Pipe joint butt joint and guide device

A technology for guiding devices and pipe joints, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as pipe joint displacement, achieve fast docking, improve construction quality, and reduce collision intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

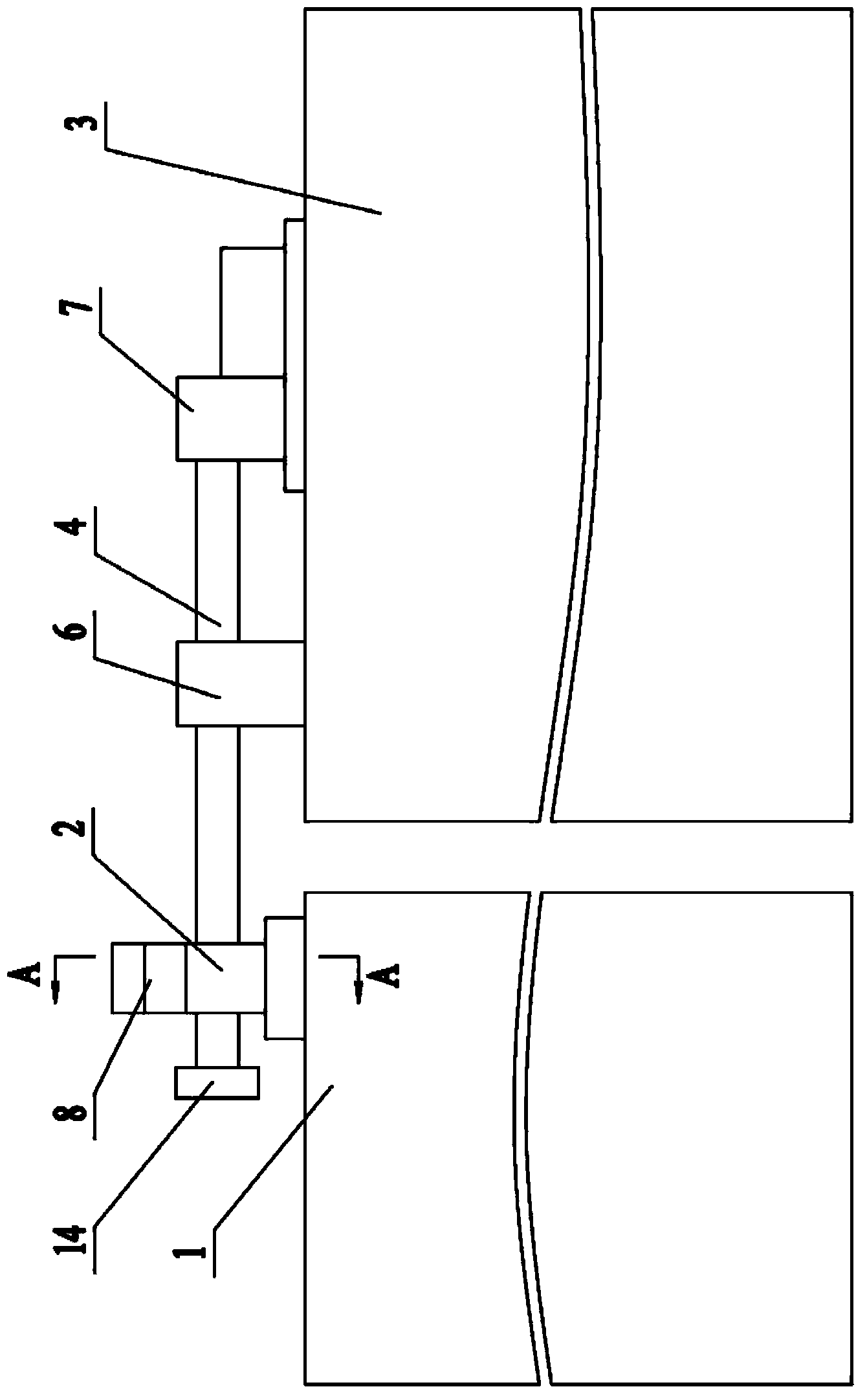

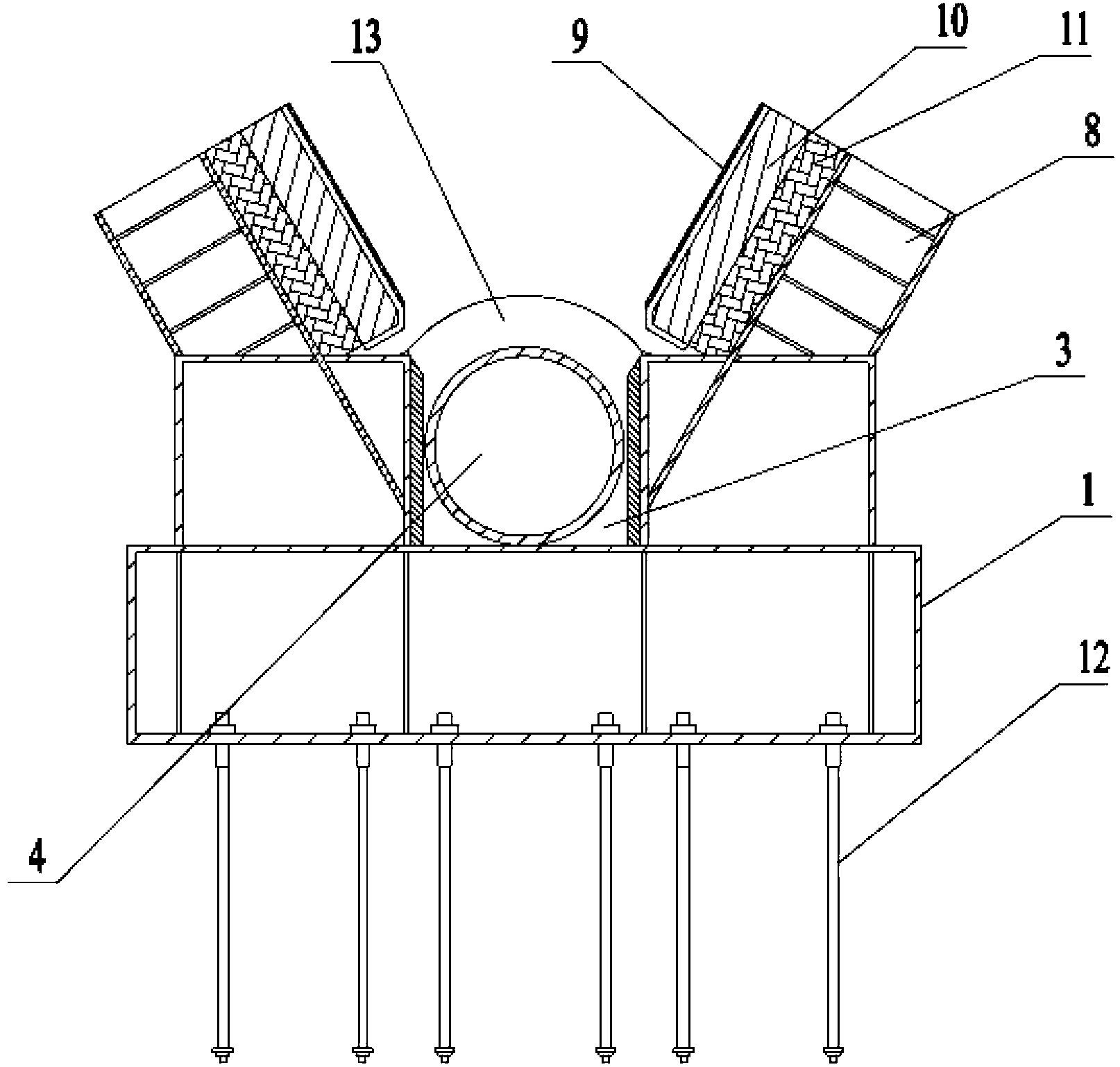

[0021] see figure 1 , figure 2 As shown, a pipe joint butt joint guide device of the present invention includes a guide frame 2 connected with the installed pipe joint 1 and a guide rod 4 connected with the pipe joint 3 to be installed; the guide frame is provided with a guide groove 5. The guide groove is used to accommodate the guide rod; the guide rod is detachably connected to the pipe joint to be installed through the guide rod front support 6 and the guide rod rear support 7; the guide frame and the installed pipe The joints are detachably connected; the guide rod is arranged at the butt end of the pipe joint to be installed, and is arranged along the axial direction of the pipe joint to be installed. The frame is arranged at the tail end of the installed pipe joint; in this embodiment, the distance between the front end of the guide rod and the butt end face of the pipe joint to be installed is at least 3200 mm; the rear end of the guide rod is connected with the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com