Earth pressure balance shield machine main drive seal test device and method

A technology of sealing test and earth pressure balance, applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and measuring the acceleration and deceleration rate of fluid, etc., can solve problems such as wear of large ring gear and pinion bearing, and achieve extended construction. The effect of construction period, increased construction costs and safety hazards, and avoidance of faulty repairs and replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

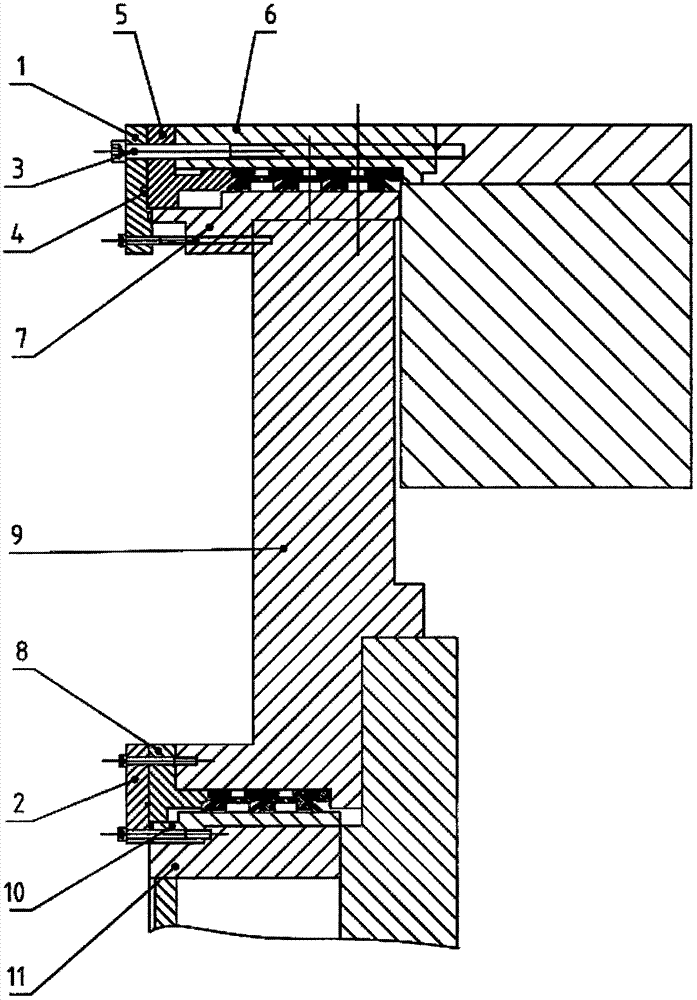

[0011] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The technical solutions of the present invention are summarized as follows: including tooling outer rings, tooling inner rings, hexagon socket bolts, and O-rings. There are two sealing systems in the gear area: the inner and outer sealing systems are responsible for sealing the oil inside the gear box and sealing the dregs in the excavation bin to prevent dregs and dust from entering the gear box. During the test, the outer ring of the tooling is installed on the outer sealing pressure ring and the outer sealing track, and the outer ring of the tooling is fixed with the outer sealing pressure ring and the ring parts with hexagon socket bolts, and the outer ring of the tooling is fixed on the outer sealing track. Use an O-ring to seal. Thus, the gap between the outer sealing pressing ring and the outer sealing raceway is sealed, thereby f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com