Device for cooling electronic element by utilizing bionic alveolar heat exchanger

A technology of electronic components and heat exchangers, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating renovation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

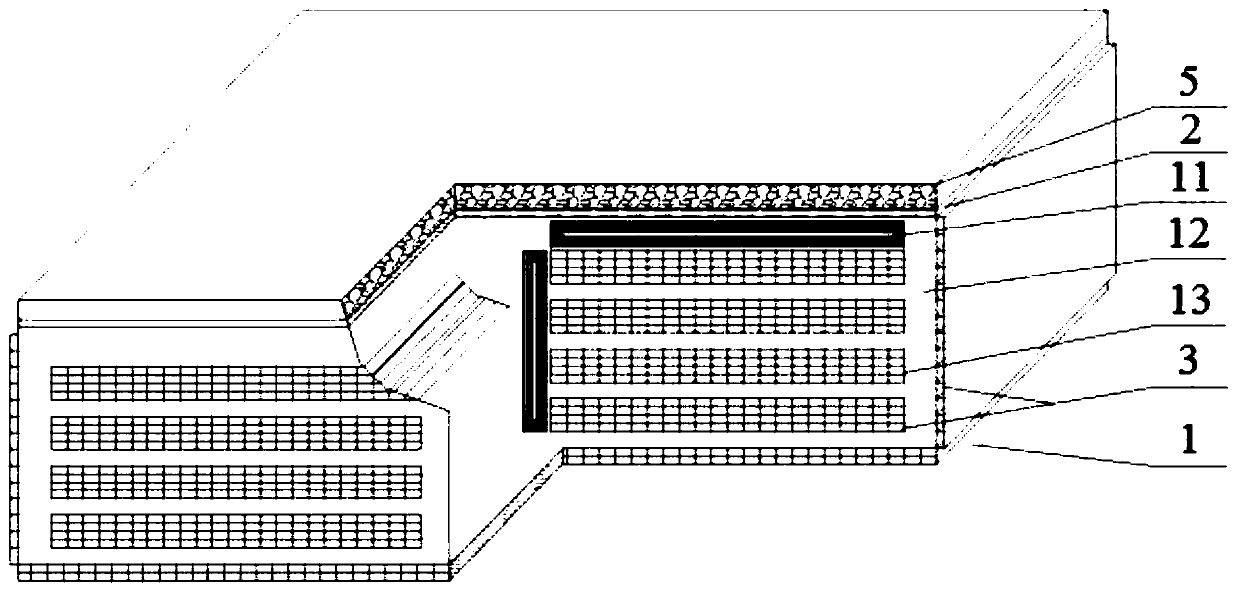

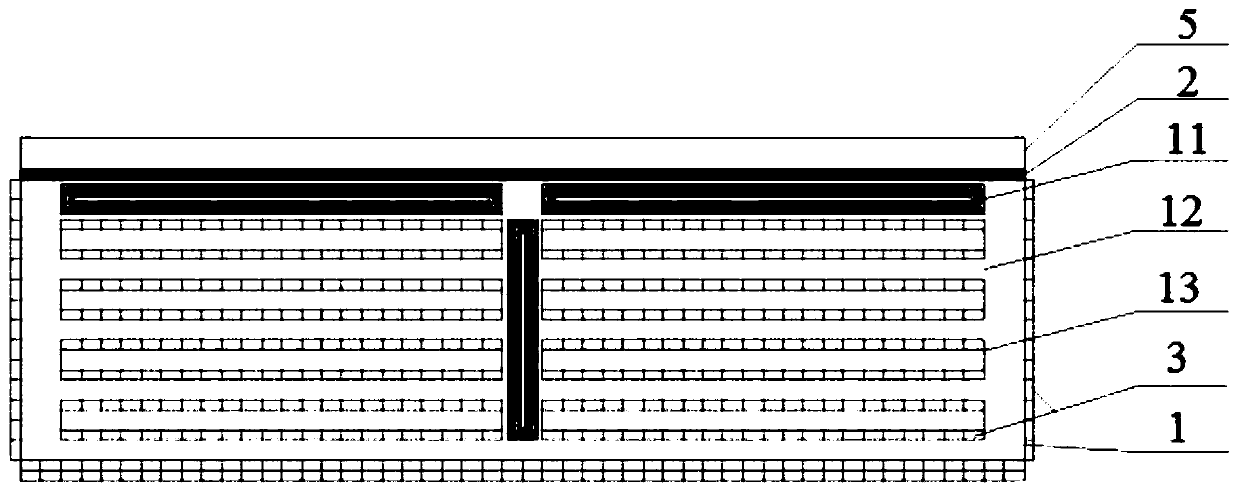

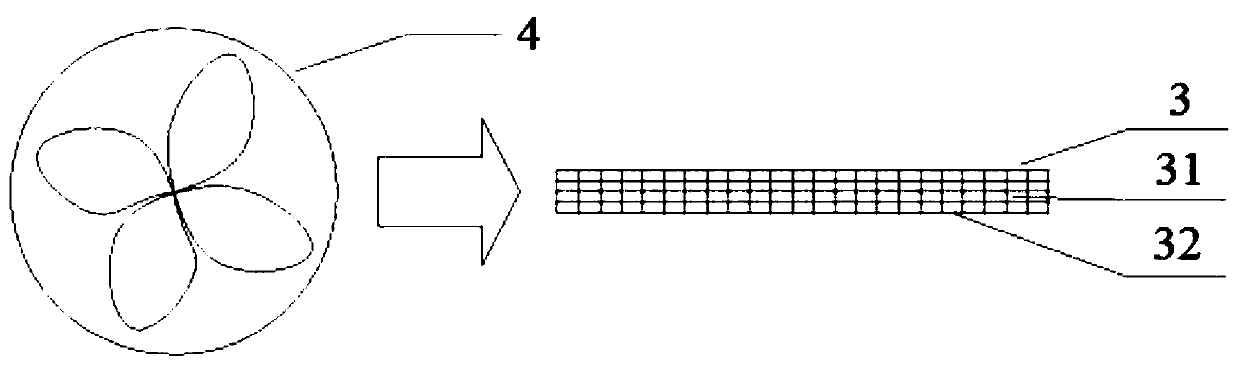

[0018] figure 1 It is a three-dimensional schematic diagram of a device for dissipating heat from electronic components using a bionic alveolar heat exchanger in an embodiment of the present invention, figure 2 It is a front view of a device for dissipating heat from electronic components using a bionic alveolar heat exchanger in an embodiment of the present invention.

[0019] Such as figure 1 with figure 2 As shown, a device for dissipating heat from electronic components using a bionic alveolar heat exchanger in this embodiment is a box for dissipating heat from electronic components 5. In addition to electronic components in the usual sense, the electronic components 5 also include microelectronic components. The components include: a bionic alveolar heat exchanger 1 and a cooling device 4 .

[0020] The bionic alveolar heat exchanger 1 is fixed on the electronic component 5 through the heat conduction fixture 2, and is used to absorb the heat generated by the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com