Method for carrying out opposite-pull construction on pipe ditch through steel jacket box

A steel-jacketed box and pipe trench technology, which is used in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of large excavation area, high manufacturing cost of concrete boxes, and large disturbance of the upper soil layer. , to achieve the effect of low construction cost, easy guarantee of construction period, and reduced risk of settlement and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

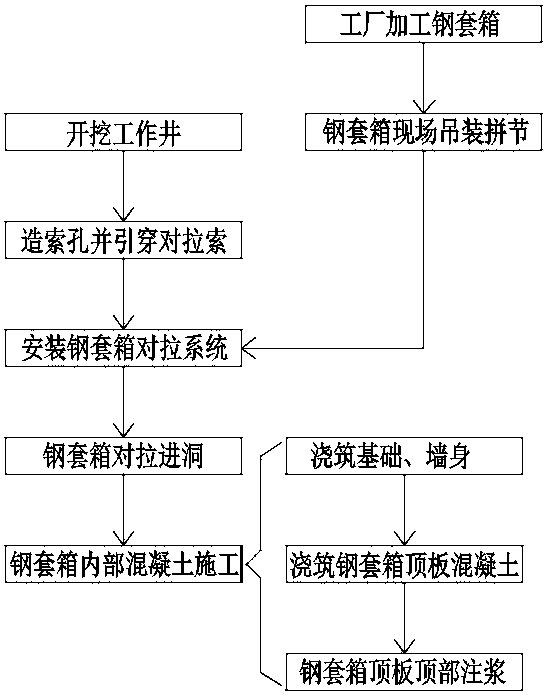

[0053] A method for constructing pipe trenches by pulling steel casings against each other, such as figure 1 shown, including the following steps:

[0054] Step A. In the excavation work, use the cable hole PE pipe method in the coarse hole to make the cable hole and lead through the pair of cables;

[0055] Step B. Install the steel box pull system;

[0056] Step C. The pair of steel casings is pulled into the hole;

[0057] Step D. Concrete construction inside the steel casing.

[0058] The invention adopts non-excavation directional drilling machine to carry out long-distance drilling, and adopts the cable hole construction method of "cloth cable hole PE pipe in the thick hole" to compensate the drilling error, and uses the positioning cable to locate the cable hole PE pipe; The casing is used as a support, and the jack in the continuous pulling system is used to pull the two-way steel casing and cover it across the section. After the steel casing is penetrated, it is pl...

Embodiment 2

[0060] This embodiment is further optimized on the basis of Embodiment 1, and the step A includes the following steps:

[0061] Step A1. Place and fix the steel hoop on the end face of the hole, carry out cable hole position measurement and setting out, and drill hole measurement control point layout, and use a horizontal directional drilling machine with a guiding accuracy greater than 150mm to drill rough holes and expand the rough holes in turn To 30cm aperture and 40cm aperture, clean the hole after reaming;

[0062] Step A2. The horizontal directional drilling rig drags the cable hole PE pipe into the coarse hole and installs the tension beam and the tension seat on the steel hoops at both ends of the coarse hole. First stretch the upper two positioning cables, and then stretch the lower two positioning cables to locate the PE pipe in the cable hole;

[0063] Step A3. Pour cement soil slurry mixed with retarder in the area between the cable hole PE pipe and the coarse ho...

Embodiment 3

[0093] This embodiment is further optimized on the basis of embodiment 1 or embodiment 2. The present invention also includes step Z of pre-reinforcing and excavating around the working well before step A, and step Z includes the following steps :

[0094] Step Z1. Arrange 10 restraint piles with a pile diameter of 1.5m×2m around the excavation area of the working shaft and pour concrete. The restraint pile layout method is to arrange 3 restraint piles on both sides parallel to the axis of the pipe trench, and vertical to the axis of the pipe trench. Two restraint piles are arranged on both sides of the direction; the construction of the ring beam at the top of the working well is carried out after the concrete strength of the restraint pile reaches the standard; the excavation of the working well is carried out after the strength of the ring beam at the top reaches the standard;

[0095] Step Z2. The internal dimensions of the excavated working well are 8m in length, 8m in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com