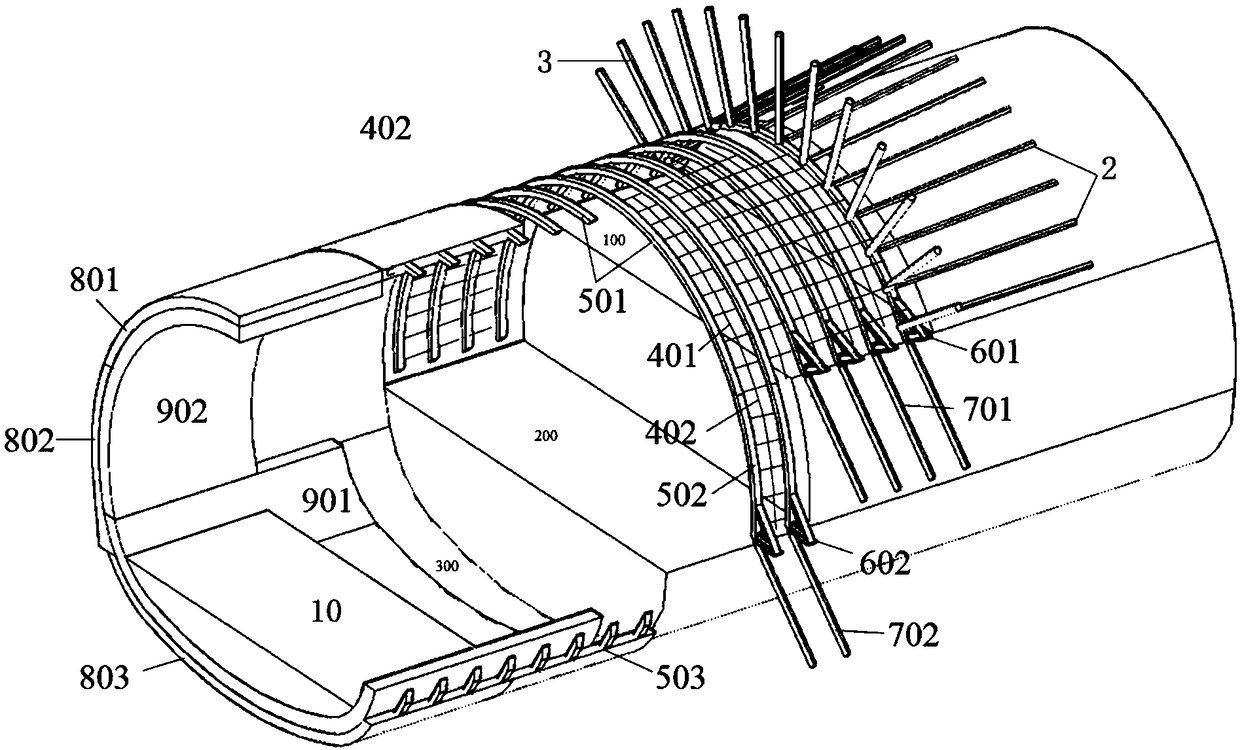

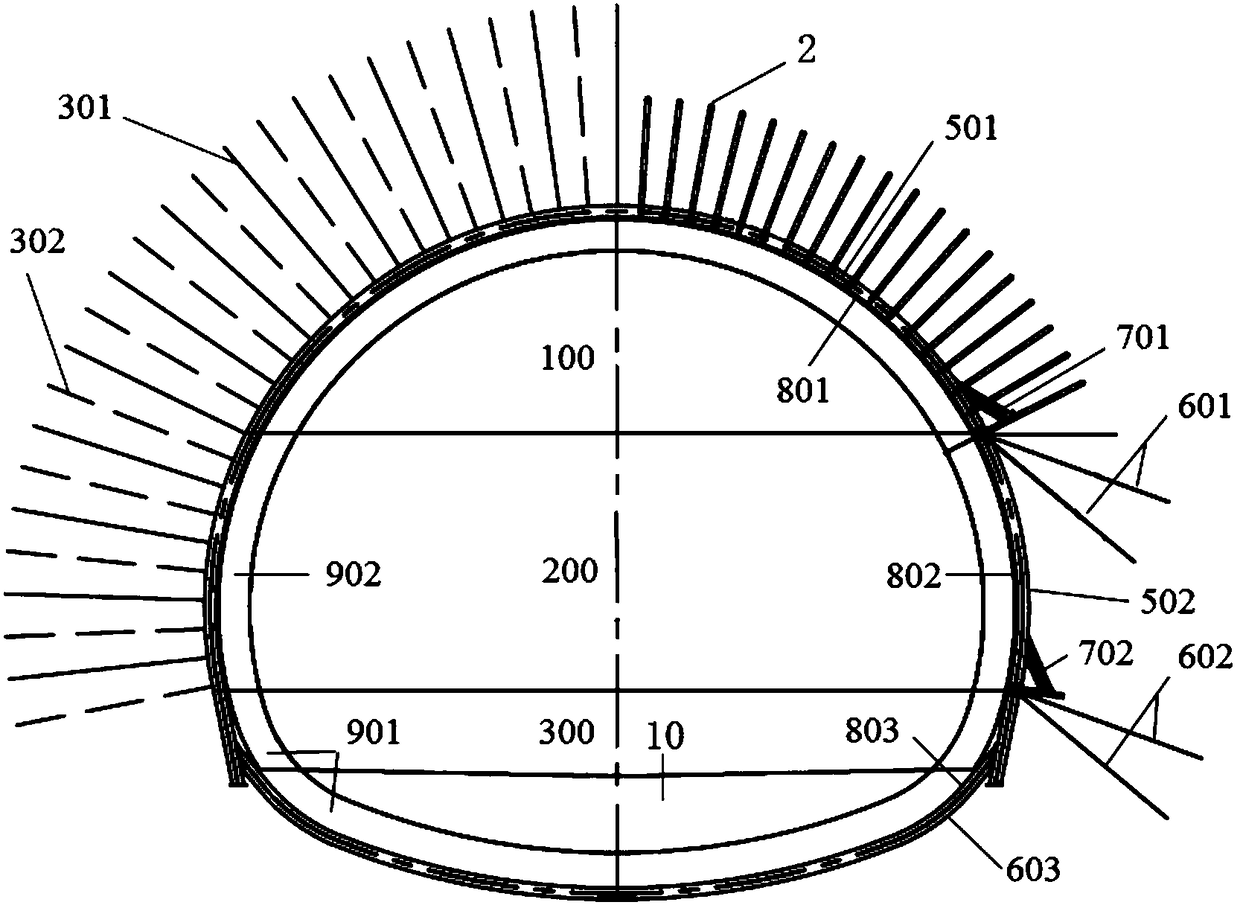

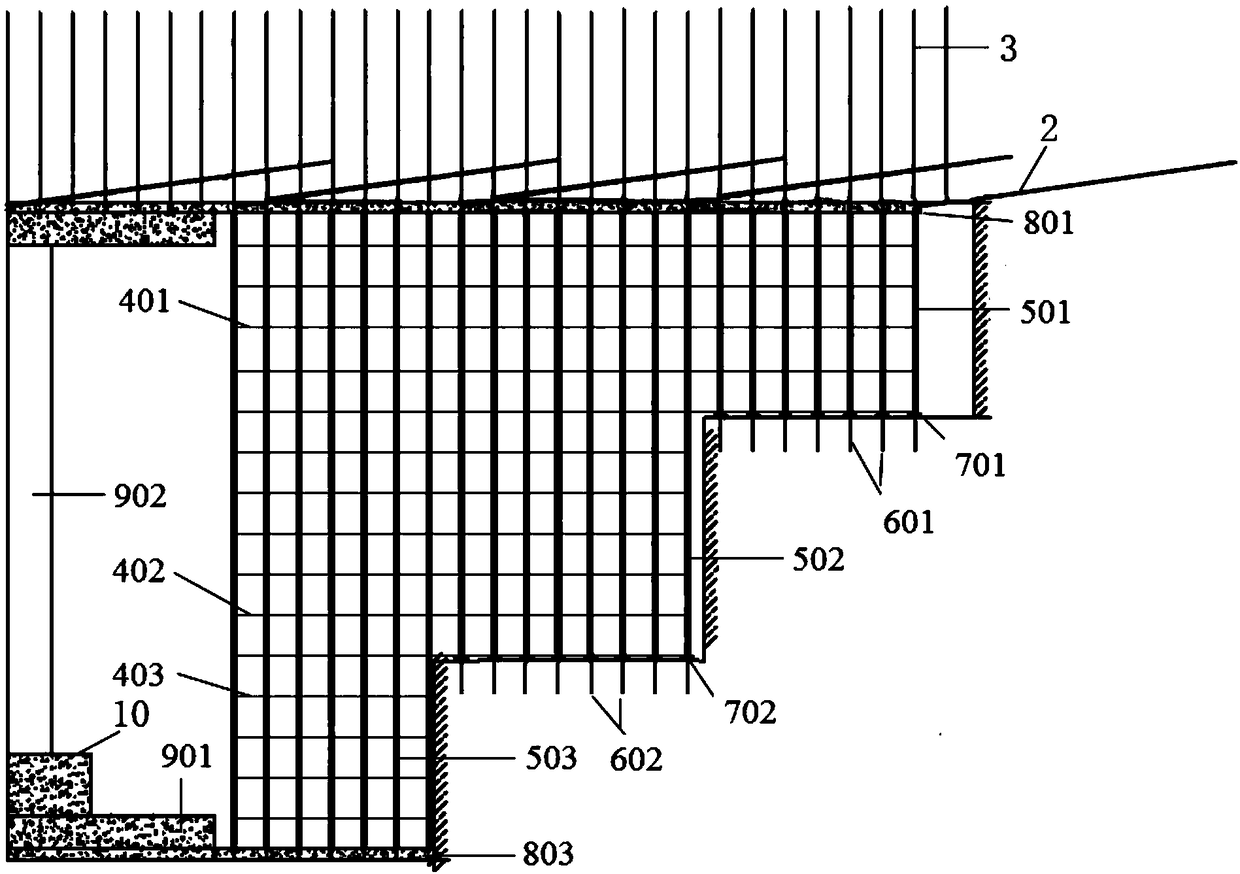

Large-arch-foot three-step tunnel rapid construction method and structure based on pipe shed pre-supports

A construction method and technology of large arch foot, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effects of prolonging the construction period, safe and fast construction, and high social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The method of this embodiment includes the following steps: the cross-section of the tunnel is divided into three steps and excavated sequentially at staggered intervals. Before the excavation of the tunnel, firstly, advance support is made along the arch of the tunnel with short tube sheds; 1. The lower steps are regarded as a cycle, and the corresponding initial support is applied immediately after the excavation of each step in a cycle is completed, and the footing of the initial support is set as a large arch foot. Since the excavation is divided into steps, there are footings after the excavation of the upper step and the lower step are completed, and the steel arch is erected. When the distance between the lower step excavated in the secondary cycle and the secondary lining of the previous cycle is 1 times the hole diameter, the inverted arch, side wall, filling layer and secondary lining shall be applied.

[0048] The advance support of the short pipe shed adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com