Split mounting type building

A prefabricated and housing technology, applied to building components, walls, buildings, etc., can solve the problems of large cement consumption, slow construction progress, waste of building resources, etc., and achieve the effect of reducing usage, increasing strength, and good air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

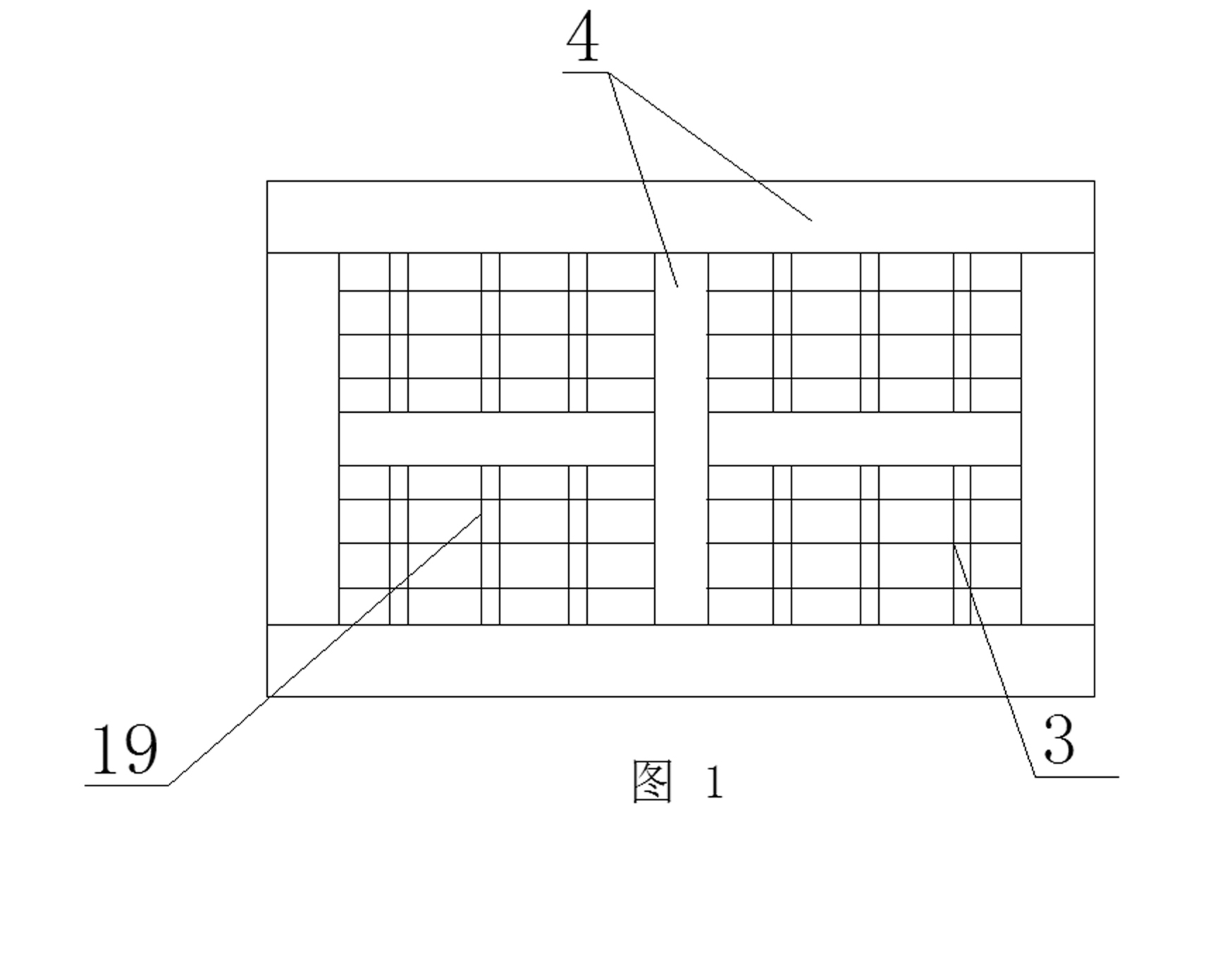

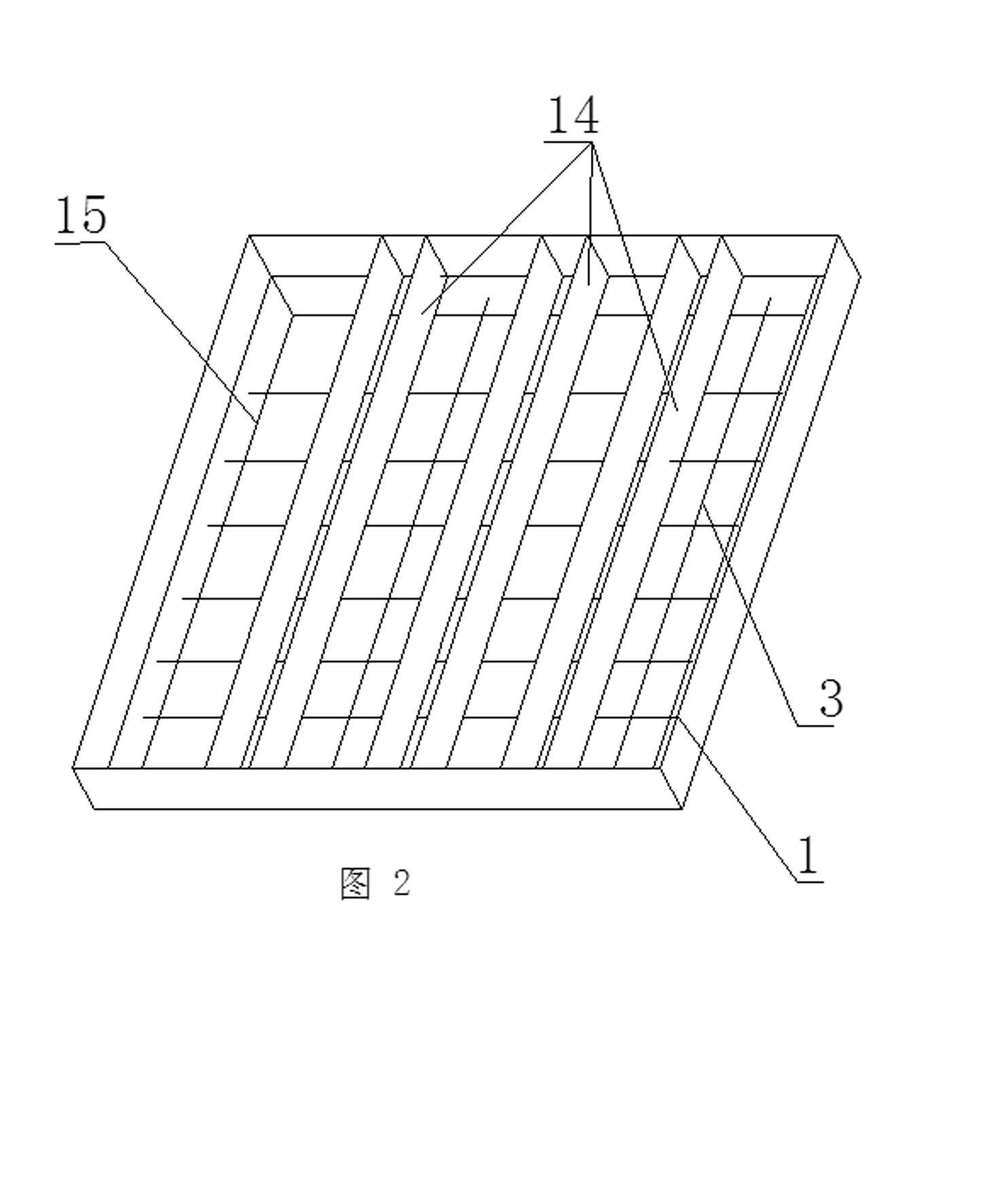

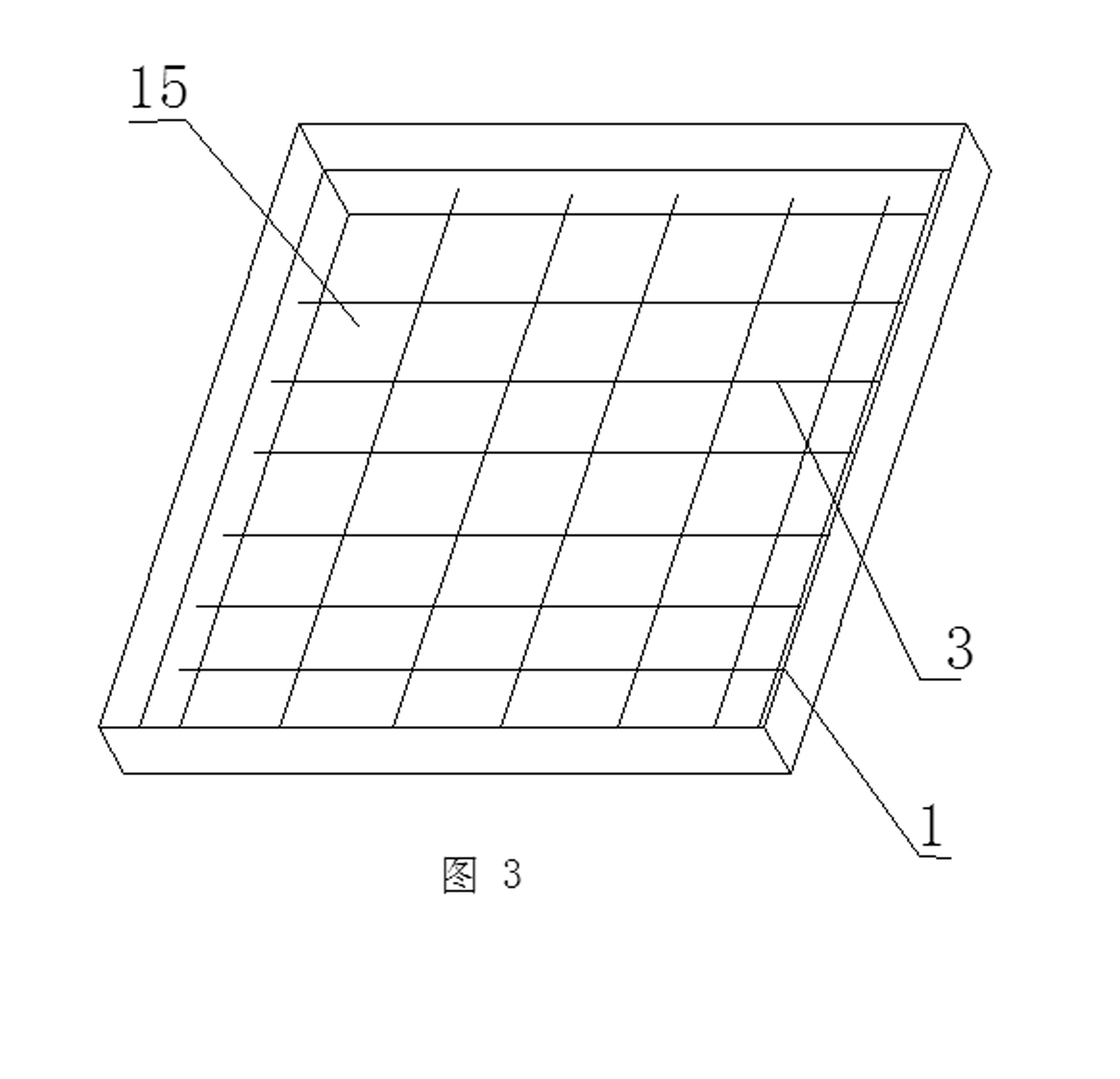

[0033] As shown in Figures 8 to 9: the present invention is a building structure group formed by horizontal and vertical connections of several frame structures.

[0034] It includes frame structure A and frame structure B, and the structures of frame structure A and frame structure B are as follows:

[0035] Such as Figure 1~7 Shown: frame structure A: it includes an upper base plate 11, a lower base plate 12 and a supporting angle steel 13, the upper base plate is a square frame structure 15 formed by welding four angle steels 1, wherein the angle steel used to form the frame structure can be adopted Channel steel, T-shaped steel or I-beam with higher strength are replaced, the side of the angle steel faces the outside of the square frame structure, the bottom edge is on the inside of the square frame structure, and the square frame structure is provided with horizontally or vertically distributed supporting channel steel 14, Since the upper floor needs to bear part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com