Ground direct-drive screw pump oil extracting device

A technology of oil production device and screw pump, which is applied in the direction of pump, earthwork drilling, pump with flexible working elements, etc. Wide range, good sealing effect, and the effect of reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

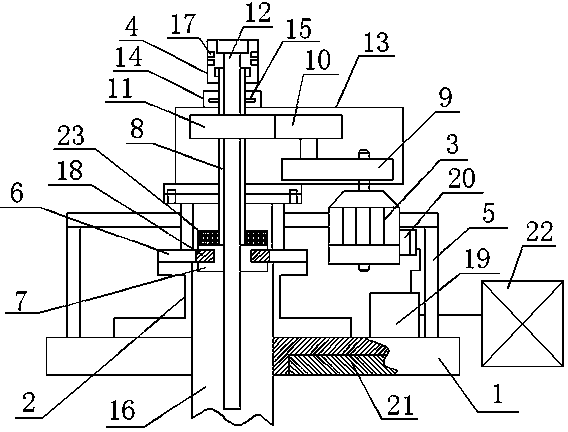

[0011] refer to figure 1 The shown ground direct-drive screw pump oil extraction device includes a base 1, a load-bearing frame 2, a driving device 3 and a sealing connection sleeve 4. The load-bearing frame 2 is installed on the base 1, and the base 1 is provided with a The frame 5 of the load-bearing frame 2, the load-bearing frame 2 is provided with a sealer 6, the sealer 6 is provided with a sealing sleeve 7, the load-bearing frame 2 is provided with a rotating shaft 8, and the driving device 3 is installed on the frame 5, the output end of the driving device 3 is connected with a gearbox 9, the output end of the gearbox 9 is connected with a driving gear 10, and the rotating shaft 8 is provided with a Given the driven gear 11, a polished rod 12 runs through the rotating shaft 8, a protective cover 13 is provided on the load-bearing frame 2, a code disc shell 14 is provided above the protective cover 13, and a code disc shell 14 is provided inside the code disc shell 14 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com