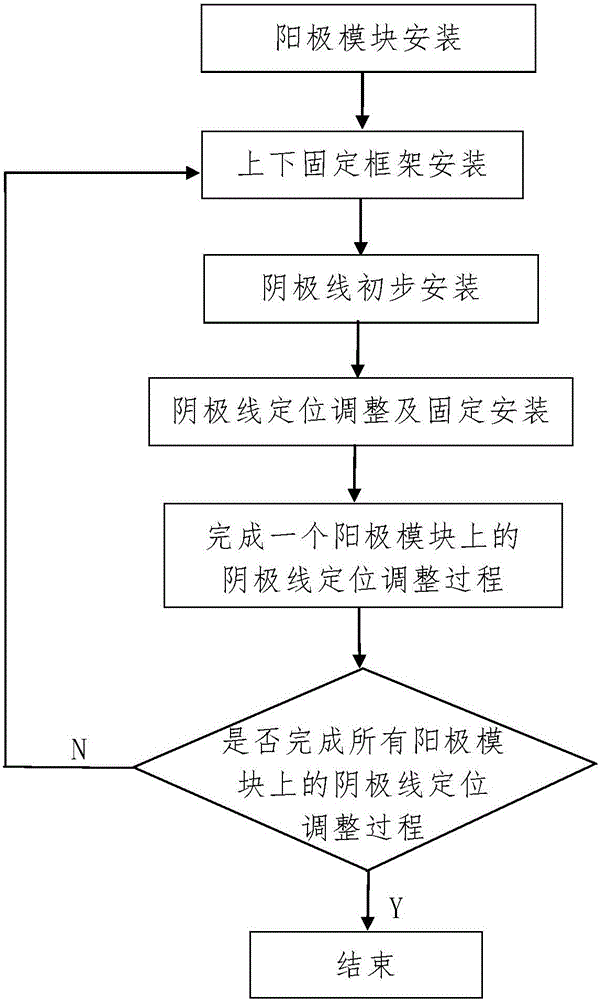

[0050] Such as figure 1 A cathodic line positioning mold is shown, comprising a rear measuring rod 1, a front measuring rod 2 arranged on the front side of the middle part of the rear measuring rod 1, and a vertical rod 3 fixed above the rear part of the front measuring rod 2, the front measuring rod 2 and the vertical rod 3 are all located in front of the rear measuring rod 1; the rear measuring rod 1 and the front measuring rod 2 are all arranged on the same horizontal plane; the rear measuring rod 1, the front measuring rod 2 and the vertical rod 3 are all straight Rod, the rear measuring rod 1 and the front measuring rod 2 are vertically arranged, and the vertical rod 3 is arranged vertically with the rear measuring rod 1 and the front measuring rod 2; the composition of the rear measuring rod 1 and the front measuring rod 2 can The horizontal positioning frame placed in the hole 5 where the adjusted cathode line 4 is installed, the hole 5 is a regular hexagonal hole, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com