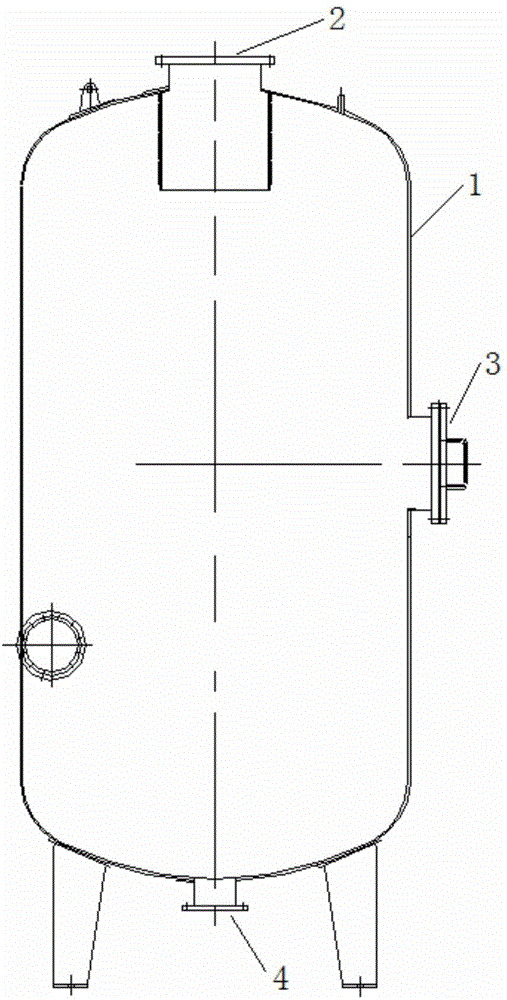

Low-pressure and low-noise steam drain water expander

A water-repellent expander and low-noise technology, which is applied in boiler cleaning devices and other directions, can solve problems such as high working pressure, high noise of steam-drain expander, and poor cooling effect, and achieve low cost, simple structure, and easy processing and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

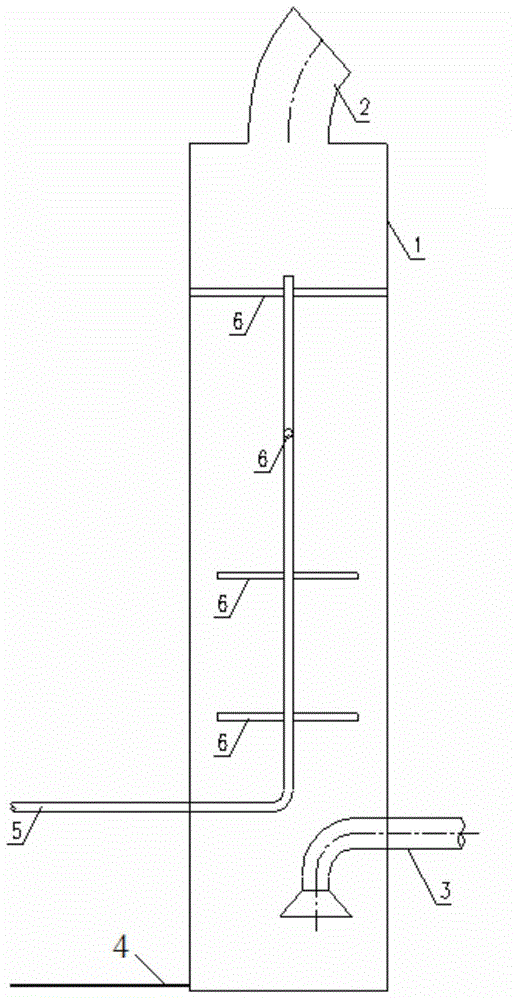

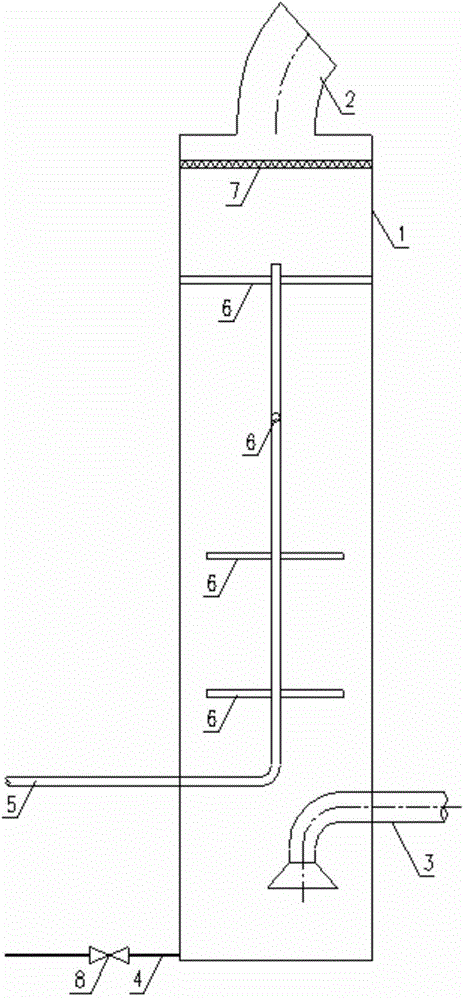

Embodiment 1

[0069] Such as figure 2 , a low-pressure, low-noise steam trap expander, comprising a vertical cylinder 1, the height of the vertical cylinder is 4m, the top of the cylinder 1 is provided with an exhaust pipe 2, and the exhaust pipe 2 is welded on the cylinder 1, And the exhaust pipe 2 communicates with the inside of the cylinder body 1, the bottom of the cylinder body 1 is provided with a drain inlet pipe 3, and the bottom of the cylinder body 1 is provided with a drain pipe 4. The warm water pipe 5 is located between the exhaust pipe 2 and the drain inlet pipe 3, and the desuperheating water pipe 5 is provided with a water spray pipe 6, and the desuperheating water pipe 5 communicates with the water spray pipe 6. The desuperheating water pipe 5 is arranged along the axial direction of the cylinder body 1 , and the water spray pipe 6 is arranged perpendicular to the desuperheating water pipe 5 . Four water spray pipes 6 are arranged on the desuperheating water pipe, and the...

Embodiment 2

[0071] Repeat embodiment 1, except that the number of water spray pipes 6 is 6.

Embodiment 3

[0073] Repeat embodiment 1, but the quantity of spray pipe 6 is 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com