Copper conductor welding machine and welding technology thereof

A technology of copper wire and welding machine, applied in the direction of welding/welding/cutting items, welding equipment, welding equipment, etc., can solve the problems of false welding and false welding, and achieve the effect of simple and convenient operation, high efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

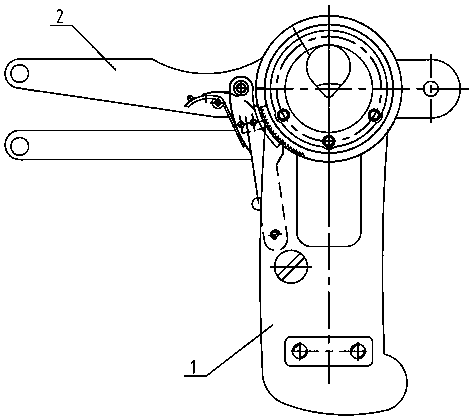

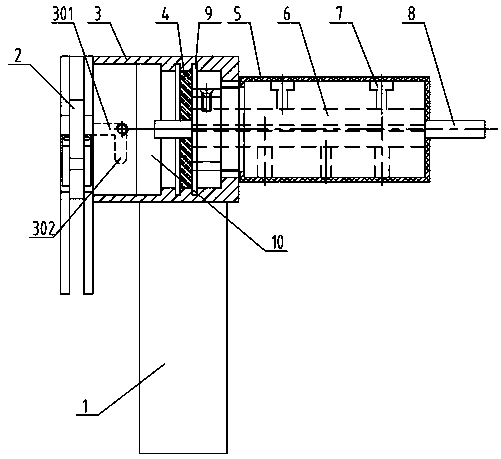

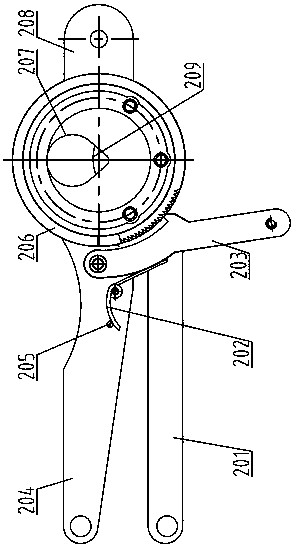

[0036] Such as Figure 1-Figure 7 As shown, the copper wire welding machine includes welding clamps and an electrical control system.

[0037] Wherein, the welding pliers includes a handle part 1, an outer cover 3 connected to the top of the handle part 1, a clamping part 2 connected to one end of the outer cover 3, an insulating sleeve 5 connected to the other end of the outer cover 3, and a Carbon rod clamp 6, the slip ring 4 which is arranged in the outer cover 3 and has a carbon rod insertion hole in the middle; the clamping part 2 includes front and rear ratchets 206, 212, and clamped front and rear ratchets 206, The dynamic and constant pressure rods 204, 201 between 212, the ratchet 203 that is hinged on the side of the dynamic pressure rod 204 and the ratchet, the torsion spring assembly that is used to drive the ratchet 203 on the side of the dynamic pressure rod 204, and the front The front end of the ratchet wheel 206 is connected to the fixed cylindrical joint 210...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com