Patents

Literature

133results about How to "Shorten the construction schedule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reflective heat-insulation type really stone paint and preparation method thereof

ActiveCN104312341AIncrease reflectionImproved reflective insulationAntifouling/underwater paintsPaints with biocidesCellulosePolymer science

The invention relates to a reflective heat-insulation type really stone paint and a preparation method thereof, wherein the reflective heat-insulation type really stone paint is prepared from the following components in parts by weight: 100-110 parts of water, 2-3 parts of cellulose, 1-2 parts of a neutralizing agent, 0.5-2 parts of a defoaming agent, 10-20 parts of an anti-freezing agent, 1-2 parts of a bactericide, 100-140 parts of a silicone acrylic emulsion, 10-15 parts of a film-forming auxiliary agent, 2-5 parts of a thickening agent, and 700-750 parts of a reflective type color sand. The prepared reflective heat-insulation type really stone paint not only has the characteristics of rich colors, stable performance, safety, no toxicity and the like, but also has the efficacies of reflective heat insulation, environmental protection, energy saving and the like.

Owner:上海复培新材料科技有限公司

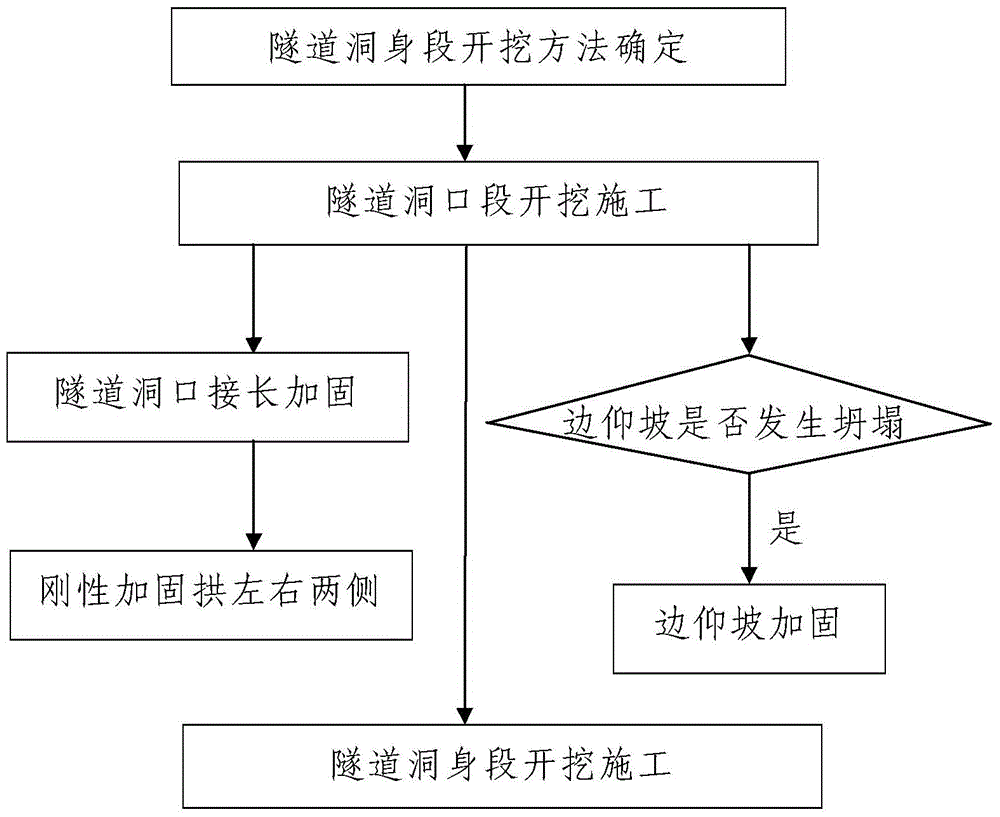

Process for excavating and constructing soft rock tunnels

ActiveCN104453921AThe process steps are simpleReasonable designTunnel liningStructural engineeringRock tunnel

The invention discloses a process for excavating and constructing soft rock tunnels. Each constructed soft rock tunnel comprises two tunnel portal sections and a tunnel trunk section. Each tunnel trunk section is arranged between the two corresponding tunnel portal sections in a connected manner, surrounding rock level of two tunnel portals of each constructed soft rock tunnel is V level, surrounding rock level of each tunnel trunk section is IV level, and entrances and exits of the constructed soft rock tunnels simultaneously start to be constructed and are constructed in opposite directions. The process includes constructing procedures of firstly, determining methods for excavating the tunnel trunk sections, to be more specific, simulating excavating and constructing procedures by the aid of tunnel excavating and constructing simulation software, and determining the methods for excavating and constructing the tunnel trunk sections according to simulation results; secondly, excavating and constructing the tunnels, to be more specific, dividing each soft rock tunnel to be constructed into a plurality of sections from the rear of the corresponding tunnel portal to the front and starting to excavate and construct the multiple sections. The tunnel trunk sections are excavated in the excavating and constructing procedures by the aid of full-section techniques. The process has the advantages of simple steps, reasonable design, convenience in construction, good service effects, safe constructing procedures and capabilities of easily and conveniently completing the soft rock tunnel excavating and constructing procedures and guaranteeing the construction periods.

Owner:CHINA RAILWAY 20 BUREAU GRP

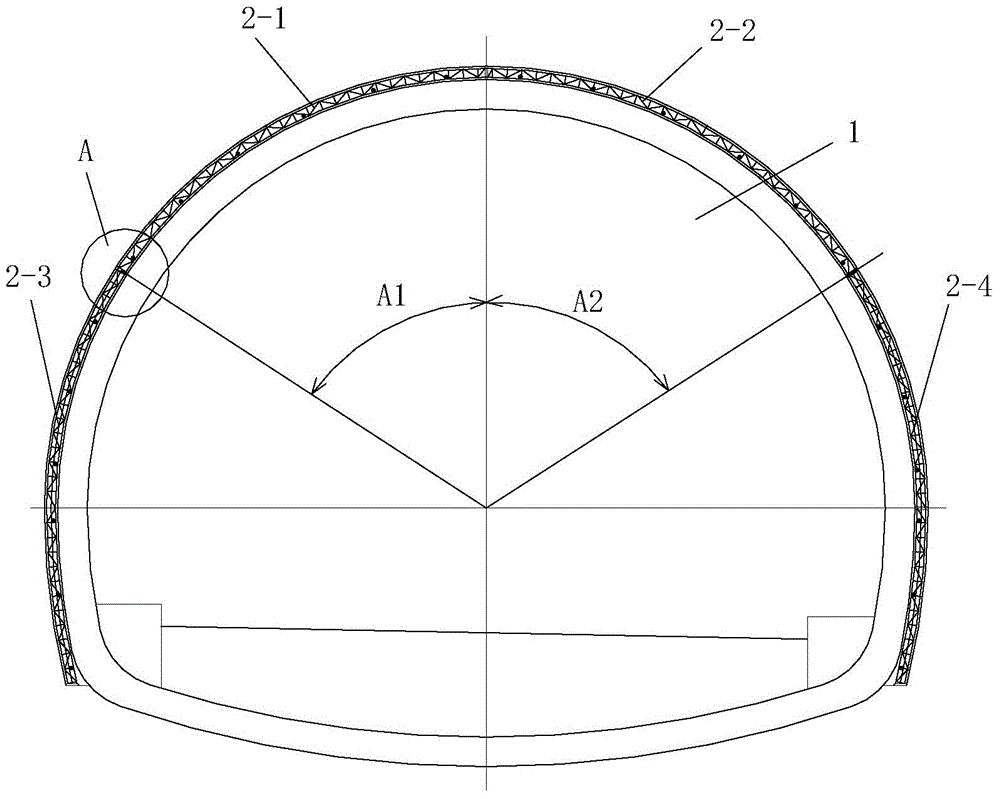

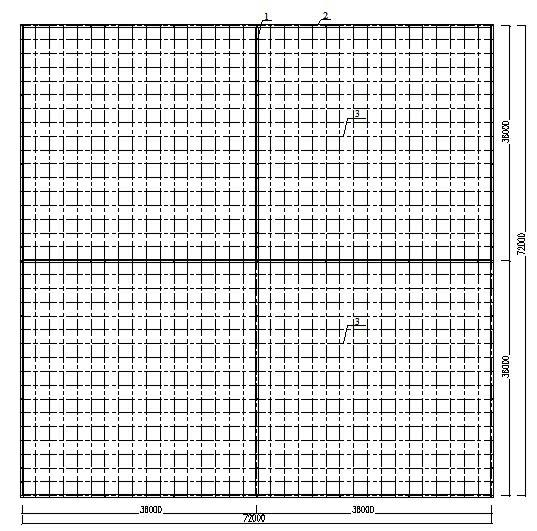

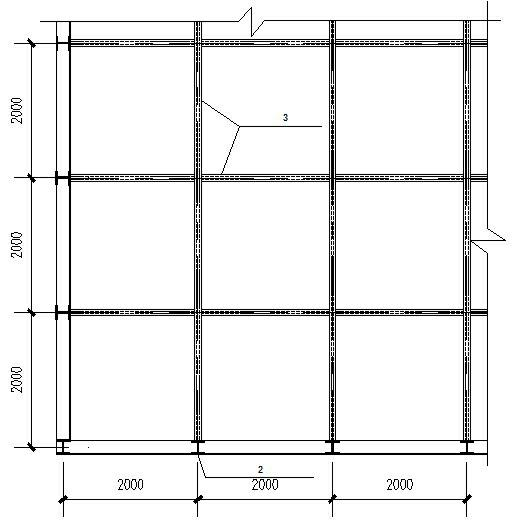

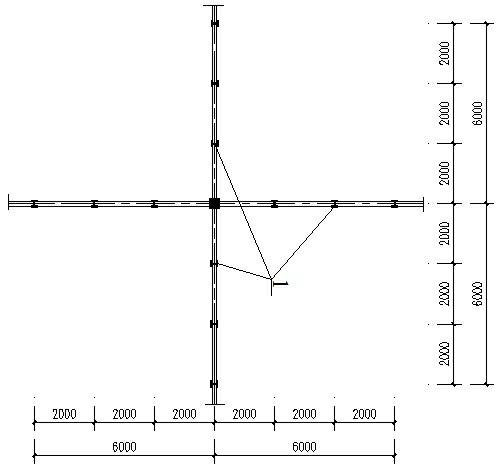

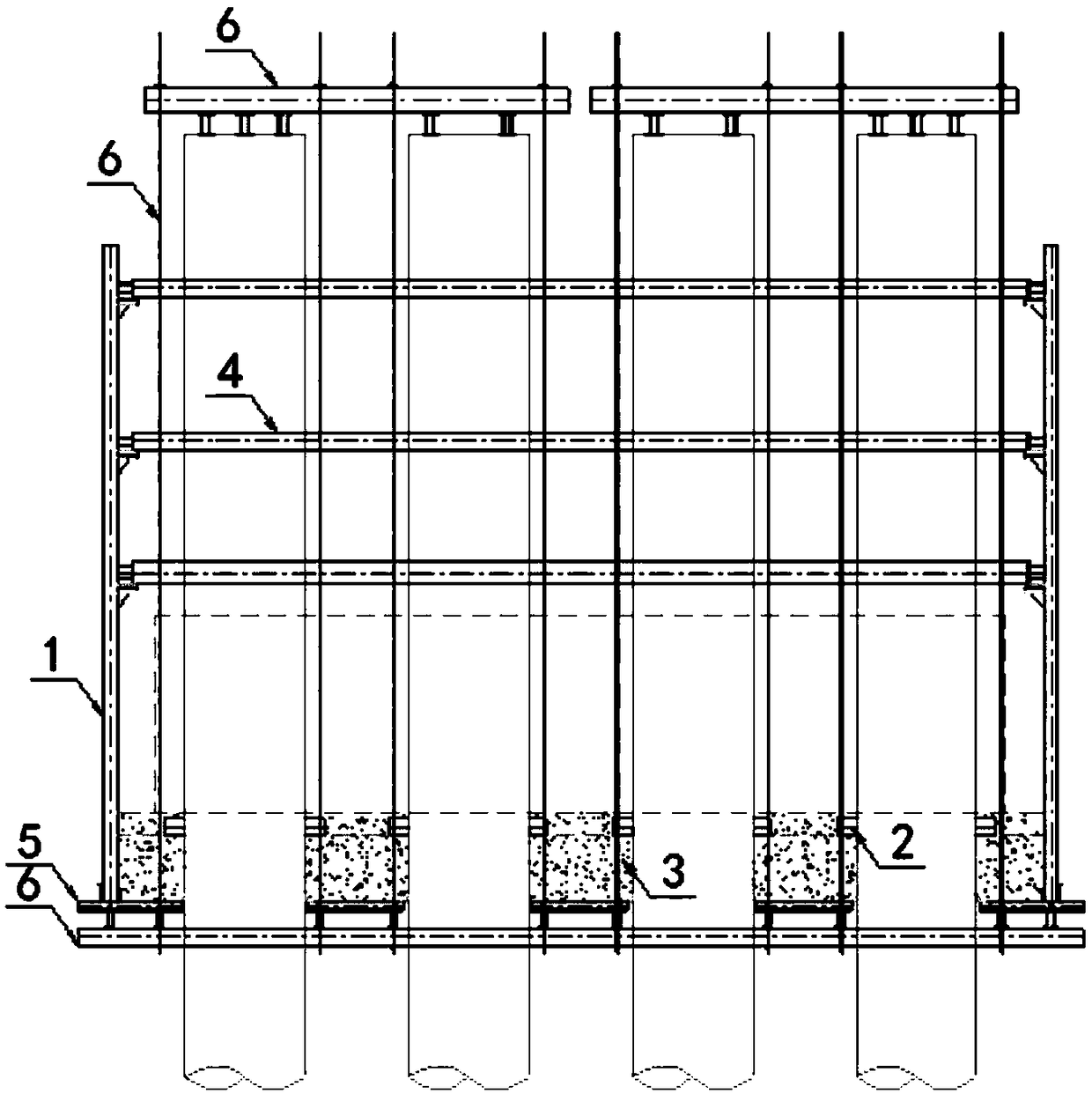

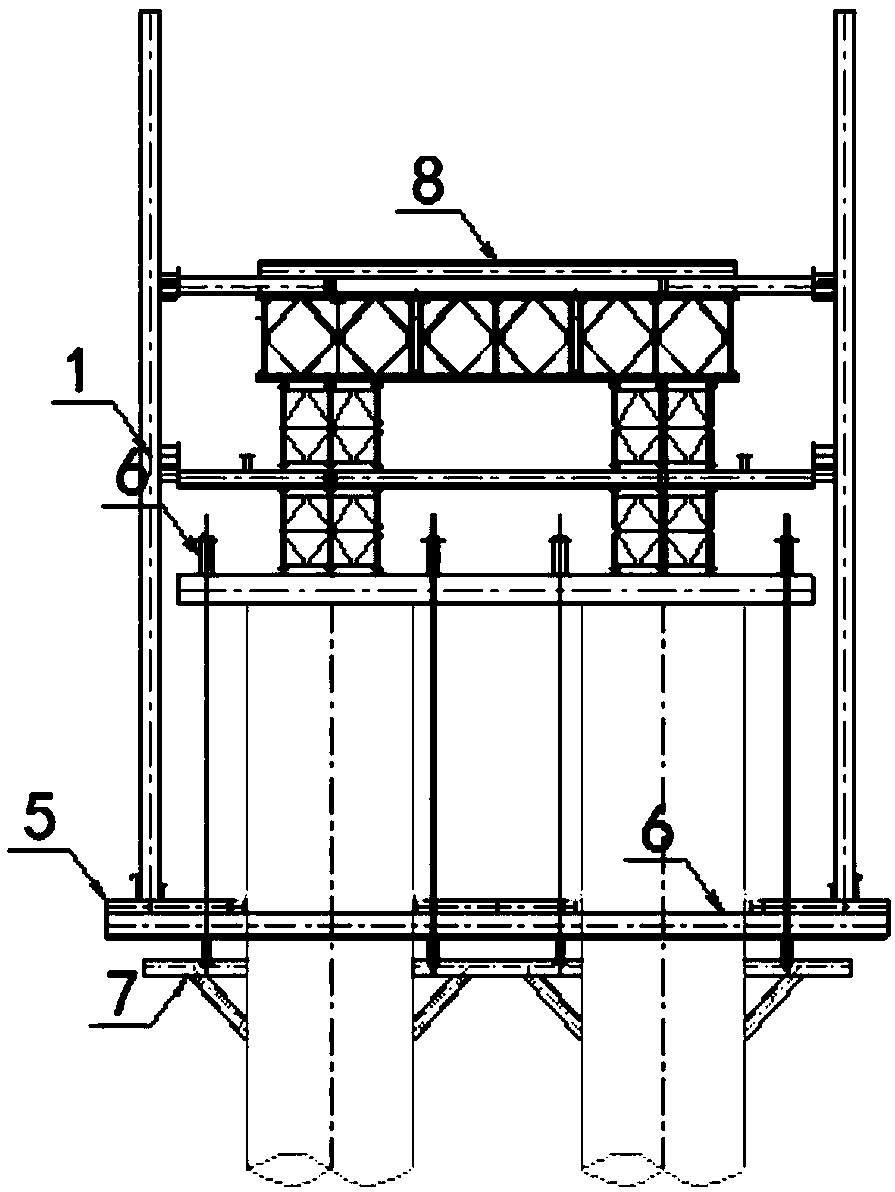

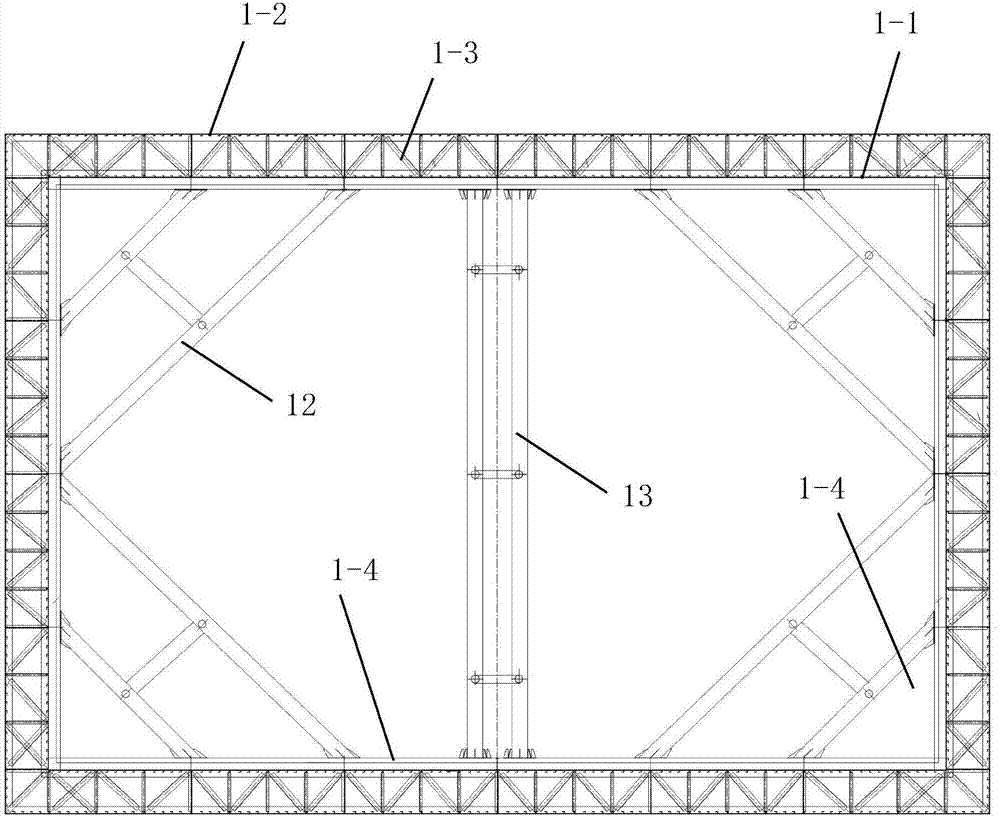

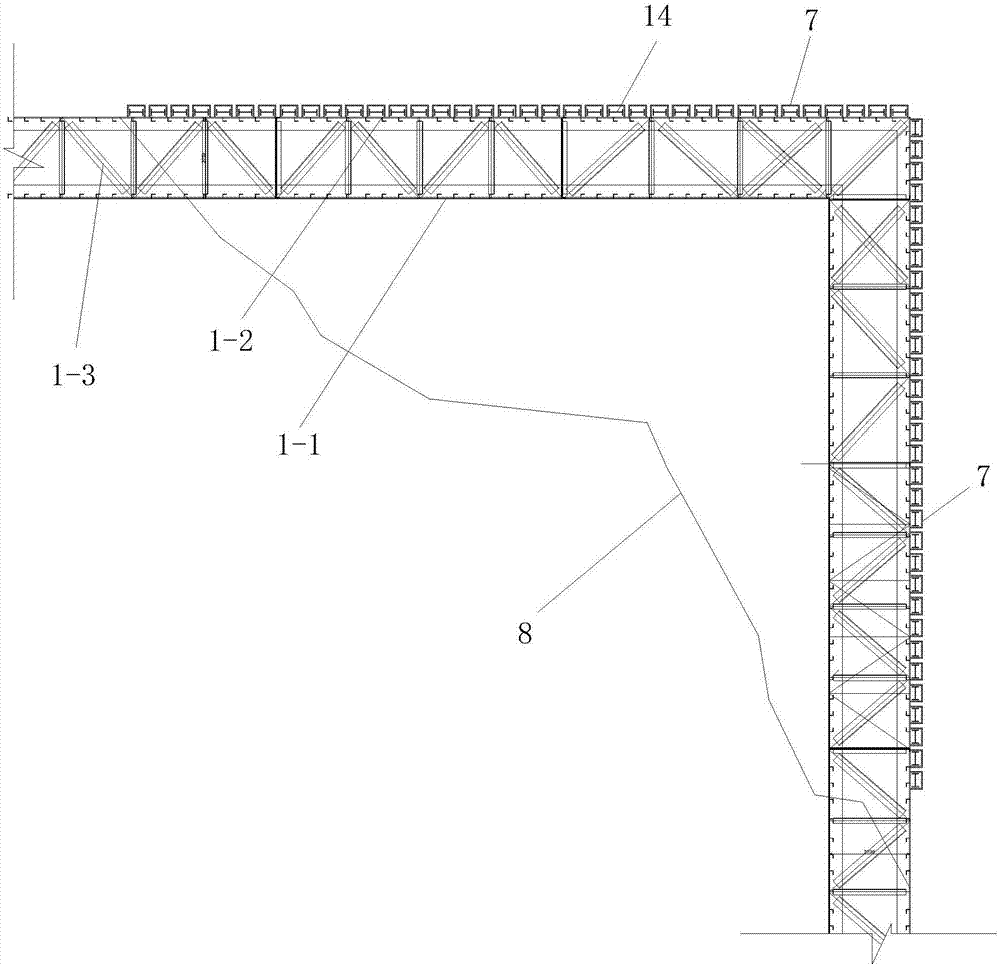

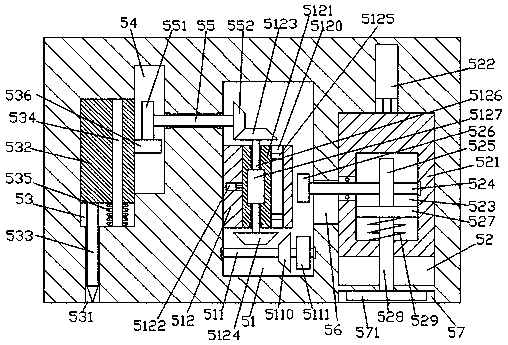

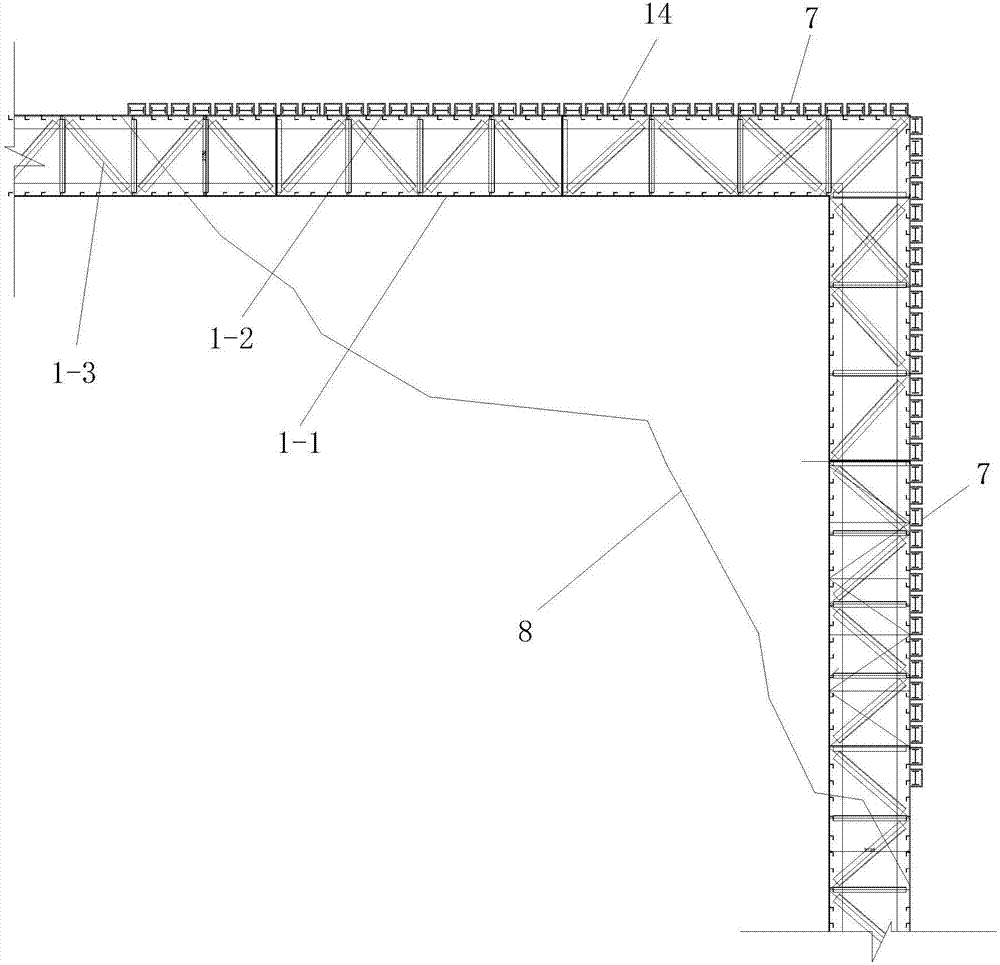

Assembled monolithic multilayer long-span bidirectional multi-span building with space steel grid box-type structures

InactiveCN102635163AEliminate fire hazardsShorten the construction scheduleWallsFloorsLateral stiffnessLong span

The invention discloses an assembled monolithic multilayer long-span bidirectional multi-span building with space steel grid box-type structures, which is characterized in that each layer of ground steel structural framework is formed into a single space steel grid box-type structure by a central cross-shaped single-layer steel grid wall frame, a surrounding single-layer steel grid-type outer wall frame and a top steel open-web sandwich plate floor frame, and the steel grid wall frames are respectively connected by small-sized assembly units prefabricated in a factory at the construction site by using high-strength bolts; all layers of single space steel grid box-type structures are upwards superposed layer by layer to form a superposed single barrel box-type structure; and four multilayer superposed single barrel box-type structures are connected with each other at the floor to form an assembled monolithic multilayer long-span bidirectional multi-span barrel bundle with the space steel grid box-type structures. According to the building disclosed by the invention, welding operations are not needed at the construction site, so that the fire hidden danger is eliminated. Compared with traditional steel framework structures, the construction cost of the steel structure is reduced by 15-20 percent, the construction progress is shortened by at least 1 / 3, and the resist lateral stiffness is increased by at least twice.

Owner:唐山建华检测股份有限公司 +6

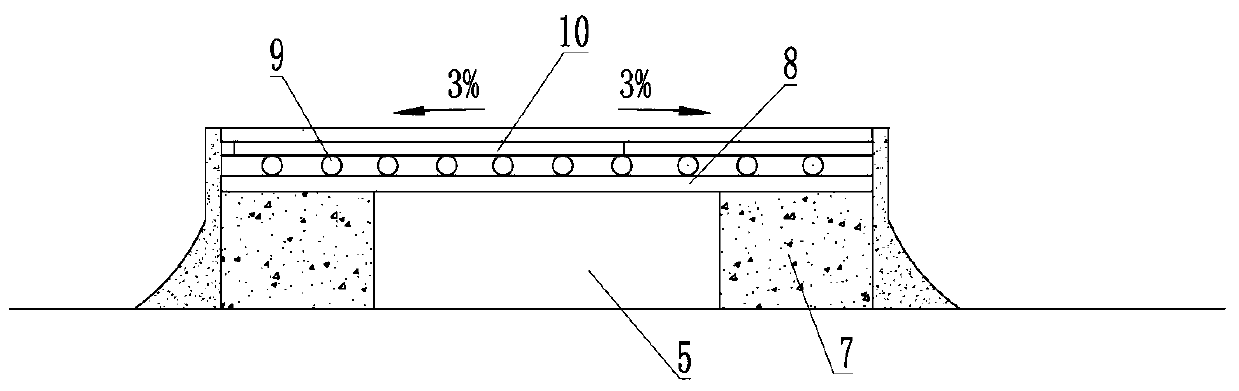

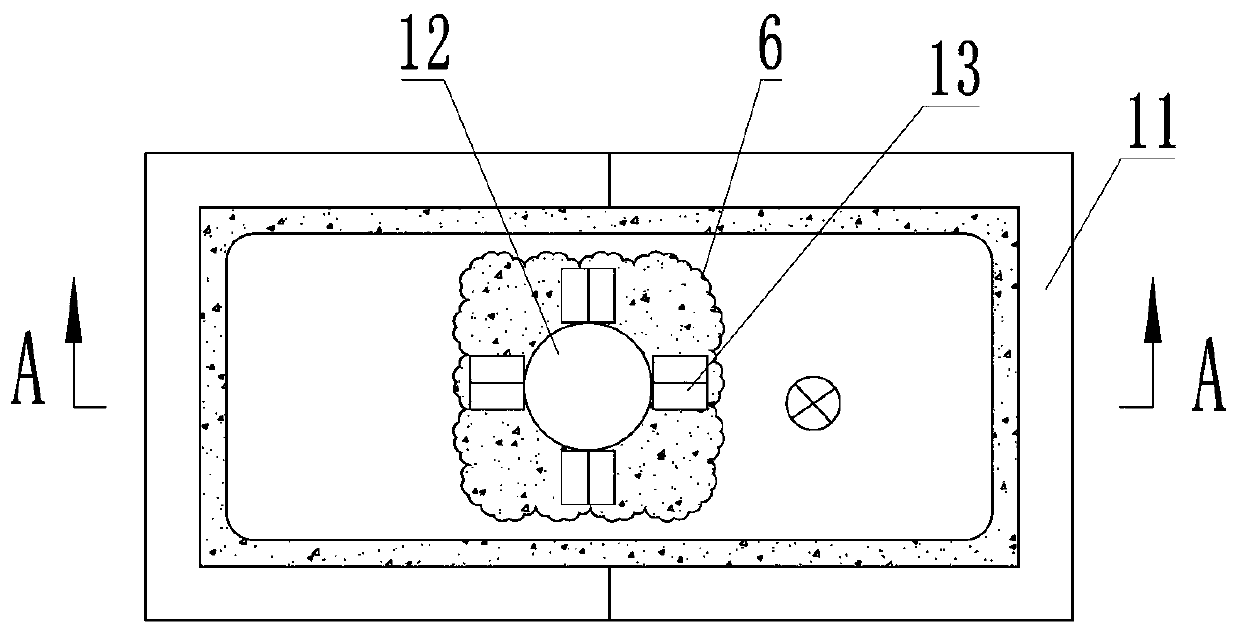

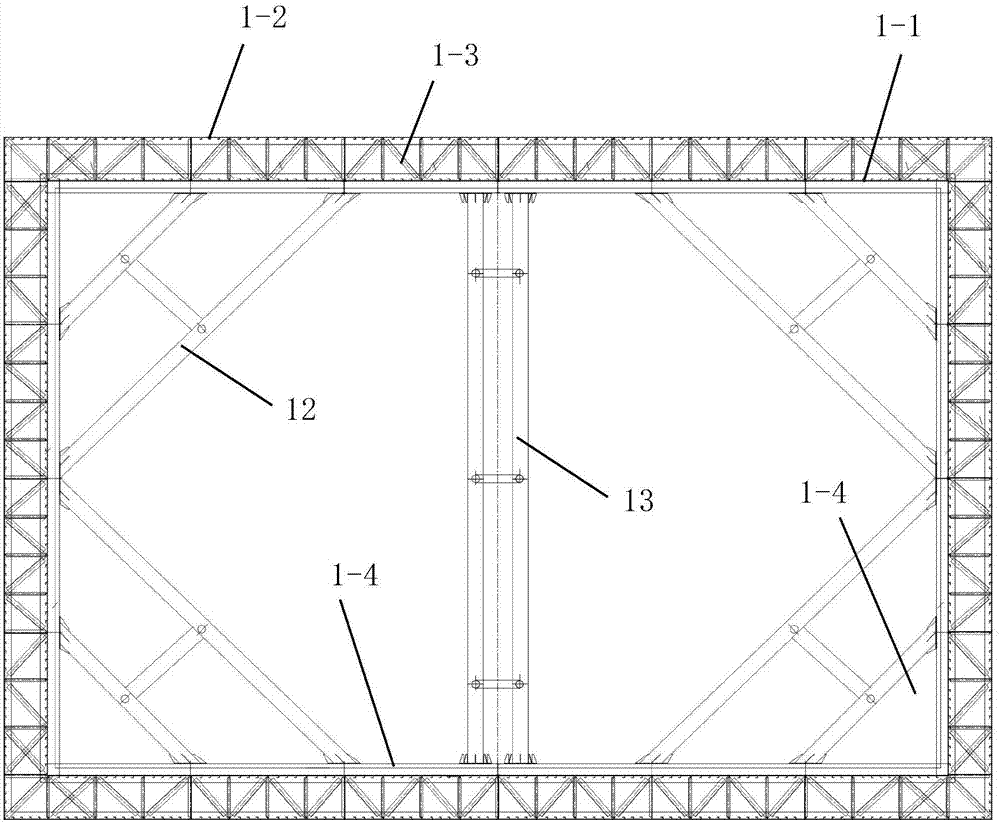

Construction method of deep water high pile bearing platform steel hanging box cofferdam

The invention discloses a construction method of a deep water high pile bearing platform steel hanging box cofferdam. The construction method comprises the following steps: 1) design of a steel hanging box cofferdam: Larson steel plate piles are adopted as wall plates of the steel hanging box cofferdam; 2) assembly and placement of the steel hanging box cofferdam: the steel hanging box cofferdam adopts high assembly and overall placement technologies; 3) bottom cover concrete construction: a bottom cover construction process is performed twice; after primary bottom covering, water in the steelhanging box cofferdam is extracted to a bottom cover surface; and then, the secondary bottom cover concrete casting is performed; and 4) disassembly of the steel hanging box cofferdam: after a bearing platform and part of underwater piers are constructed, the water is injected in the steel hanging box cofferdam to reach balanced inner and outer water levels; and the steel hanging box cofferdam isdisassembled. In the construction method, through the Larson steel plate piles as the wall plates of the steel hanging box cofferdam and twice bottom cover construction process, the construction progress can be accelerated, the economical cost is saved, and the engineering quality is guaranteed.

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

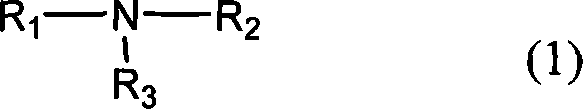

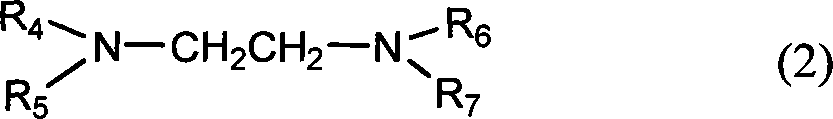

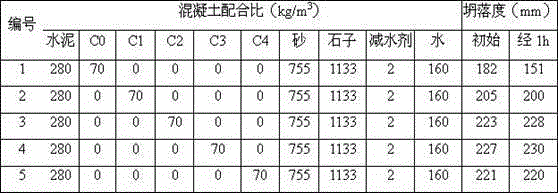

Composite liquid for increasing early strength of concrete mixed with polycarboxylate additive

The invention relates to a compound liquid for improving the early strength of the concrete mixed with polycarboxylate additive and a preparation method thereof. The compound liquid is prepared with the following components in weight proportion: 25-40percent of water soluble sulphate, 3-6 percent of organic alkoxyl amine and the rest is water. The preparation method is: 1) water is put into a reaction vessel and heated to 40DEG C- 60DEG C, and organic alkoxyl amine is added and well stirred; 2) water soluble sulphate is added and stirred to form a homogenous solution. The preparing process of the invention is simple and easy to apply; the invention does not corrode steel, and does not affect the condensation of concrete and reduce the later strength of concrete. The addition of the compound liquid is 0.5-1.5 percent of cementing material content and can improve the compressive strength of the concrete by 30-60 percent in 16h, by 25-40percent in 1d and by 15-25 percent in 3d, and the compressive strength of the concrete does not fall in 28d, which greatly shortens maintenance period, expedites construction progress, advances turnover rate of template, shortens construction period and lowers cost.

Owner:JIANGSU SUBOTE MATERIAL

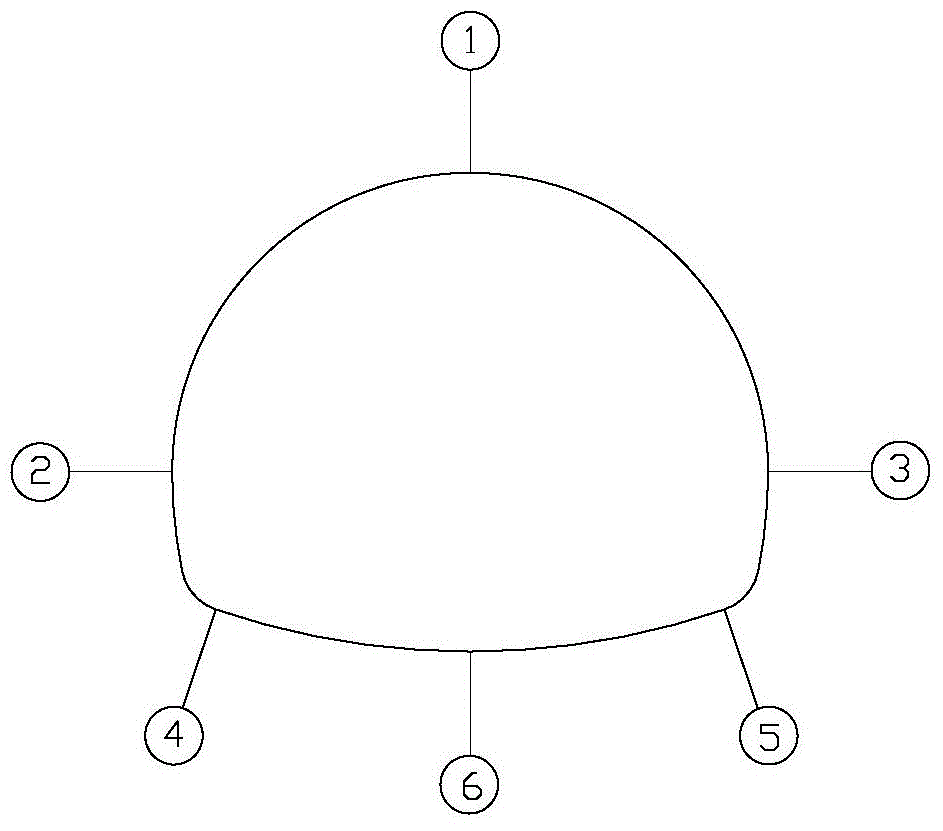

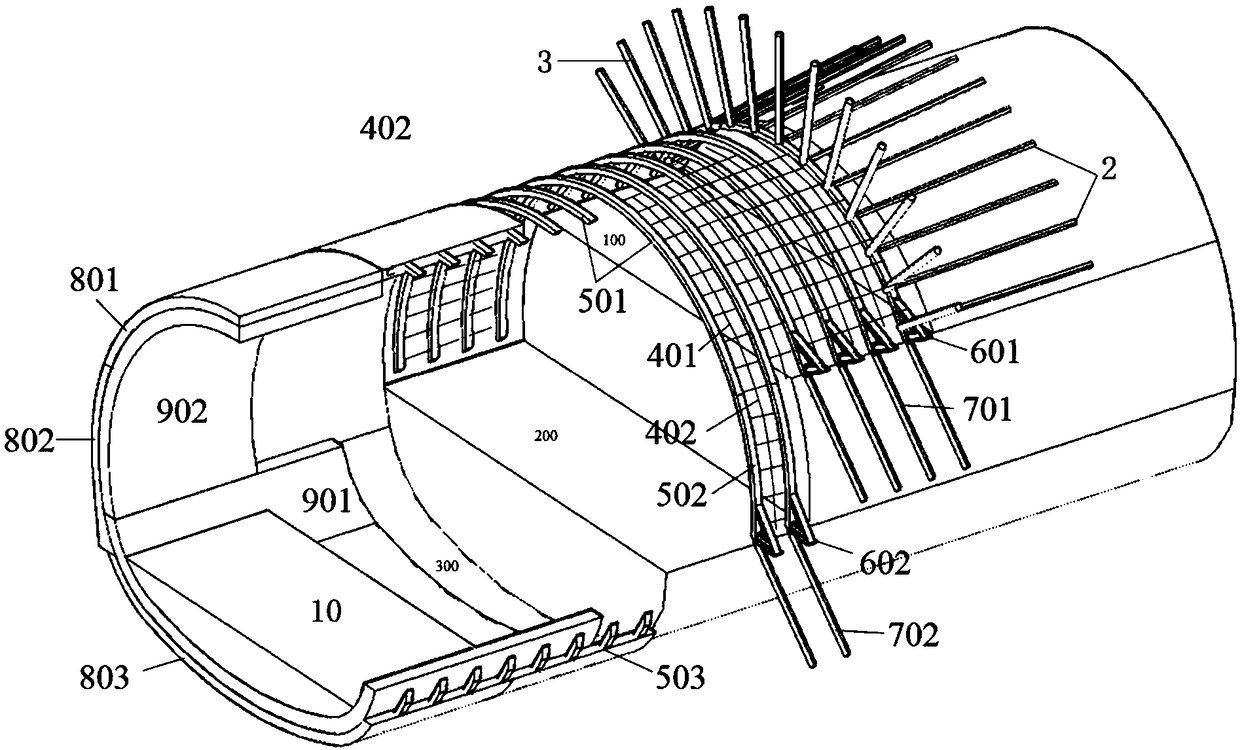

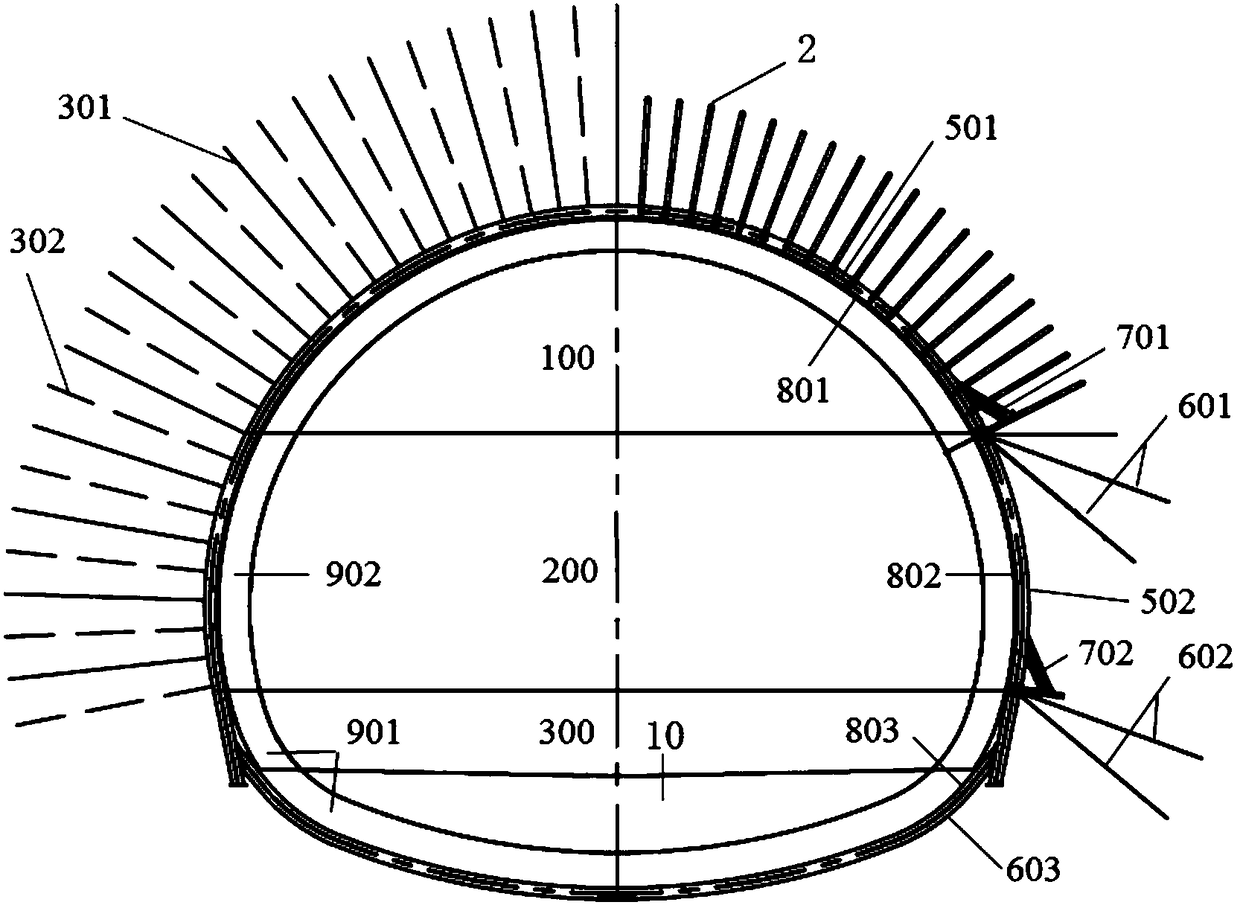

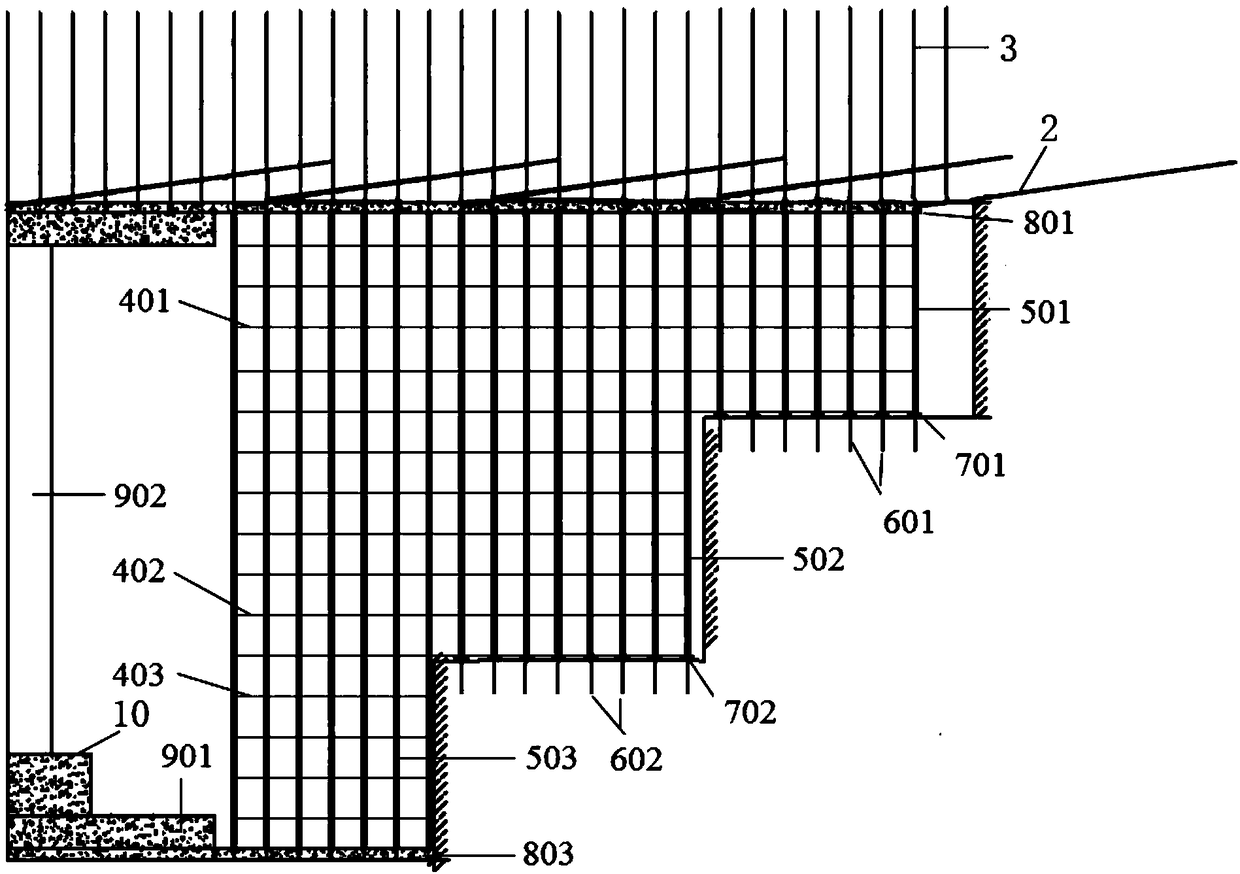

Large-arch-foot three-step tunnel rapid construction method and structure based on pipe shed pre-supports

PendingCN108278115AConstruction safetyLarge amount of workUnderground chambersTunnel liningDeformation controlFoot type

The invention discloses a large-arch-foot three-step tunnel rapid construction method and structure based on pipe shed pre-supports. Short pipe sheds are constructed through a hole interior non-work-room pipe shed construction technology to reinforce and support surrounding rock in front of a tunnel face in advance; large arch feet are arranged at bases all stages of steps; and under dual controlmeasures, the tunnel cross section is sequentially excavated by three steps, according to the specific processes, firstly, short pipe shed advance supports are constructed within a certain range alongan arch part of a tunnel, the upper, middle and lower steps are sequentially excavated with alternate distances, after excavation of each step, the primary supports are constructed instantly, footings of the primary supports are designed to of a large-arch-foot type, and when the lower step is away from a secondary lining of a former cycle by the tunnel diameter, an inverted arch, side walls, a filled layer and a secondary lining are constructed. The problem that under the condition of the shallow-buried weak surrounding rock, deformation control over the tunnel is difficult is solved, and meanwhile the disadvantages that under the same condition, a traditional construction method is many in subsection, numerous in working procedure, slow in construction, many in temporary support and thelike are further overcome.

Owner:CENT SOUTH UNIV

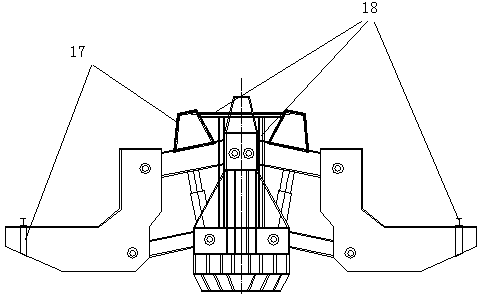

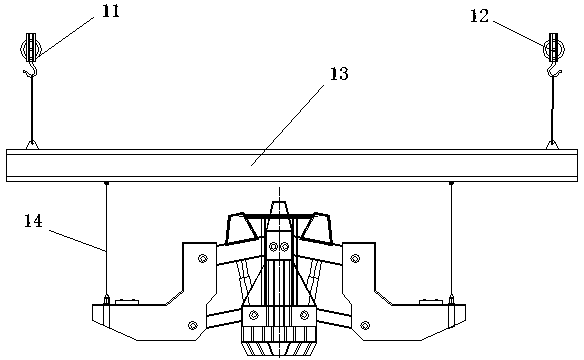

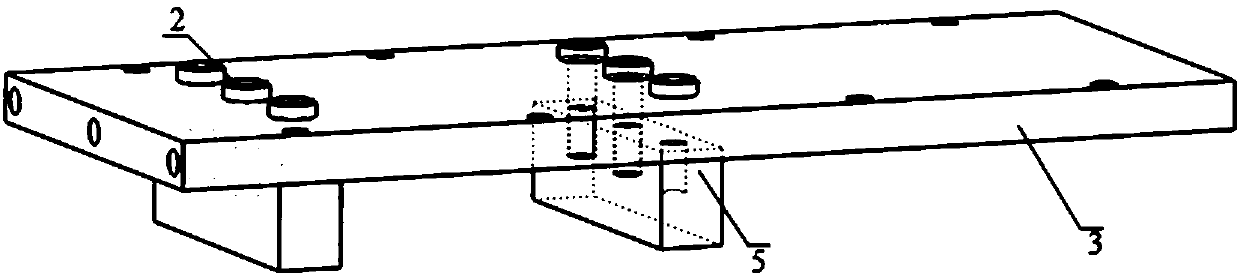

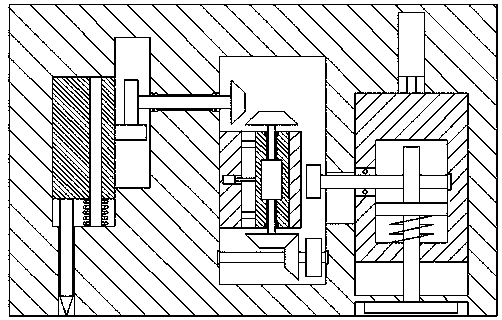

Modularization installing construction method for slab continuous casting machine bale rotary table

ActiveCN103406528AImprove construction qualityGuaranteed assembly accuracyMelt-holding vesselsFixed positionHydraulic cylinder

A modularization installing construction method for a slab continuous casting machine bale rotary table comprises the steps of assembling the bale rotary table; reinforcing a bale rotary table pin shaft part; guaranteeing that the pin shaft part and a hydraulic cylinder are at fixed positions, and enabling the whole rotary table to form a rigid whole; and lifting the bale rotary table to be in place. According to the modularization installing construction method for the slab continuous casting machine bale rotary table, assembly precision is guaranteed, work at heights is reduced, safety risk in the construction process is reduced, and safe and civilized construction of employees is effectively achieved; integral hoisting is adopted, crane operation is reduced, and construction cost is reduced; construction can be performed synchronously parallelly with other processes of a continuous casting machine set, the construction period is shortened, construction progress is guaranteed, and the construction cost is reduced.

Owner:CHINA 22MCC GROUP CORP

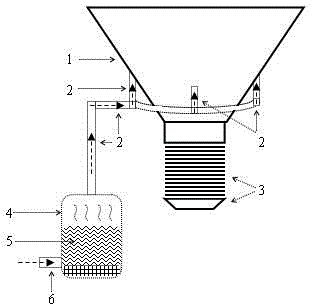

Fly ash surface modifying material and using method thereof

InactiveCN104961369AImprove liquidityDoes not affect setting timeSolid waste managementWater reducerSURFACTANT BLEND

The invention provides a fly ash surface modifying material and a using method thereof. The fly ash surface modifying material is prepared with a surfactant commonly used as a concrete admixture and an air entraining agent. The fly ash surface modifying material is prepared by dissolving the surfactant and the air entraining agent in water to prepare a modifying material water solution, forming a modifying material atomized agent through an atomizer, utilizing compressed air to feed the modifying material atomized agent into a fly ash bin from the bottom of the fly ash bin to be fully mixed with fly ash so as to enable carbon particles in the fly ash to pre-adsorb the surface modifying material. Microporous surfaces of the carbon particles are blocked, so that adsorption effect, on a water reducing agent, of the fly ash surface modifying material when the fly ash is used for concrete is reduced, and fluidity of the concrete is improved; the modifying material adhered on the surfaces of other spherical particles of the fly ash can play a role in lubricating, so that fluidity of fly ash concrete is further improved; the surface modifying material is extremely low in consumption, and a gas arch breaking device originally in the fly ash bin can be utilized to complete surface modification of the fly ash, so that the fly ash surface modifying material and the using method are low in cost.

Owner:TONGJI UNIV

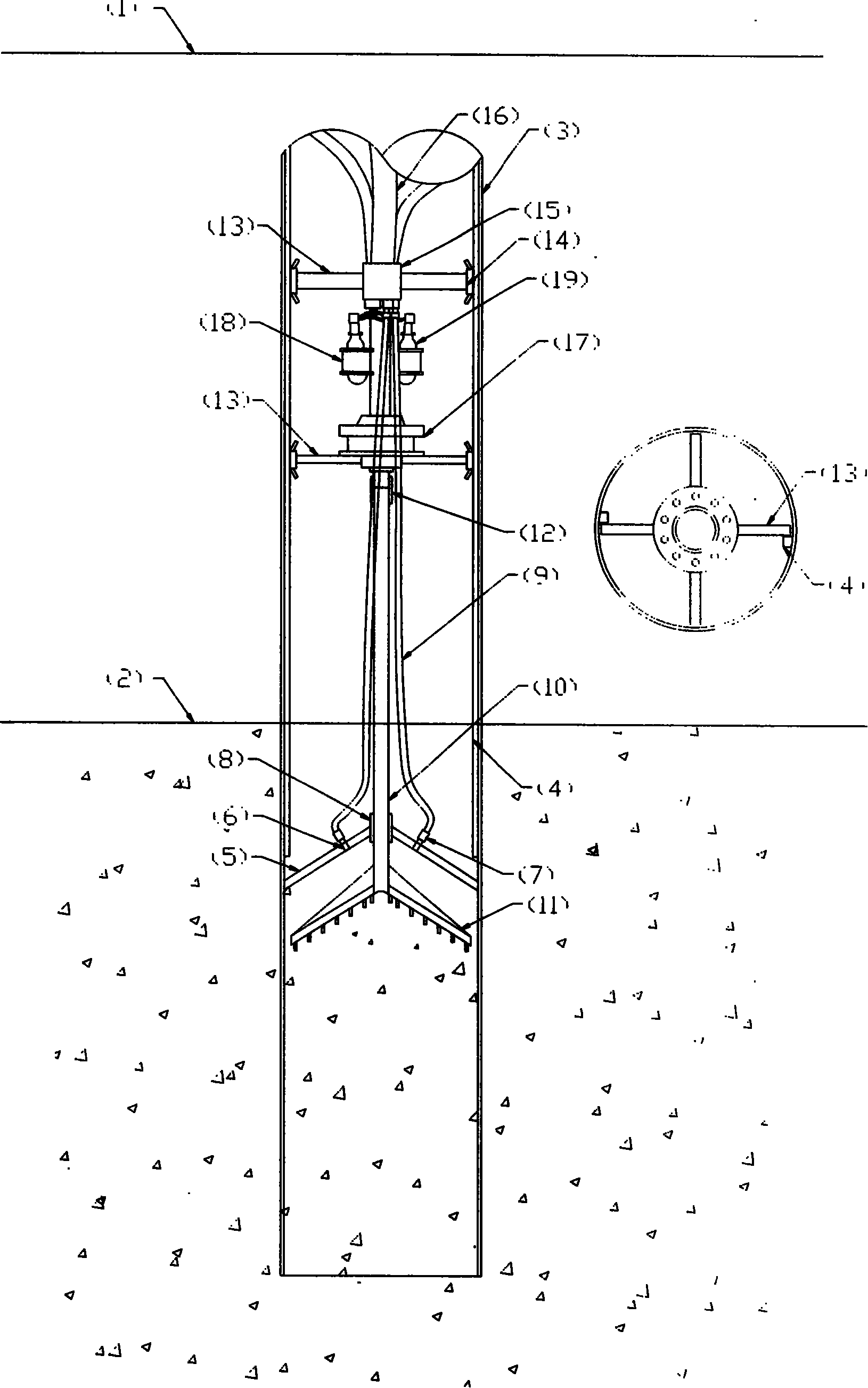

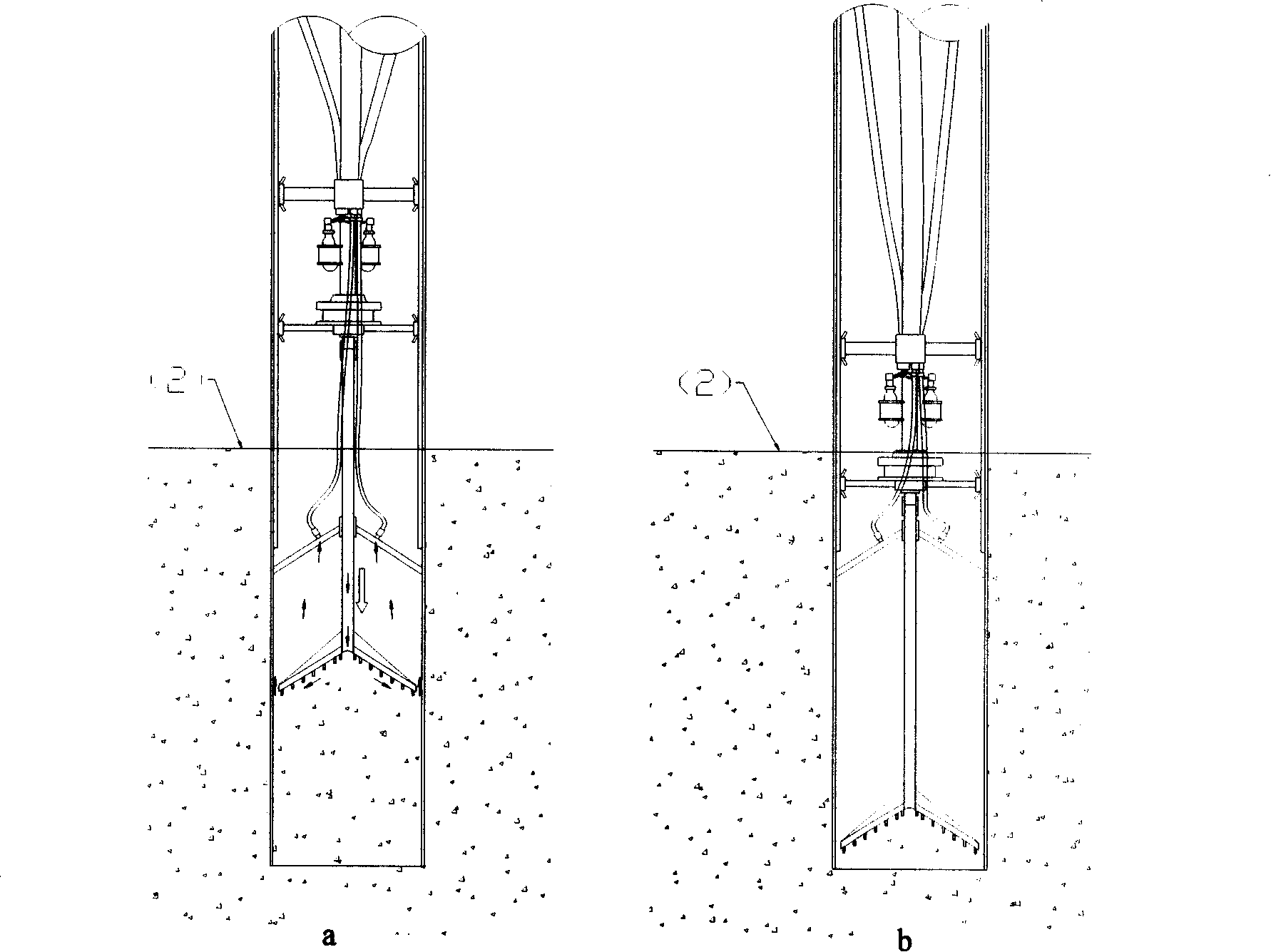

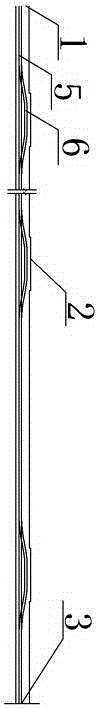

Drill absorption pile structure and construction method thereof

InactiveCN101196005AAvoid construction difficultySimple structureBulkheads/pilesWater dischargePore water pressure

The invention relates to an offshore drilled absorbing pile and the construction method thereof. When a drilling bit (11) breaks the ground and is drilled, an immersed tube is drilled into a high pressure water pump (18) on the main machine of a drilling machine, and supplies high pressure water for the lower part of the drilling bit through the central tube of a drilling rod to form high pressure slurry, and the slurry is discharged out of the drilled absorbing pile through a one-way valve (7) installed on a baffle plate and a slurry discharging tube (9) connected with the one-way valve. The drilling bit is drilled and breaks the ground from the upper part of the sealed bin of the drilled absorbing pile to the bottom of the drilled absorbing pile to clean all the soil plugs in the sealed bin out of the drilled absorbing pile, the drilling bit is stopped, and simultaneously the high pressure water pump (18) stops supplying water. A submersible sewage pump on the drilling machine is started up, the one-way valve (7) on the cone shaped baffle plate is closed to ensure that a sealed space is formed at the lower part, the sea water is discharged from the sealed space through the submersible sewage pump (19) to form negative pressure, the drilled absorbing pile is immersed into the sea bed under the sea water pressure, the drilling bit is supported on the mud surface and keeps still when the drilled absorbing pile is immersed, the cone shaped baffle plate of the drilled absorbing pile is lowered to the drilling bit position along the drilling rod (10) to stop the water discharging of the submersible sewage pump, and thus the primary drilling of the drilled absorbing pile is completed. The former operations are repeated to ensure the drilled absorbing pile to enter into the sea bed in a step-by-step immersed tube drilling way, in order to complete the driving-in construction of the drilled absorbing pile.

Owner:天津市海恩海洋工程技术服务有限公司

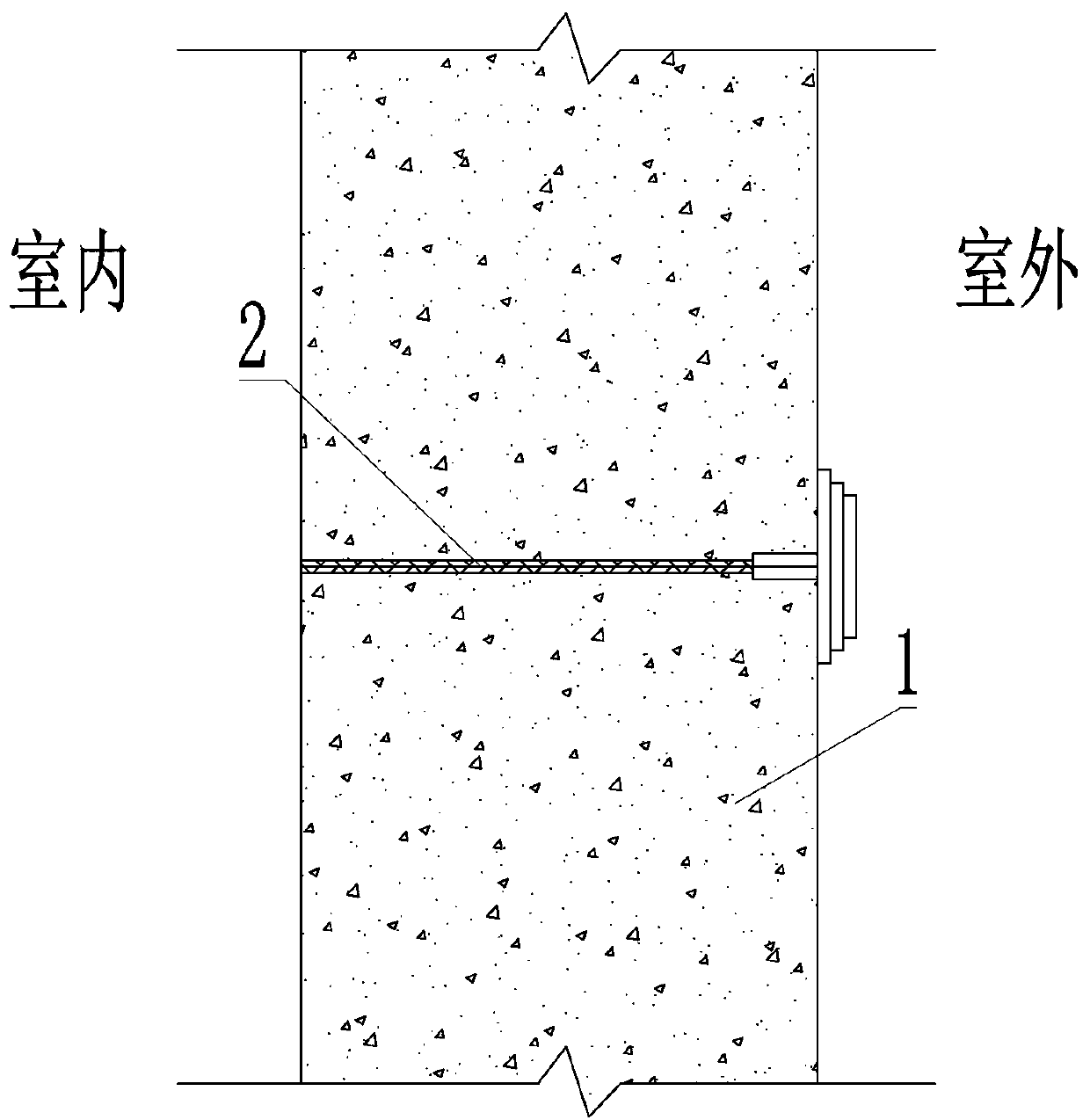

High-rise residence full professional interlacing construction storey water intercepting method

ActiveCN111305566ASimple construction processLow investment costSewerage structuresBuilding material handlingArchitectural engineeringWater resources

A high-rise residence full professional interlacing construction storey water intercepting method comprises the following two water intercepting modes, namely, the first water intercepting mode whichis a storey water blocking mode, wherein construction positions of the storey water blocking mode comprise an outer wall reserved bolt hole, a storey horizontal reserved hole, a storey edge portion and a firefighting pipeline reserved hole; and the second water intercepting mode which is a storey water drainage and guide discharging mode, wherein construction positions of the storey water drainageand guide discharging mode comprise an outer wall, a lift shaft, a stairwell and a bathroom drainage pipeline reserved hole. According to the method, water intercepting construction modes of all positions of the inside and outside of a storey are determined, the whole construction technology is simple, the investment measure cost is low, and the effect that upper structure construction of a building, lower portion refined decoration and mechanical and electrical installation can be conducted at the same tie is achieved, professional construction is not influenced on rainy days, a dry operation environment is provided, and the purposes of environment-friendly construction and water resource saving can be achieved.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

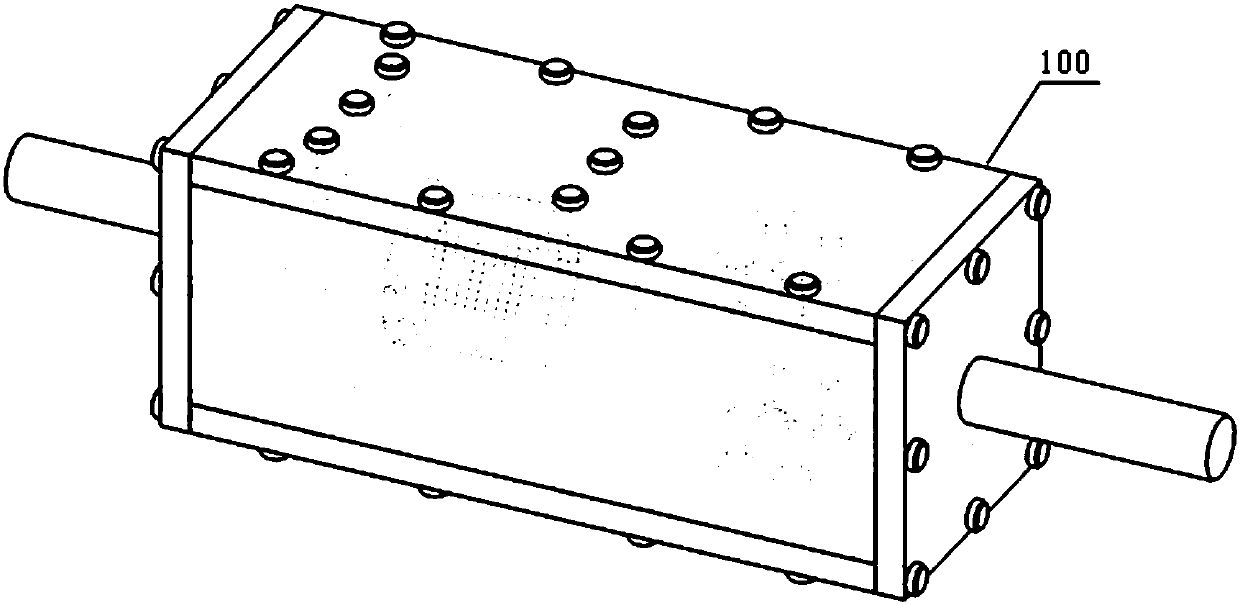

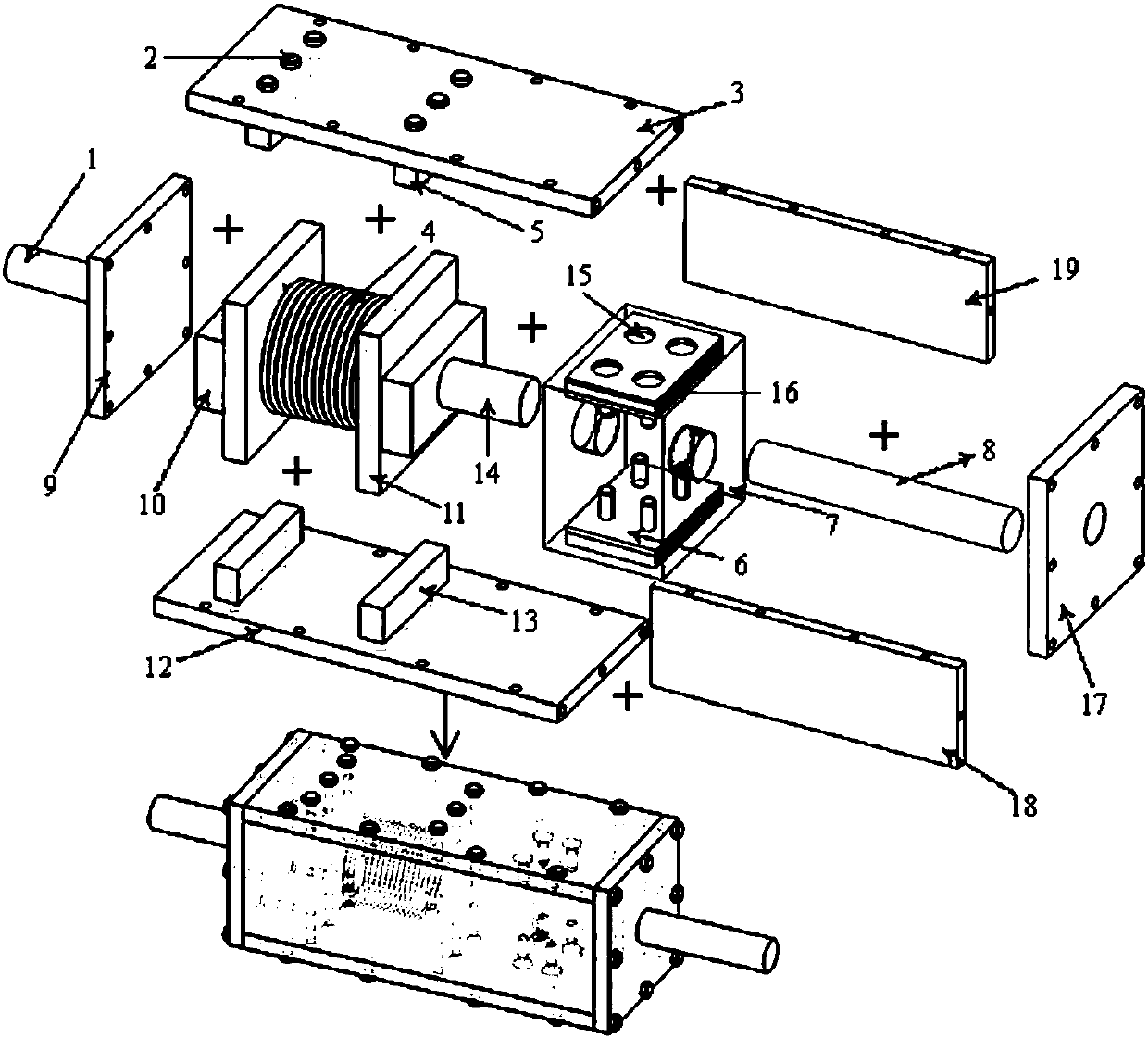

Self-reset friction damper

InactiveCN110130513AImprove energy consumptionImprove featuresProtective buildings/sheltersShock proofingEarthquake resistanceStored energy

The invention relates to the technical field of civil engineering earthquake resistance and disaster prevention, in particular to a self-reset friction damper. An energy dissipation assembly and a reset assembly of the damper are mounted in an outer sleeve in a sleeved mode, static friction force exists between the energy dissipation assembly and the outer sleeve, and the energy dissipation assembly and the reset assembly are coaxially connected through a connecting shaft. When the energy dissipation assembly is subjected to the effect of outer force to slide in the axial direction of the connecting shaft, the static friction force can be overcome, and the reset assembly can be pushed to store energy; the reset assembly has preset elastic potential energy and is used for utilizing the elastic potential energy to drive the energy dissipation assembly to reversely move and reset after the energy dissipation assembly slides, the energy dissipation assembly with the stored energy is resetthrough the reset assembly, thus large residual deformation generated by an existing friction damper after an earthquake is effectively reduced and even eliminated, the self-reset friction damper hashigh energy dissipation and the self-reset characteristic, and both the friction force and restoring force can be adjusted; and meanwhile, full-prefabricated machining and fabricating can be implemented, demounting can be conducted in the using period, overhauling and maintenance are easy, and the self-reset friction damper can be replaced after the earthquake.

Owner:北京市道路工程质量监督站 +1

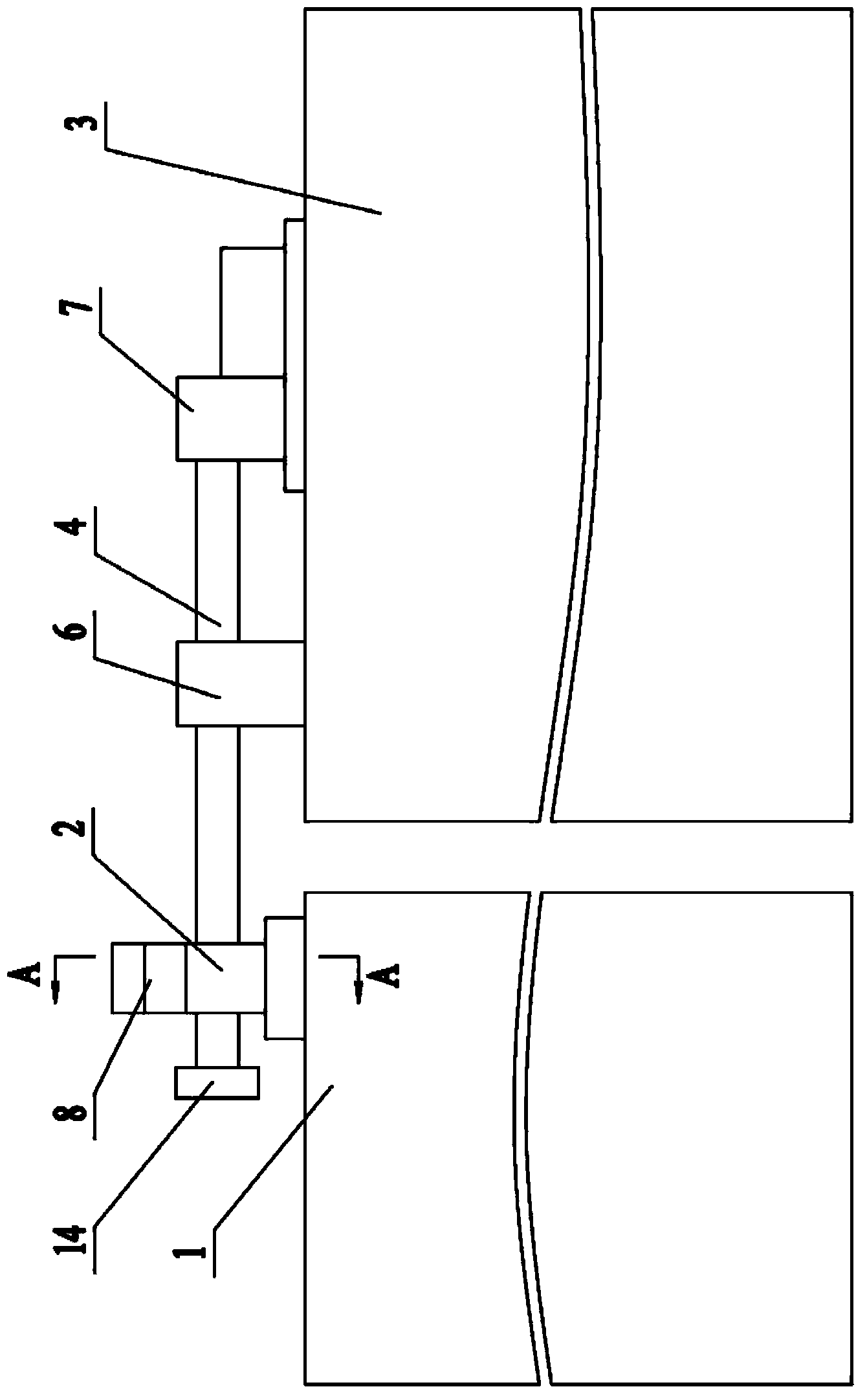

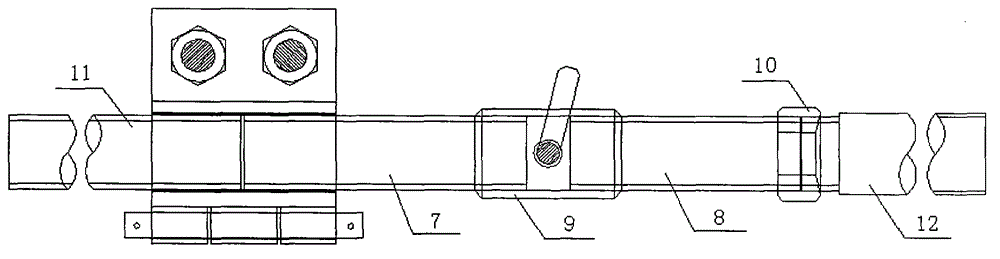

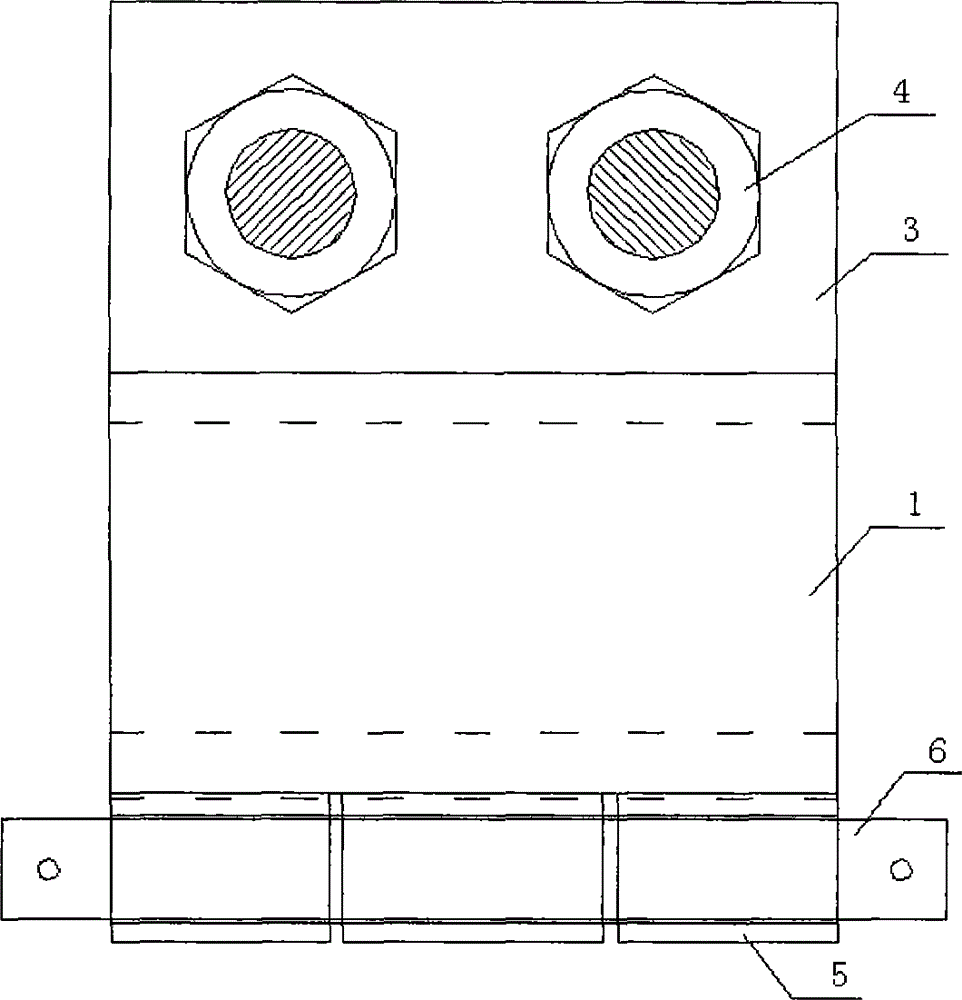

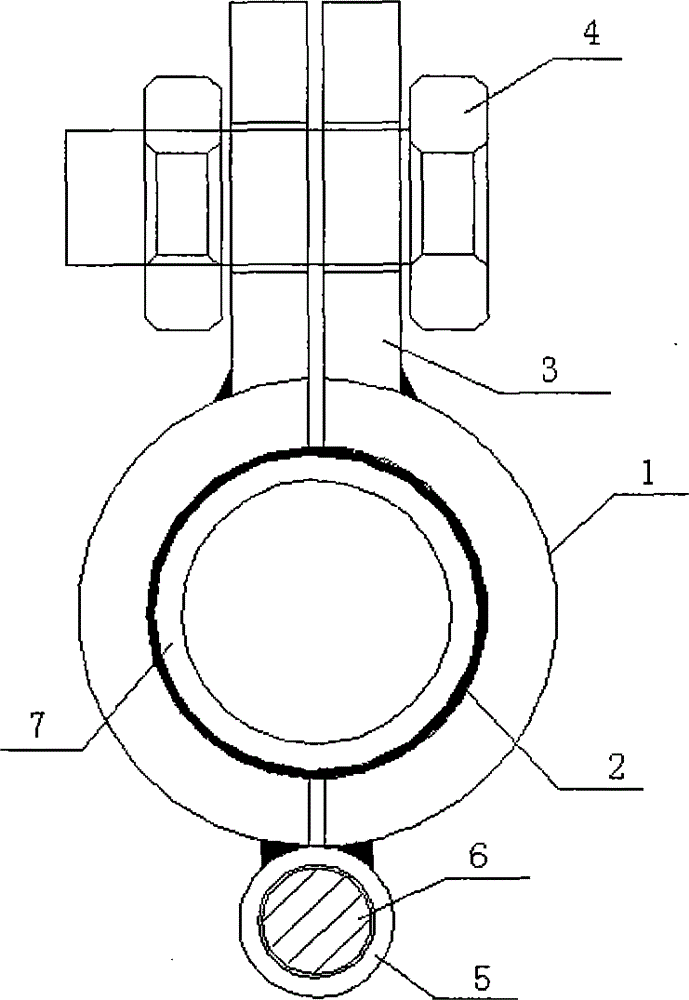

Pipe joint butt joint and guide device

ActiveCN103898922AQuick dockingDock stableArtificial islandsUnderwater structuresButt jointEngineering

The invention relates to a pipe joint butt joint and guide device, in particular to a butt joint and guide device applied to pipe joint butt joint operation in immersed pipe tunnel construction. The device comprises a guide frame and a guide rod, wherein the guide frame is connected with an installed pipe joint, the guide rod is connected with a pipe joint to be installed, a guide groove is formed in the guide frame, and the guide groove is used for containing the guide rod. By the design of the guide rod and the guide frame, the guide rod can be placed into the guide groove, and the two pipe joints are made to basically align with each other, namely the axes of the two pipe joints basically coincide with each other; the butt joint end of the pipe joint to be installed finally aligns with and draws close to the tail end of the installed pipe joint; by the adoption of the structure, butt joint is more quickly and smoothly conducted; the construction progress is shortened, and butt joint accuracy is improved; work faults are reduced, and major accidents are avoided.

Owner:CCCC FIRST HARBOR ENG +1

Transport system and method for small-section extra-long tunnel

ActiveCN105221162AReasonable designFast shippingTunnelsUnderground transportParking areaTransport system

The invention relates to a transport system for a small-section extra-long tunnel. The transport system comprises traction locomotives, rail-mounted transport carts, an intra-tunnel transport route and an extra-tunnel transport route. The intra-tunnel transport route is a monorail transport route, a plurality of meeting lanes are arranged on a rail of the monorail transport route, and the meeting lanes are single-turnout meeting lanes and are arranged on the same side of the rail of the intra-tunnel transport route. The extra-tunnel transport route comprises a turning area, a slag unloading area, a loading and emergency area, a charging overhaul area and a parking area, wherein the turning area is communicated with the intra-tunnel transport route, and the slag unloading area, the loading and emergency area and the charging overhaul area are communicated with the turning area. The turning area comprises at least two rail lines and is communicated with the part, extending out of a portal, of the rail of the intra-tunnel transport route through a turnout. The slag unloading area comprises a slag unloading platform and at least two slag unloading rail lines, and the slag unloading rail lines are communicated with the turning area through a turnout and a rail. The invention further relates to a transport method for the small-section extra-long tunnel.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

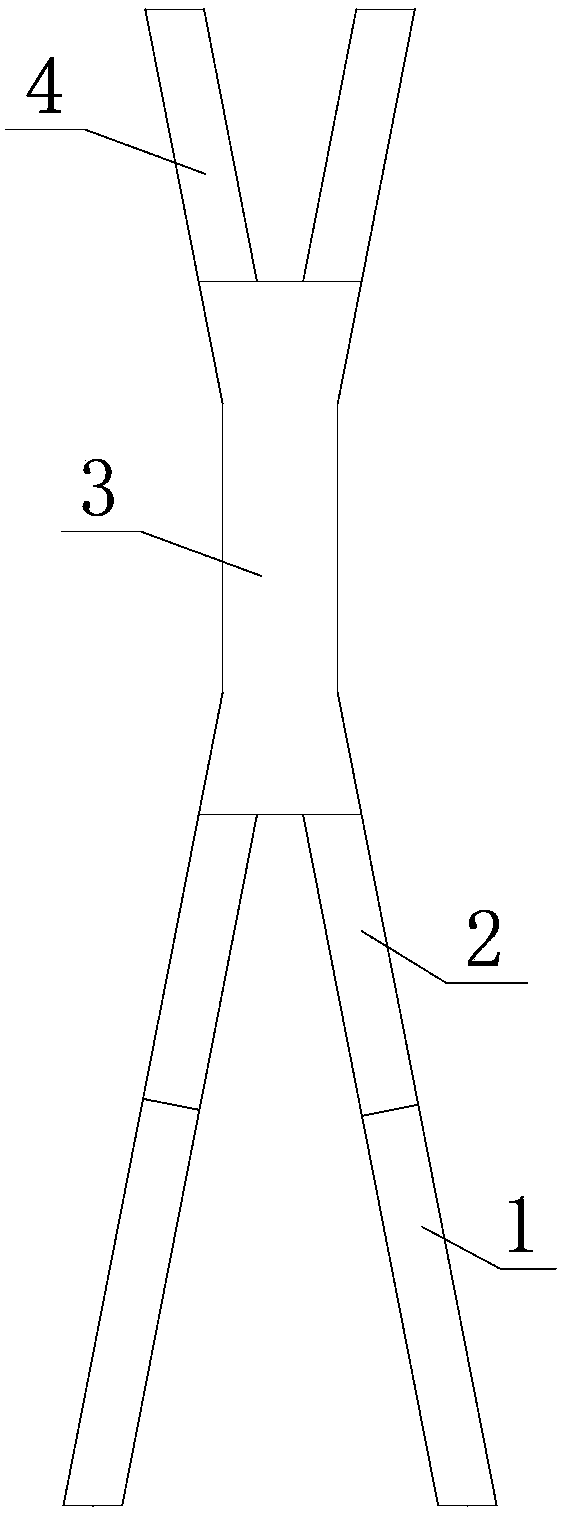

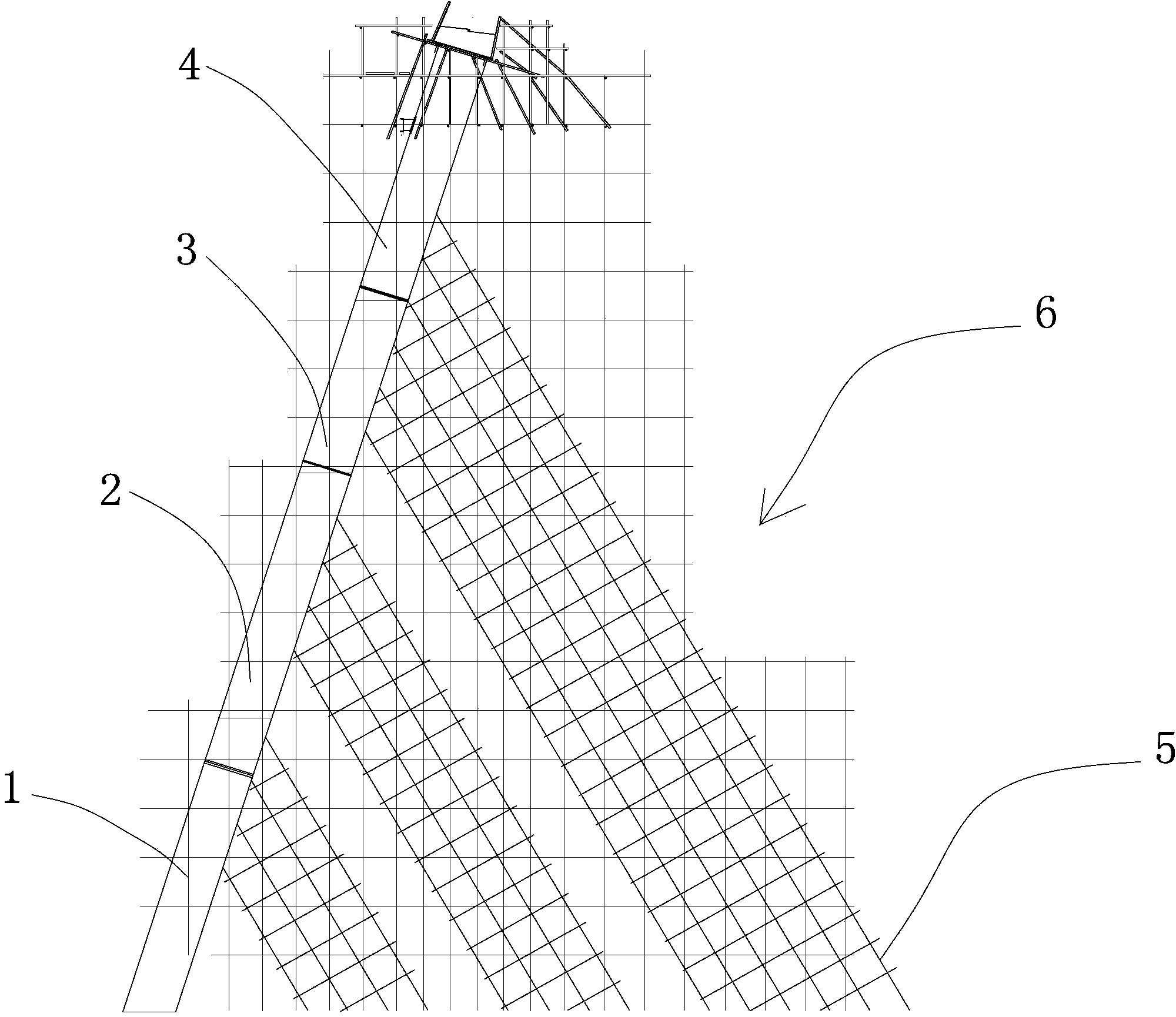

Air cooling tower X-shaped pillar construction method

InactiveCN103397780AAvoid deformation or even collapse accidentsEasy to checkBuilding material handlingButtressCooling tower

The invention discloses an air cooling tower X-shaped pillar construction method and belongs to the field of construction. An air cooling tower X-shaped pillar graphic model is drawn by computer software according to a proportion, the center control point and the corner control point of an air cooling tower X-shaped pillar are projected to an annular foundation from the upper portion of the air cooling tower X-shaped pillar to work out data. Practical measurement on control points in the field are carried out by utilizing a total station, oil paint is used for marking, the inclined angle of a joint bar is well adjusted according to the oil paint mark, and the joint bar is inserted into a buttress and is firmly fixed. Other subsequent control points are marked again on a rough terrace inside an air cooling tower. Steel bar frames of the air cooling tower X-shaped pillar are bound and connected and a formwork is fixed according to the marked control points, and meanwhile a scaffold is built. The actual positions of all control points are verified again, and concrete is poured. Due to the fact that the computer software is utilized for projecting the air cooling tower X-shaped pillar and determining the control points, compared with the method that the control points are mapped according to graph paper one by one, the method is faster and more accurate, steel bars and the formwork can be verified conveniently in the process of construction, and the period of construction is shortened.

Owner:SICHUAN NO 3 ELECTRIC POWER CONSTR

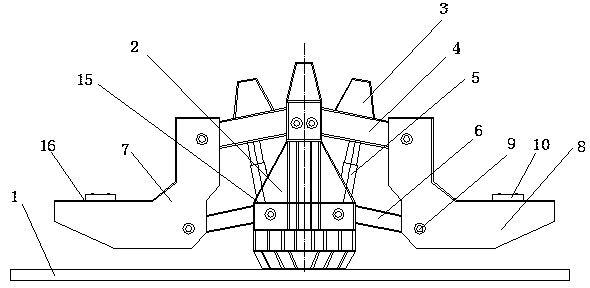

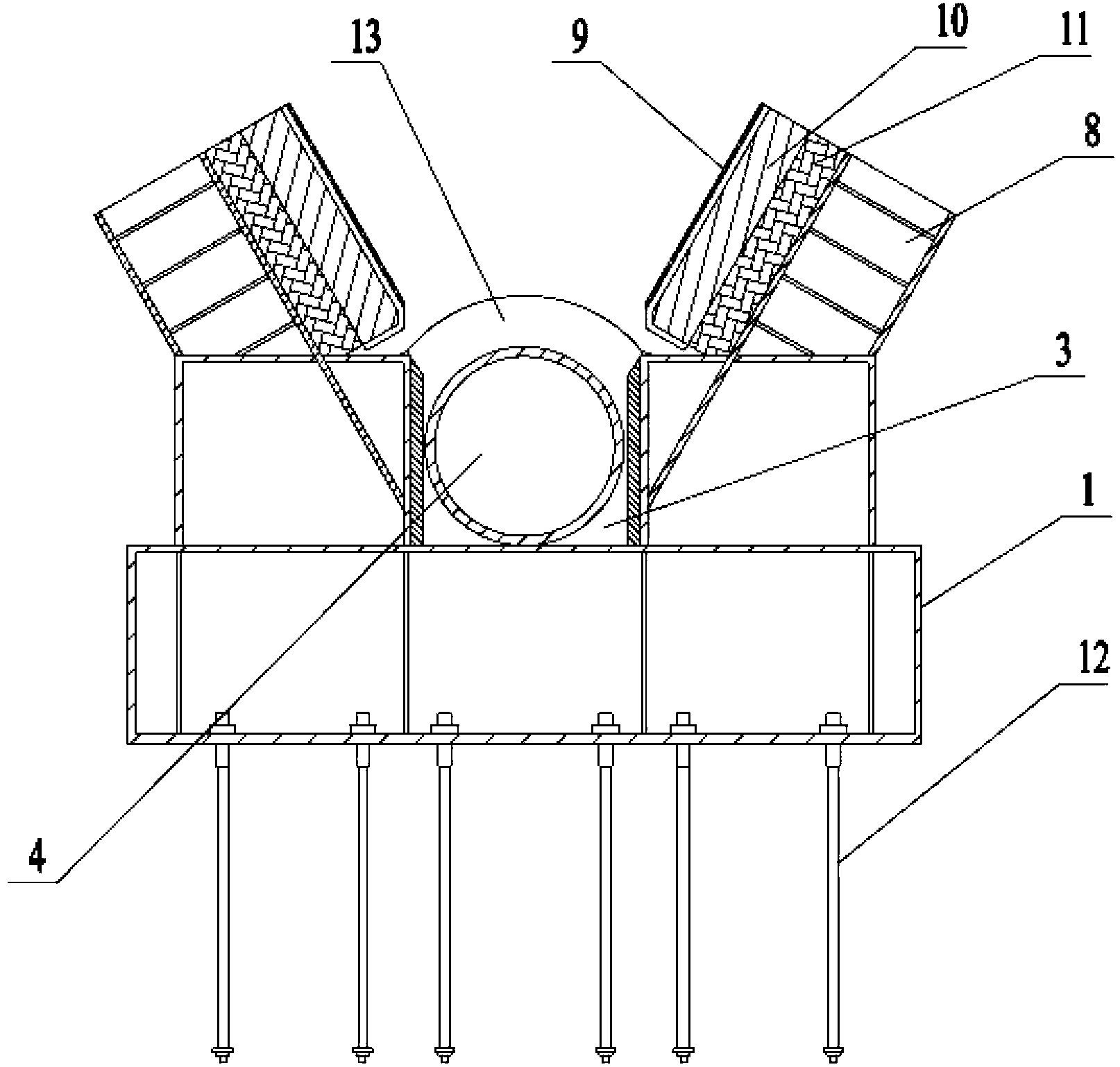

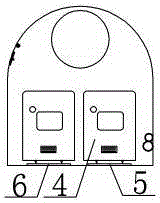

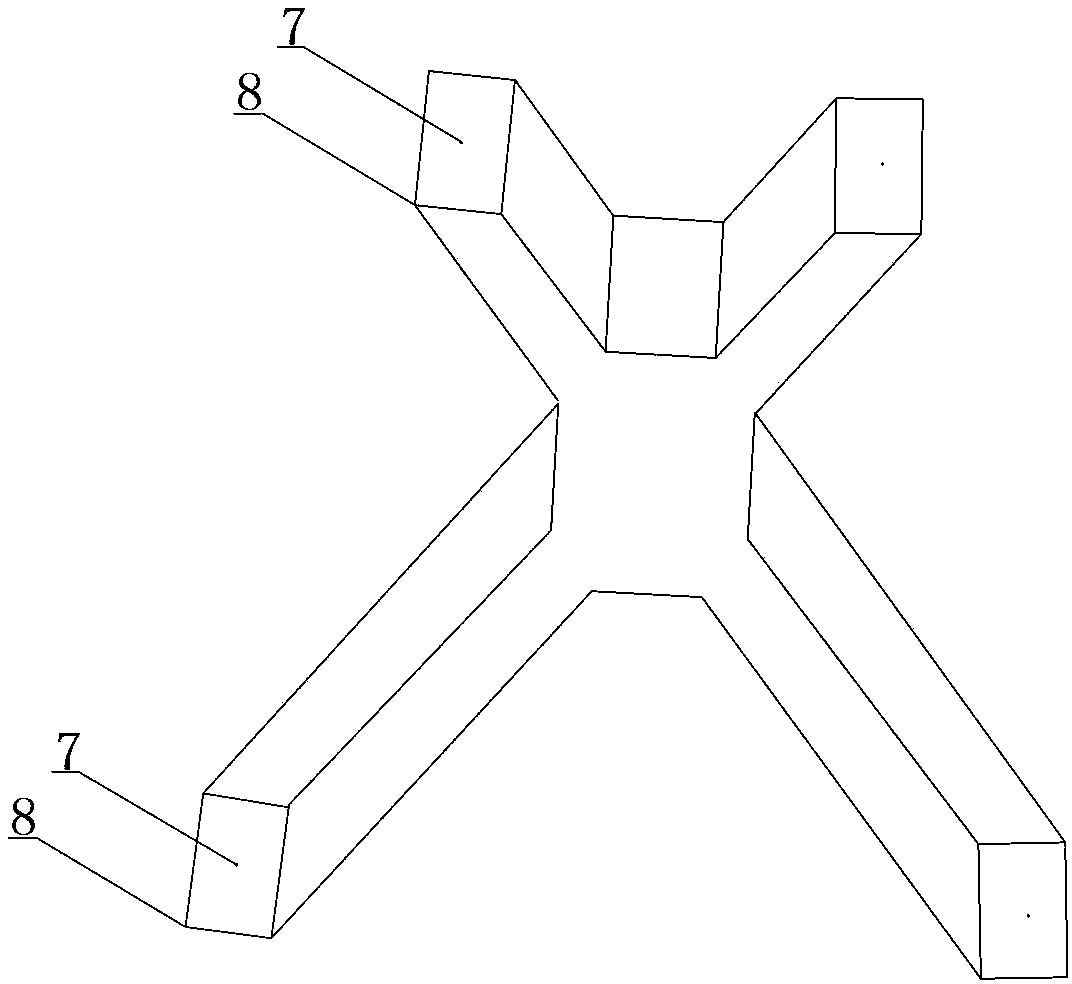

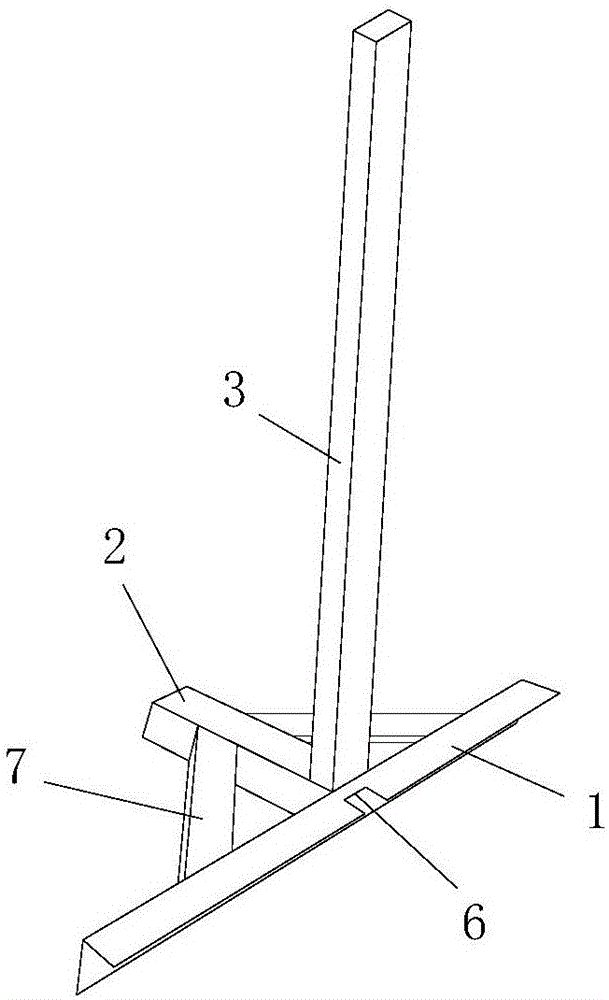

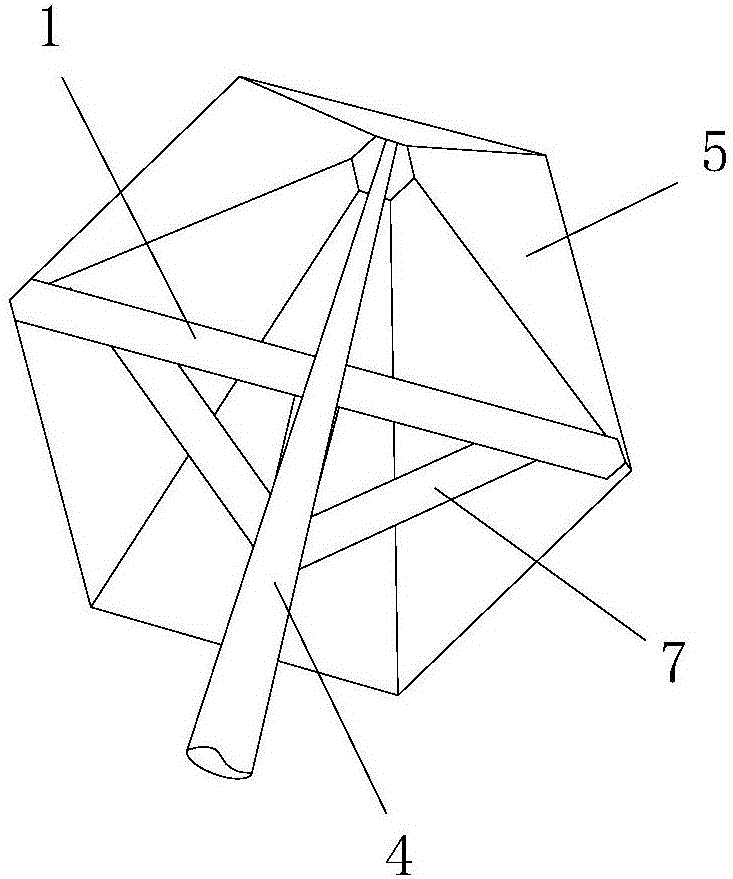

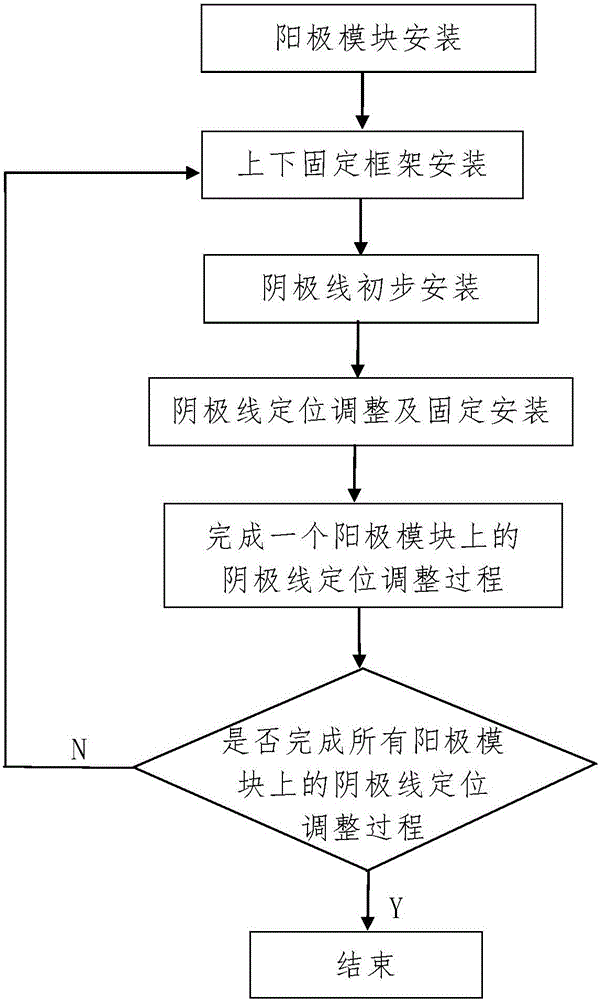

Cathode line positioning die and cathode lien positioning and adjustment construction method

ActiveCN106238212ASimple structureEasy to processElectrostatic separation detailsArchitectural engineeringAnode

The invention discloses a cathode line positioning die and a cathode lien positioning and adjustment construction method. The positioning die comprises a rear measuring rod, a front measuring rod arranged on the front side of the middle of the rear measuring rod and a vertical rod fixed behind the rear portion of the front measuring rod, wherein the front measuring rod and the vertical rod are located in front of the rear measuring rod, the rear measuring rod, the front measuring rod and the vertical rod are straight rods, the rear measuring rod and the front measuring rod are arranged in a perpendicular mode, the rear measuring rod and the front measuring rod form a horizontal positioning rack, and a clamping groove for positioning an adjusted cathode line is formed in the rear side of the middle of the rear measuring rod. The constriction method comprises the steps that 1, anode module installation is performed; 2, cathode line installation construction is performed: when the cathode line is installed on any group of anode modules, the process is that 201, upper and lower fixing frames are installed; 202, preliminary cathode line installation is performed; 203, cathode line positioning, adjustment and fixing installation are performed. The cathode line positioning die is reasonable in design, simple and convenient to use and operate, good in using effect and capable of simply, conveniently and rapidly perform accurate cathode line positioning and ensuring cathode line installing precision.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

Split mounting type building

InactiveCN101984206APromote circulationReduce usageStrutsWallsHouse buildingUltimate tensile strength

The invention relates to a split mounting type building which is fast to mount and has less consumable items. The building is composed of a building structure group formed by transverse and longitudinal connection of a plurality of frame constructions; after the connection of the frame structure is completed, the outer wall and stairs are fixed on a support column to form a architectural complex frame of the building; and finally, cement is poured and paved to form the building. The building of the invention has high strength, good air flow effect, less usage amount of build consumable items.

Owner:郑勤民

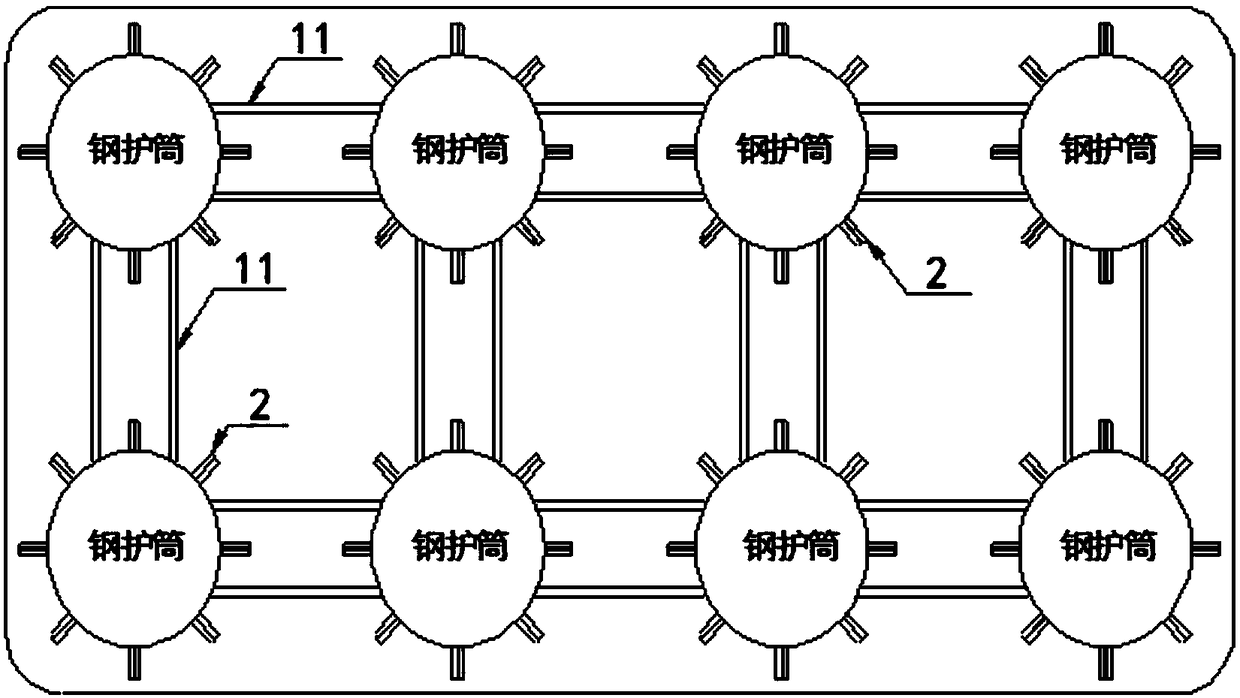

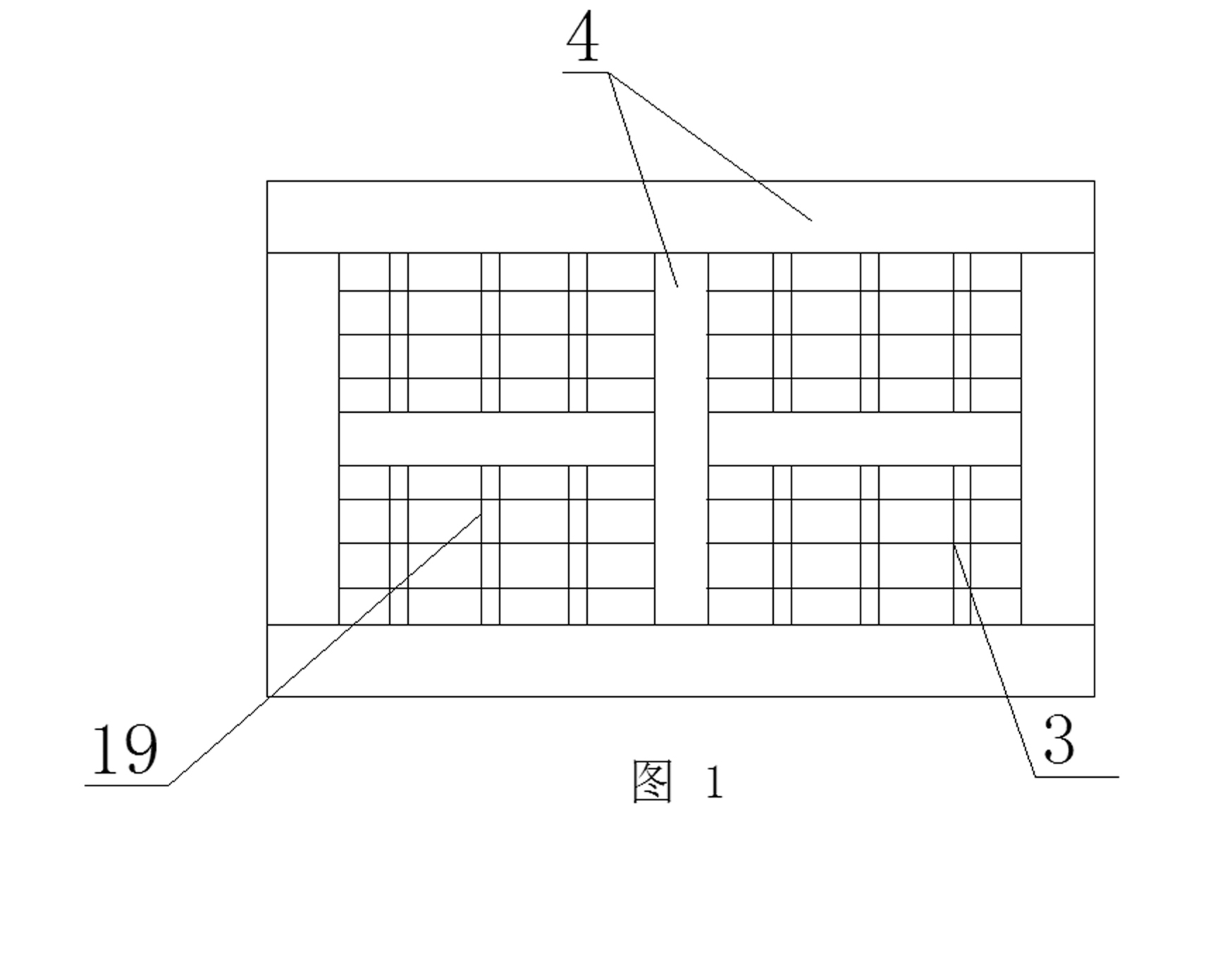

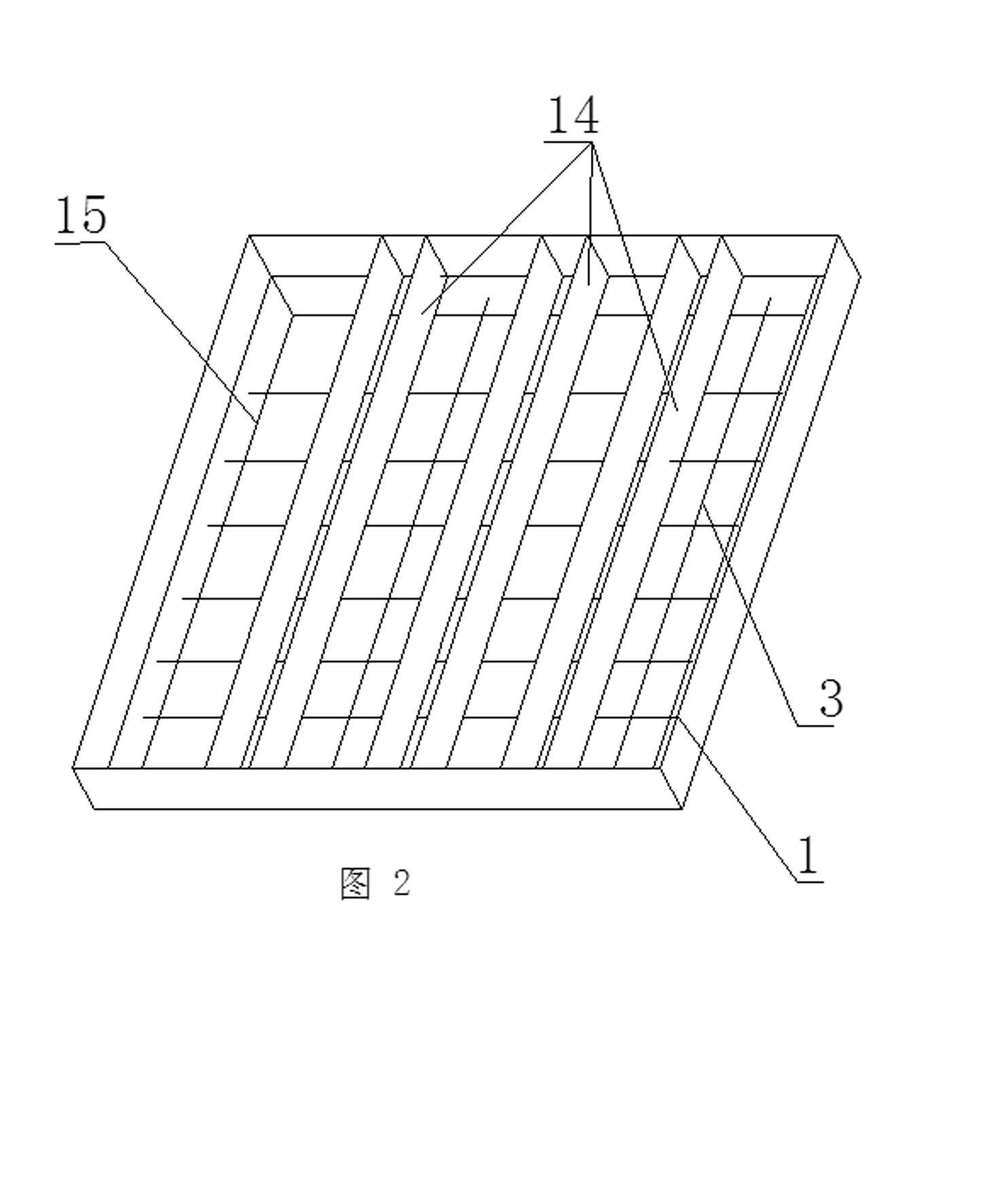

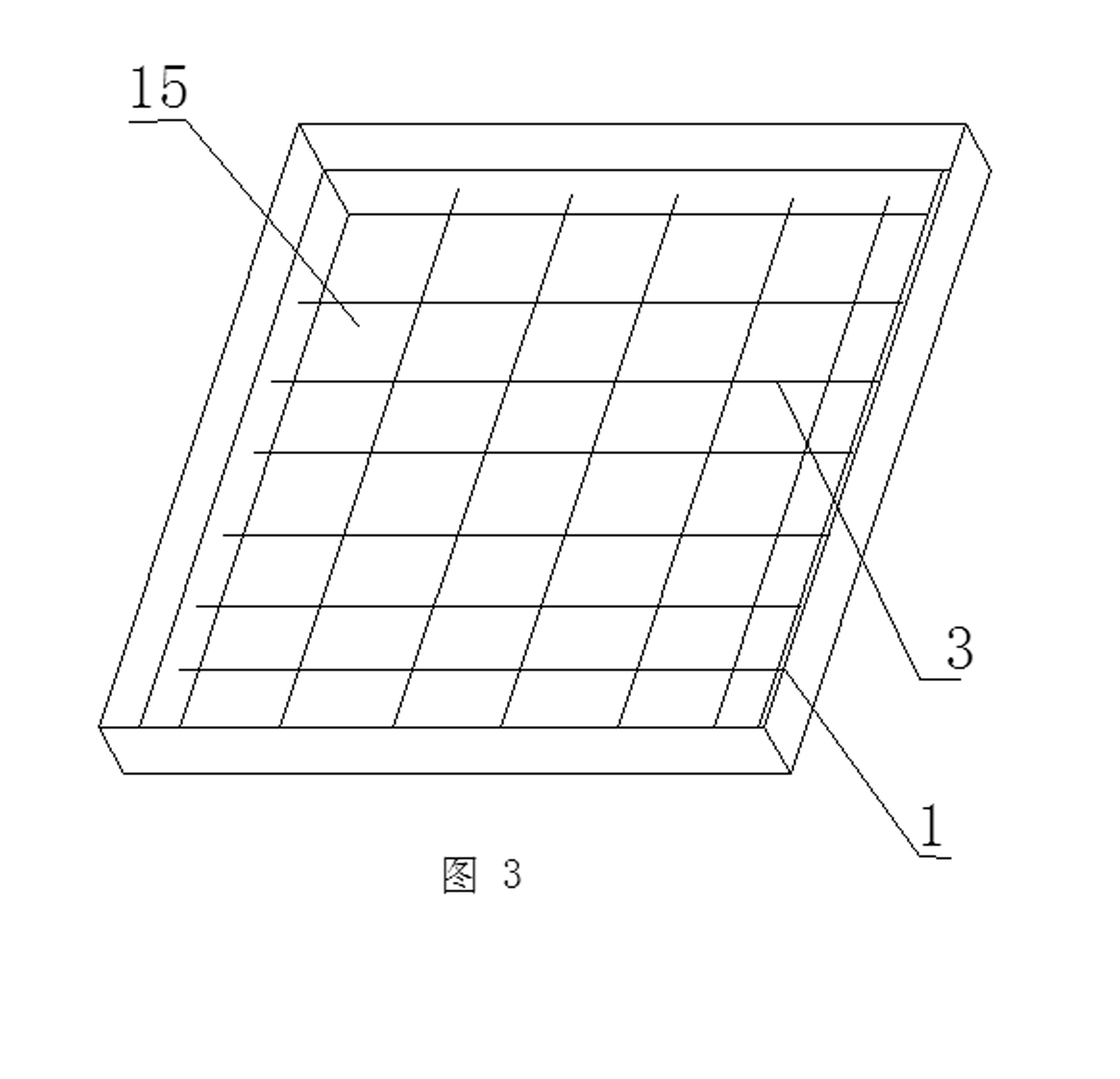

Construction method for rock riverbed bearing platform in water

ActiveCN107489106AThe method steps are simpleEasy constructionFoundation engineeringBridge erection/assemblyCofferdamBottom water

The invention discloses a construction method for a rock riverbed bearing platform in water. The construction method includes the steps of construction of a cofferdam, transfer of protective steel canisters to a lower level, bottom sealing construction of the cofferdam, construction of drilling piles, water extraction inside the cofferdam and excision and removal of the protective steel canisters, anti-drainage construction and construction of the bearing platform, wherein during the anti-drainage construction, an anti-drainage structure is constructed inside the steel cofferdam, the anti-drainage structure includes a water-permeable layer, a bottom water-separating layer and lateral water-separating layers, and the bottom water-separating layer is connected with the four lateral water-separating layers to form an integrated type water separating layer; during the construction of the bearing platform, molding construction is conducted on the bearing platform in the water inside the integrated type water separating layer. According to the construction method for the rock riverbed bearing platform in the water, by drilling multiple guide holes in hard rock where the drilling piles are located from top to bottom, sifter holes are formed in the hard rock where the drilling piles are located to increase a rock fissure surface; moreover, by adopting a prestress anchor device to fixedly connect the steel cofferdam with the drilling pies in an integrated mode, so that the pile foundation construction progress and construction quality can be effectively ensured, and meanwhile, the integrated type water separating layer is arranged on the molding pile foundation after construction and can effectively ensure the concrete pouring quality of the bearing platform.

Owner:CHINA RAILWAY 20 BUREAU GRP +1

Novel letter box device

InactiveCN107803528ASimple structureEasy to operateTypewritersBoring/drilling machinesVehicle frameEngineering

The invention discloses a novel letter box device. The novel letter box device comprises a vehicle frame body and a shell cover fixedly installed in the vehicle frame body. Leg pillars are fixedly installed at the four vertex corners of the bottom end face of the vehicle frame body, and antiskid pads are arranged at the bottom end faces of the leg pillars in an adhesive mode. A main cavity is formed in the shell cover. A drilling device is arranged in the position, on the left side of the main cavity, of the shell cover. The drilling device comprises a first sliding cavity formed in the shellcover and a sliding block arranged in the first sliding cavity in horizontal sliding fit and connection modes. A first through hole penetrating through the bottom end face of the shell cover is formedin the inner bottom wall of the left side of the first sliding cavity. A drilling pillar extending upwards is connected in the first through hole in a transitional fit mode. The novel letter box device is simple in structure and convenient to operate, the labor intensity of workers is relieved, the construction efficiency is improved, and the construction progress of letter box processing is greatly accelerated.

Owner:张国强

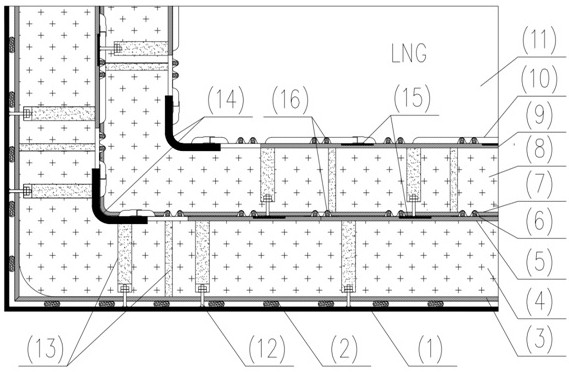

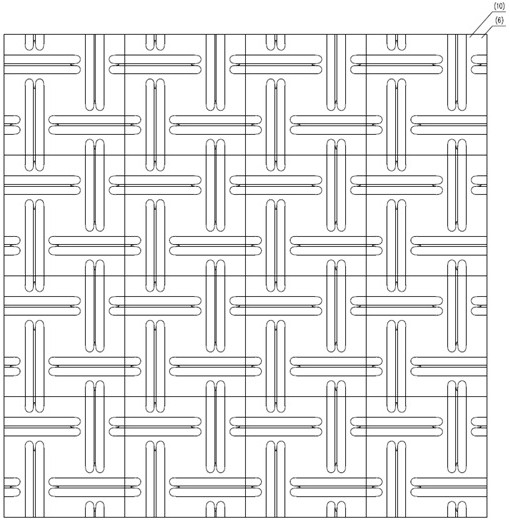

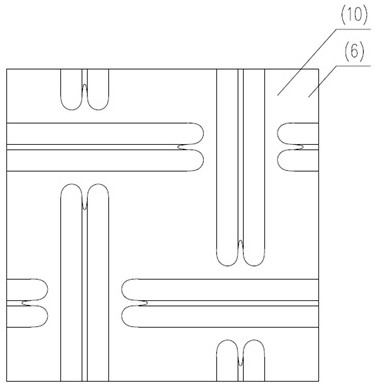

Bimetal low-temperature film storage cabin for storing liquefied natural gas

InactiveCN112032550AReduce dependenceReduce workloadVessel manufacturingVessel geometry/arrangement/sizeAdhesive glueProcess engineering

The invention discloses a bimetal low-temperature film storage cabin for storing liquefied natural gas. Metal film plates are used for replacing existing films, the dependence on the films of specialequipment is reduced, global supply is achieved, the metal film plates are used for replacing the existing films, the application of low-temperature-resistant glue in field construction is reduced, alarge number of workshop pre-insulating plates are greatly used, the field workload is reduced, and the construction progress is accelerated. Besides, generally mature automatic welding and manual welding work is adopted for the metal film plates, so that the workload is reduced, the safety of the low-temperature film storage cabin is improved, the limitation of the cargo cabin on free liquid level loading of liquid cargoes is reduced, and the application and time consumption of the low-temperature-resistant glue in the construction process are reduced; and a mature and safe bimetal film platewelding design manner and an environment-friendly manner of prefabricating foaming insulation panels in advance are adopted, so that the construction workload is reduced, the construction period is shortened, the equipment safety is improved, and the concept of environmental protection can be achieved.

Owner:SINOTECH MARINE CO LTD

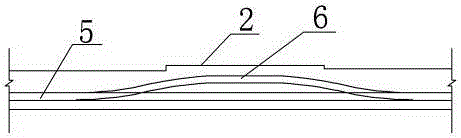

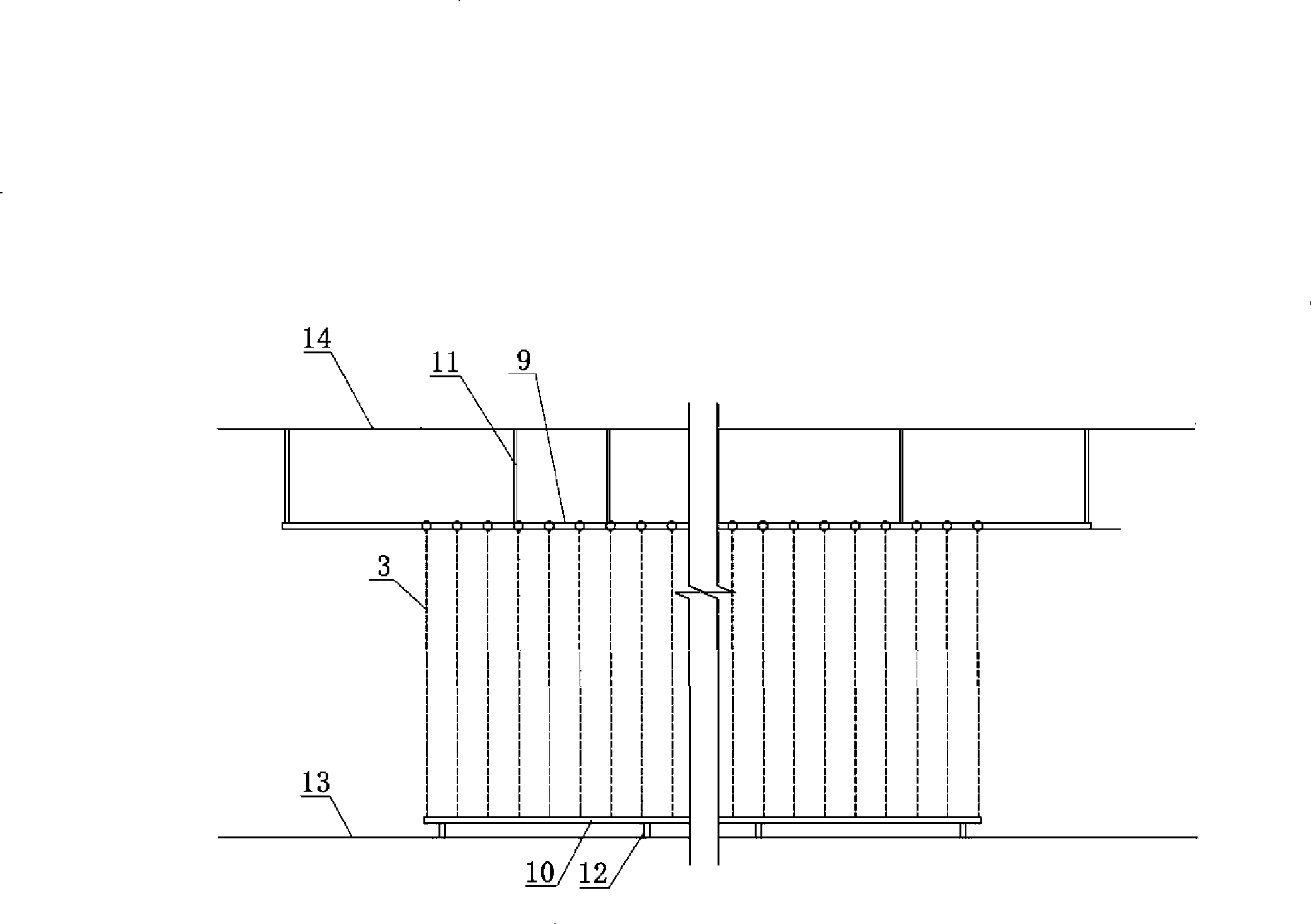

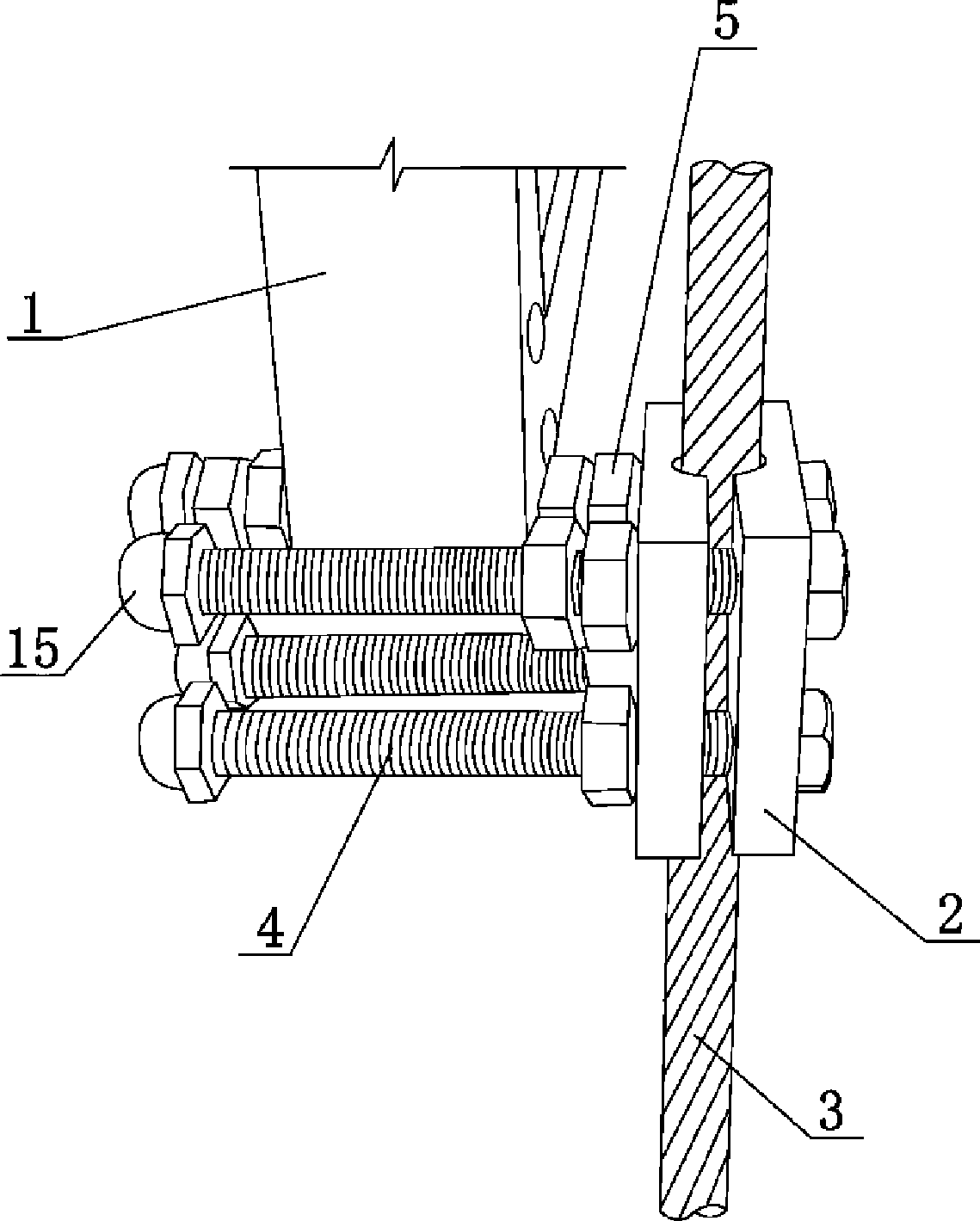

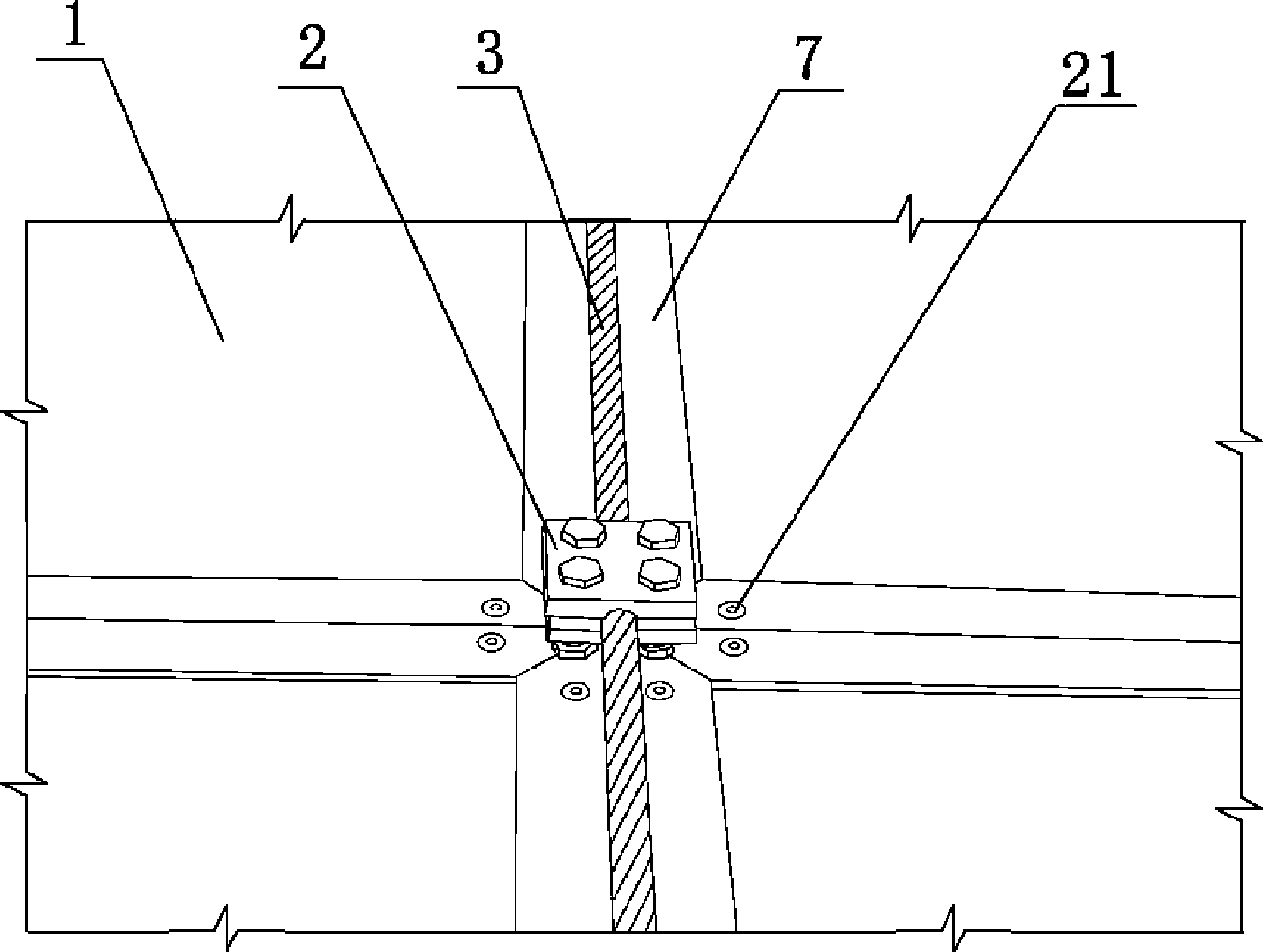

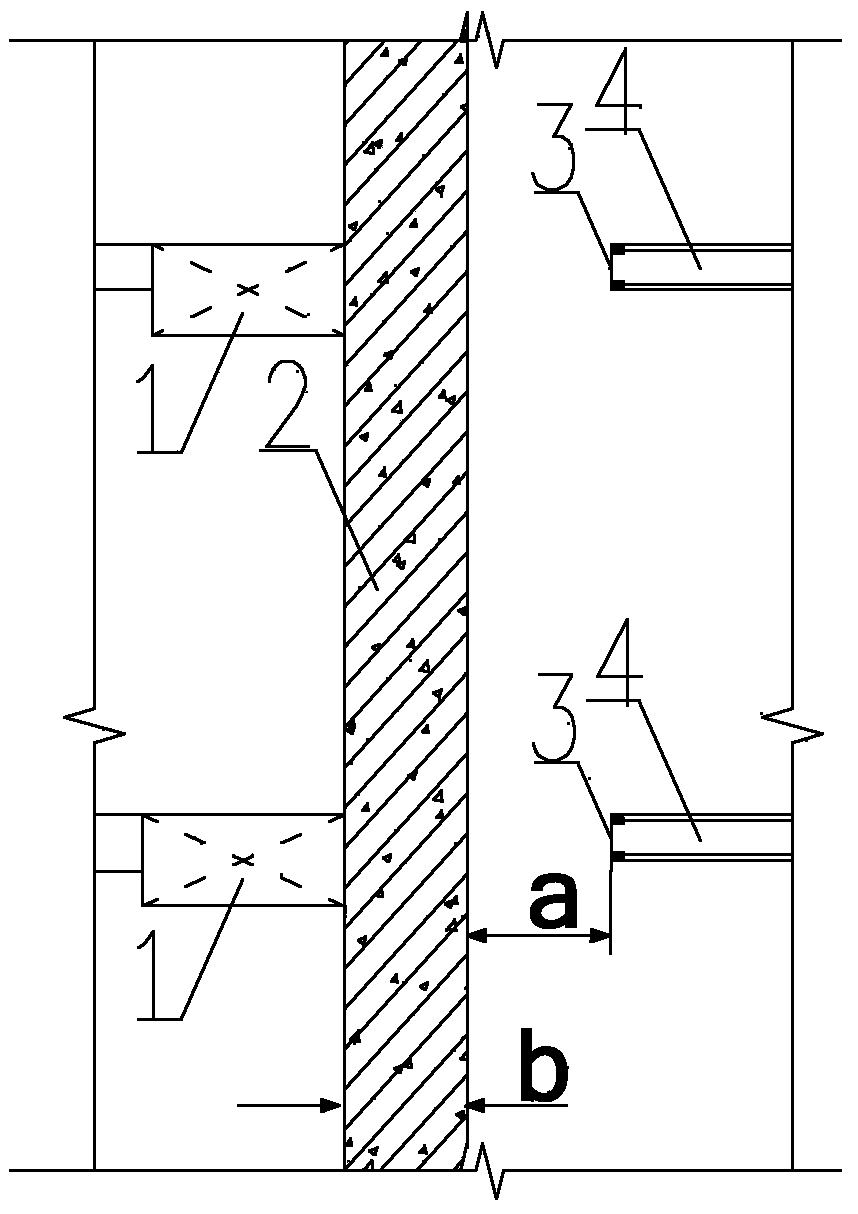

Light partition of one-way single-layer suspended-cable structure and construction method thereof

ActiveCN101435236AWeight increaseEasy to transportWallsSound proofingSuspended cableBuilding envelope

The invention discloses a unidirectional single layer suspended cable structure light partition wall and construction method thereof. The light partition wall is composed by combining a sound-absorbing board, a support frame, and a connecting member for connecting the sound-absorbing board and the support frame. The support frame comprises an upper beam connected under the roof, a lower beam connected to the floor, and unidirectional suspended cables connected at interval between the upper beam and the lower beam, wherein the interval among the unidirectional suspended cables is equal to the width of the sound-absorbing board; the four edges of the sound-absorbing board are connected with frames, and the four corners of the frames are connected with corners via screws, and the four corners are provided with screw holes; the connecting member is formed into a clamping plate type connecting member by a pair of clamping plates, four screws passing through the clamping plates, and a nut assembly, the middle parts of the clamping surfaces are respectively provided with an arc slots used for clamping the unidirectional suspended cables, the four corners of the two clamping plates are both opened with through holes, the four screws respectively pass through the through holes of the clamping plates and the screw holes on the corners of one sound-absorbing board, and the nut assembly connects the sound-absorbing board and the unidirectional suspended cabled fixedly. The invention solves the technical problems that the sound-absorbing wall in not attached to a building envelope and need cool construction.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG +1

Method for dismantling division wall between foundation pits in semi-reversed construction mode

ActiveCN103726494AReduce construction costsSpeed up the construction progressEmbankmentsExcavationsStructural engineeringBuilding construction

The invention provides a method for dismantling a division wall between foundation pits in a semi-reversed construction mode. The method is used for dismantling the division wall between an early-constructed foundation pit structure and a post-constructed foundation pit structure. The method includes the steps that the early-constructed foundation pit structure is constructed firstly; after earth excavation of the post-constructed foundation pit is completed, the structure is reconstructed upwards from a base plate structure, and the vertically-interpenetrating post-pouring belt space is reserved between each layer of the post-constructed foundation pit structure and the division wall from the base plate structure; the division wall is cut into concrete blocks convenient to hoist from bottom to top, and then a crane is utilized to directly hoist the concrete blocks out of the post-pouring belt space of the post-constructed foundation pit structure. Through the arrangement of the post-pouring belt space, the method has the advantages that the method enables the division wall to be dismantled more conveniently, effectively reduces construction cost, accelerates construction progress, saves resources, and has the effect of low-carbon construction.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

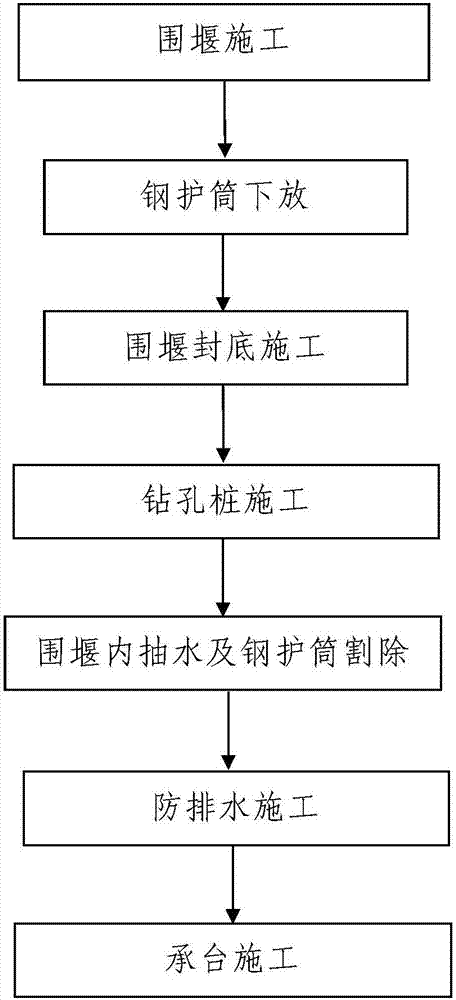

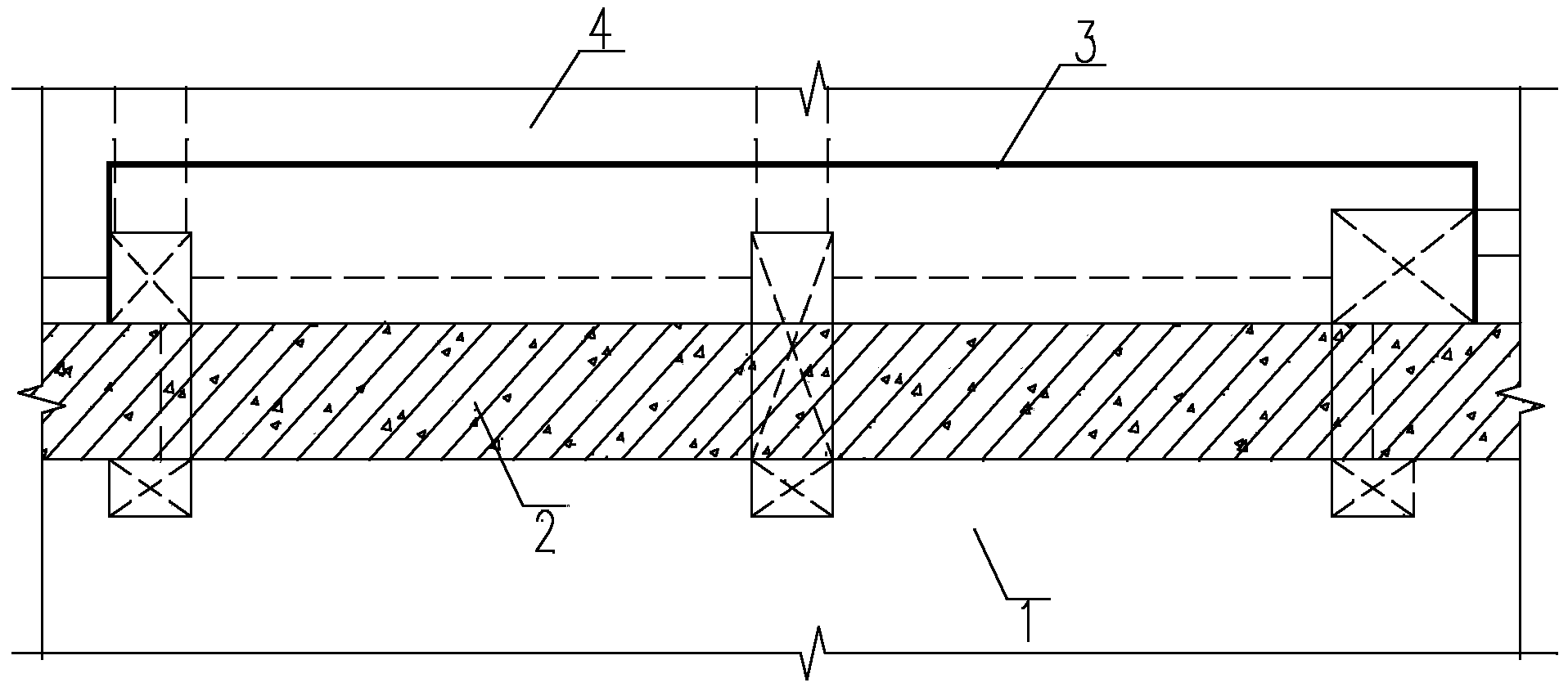

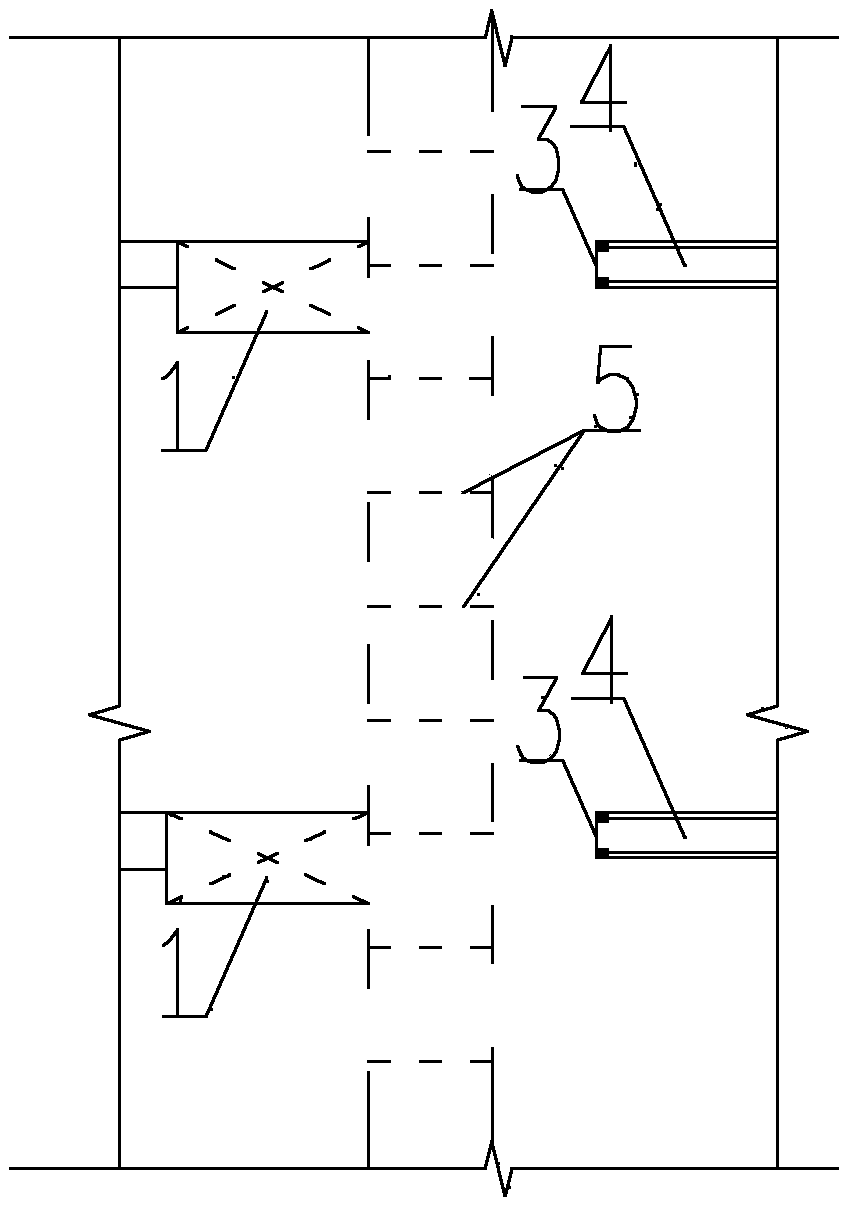

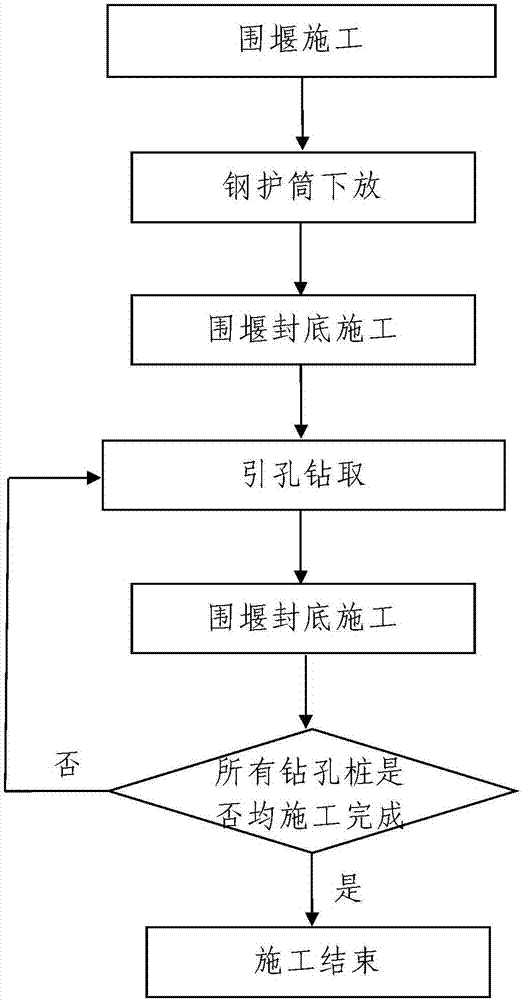

Construction method for large-size deep water foundation of rock riverbed

ActiveCN107620316AThe method steps are simpleEasy constructionProtective foundationCofferdamLarge size

The invention discloses a construction method for a large-size deep water foundation of a rock riverbed. The construction method comprises the following steps of: step I, cofferdam construction; stepII, steel casing dropping; step III, cofferdam bottom-sealing construction; step IV, drilling pile construction, wherein when any drilling pile is constructed, the step IV comprises the following steps of: 401, lead-hole drilling; and 402, drilling pile construction; step V, water pumping in cofferdam and steel casing cut-off; step VI, bearing platform construction; and step VII, concrete pier construction. According to the construction method disclosed by the invention, a plurality of lead holes are drilled in a hard rock on which the drilling pile is located from top to bottom, so that the hard rock on which the drilling pile is located forms sieve holes for increasing rock crack surfaces, and therefore, a deep water foundation construction process can be simply and quickly completed.

Owner:NO 1 ENG LIMITED OF CR20G

Construction technology for deep water foundation pile foundation

ActiveCN107503345AThe method steps are simpleEasy constructionBulkheads/pilesMultiple edgesCofferdam

The invention discloses a construction technology for a deep water foundation pile foundation. The construction technology includes the following processes that firstly, a cofferdam is constructed; secondly, a steel protection cylinder is put down; thirdly, bottom sealing construction is conducted on the cofferdam; and fourthly, drilling piles are constructed, wherein the multiple drilling piles are constructed respectively. Construction of the drilling piles includes the steps that 401, lead hole drilling is conducted, wherein multiple lead holes are drilled from top to bottom in hard rock where the currently-constructed drilling piles are located, and the 8-10 lead holes are vertically arranged and include multiple edge holes and one middle hole; 402, the drilling piles are constructed; and 403, the step 401 and the step 402 are repeated multiple times till the construction process of all the drilling piles is completed. By means of the construction technology, due to the fact that the multiple lead holes are drilled from top to bottom in the hard rock where the drilling piles are located, the number of the lead holes and the arrangement positions of all the lead holes are limited so that screen holes can be formed on the hard rock where the drilling piles are located and rock fracture planes can be increased, and the problem that due to the fact that the rock is hard and complete and the drilling construction progress of the drilling piles is affected can be effectively solved.

Owner:CHINA RAILWAY 20 BUREAU GRP

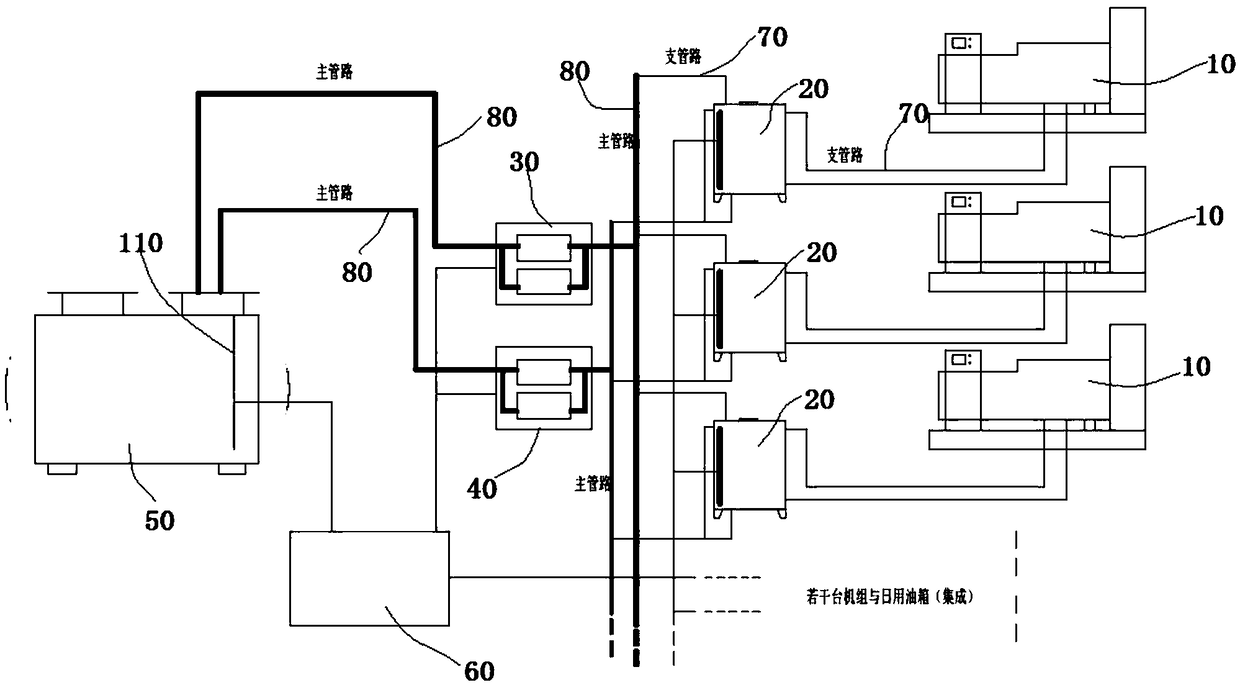

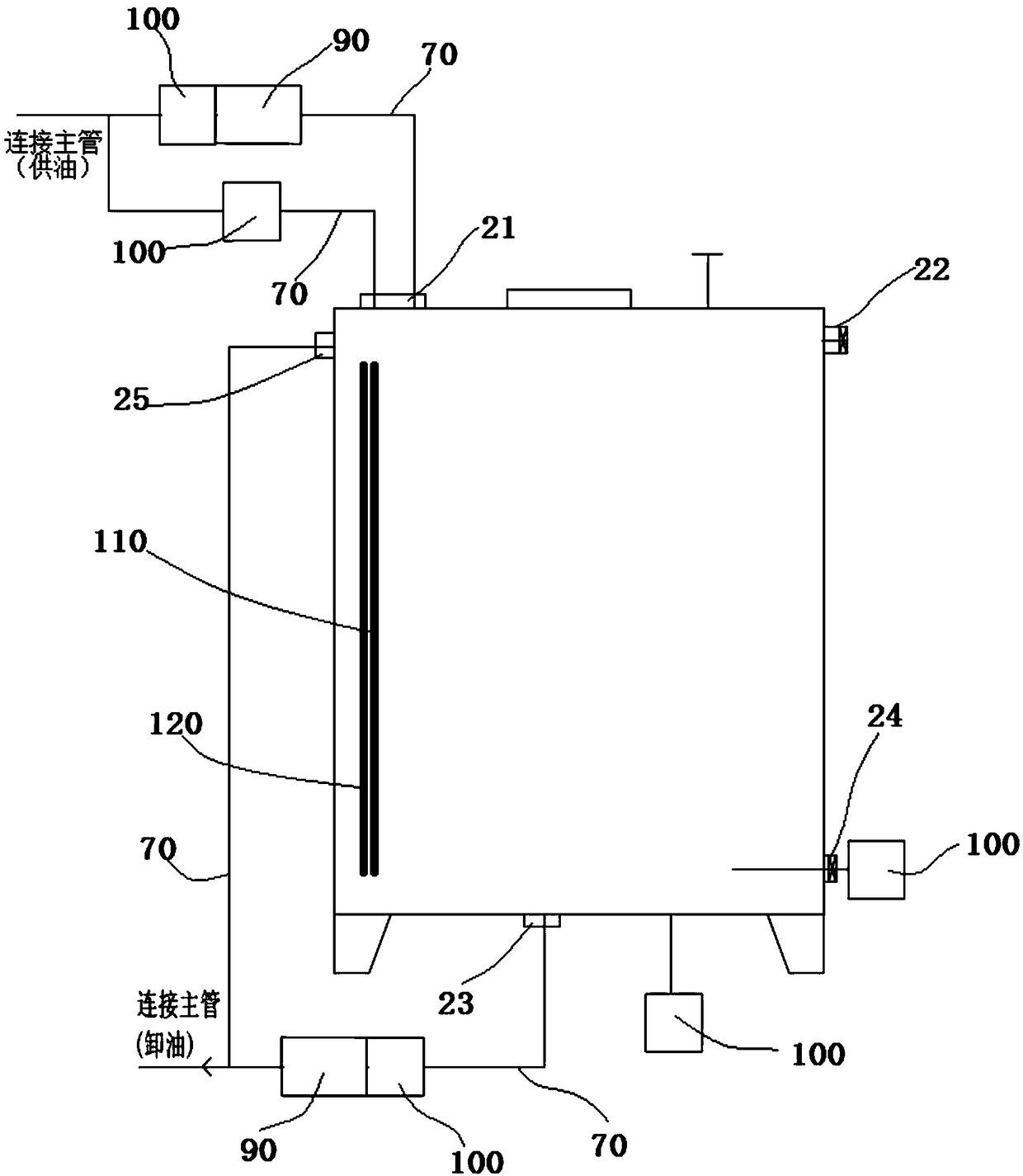

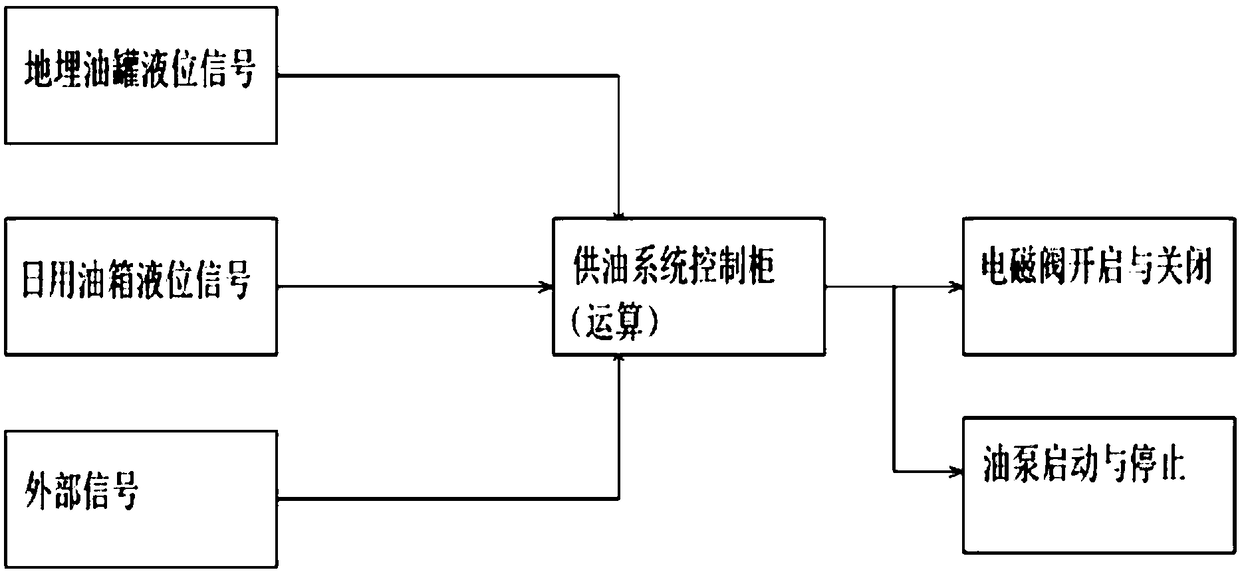

Data center oil supply system of distributed electromagnetic valve integrated oil pump

InactiveCN108798951AWith emergency manual functionEnsure safetyMachines/enginesLiquid fuel feedersData centerFuel tank

The invention provides a data center oil supply system of a distributed electromagnetic valve integrated oil pump. The data center oil supply system comprises multiple diesel generating units, multiple daily oil tanks, a main oil supply standby oil pump, a main oil unloading standby oil pump, a buried oil tank and an oil supply system control cabinet. Each daily oil tank is connected with the corresponding diesel generating unit. One end of the main oil supply standby oil pump is connected with the daily oil tanks through branch pipelines. One end of the main oil unloading standby oil pump isconnected with the daily oil tanks through branch pipelines. One end of the buried oil tank is connected with the main oil supply standby oil pump and the main oil unloading standby oil pump through main pipelines. The oil supply system control cabinet is used for receiving external signals, liquid level signals of the daily oil tanks and liquid level signals of the buried oil tank and sending aninstruction to control the main oil supply standby oil pump and the main oil unloading standby oil pump. The data center oil supply system is simple in structure, small in occupied space, highly integrated, fully automatic and low in investment and maintenance cost, the flexibility of the system is improved, the construction period is short, and the system runs safely and reliably.

Owner:SHANGHAI HENGJIN POWER TECH

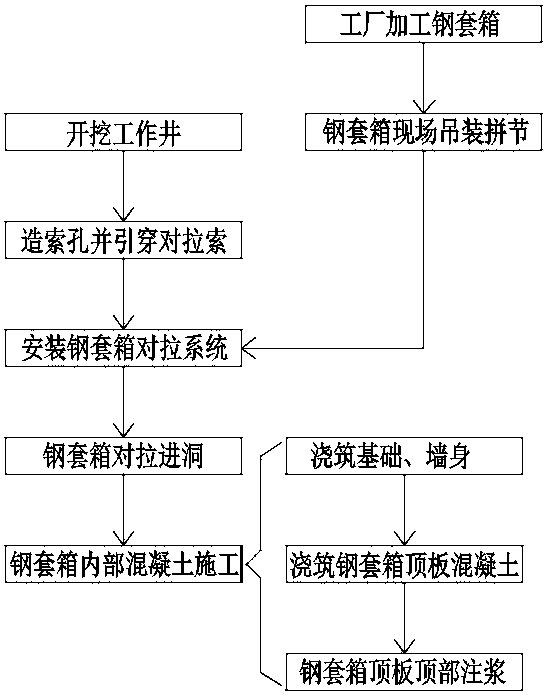

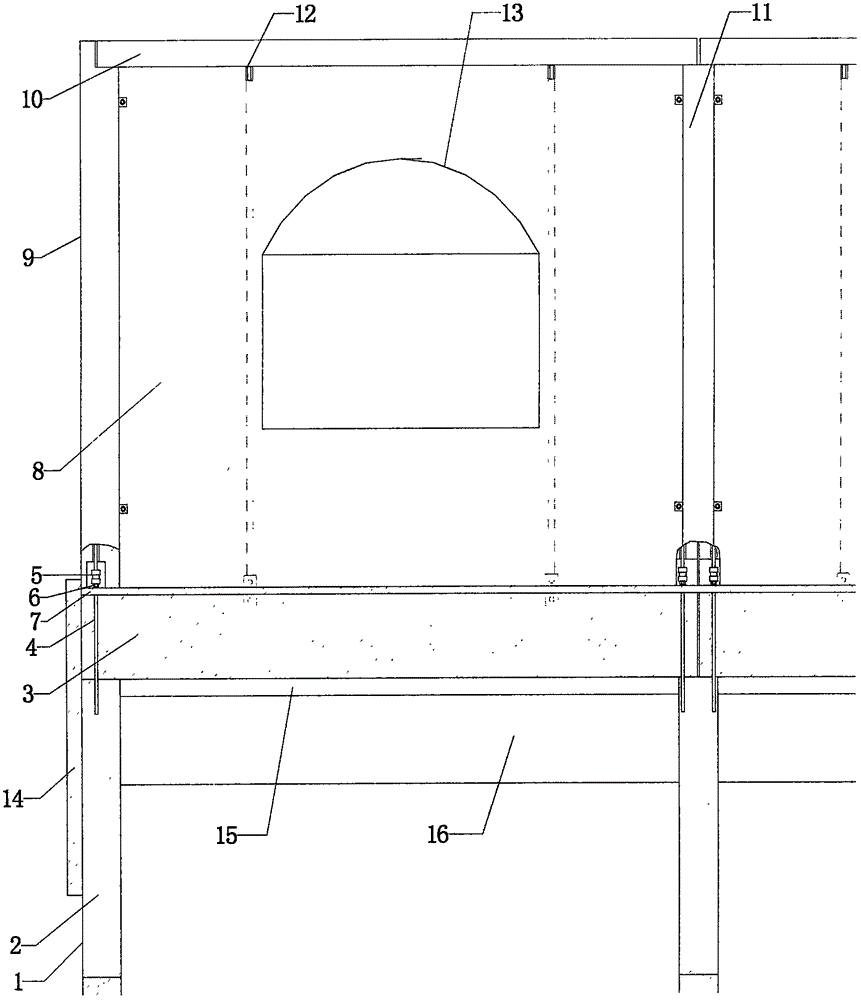

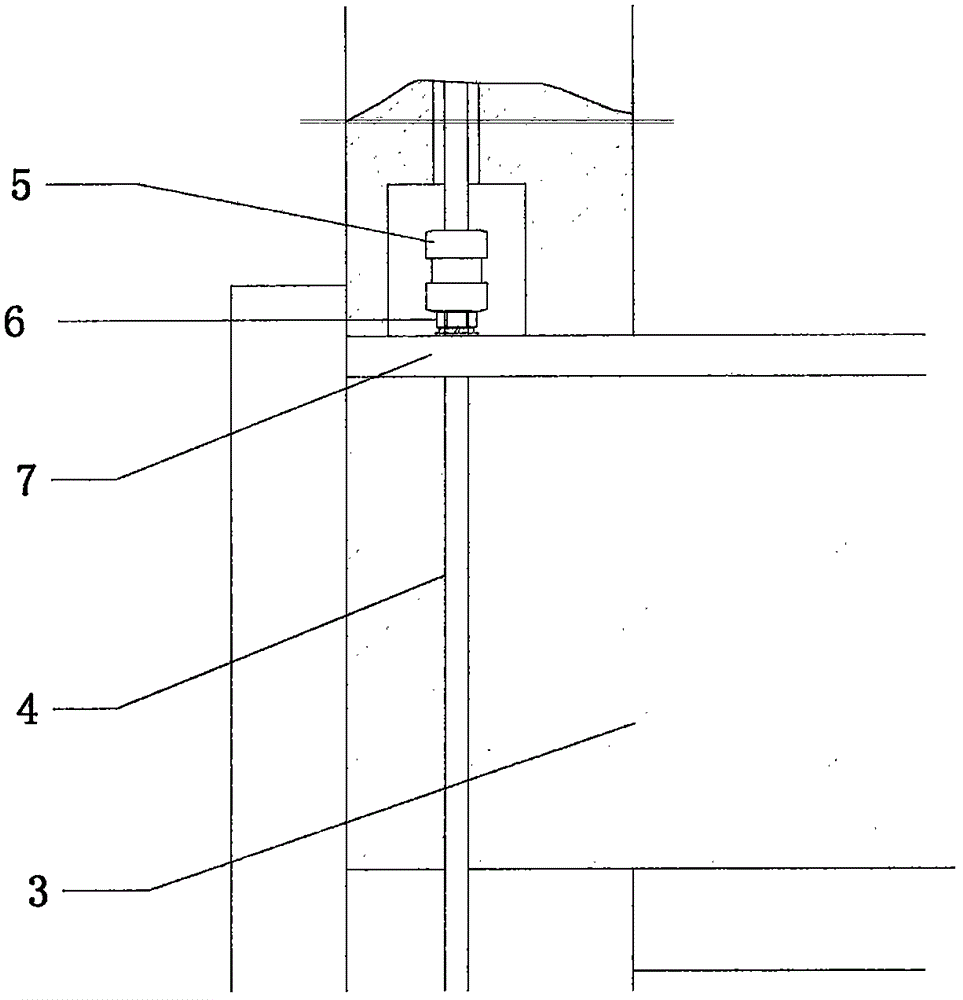

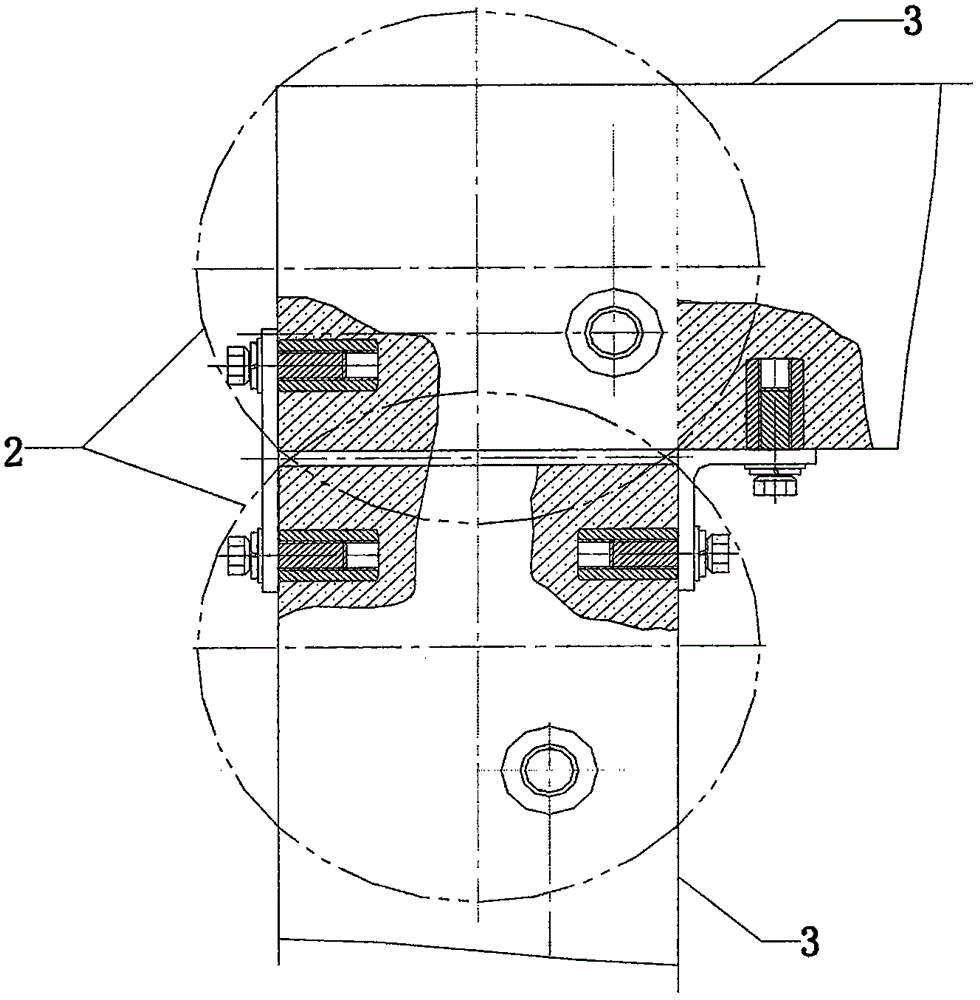

Method for carrying out opposite-pull construction on pipe ditch through steel jacket box

ActiveCN109024669ADense enoughShort construction timeArtificial islandsUnderwater structuresSteel jacketArchitectural engineering

The invention discloses a method for carrying out opposite-pull construction on a pipe ditch through a steel jacket box. Hidden penetration construction of the pipe ditch is completed through the method that an opposite-pull rope and an opposite-pull system cooperate to carrying out opposite-pull jacking on the steel jacket box and then soil is excavated. The method comprises the following steps that A, the opposite-pull rope is lead after a rope hole is formed through a method of arranging a rope hole PE pipe in a coarse hole during headwork; B, the opposite-pull system of the steel jacket box is mounted; C, the steel jacket box enters a hole in an opposite-pull manner; and D, concrete construction in the steel jacket box is carried out. Compared with a traditional pipe ditch constructionmethod, pipe ditch ground construction is carried out by adopting the method for carrying out opposite-pull hidden penetration on the pipe ditch through the steel jacket box, and the method has the advantages of being low in construction cost, ecological, environment-friendly and small in safety rick and not influencing ground facilities are achieved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG

Full-assembly detachable building structure and installation and construction technology

ActiveCN105672479AAvoid it happening againReduce the number of linksBuilding material handlingUltimate tensile strengthFloor plate

The invention discloses a full-assembly detachable building structure and an installation and construction technology, and relates to the field of building structures. The structure comprises a pile foundation hole formed in a foundation, a pile foundation is installed in the pile foundation hole, a foundation beam is installed above the pile foundation, a prefabricated house structure is installed on the foundation beam, and the prefabricated house structure comprises a load bearing gable wall, load bearing front and rear walls, a load bearing partition wall and a floor plate or a roof plate; according to the installation sequence, the load bearing front and back walls are installed, then the load bearing gable wall is installed, then, the load bearing partition wall is installed, and the floor plate or the roof plate is installed. The body building components of the full-assembly detachable building structure can be industrialized produced, a building can be detached and recycled, the labor intensity is lowered, the building construction speed is increased, the cost is lowered, the intensity of the house is ensured, and energy conservation and environmental protection are achieved while it is ensured that the intensity of the house achieves the anti-seismic performance.

Owner:黑龙江高格建筑科技产业(集团)有限公司

Slurry filling device for tunnel pipe

ActiveCN103061784AMake sure it doesn't leakShorten cycle timeUnderground chambersTunnel liningEngineeringSlurry

The invention discloses a slurry filling device for a tunnel pipe. The slurry filling device comprises a slurry filling pipe of a tunnel and is characterized by further comprising a slurry pressing device and a connection device. The slurry pressing device is composed of a round connection pipe, a fixing member, a sealing ring and a hinge mechanism, wherein the round connection pipe is composed of two semi-round pipes, the sealing ring is arranged in the round connection pipe, one end of the round connection pipe is connected with the slurry filling pipe of the tunnel, the other end of the round connection pipe is connected with the connection device communicated with a slurry filling pump, and the fixing member for fastening the round connection pipe and the hinge mechanism for opening and closing the round connection pipe are connected onto the outer wall of the round connection pipe, and the fixing member and the hinge mechanism are oppositely arranged. The slurry filling device ensures that the slurry cannot be leaked during filling, simultaneously can achieve continuous and intermittent slurry filling, is good in slurry filling reinforcing effect, greatly reduces the cycling time of slurry filling operation, is high in working efficiency, simultaneously shortens the time for slurry filling of surrounding rocks, is easy and convenient to operate, does not need welding operation at site, performs binding reinforcing operation through iron wires manually, is low in labor intensity and easy to process and manufacture, can be utilized fully and repeatedly and saves materials.

Owner:中铁二十二局集团第四工程有限公司 +2

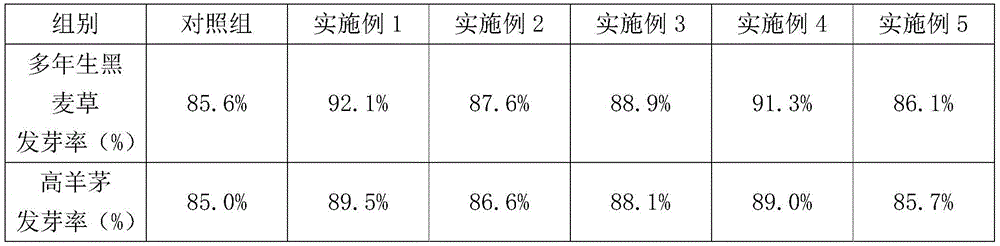

Method for preventing pipeline from being blocked by too-wet dressing soil in slope dressing soil dry-spraying operation

ActiveCN105484273AAvoid clogging pipesGuaranteed greening effectClimate change adaptationAfforestationVegetable matterSoil science

The invention discloses a method for preventing a pipeline from being blocked by too-wet dressing soil in slope dressing soil dry-spraying operation. The method includes the following steps that firstly, improved dressing soil is prepared, wherein a sand material and vegetable matter are added to the water-contained dressing soil to be stirred and evenly mixed; and secondly, the improved dressing soil is sprayed to a mountain slope beside a road through a dressing soil dry-spraying process. By the adoption of the method, a dressing soil ratio improving method is adopted, bonded particles are effectively scattered, the matrix wall bonding phenomenon is effectively avoided, viscosity is reduced, and the aggregation phenomenon is reduced; the wall bonding phenomenon is reduced; and the pipeline blocking phenomenon generated in dry-spraying operation can be effectively prevented, smooth construction is guaranteed, waste is used, cost is reduced, the soil is evenly sprayed to the slope face of the slope, the construction progress is guaranteed, and the afforesting effect of the slope can be guaranteed.

Owner:TIANJIN RES INST OF BUILDING SCI

Multifunctional connecting device for tunnel escape pipeline

PendingCN110259505AEasy to moveShorten the construction scheduleSafety equipmentsRailway tunnelFunctional connectivity

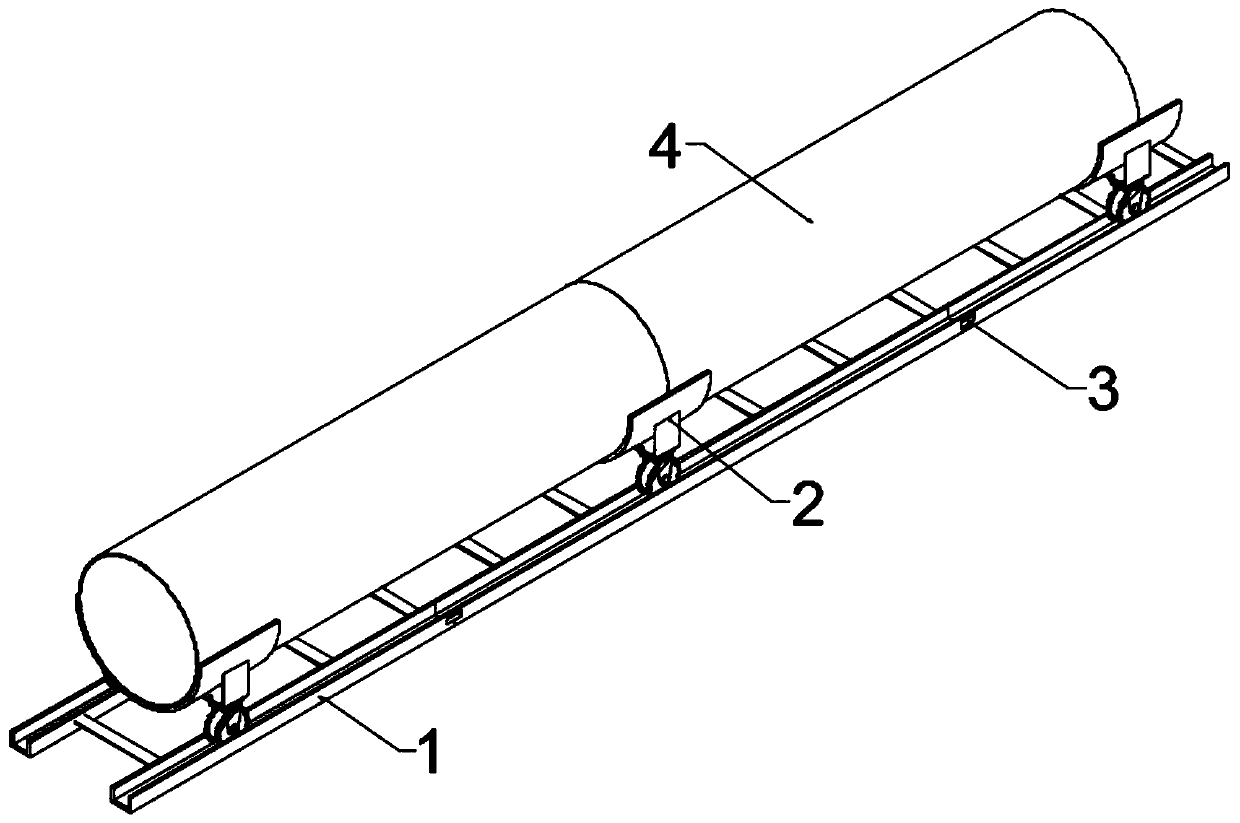

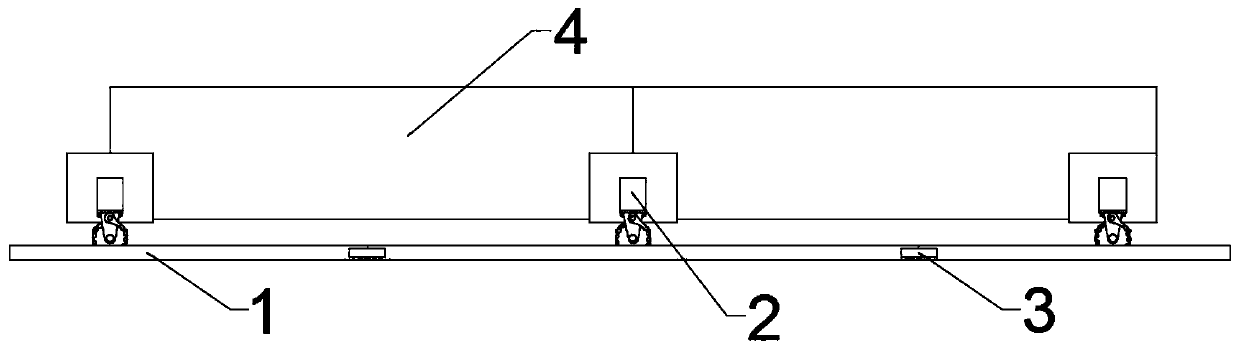

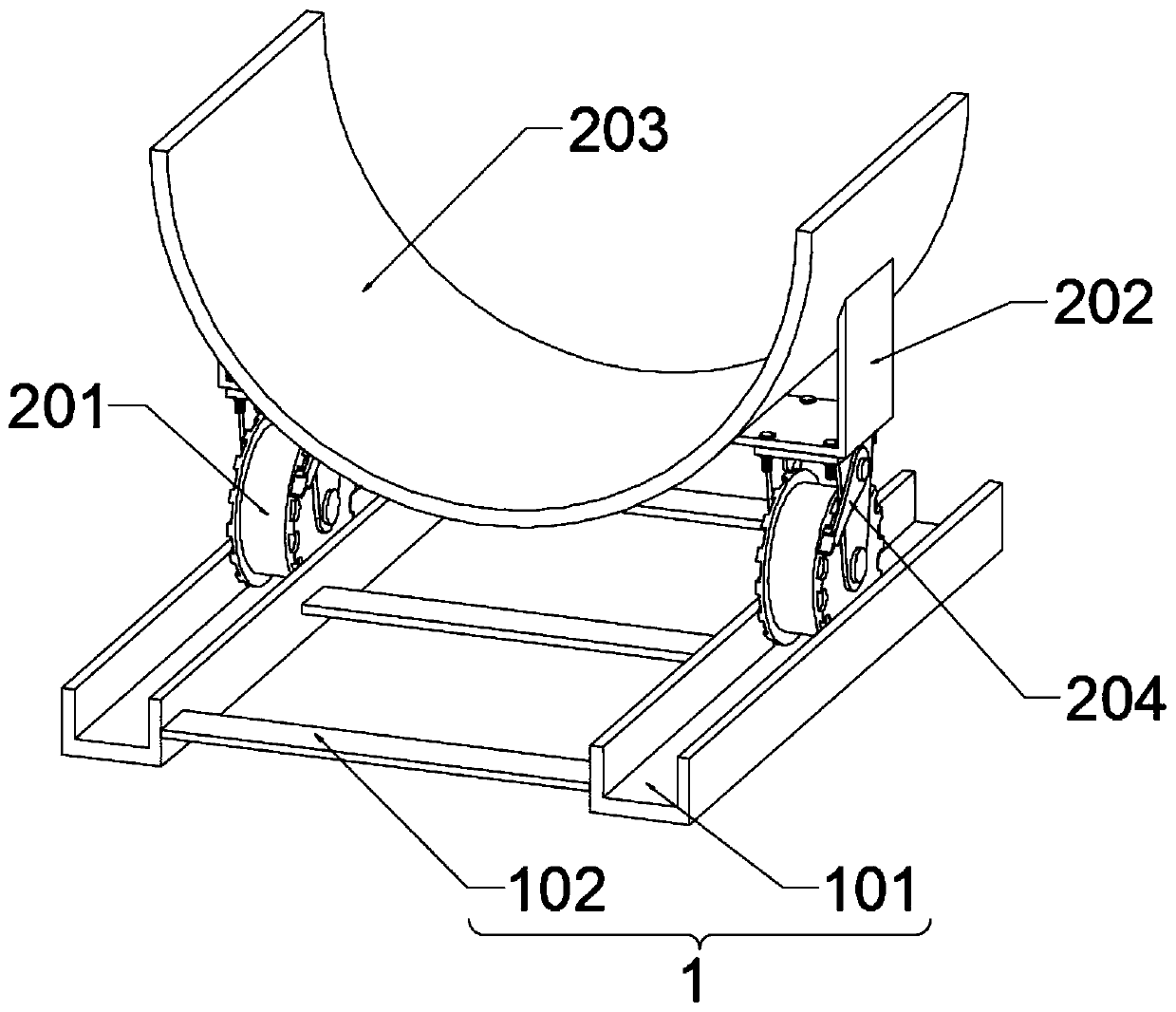

The invention relates to the technical field of highway and railway tunnel safety construction, and discloses a multifunctional connection device for a tunnel escape pipeline, whichcomprises a track assembly, the track assembly is provided with a matching mobile connection assembly, the mobile connection assembly is provided with a parking part,the mobile connection assembly comprises moving parts matched with the track assembly, each of the two or more moving parts is detachably connected with a supporting part, and the supporting part is provided with a pipeline connecting part; and the pipeline connecting part is provided with an escape pipeline unit section, a pipeline connection part is of an arc-shaped structure, and the escape pipeline unit section is a circular pipe and exactly arranged in the pipeline connecting part. The device is to solve the problem of the advancing movement of the escape pipe inside the tunnel, and the connection problem between the escape pipeline unit sections is also solved, thus laying and moving of the escape pipeline are easy and quick, and the tunnel construction efficiency is greatly improved.

Owner:杭州中筑交通科技有限公司

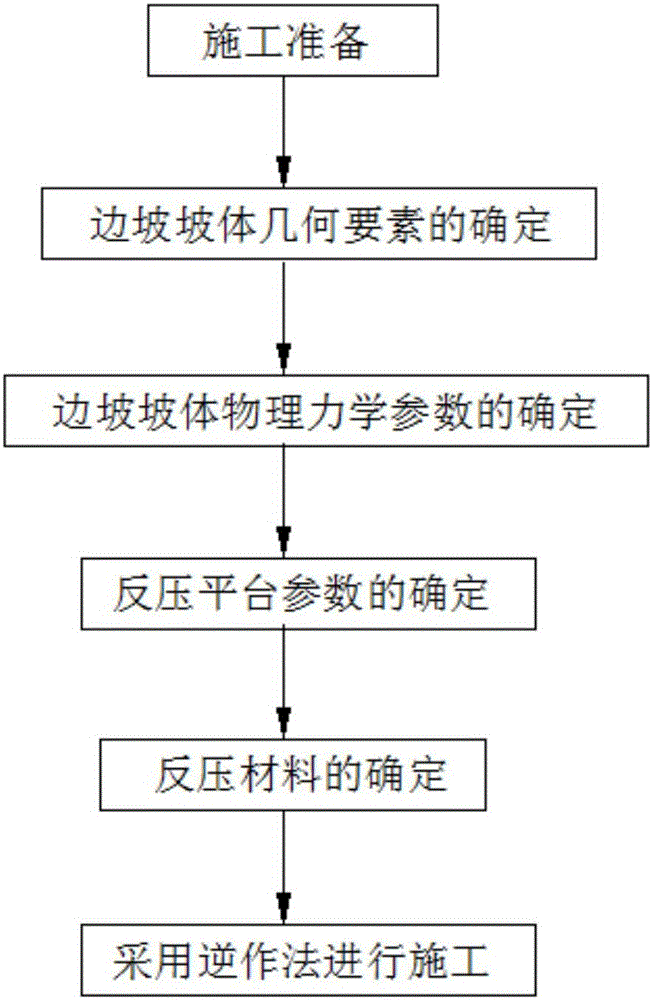

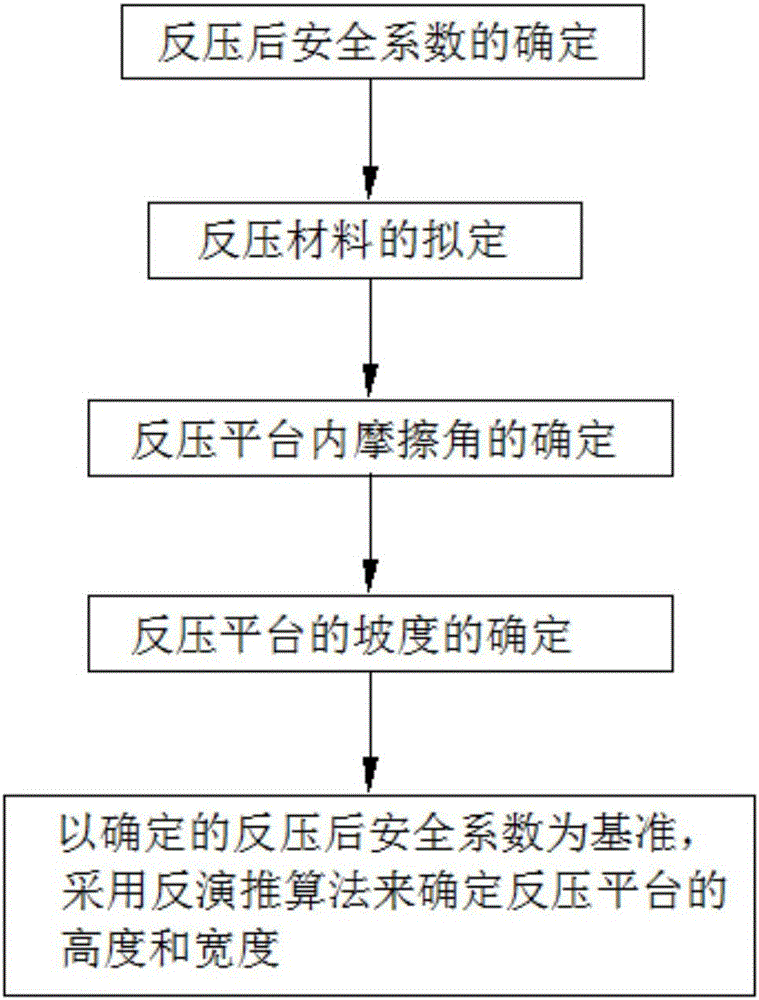

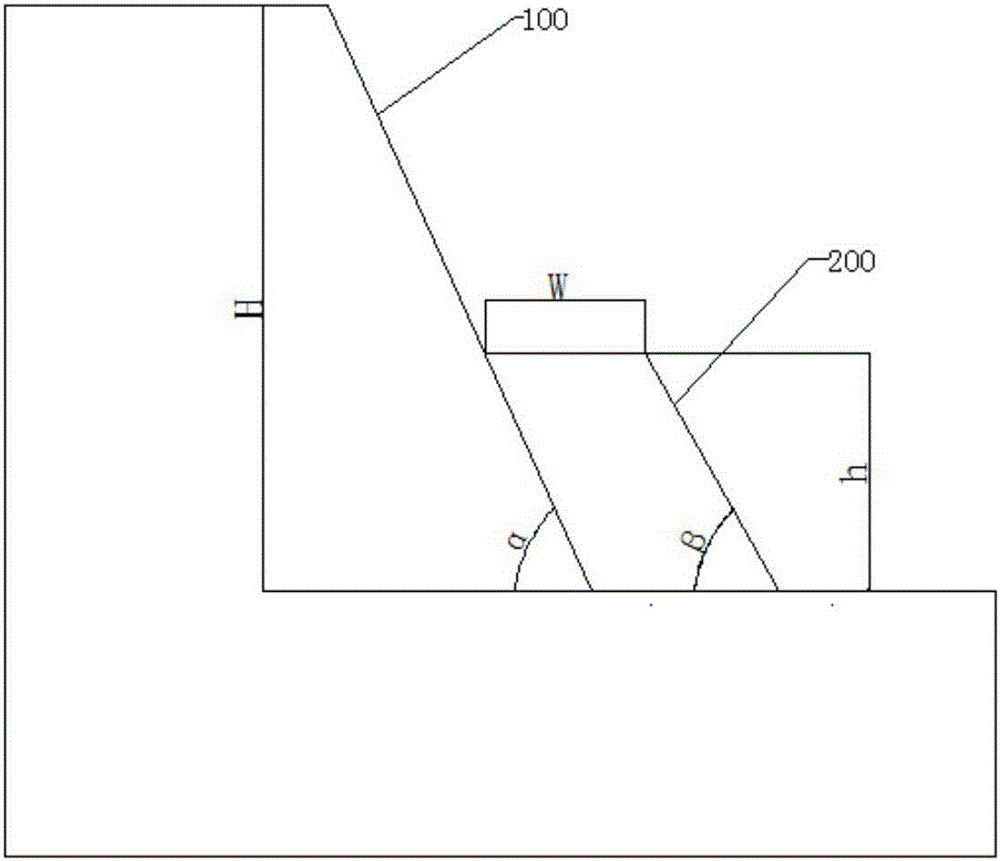

Side slope rescuing counter pressure adverse construction method and structure thereof

ActiveCN106436785AHigh stability factorIncrease frictionFoundation testingExcavationsCounter pressureEngineering

The invention relates to the technical field of side slope stability prevention and treatment research and relates to a side slope rescuing counter pressure adverse construction method and a structure thereof. The side slope rescuing counter pressure adverse construction method comprises the following steps that 1, side slope body geometric elements are determined, and side slope body physical and mechanics parameters are determined; 2, counter pressure platform parameters are determined, and counter pressure materials are determined; and 3, an adverse method is adopted for carrying out construction. The side slope rescuing counter pressure adverse construction method has the beneficial effects of being convenient in construction, fast, safe, low in cost, small in disturbance to a slope body and the like. Moreover, the method can be applied to filling embankments of highways and railways, water conservancy embankment projects, soft soil foundation pit projects and various side slope rescuing projects.

Owner:重庆市高新工程勘察设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com