Slurry filling device for tunnel pipe

A grouting device and tunnel technology, applied in tunnels, tunnel linings, shaft equipment and other directions, can solve the problems of potential safety hazards, low work efficiency, troublesome removal, etc. Good effect of slurry reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

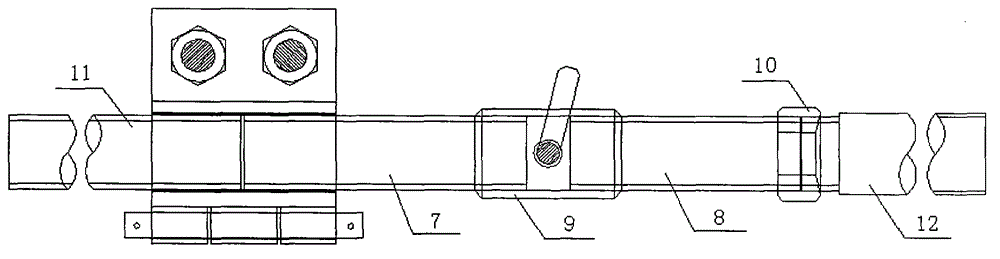

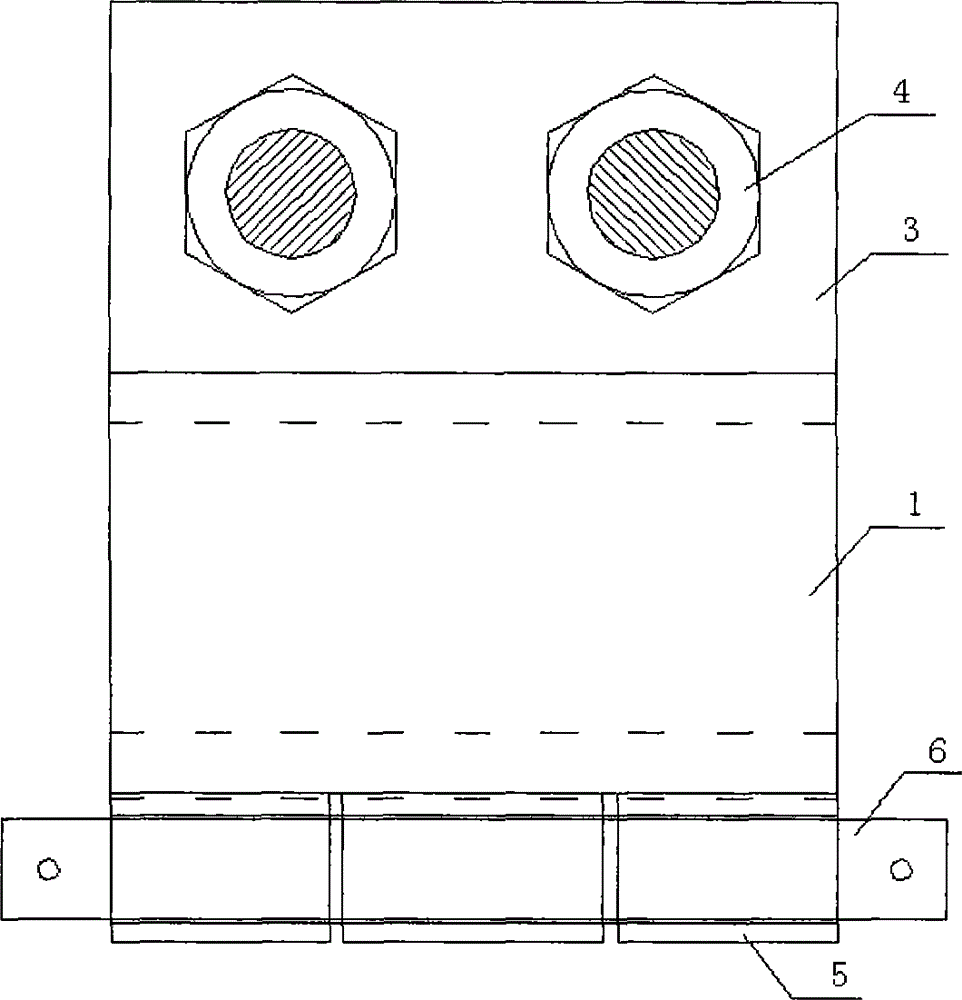

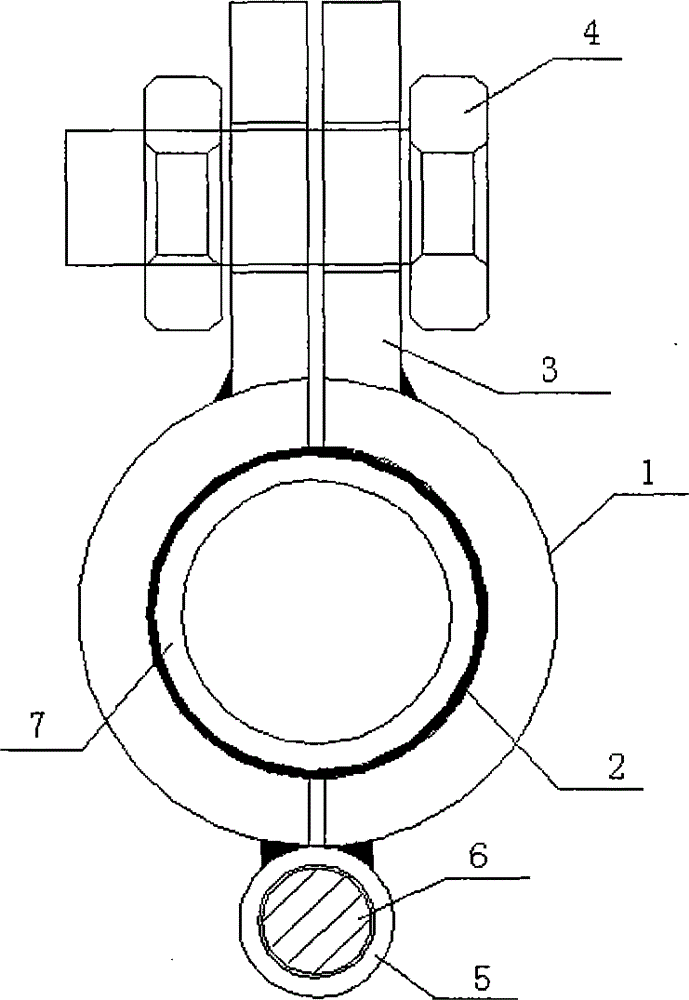

[0019] Figure 1-3 As shown, a tunnel conduit grouting device, including a tunnel grouting conduit, is characterized in that: it also includes a grouting device and a connecting device; the grouting device is composed of a round joint, a fixing piece, a sealing ring and a loose-leaf mechanism, The circular connecting pipe is composed of two semicircular pipes, a sealing ring is set in the circular connecting pipe, one end of the circular connecting pipe is connected to the tunnel grouting conduit, and the other end is connected to a connecting device communicated with the grouting pump, and the outer wall of the circular connecting pipe is connected with a The fixing piece for fastening the round joint and the loose-leaf mechanism for opening and closing the round joint, the fixing piece and the loose-leaf mechanism are arranged oppositely.

[0020] The circular connecting pipe is made of a steel pipe, which is cut and divided into two halves, and each section is ground off by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com