Patents

Literature

49results about How to "Avoid construction difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

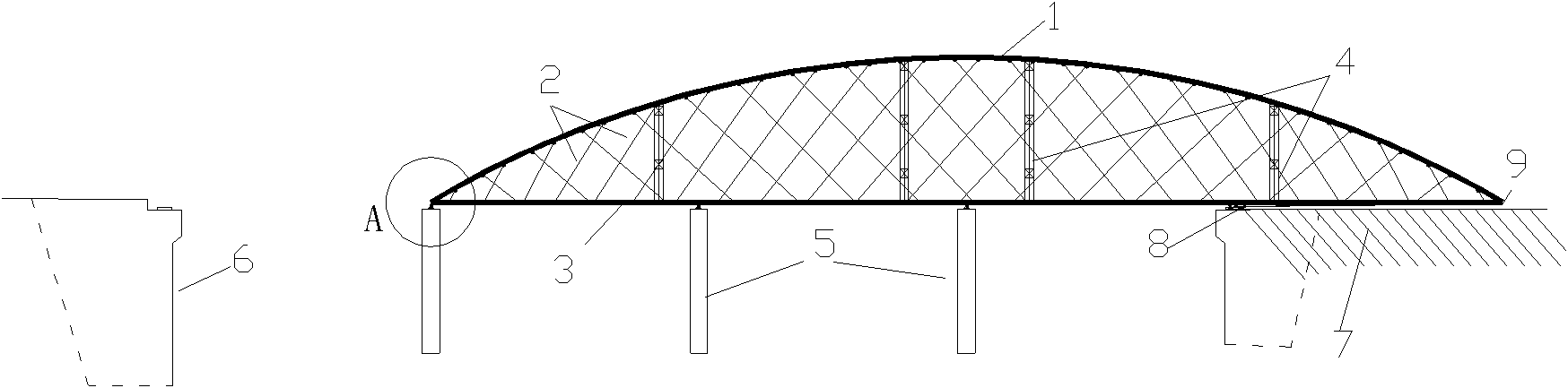

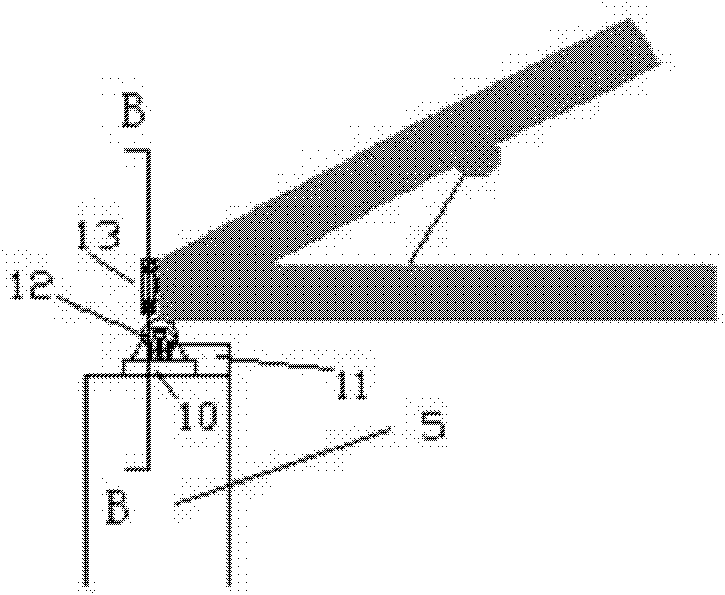

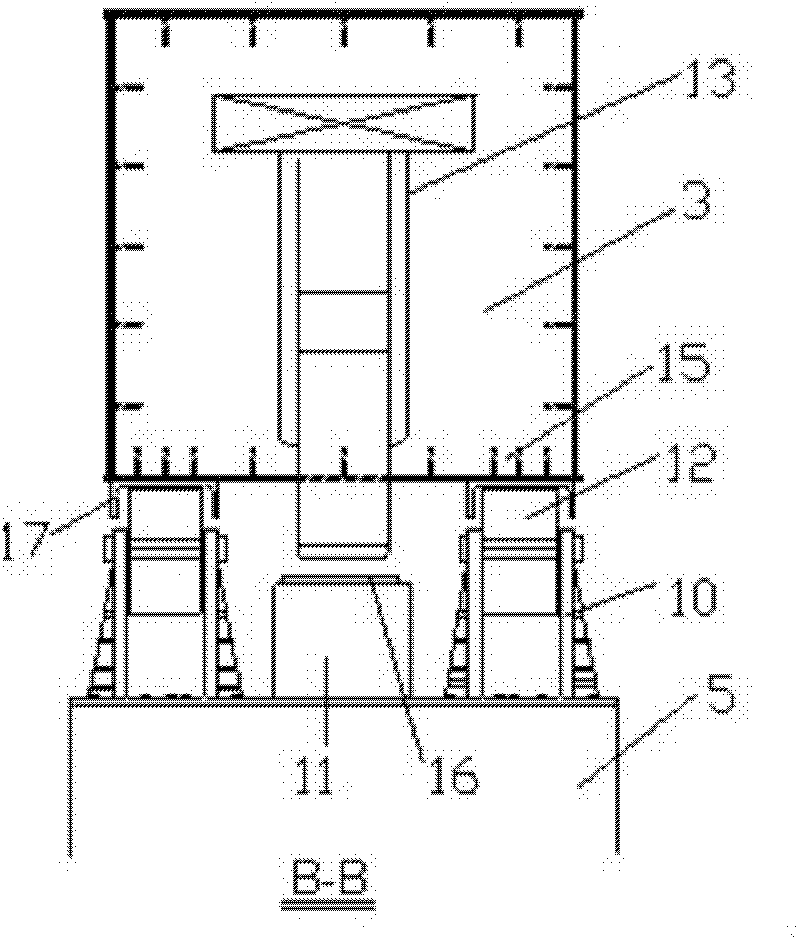

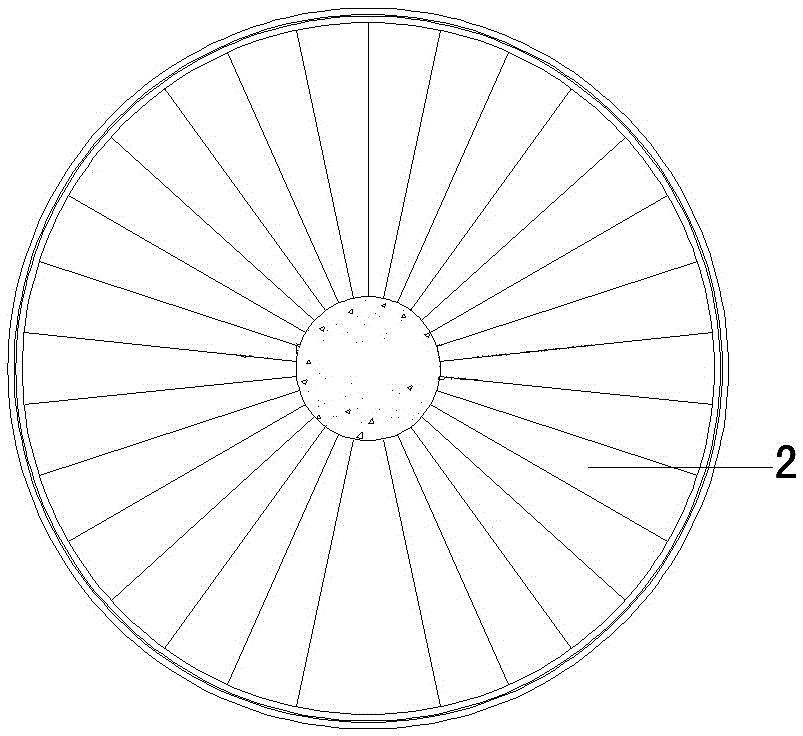

Integral Pushing Construction Method of Network Tied Arch Bridge

InactiveCN102261039AFast constructionReduce coefficient of frictionBridge erection/assemblyArch-type bridgeEngineeringPiston

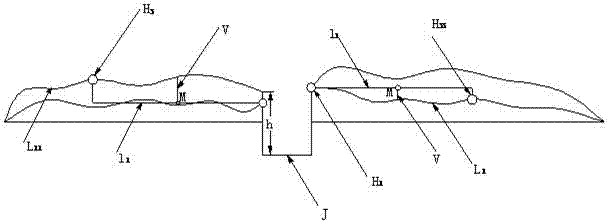

The invention relates to a guiding-beam-free integral thrusting construction method of a network tied arch bridge. The method is characterized in that the following structure and method are adopted for thrusting the network tied arch bridge: a vertical jack is arranged at the front end in the thrusting direction of a steel box tie beam; a sliding mechanism which can ensure a piston of the jack toslide on the top surfaces of temporary piers is arranged on the top surfaces of the temporary piers; during thrusting, when the front end of the arch bridge is close to the temporary piers, the piston of the jack moves downwards to push against the sliding mechanism and the height of the front end of the arch bridge relative to the top surfaces of the temporary piers is adjusted by controlling the extension elongation of the piston to ensure chutes at the bottom of the steel box tie beam to fall on pulleys; and the chutes are supported by the pulleys and slide relative to the pulleys along with thrusting movement of the arch bridge. The method has the following beneficial effects: in the thrusting process, a main arch ring, inclined hangers, the steel box tie beam, the temporary supports and the like are integrally thrust, thus giving play to the function of partial inclined hangers to enhance the structural rigidity in the thrusting process, simultaneously avoiding installation inconvenience and construction difficulty after the members are thrust in place and improving the thrusting construction efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

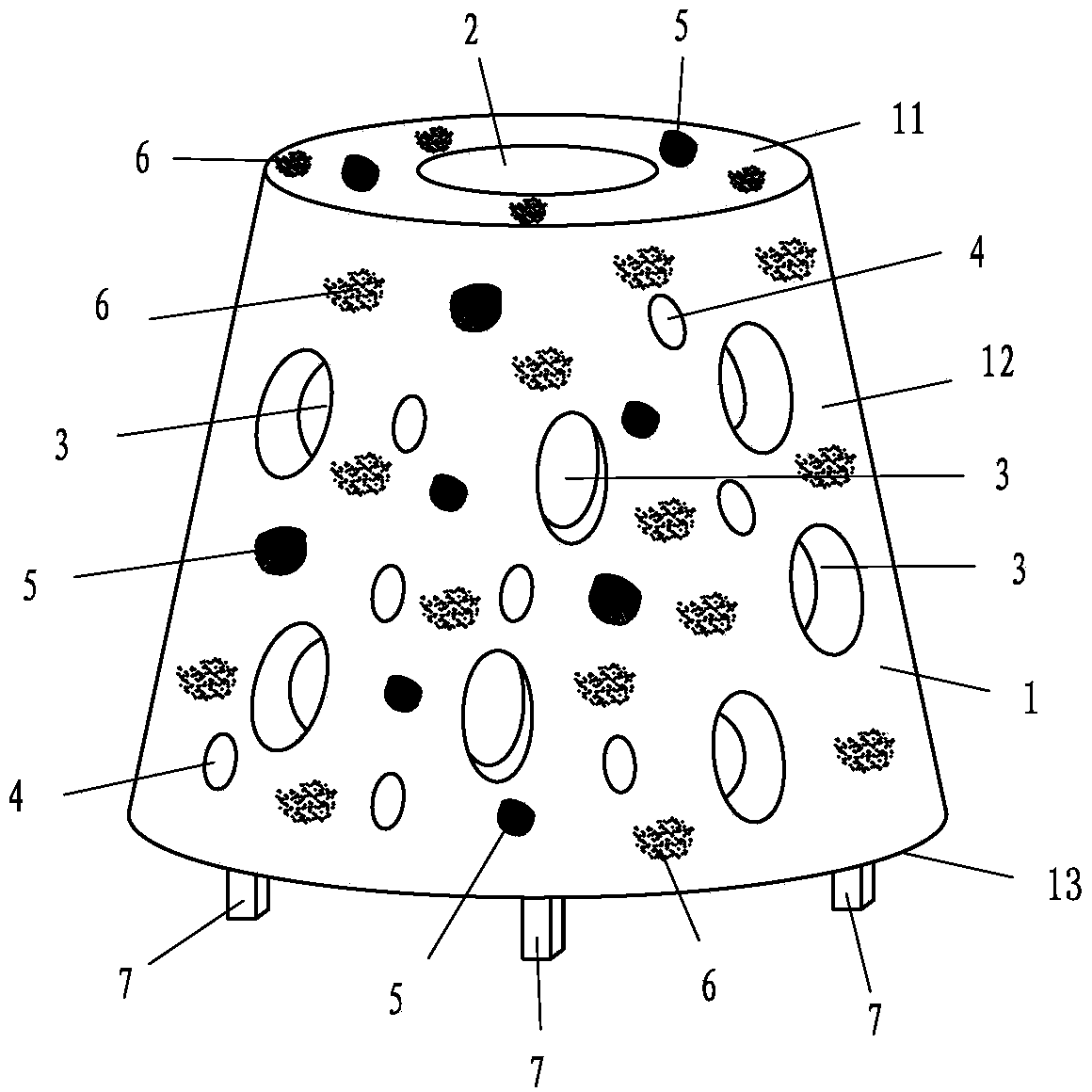

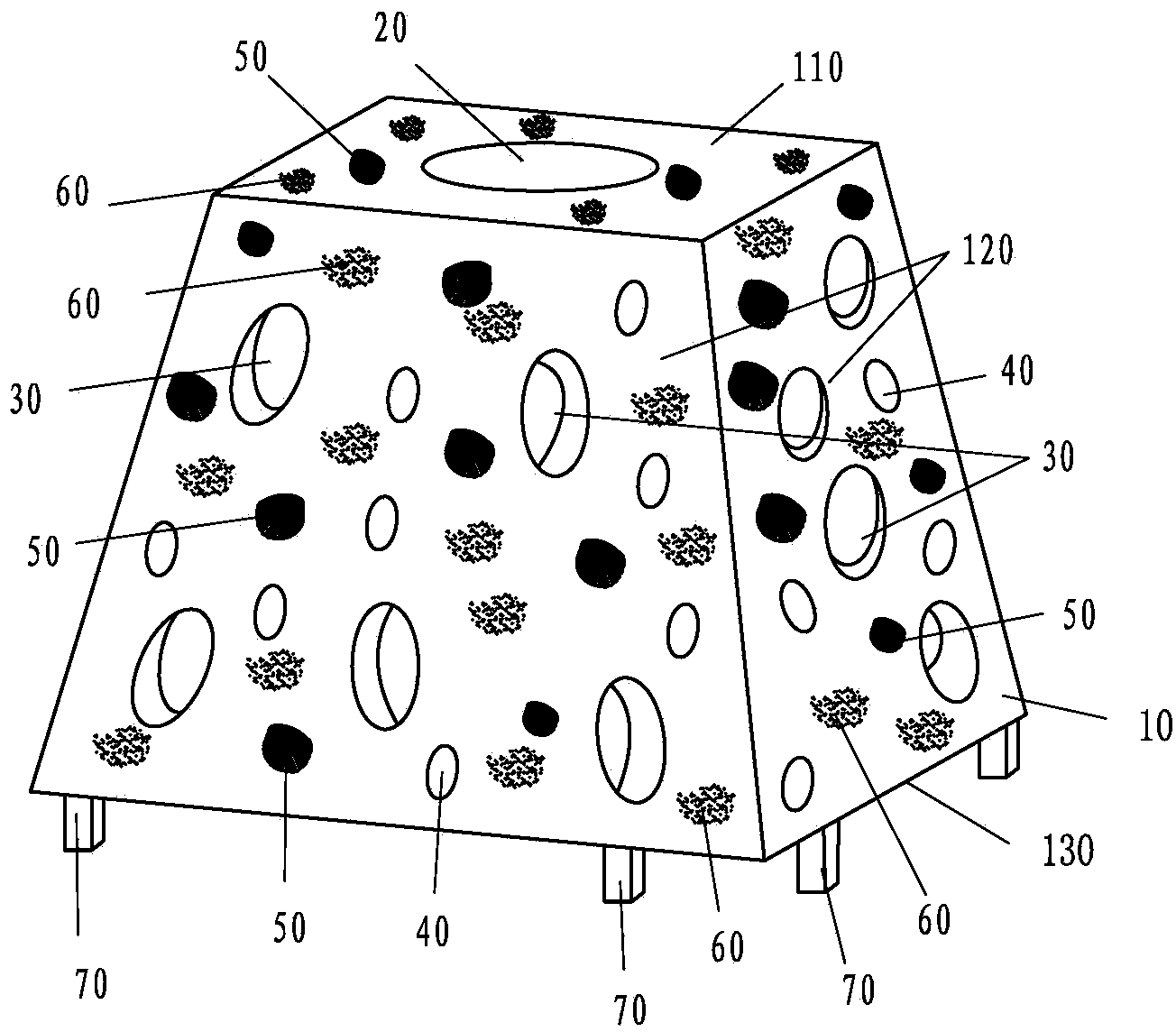

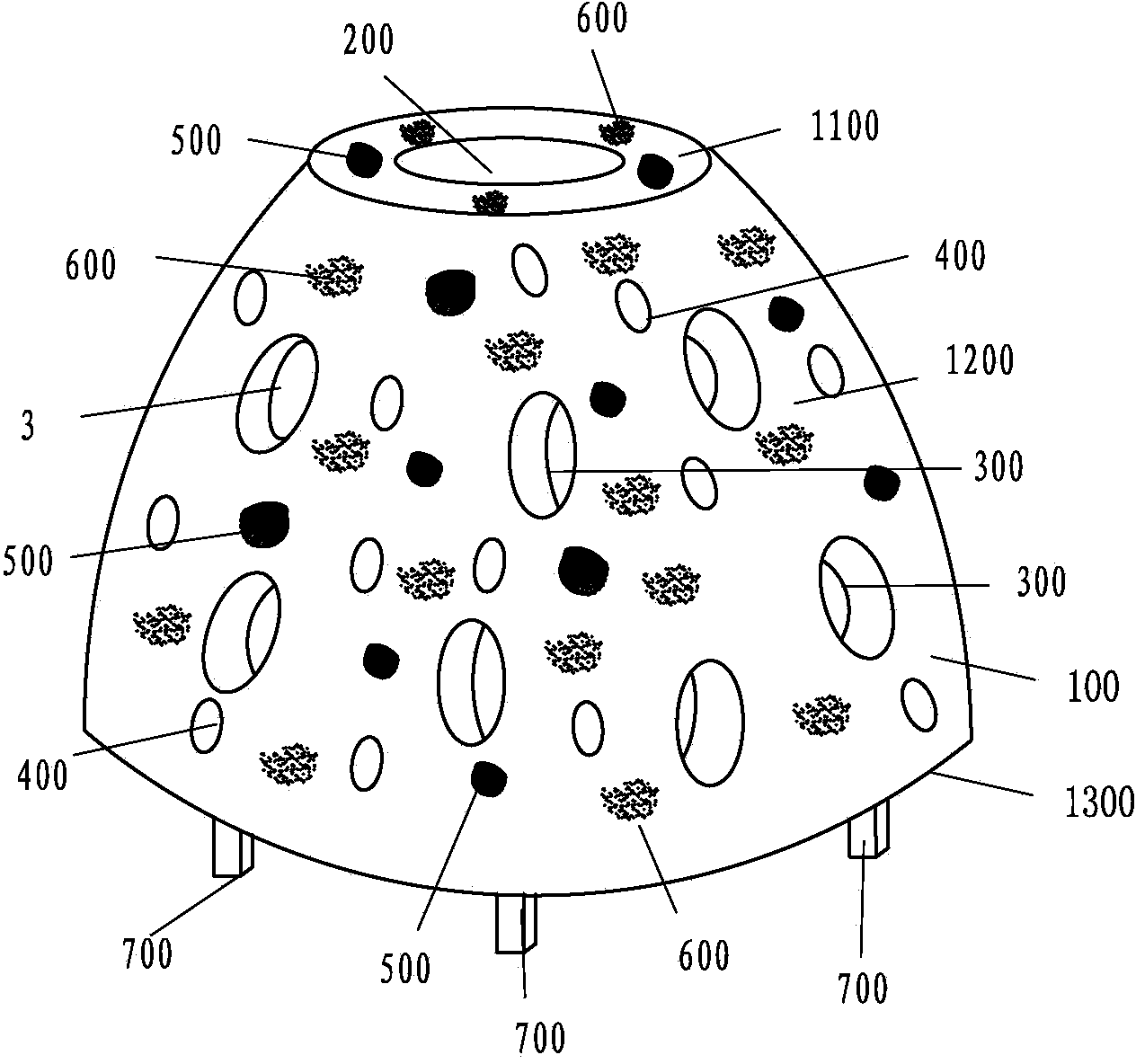

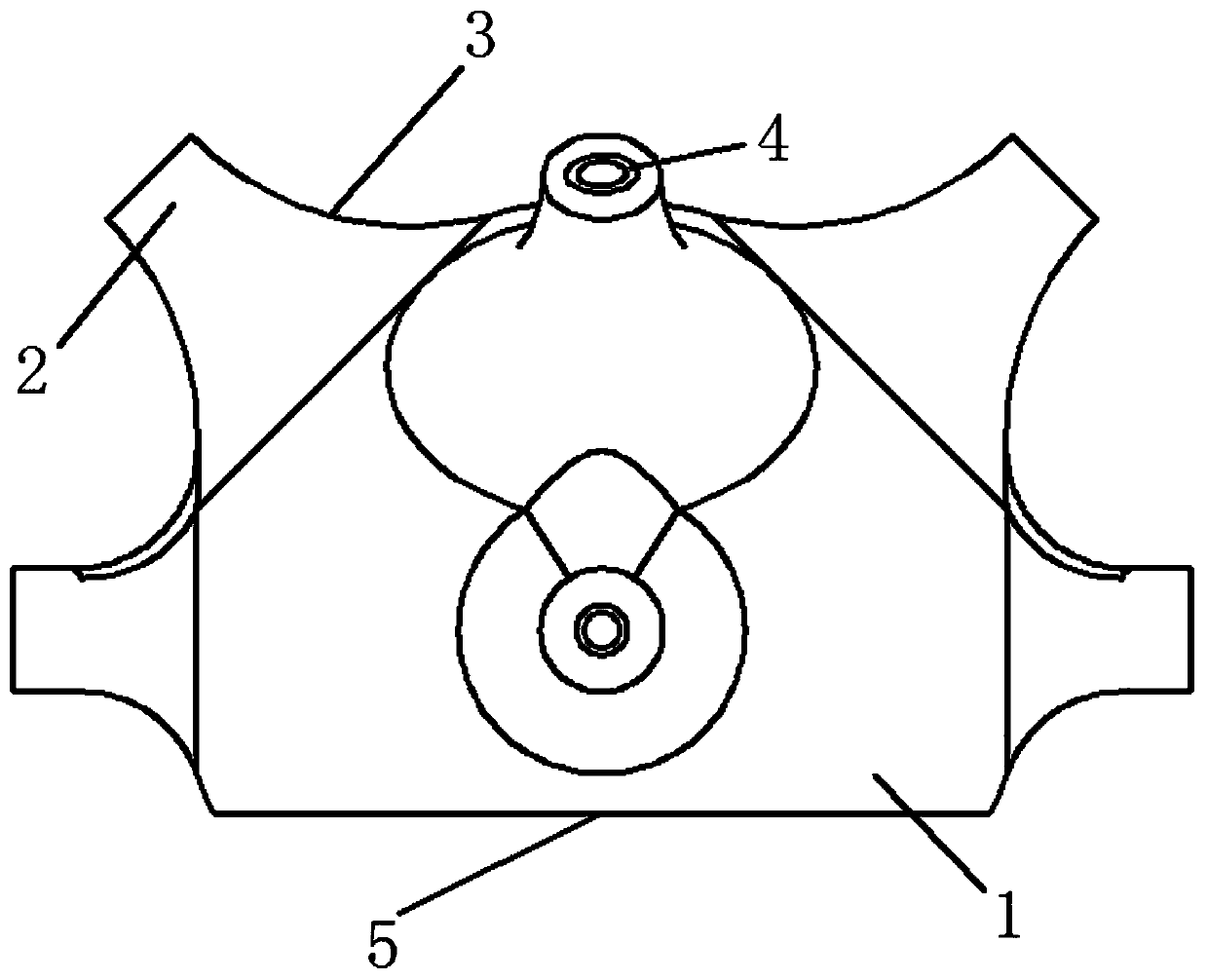

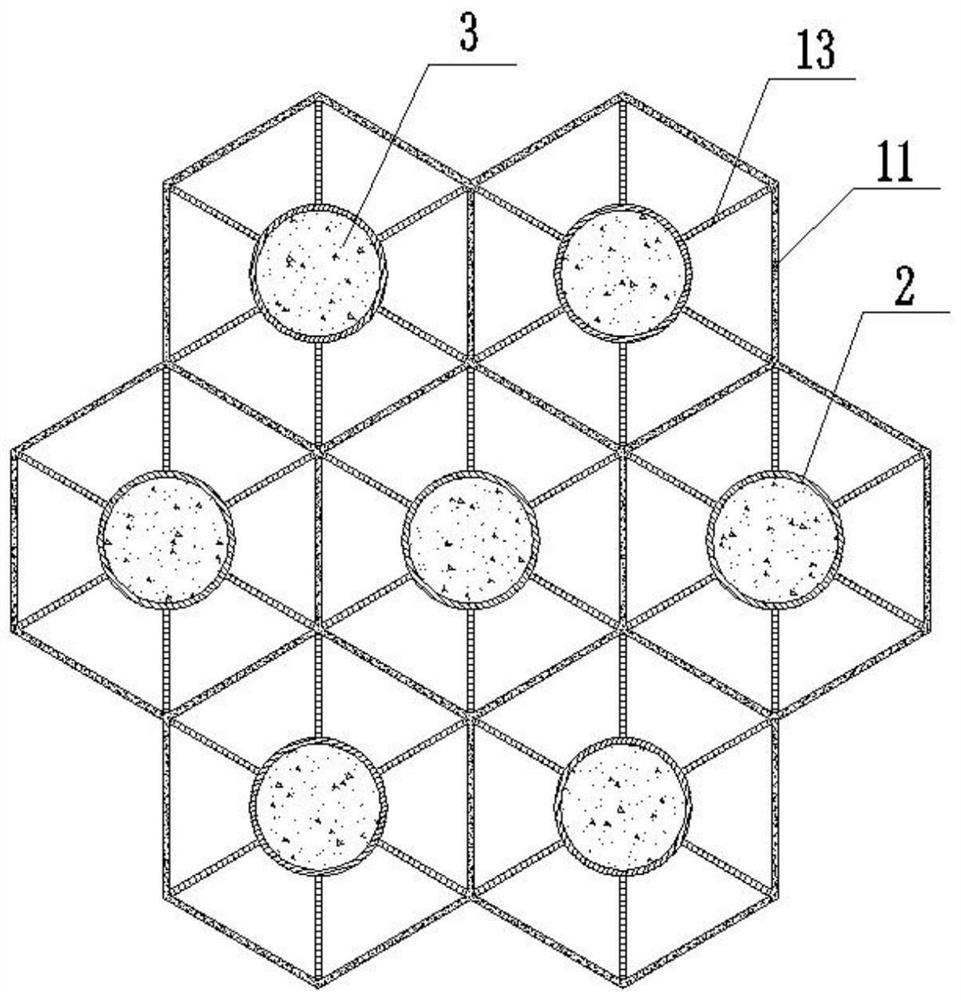

Artificial ecological barrier reef

InactiveCN103960179AEasy constructionLow costClimate change adaptationPisciculture and aquariaEcological environmentOyster shells

The invention discloses an artificial ecological barrier reef and relates to an artificial building block suitable for growth of marine organisms. According to the artificial ecological barrier reef, a body is a concrete building block with a vertical penetrating hole, a steel bar or other metal reinforced bars do not exist in the body, micro silicon powder is mixed in the body, the body is a big-end-down table-shaped object, a plurality of holes which penetrate to the vertical penetrating hole and a plurality of concave pits are formed in the side face of the body, fragments of one or more of the organic substances of plants, shells, oyster shells and organism skeletons are added into the body, and parts of the organic substance fragments are exposed on the surface of the body. Cost, conveying, island conditions and bank protection can be integrated, and the requirement for ecological environment protection can be met.

Owner:JIMEI UNIV

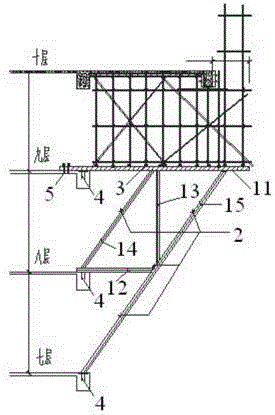

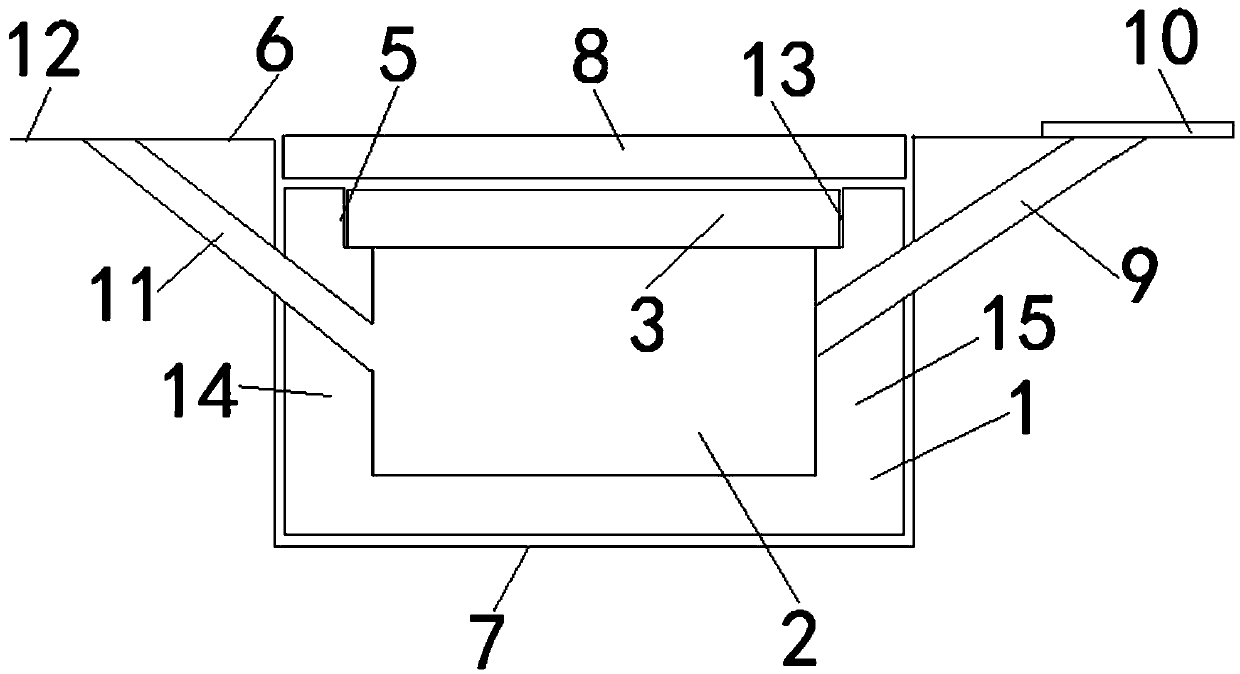

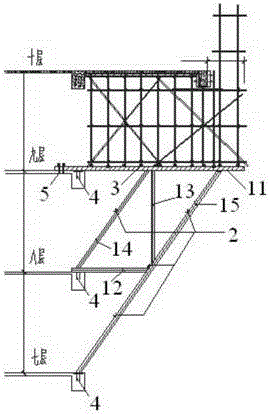

High-altitude large-cantilever concrete structure structural steel supporting platform

The invention relates to a high-altitude large-cantilever concrete structure structural steel supporting platform. The high-altitude large-cantilever concrete structure structural steel supporting platform comprises a multi-truss structural steel triangular supporting bracket, a box iron horizontal connecting beam and a plurality of box iron horizontal purlines. The multi-truss structural steel triangular supporting bracket comprises a main beam, a horizontal rod, a vertical rod, a first inclined supporting rod and a second inclined supporting rod. The main beam is installed on a boundary beam of a frame structure on the next layer of a cantilever structure needing to be constructed, the first inclined supporting rod and the second inclined supporting rod are installed on a boundary beam of a frame structure on the next second layer and a boundary beam of a frame structure on the next third layer of the cantilever structure needing to be constructed respectively, the horizontal rod is connected with the first inclined supporting rod and the second inclined supporting rod, the joint of the second inclined supporting rod and the horizontal rod is connected with one end of the vertical rod, the other end of the vertical rod is connected with the main beam, the box iron horizontal purlines are welded to the upper surface of the main beam in a laying mode and are used for erecting a formwork support and an external scaffold, and multi-truss structural steel triangular supporting brackets are connected through box iron horizontal connecting beams in a welding mode. The high-altitude large-cantilever concrete structure structural steel supporting platform solves the problem that the construction difficulty of an ultrahigh and large-cantilever structure with large component loads is high.

Owner:SHANGHAI ZHONGJIN CONSTR GRP

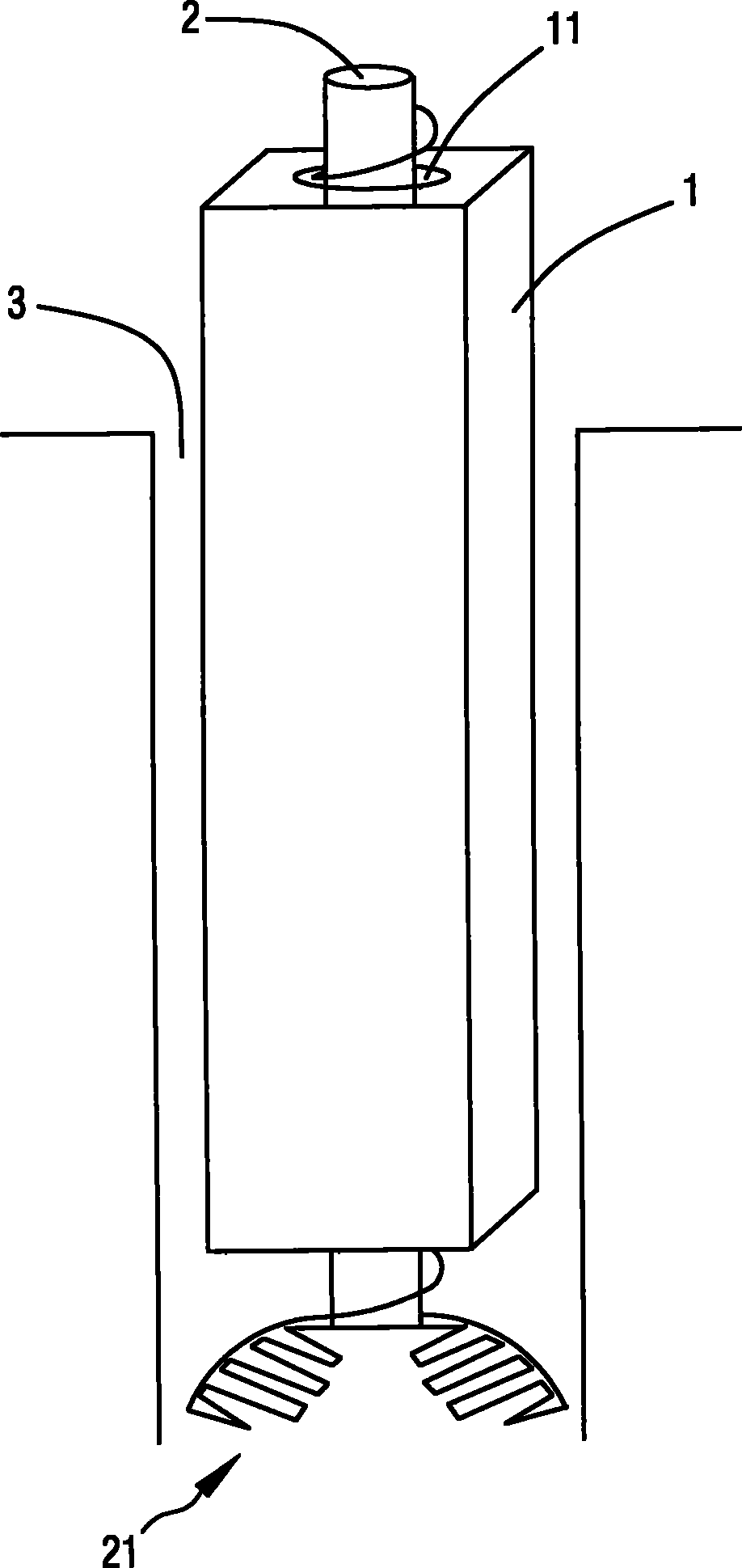

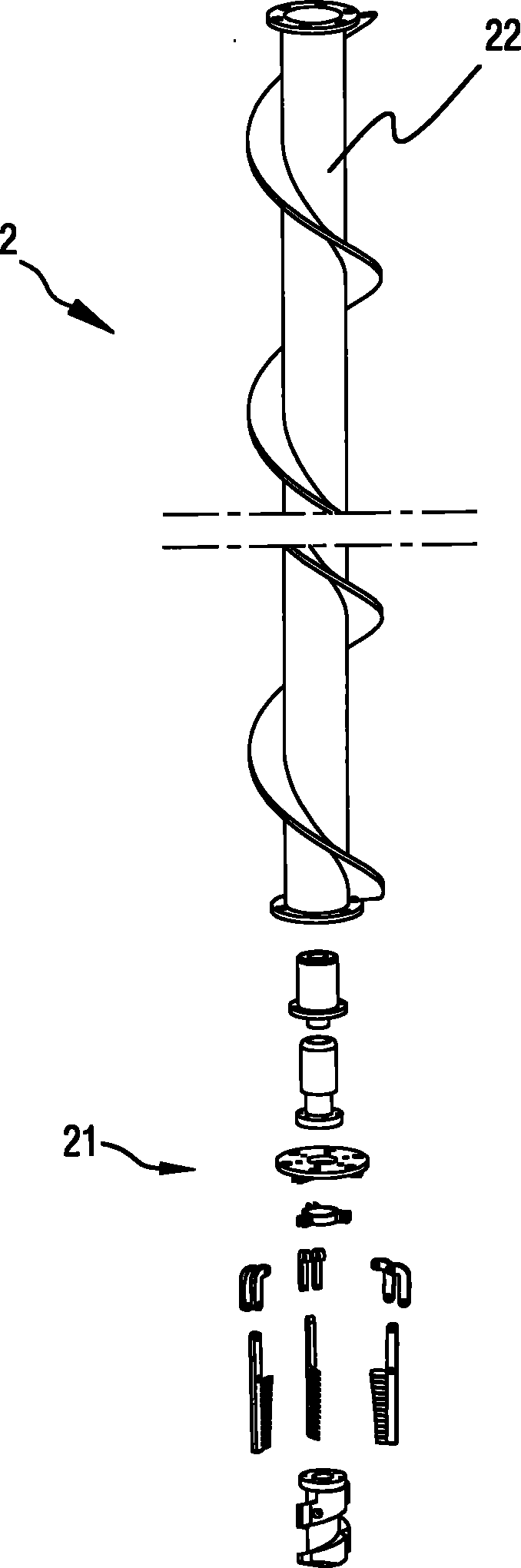

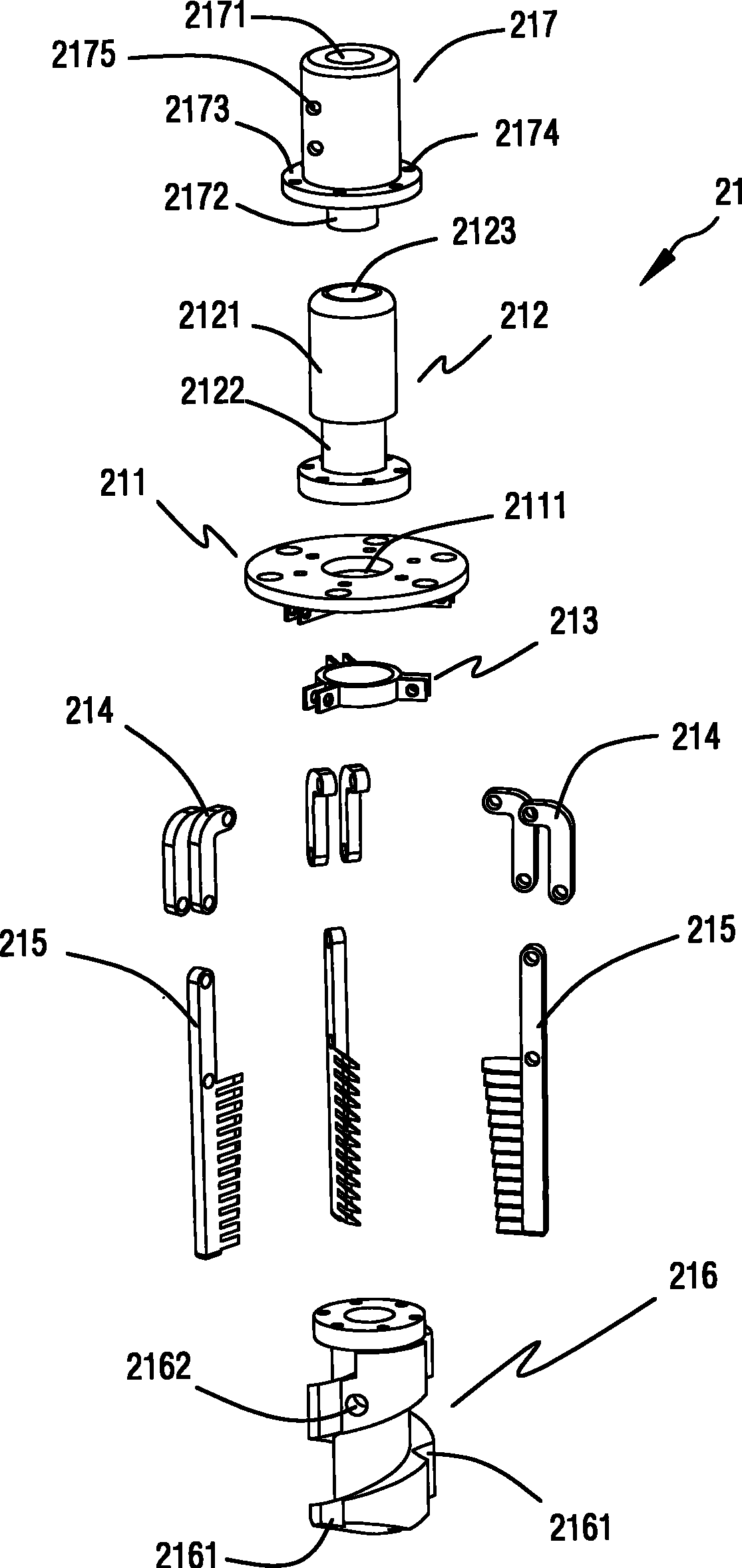

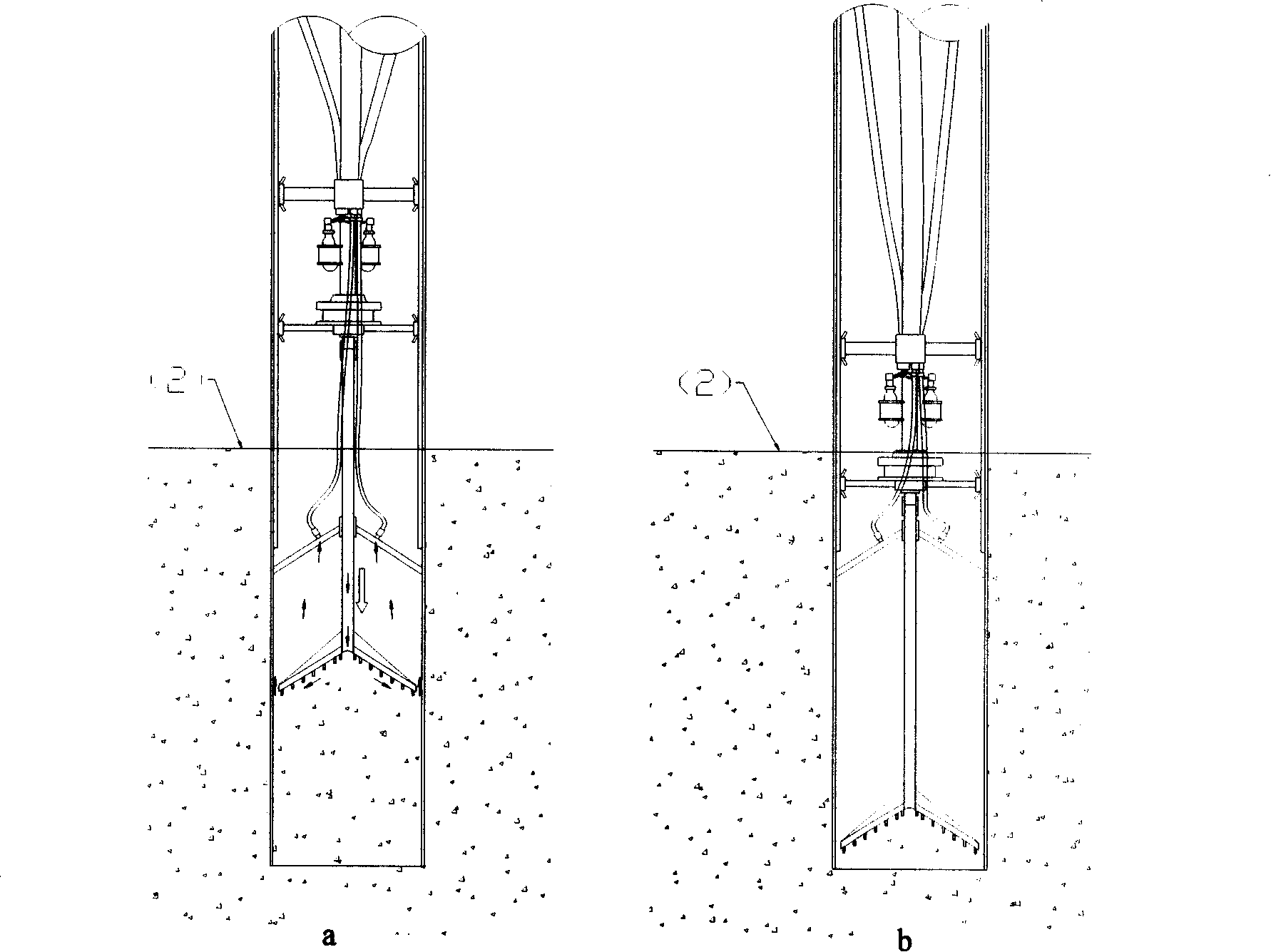

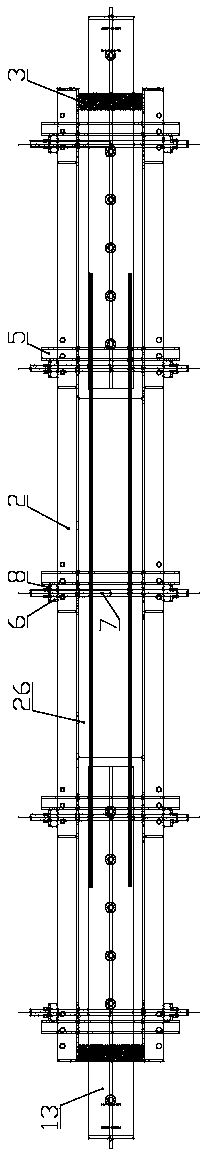

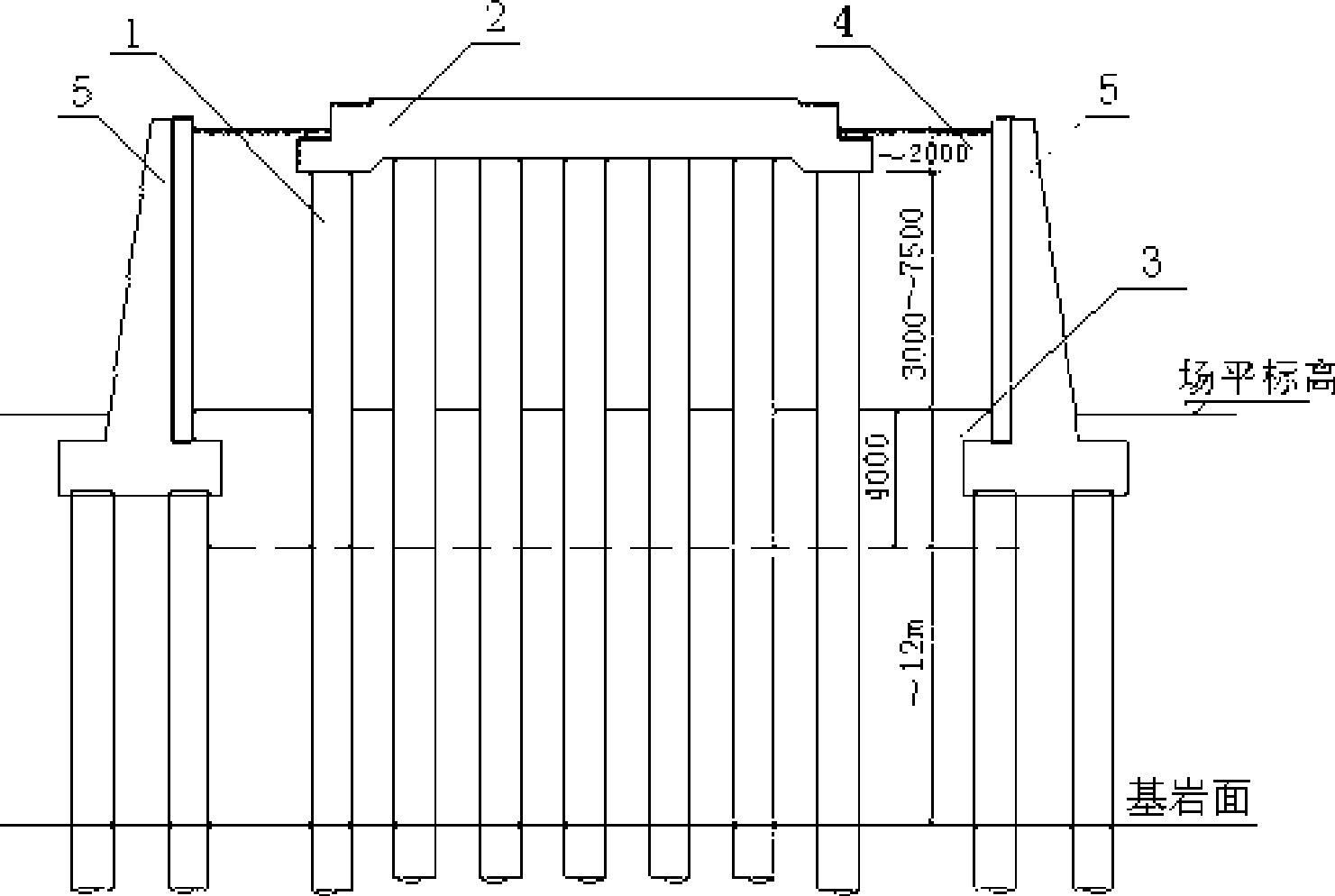

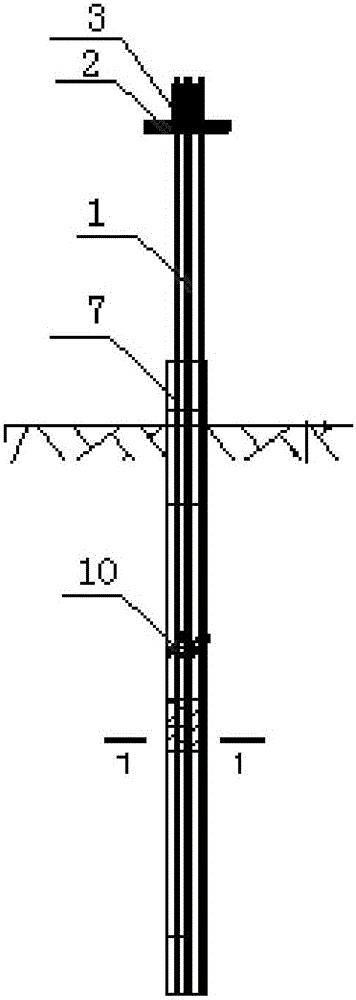

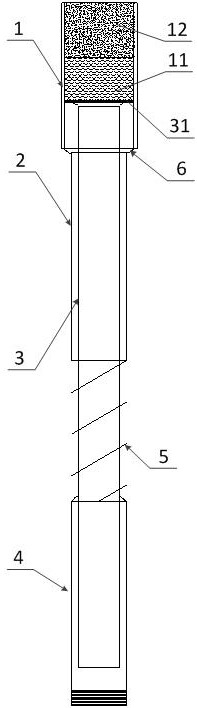

Pile-embedding method for hollow pile and auger drill for implementing same

InactiveCN101974905AQuality assuranceReduce adverse effectsDrill bitsCeramic shaping apparatusStructural engineeringEngineering

The invention relates to a pile-embedding method for a hollow pile. The pile-embedding method comprises the following steps of: hoisting the hollow pile to a pile-embedding position and hanging the hollow pile vertical to the ground; penetrating a central through hole of the hollow pile from top to bottom by using an auger drill with a reamer bit to reach the ground and starting to drill and carry soil; after the reamer bit is extended to the underground, carrying soil and expanding the reamer bit at the same time; along with the deep penetration of the drilling and soil-carrying operation, conveying the soil by using the auger drill; and embedding the hollow pile into the drill hole gradually until the hollow pile reaches to the set depth. The invention also provides the auger drill for implementing the pile-embedding method. Due to the construction by the auger drilling, soil-carrying and pile-embedding method, the problems of difficult soil extrusion in the pile-embedding process and difficult pile-embedding operation on hard-soil foundation can be solved; the project schedule is accelerated; the quality of the pile body is guaranteed; and adverse influence of construction on the ambient environment is reduced to a maximum degree.

Owner:SHANGHAI ZHONGJI PILE IND

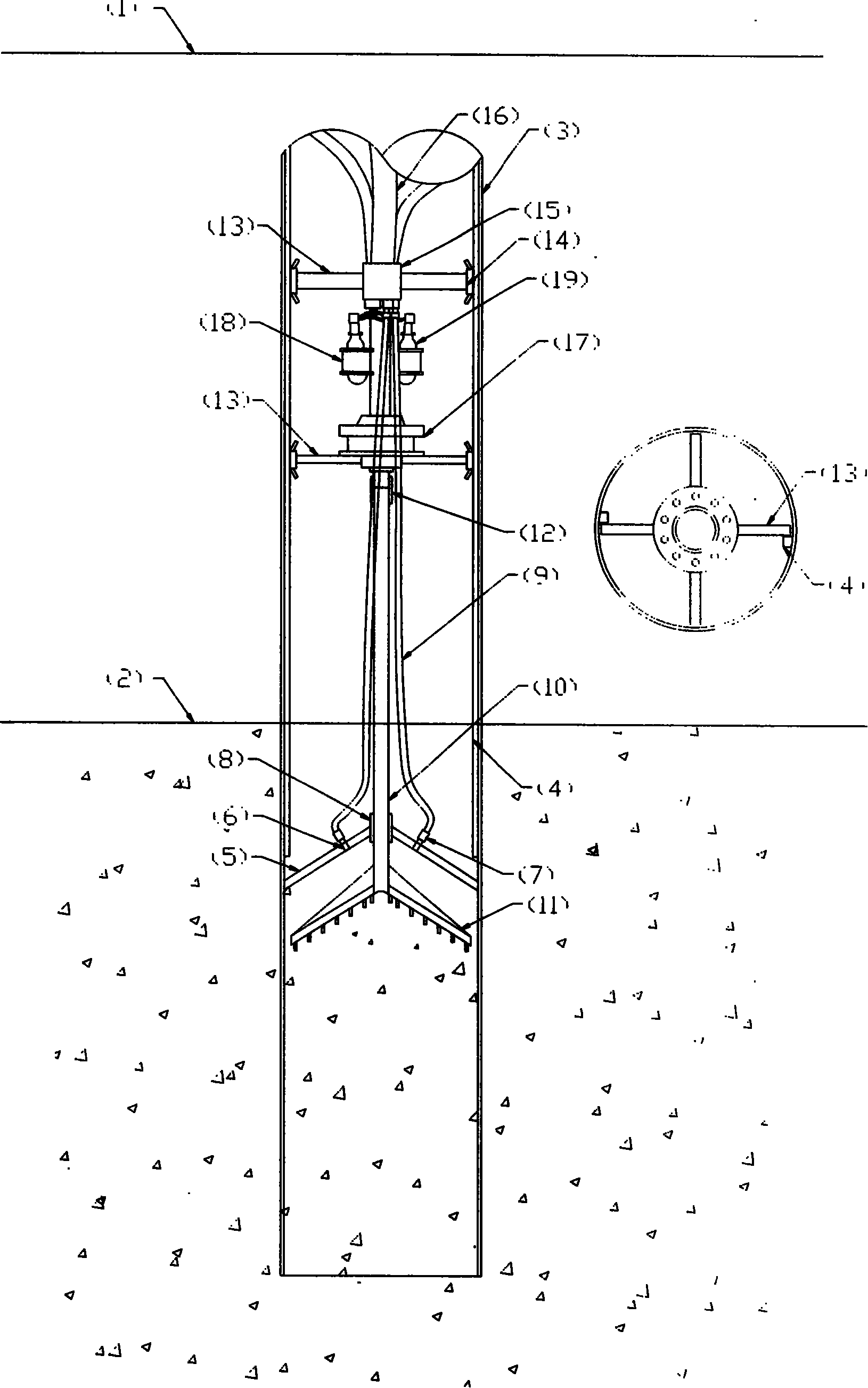

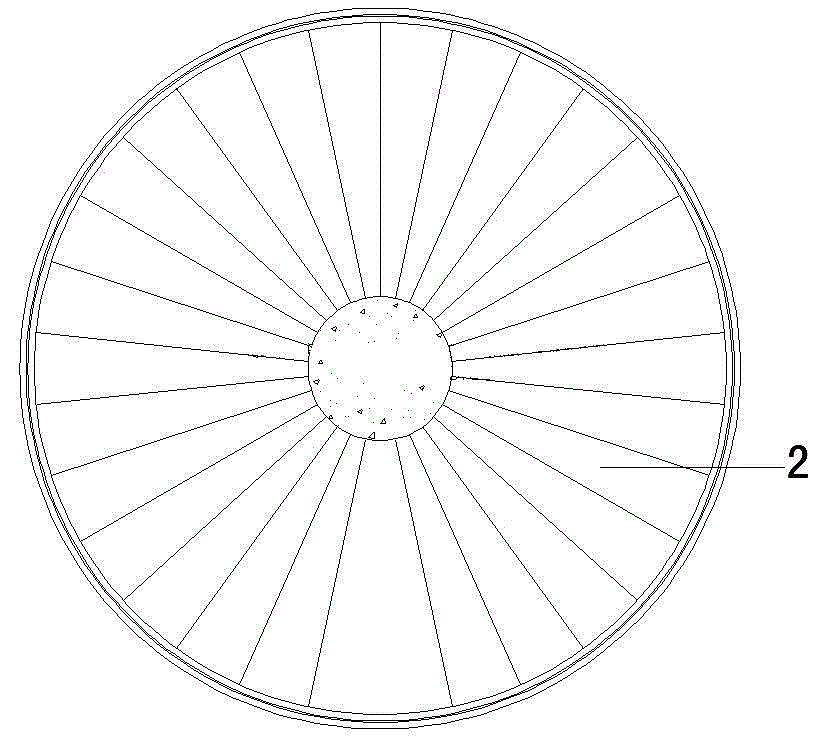

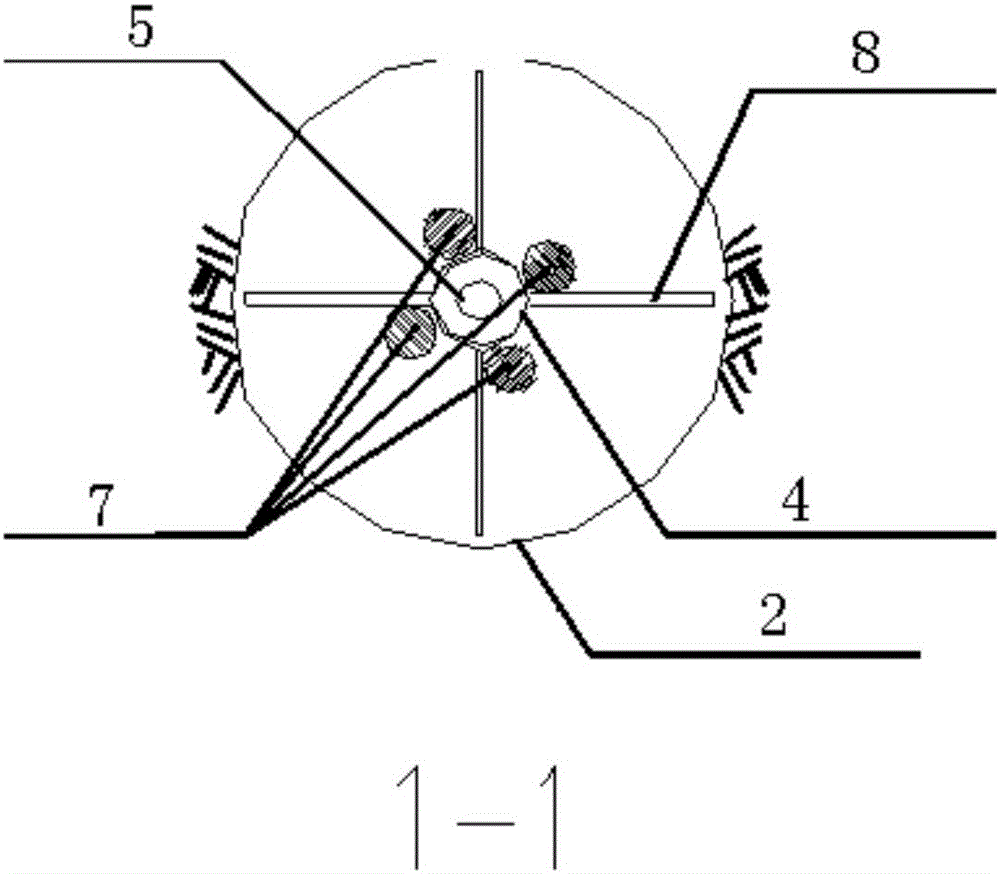

Drill absorption pile structure and construction method thereof

InactiveCN101196005AAvoid construction difficultySimple structureBulkheads/pilesWater dischargePore water pressure

The invention relates to an offshore drilled absorbing pile and the construction method thereof. When a drilling bit (11) breaks the ground and is drilled, an immersed tube is drilled into a high pressure water pump (18) on the main machine of a drilling machine, and supplies high pressure water for the lower part of the drilling bit through the central tube of a drilling rod to form high pressure slurry, and the slurry is discharged out of the drilled absorbing pile through a one-way valve (7) installed on a baffle plate and a slurry discharging tube (9) connected with the one-way valve. The drilling bit is drilled and breaks the ground from the upper part of the sealed bin of the drilled absorbing pile to the bottom of the drilled absorbing pile to clean all the soil plugs in the sealed bin out of the drilled absorbing pile, the drilling bit is stopped, and simultaneously the high pressure water pump (18) stops supplying water. A submersible sewage pump on the drilling machine is started up, the one-way valve (7) on the cone shaped baffle plate is closed to ensure that a sealed space is formed at the lower part, the sea water is discharged from the sealed space through the submersible sewage pump (19) to form negative pressure, the drilled absorbing pile is immersed into the sea bed under the sea water pressure, the drilling bit is supported on the mud surface and keeps still when the drilled absorbing pile is immersed, the cone shaped baffle plate of the drilled absorbing pile is lowered to the drilling bit position along the drilling rod (10) to stop the water discharging of the submersible sewage pump, and thus the primary drilling of the drilled absorbing pile is completed. The former operations are repeated to ensure the drilled absorbing pile to enter into the sea bed in a step-by-step immersed tube drilling way, in order to complete the driving-in construction of the drilled absorbing pile.

Owner:天津市海恩海洋工程技术服务有限公司

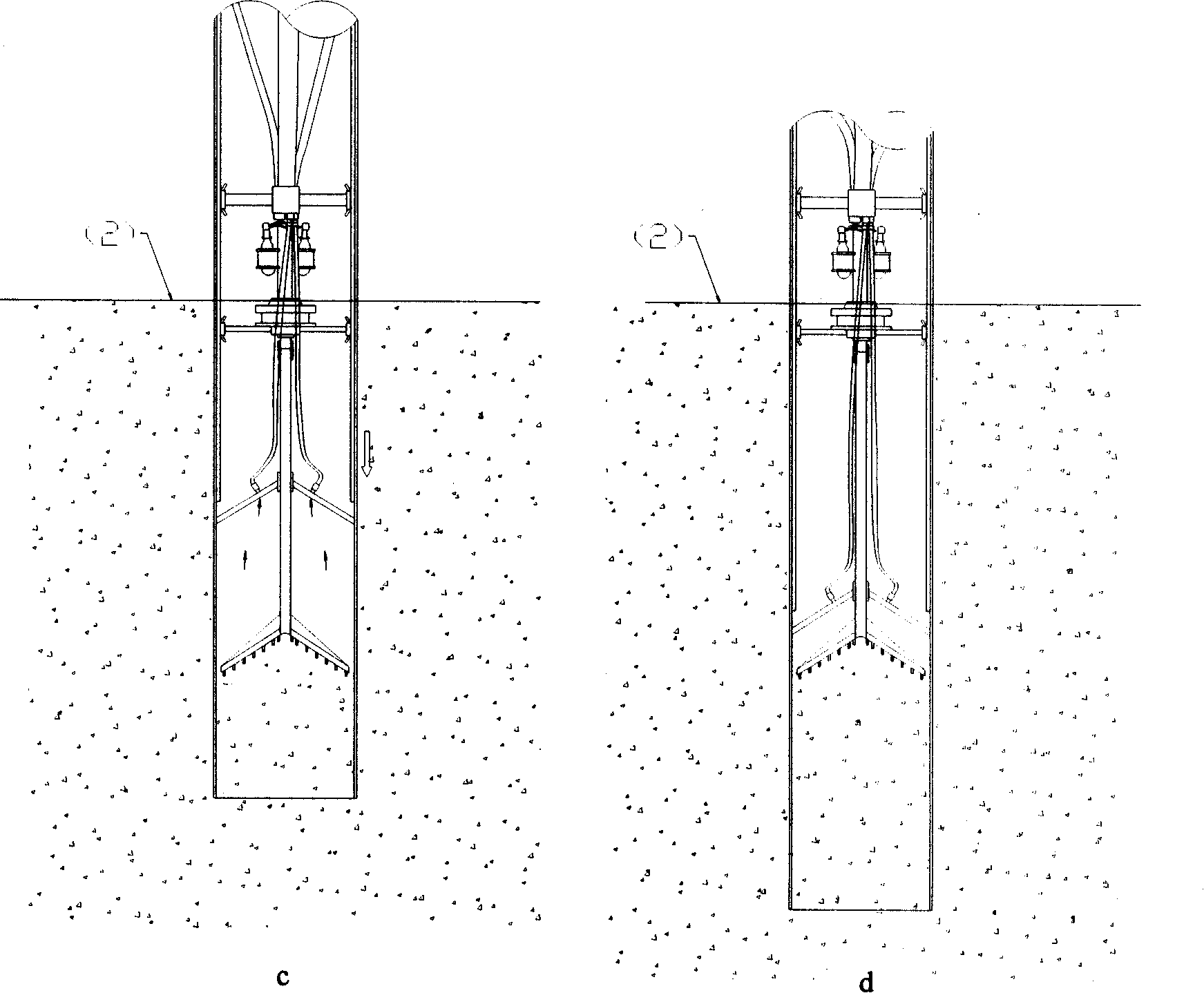

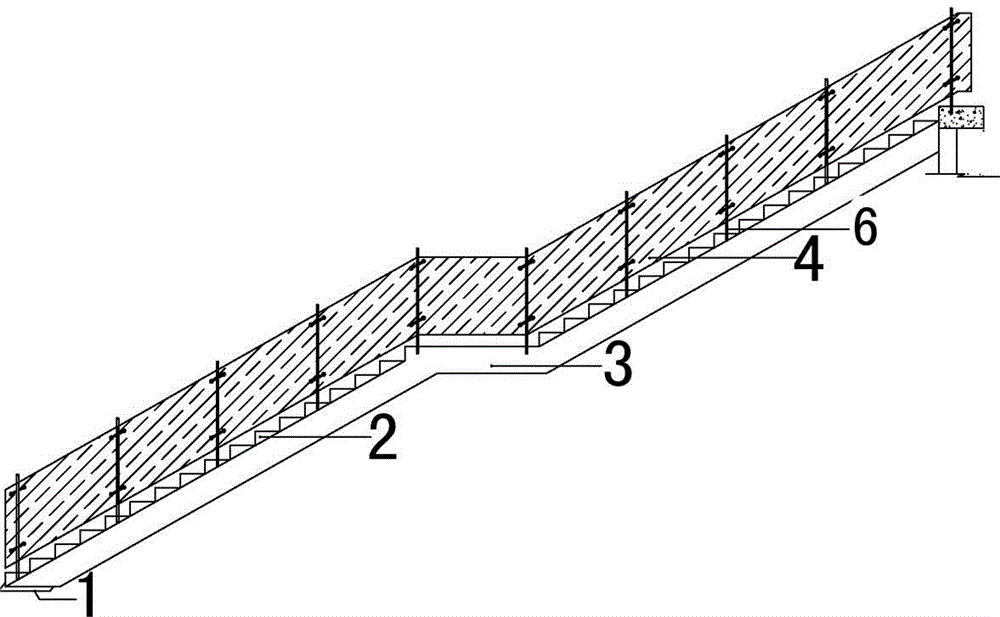

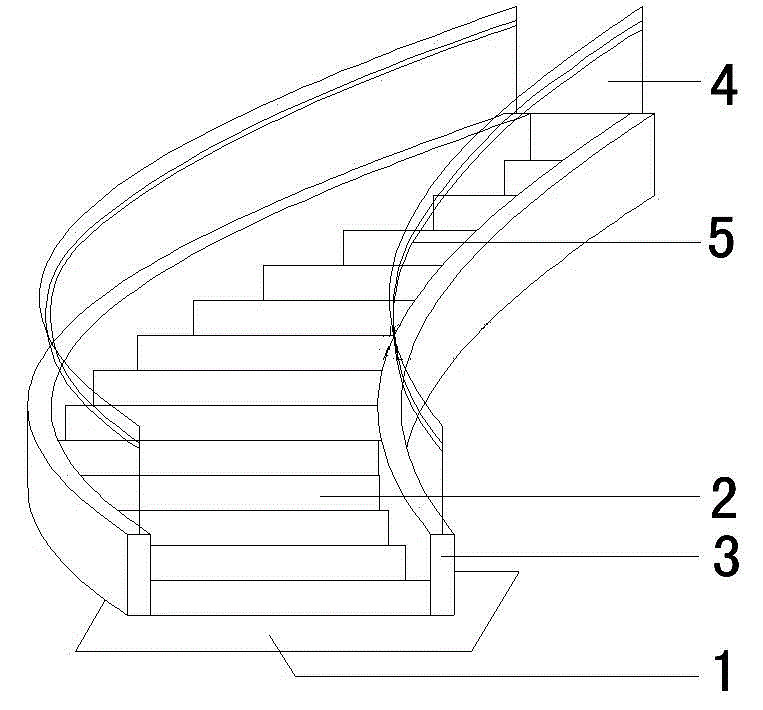

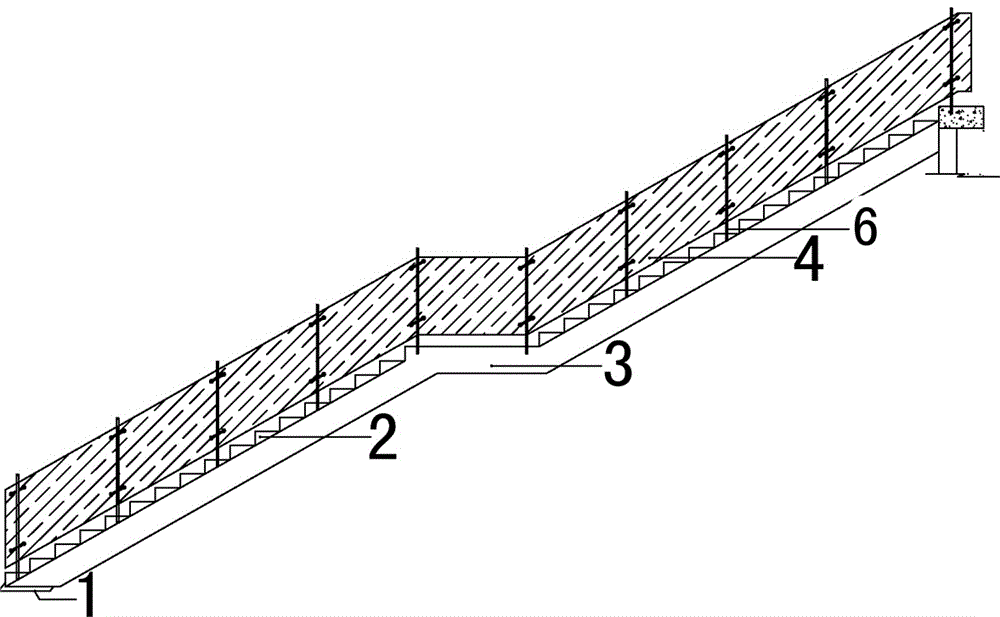

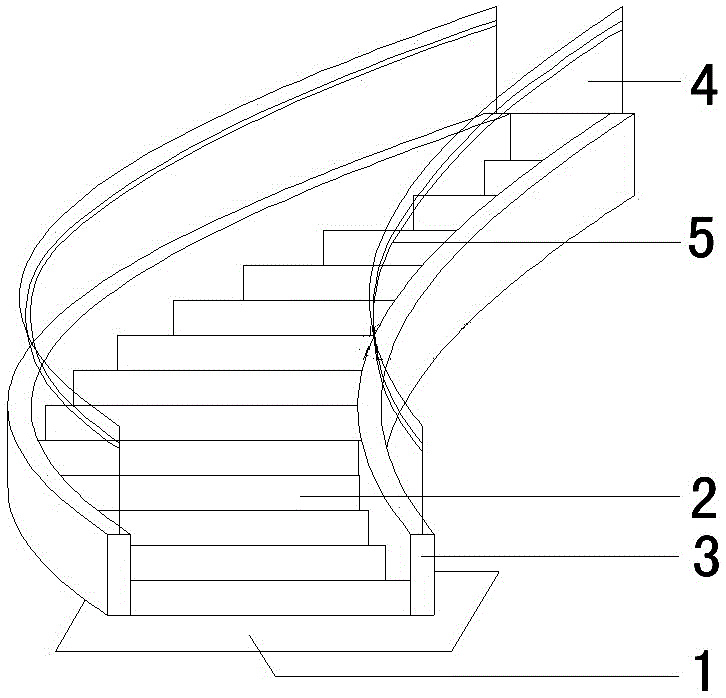

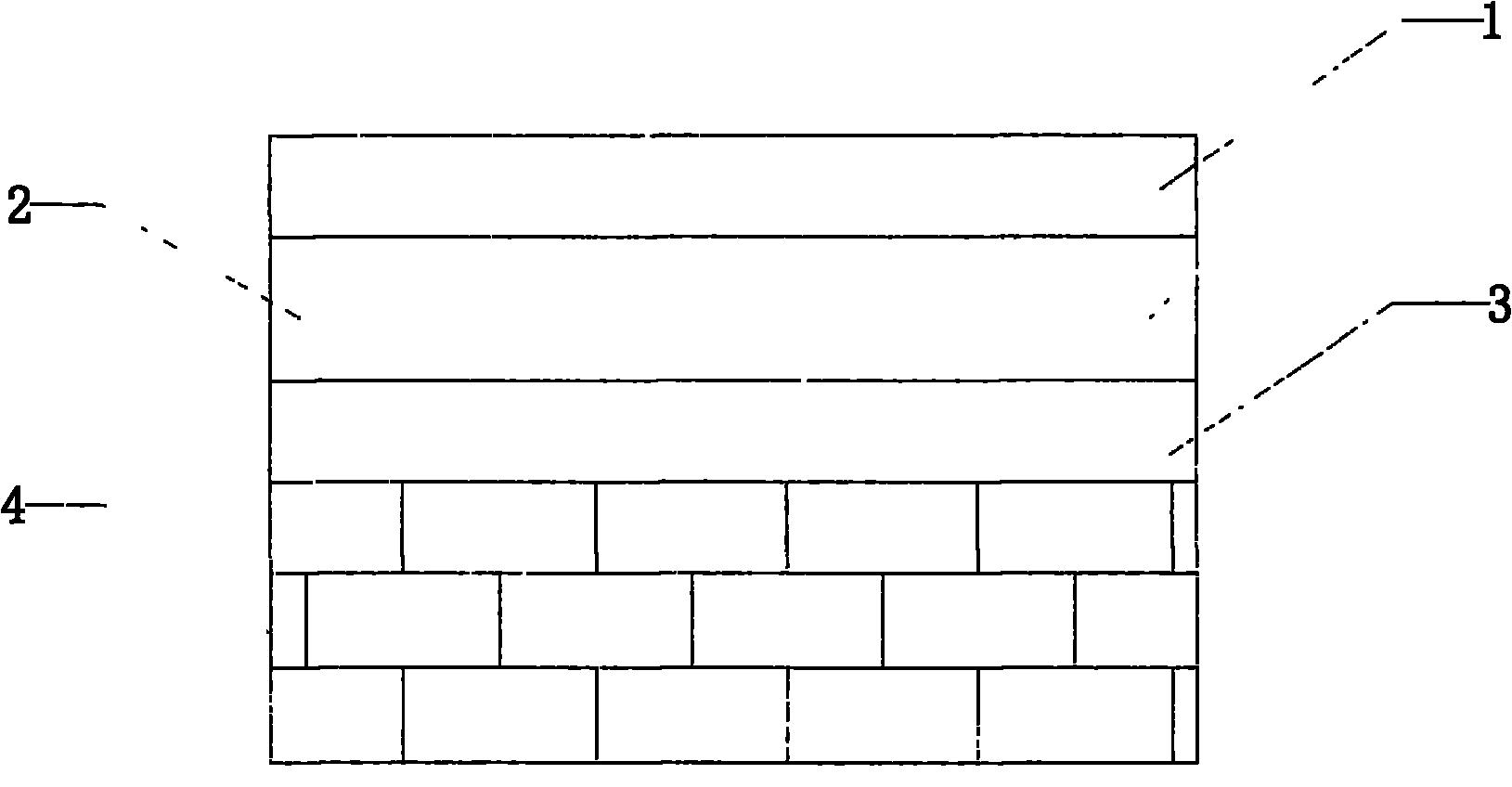

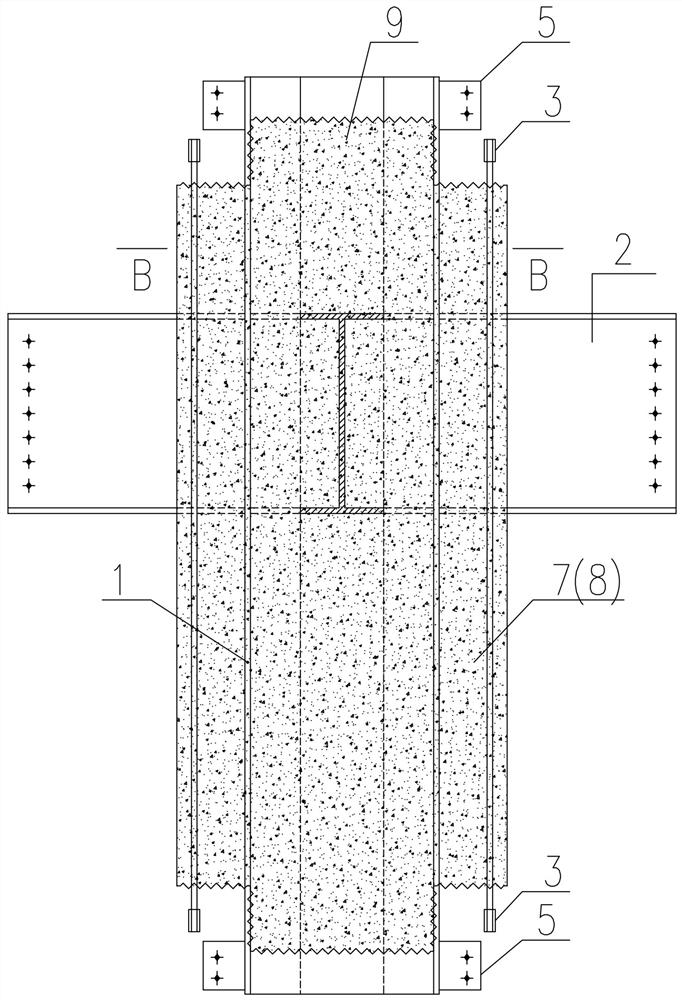

Non-support steel-structure spiral staircase

The invention discloses a non-support steel-structure spiral staircase comprising a first-layer reinforcing platform (1), stair steps (2), skirting waist lines (3) and handrails (5). The lower corners of the skirting waist lines (3) are welded to the first-layer reinforcing platform (1). The stair steps (2) are welded to the skirting waist lines (3). Two sides of the stair steps (2) are provided with a plurality of supporting columns (6). The supporting columns (6) are embedded in the skirting waist lines (3) in a weld fixing manner and are provided with grooves with the skirting waist lines (3). Glass guardrails (4) are embedded in the grooves. The handrails (5) are fixed on the glass guardrails (4) through connectors. The non-support steel-structure spiral staircase has the advantages that force bearing requirements can be guaranteed, non-support technical feasibility is realized, construction period is shortened, and construction difficulty is reduced; the quality defects of break due to unbalanced force bearing can be prevented effectively, and the problem that material consumption is high is controlled.

Owner:GOLD MANTIS CONSTR DECORATION

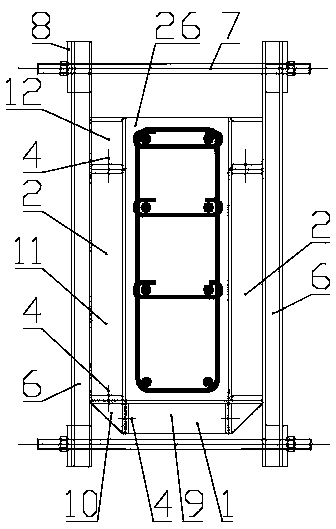

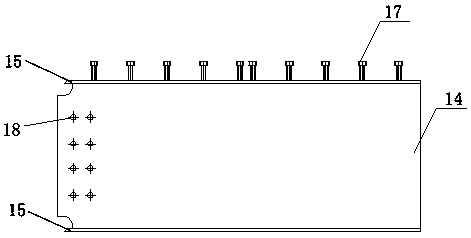

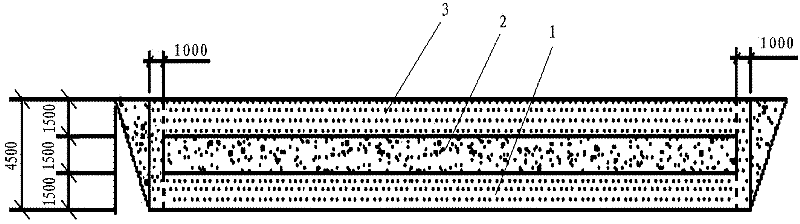

Hybrid beam manufacturing device and manufacturing method

The invention provides a hybrid beam manufacturing device and manufacturing method. The hybrid beam manufacturing device comprises a template and a steel reinforcement cage; the template comprises analuminum alloy bottom board, aluminum alloy side boards, foam boards, heightened square pipes, strengthened square pipes, strengthened screw rods, nuts and strengthened backing boards; and the steel reinforcement cage comprises H-shaped steels, beam face reinforcements, beam bottom reinforcements, hoop reinforcements, beam waist reinforcements and tied reinforcements. The method comprises the following steps of protective layer reinforcement welding, steel reinforcement cage skeleton welding, steel reinforcement cage bandaging, die assembling, releasing agent brushing, steel reinforcement cagedie entering, hoisted embedded part mounting, template reinforcing, pouring and vibration, maintenance and die stripping. The hybrid beam manufacturing device and manufacturing method have the advantages that by using an aluminum template, the aluminum template can be recycled, and materials are saved; double advantages of a steel structure and a concrete structure are combined; the problem of collision of the reinforcements when a pure concrete beam component is mounted as well as the construction difficulty and the quality control difficulty caused by a great quantity of wet work in the field and the like are effectively avoided; and the hybrid beam manufacturing device and manufacturing method are suitable for large-scale production, simpleness, convenience and feasibility in technology and low manufacturing cost.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD +1

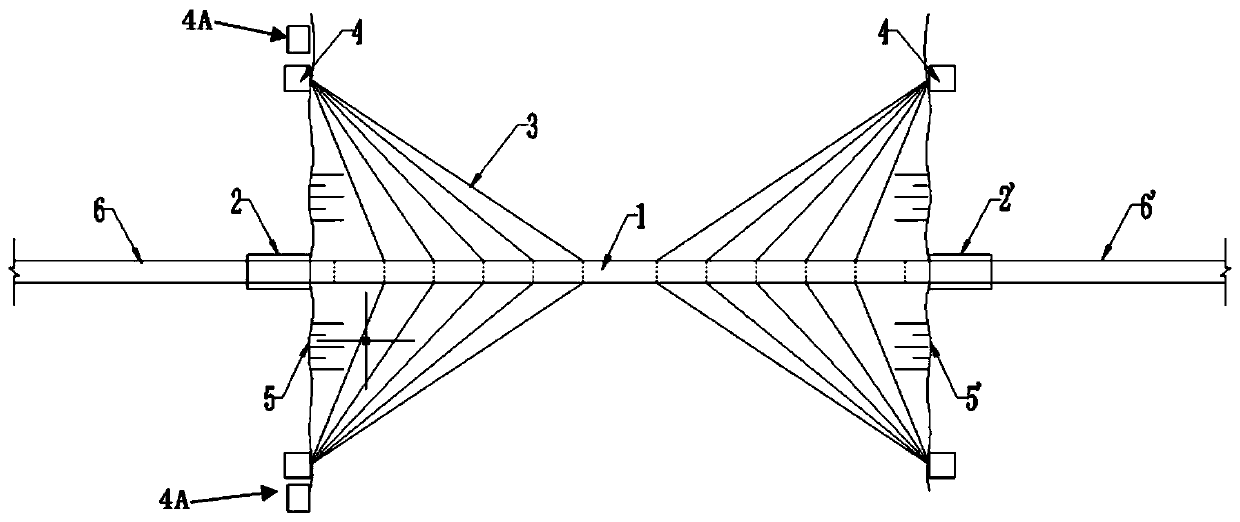

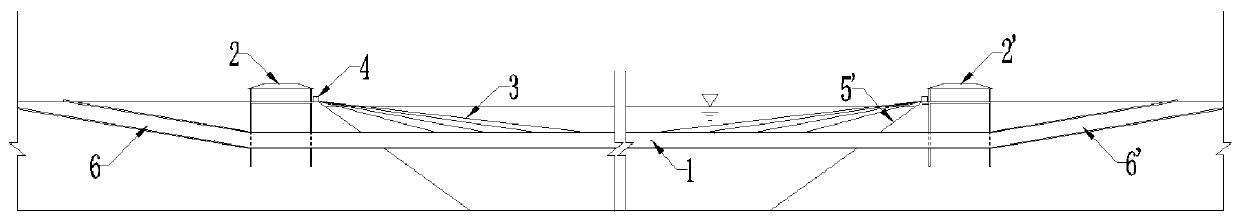

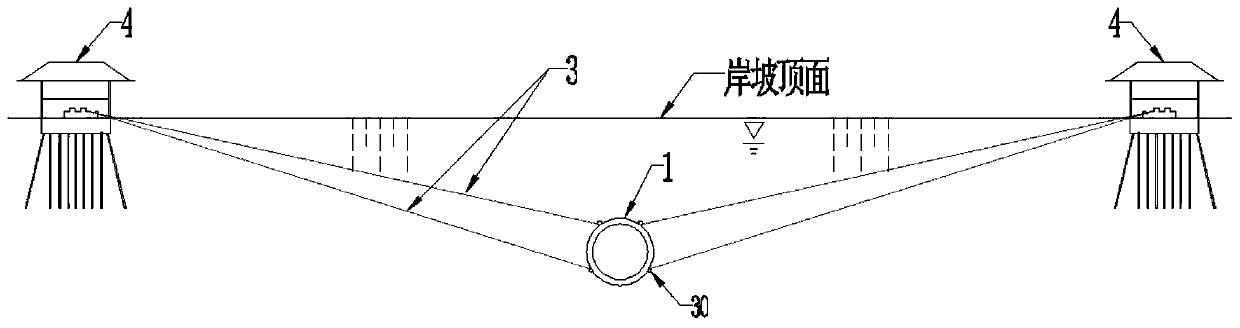

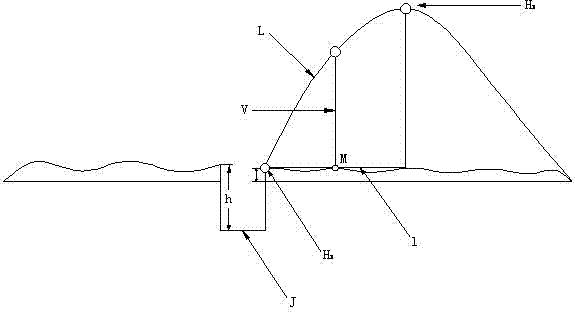

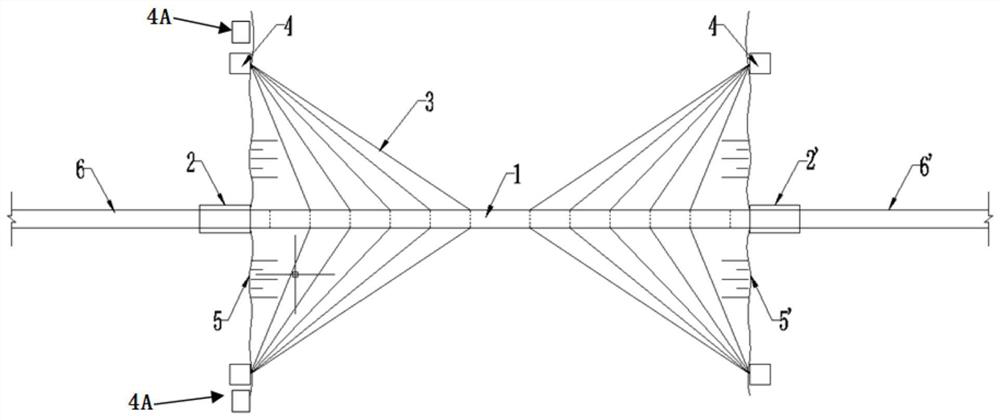

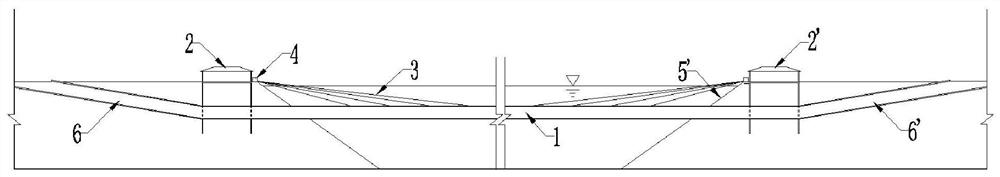

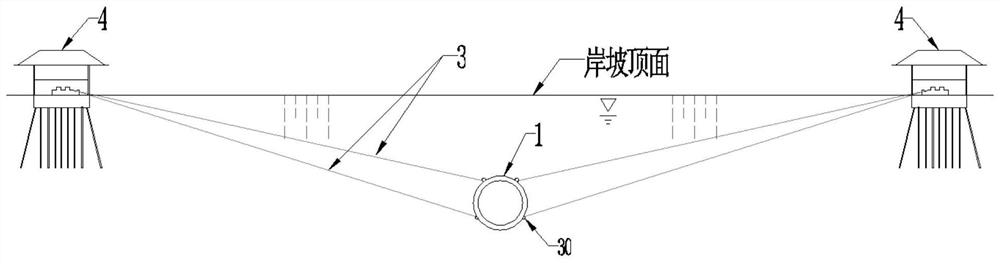

Incremental launching technology of submerged cable-stayed floating tunnel

ActiveCN111254982AReduce security risksAvoid construction difficultyArtificial islandsUnderwater structuresWind waveArchitectural engineering

The invention discloses incremental launching technology of a submerged cable-stayed floating tunnel. The incremental launching technology of the submerged cable-stayed floating tunnel comprises the following steps that all pipe joints of the submerged floating tunnel in a land area prefabrication yard are prefabricated, then the pipe joints are transported to an incremental launching side shore connecting structure through a land area slope tunnel, secondary outfitting is successively carried out, the pipe joints are docked with the subsequent pipe joints and sealed into water, then the pipejoints are in a receiving side shore connecting structure section by section in an incremental launching manner; stay cables are installed on the pipe joints one by one along with incremental launching and pulled to a stay cable anchorage pier; and after incremental launching is completed, concrete on the outer surface of the pipe joints at both ends of the submerged floating tunnel is poured intothe incremental launching side shore connecting structure and the receiving side shore connecting structure, the consolidation of the pipe joints at both ends of the submerged floating tunnel is completed, then the buoyant weight ratio can be adjusted by adjusting the ballast water volume in each pipe joint, and the cable force adjustment of the stay cable is carried out and the sealing anchor iscarried out at the stay cable anchorage pier. The incremental launching technology of the submerged cable-stayed floating tunnel has little influence by wind, wave, current, ship traveling wave and the like, greatly reduces the safety risk of man-machine for offshore construction, and has high construction efficiency and short construction period.

Owner:CCCC THIRD HARBOR ENG +1

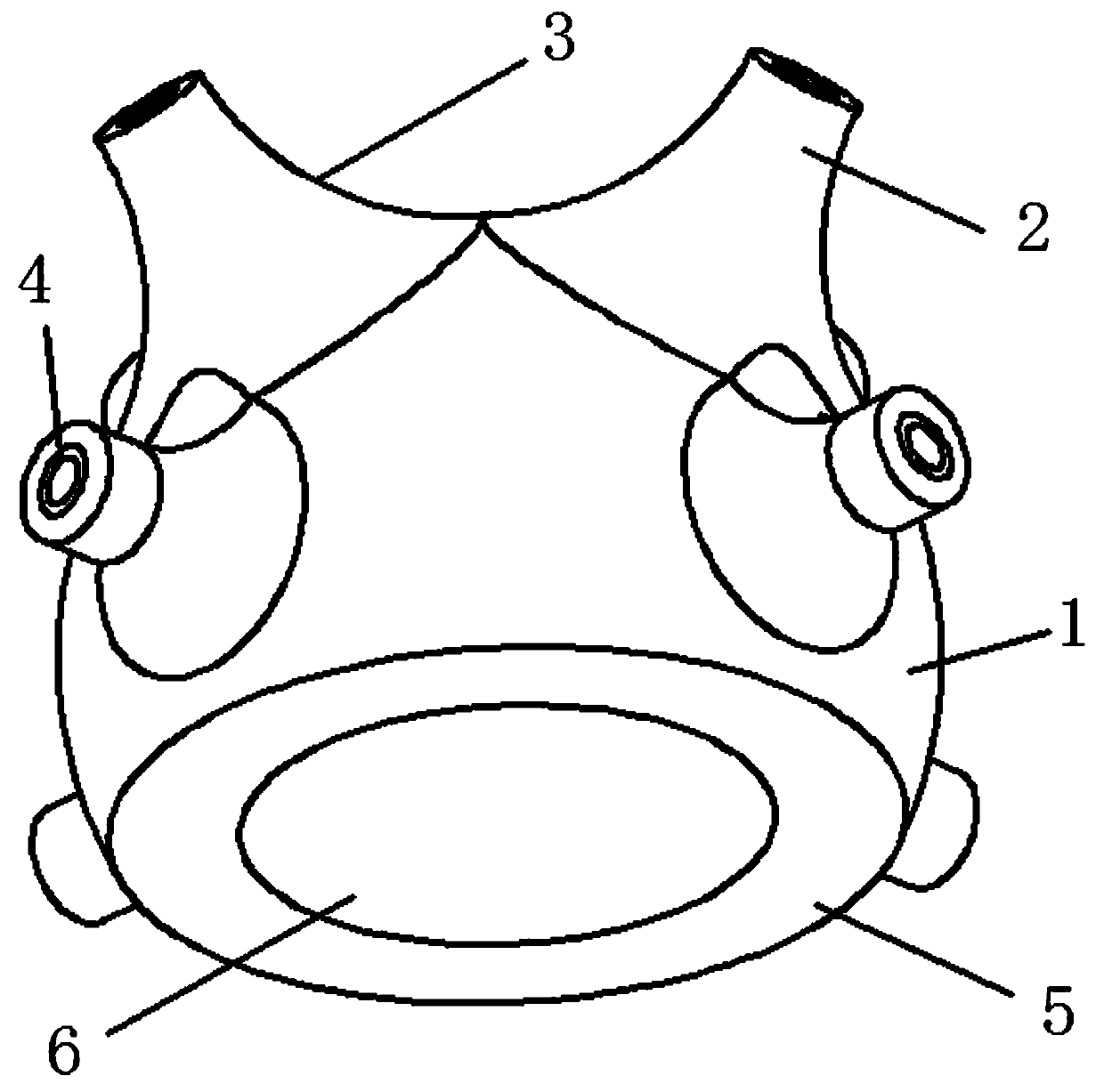

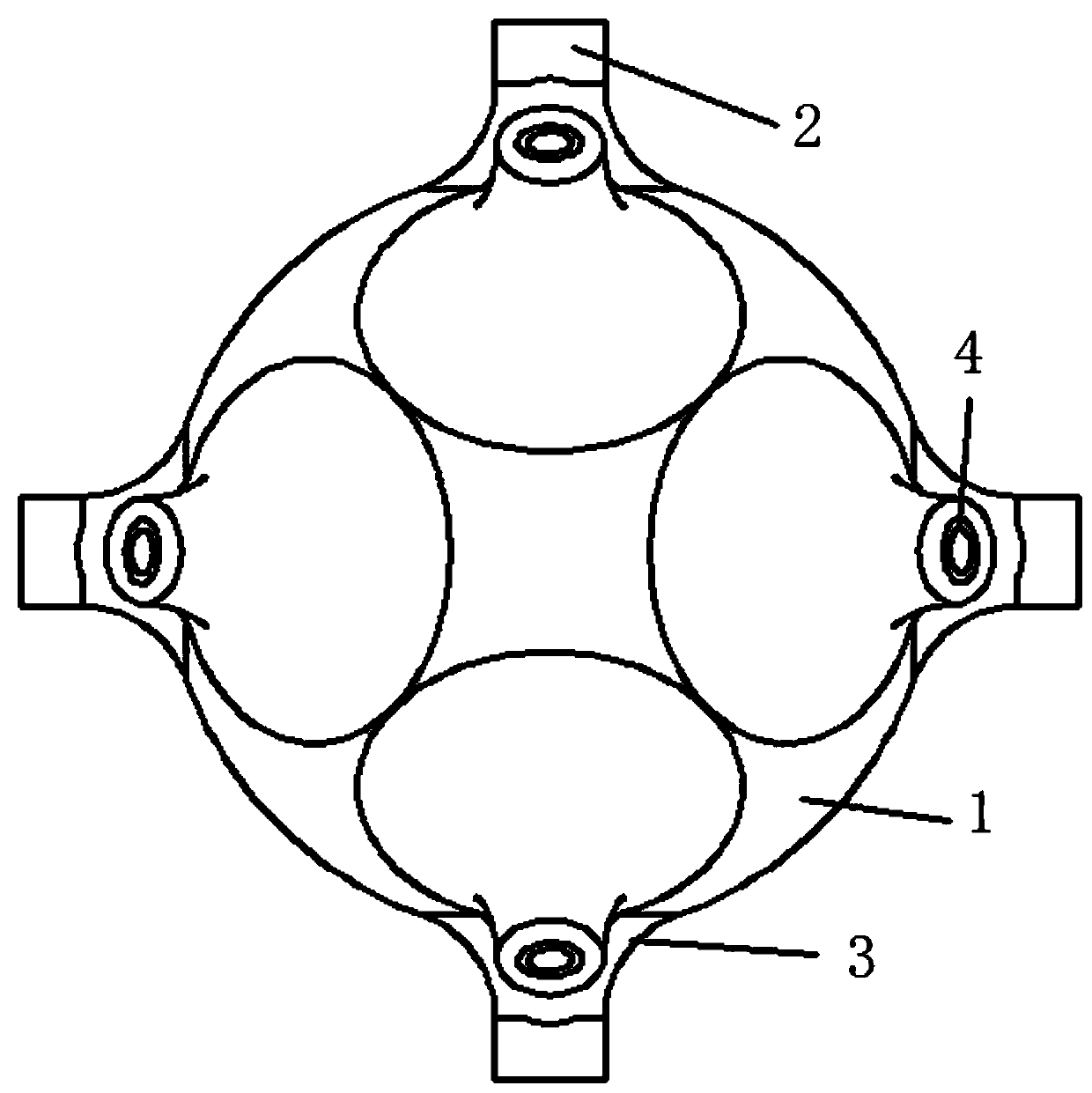

Novel bolt-ball joint and preparation method thereof

PendingCN107829494ALight weightImprove bearing capacityFoundry mouldsBuilding constructionsSolid structureSteel ball

The invention relates to a novel bolt-ball joint and a preparation method thereof, and belongs to the technical field of bolt-ball joint design. The novel bolt-ball joint comprises a steel ball and branch tubes, a cavity structure is arranged inside the steel ball, the branch tubes are arranged on the steel ball and used for connecting and bearing steel rods, the steel ball and the branch tubes are integrally formed, the steel ball is in the shape of a partially cut ball crown, the height of the ball crown is larger than the radius of the steel ball, the branch tubes with solid structures arearranged outwards along the normal direction of the steel ball and uniformly distributed along the circumferential direction of the steel ball, counter bored holes are formed in the branch tubes alongthe normal direction, fillet surfaces for smooth coherent transition of the adjacent branch tubes are arranged on the surface of the steel ball, the surface of the steel ball is in the shape of a curved surface calculated by topological optimization taking the number of the branch tubes, the positions of the branch tubes, the diameters of the branch tubes and the diameters of the counter bored holes as parameters, and the stress of the curved surface is matched with that of the borne steel rods. The bolt-ball is subjected to topological optimization analysis, so that the bolt-ball joint meetsbearing capability, the dead weight of the bolt-ball joint is greatly reduced, and service performance is improved.

Owner:HENAN UNIVERSITY

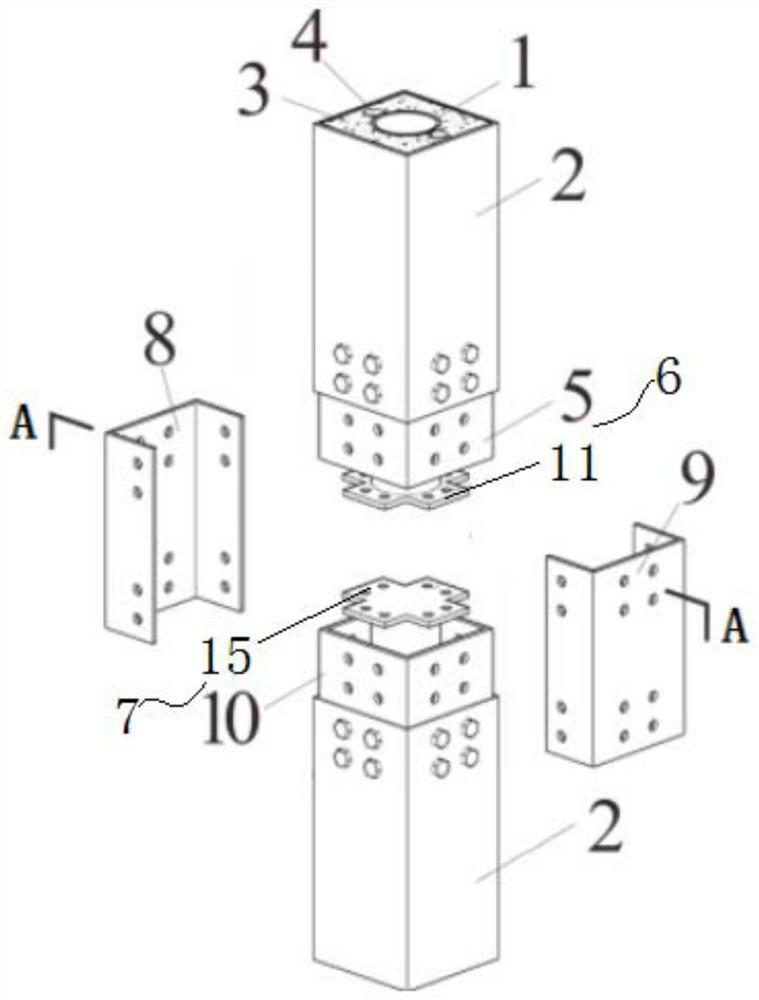

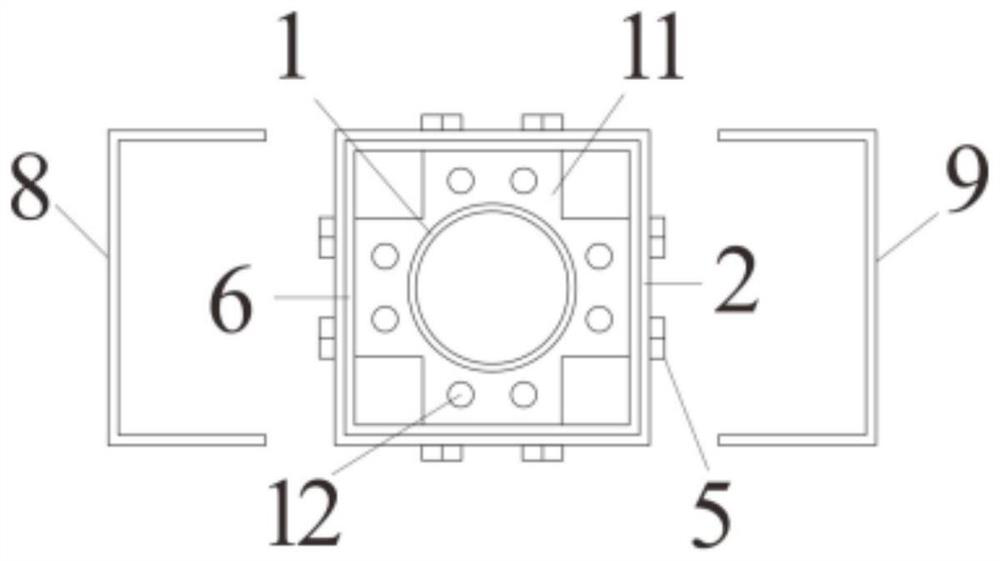

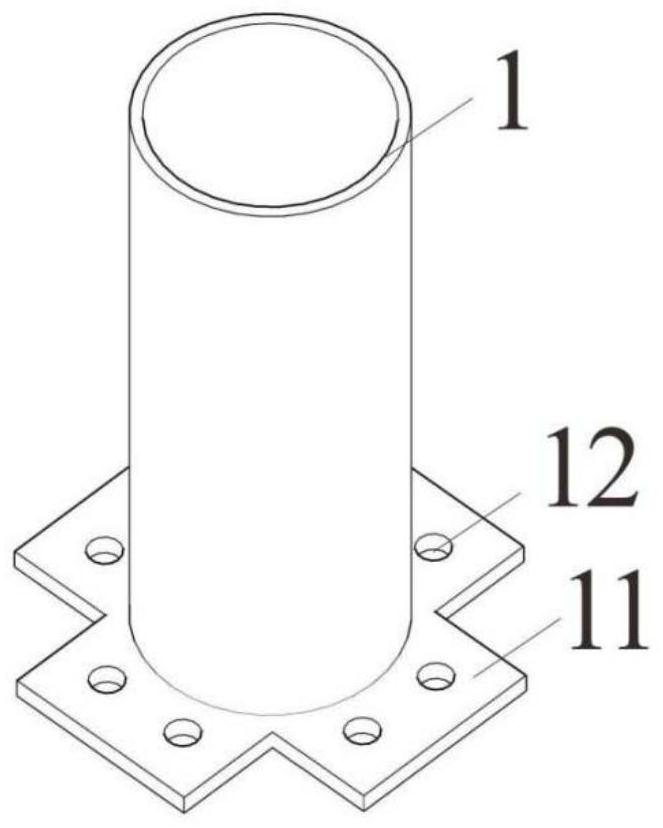

Assembly type joint of round-inside and square-outside compound steel structure type column, connection and generation method thereof

PendingCN112282212ARealize assembly constructionReduce on-site weldingStrutsProtective buildings/sheltersSteel tubeManufacturing engineering

The invention discloses a assembly type joint of a round-inside and square-outside compound steel structure type column. The assembly type joint comprise a first joint connector and a second joint connector, the first joint connector comprises a first cross-shaped connecting panel which is connected with the lower end part of an upper side inner round steel pipe and a first sleeve connector whichis connected with the inner wall of the lower end part of an upper side outer square steel pipe, the second joint connector is consistent with the first joint connector in structure, and a first channel steel connector and a second channel steel connector are further included. Through reasonable arrangement of part structures, field welding and concrete operation are reduced, the construction quality is guaranteed, the construction speed is increased, and meanwhile the construction cost is saved; by the adoption of the assembly type splicing joint for the round-inside and square-outside hollowinterlayer type compound concrete-filled steel tubular column and the connecting method, assembly construction of a compound concrete-filled steel tubular structure can be achieved, and the buildingindustrialization process is accelerated; and meanwhile, a user does not need to manually carry out position selection and parameter setting on a connecting part, and then the column splicing joint required in design software can be automatically generated.

Owner:CHANGAN UNIV

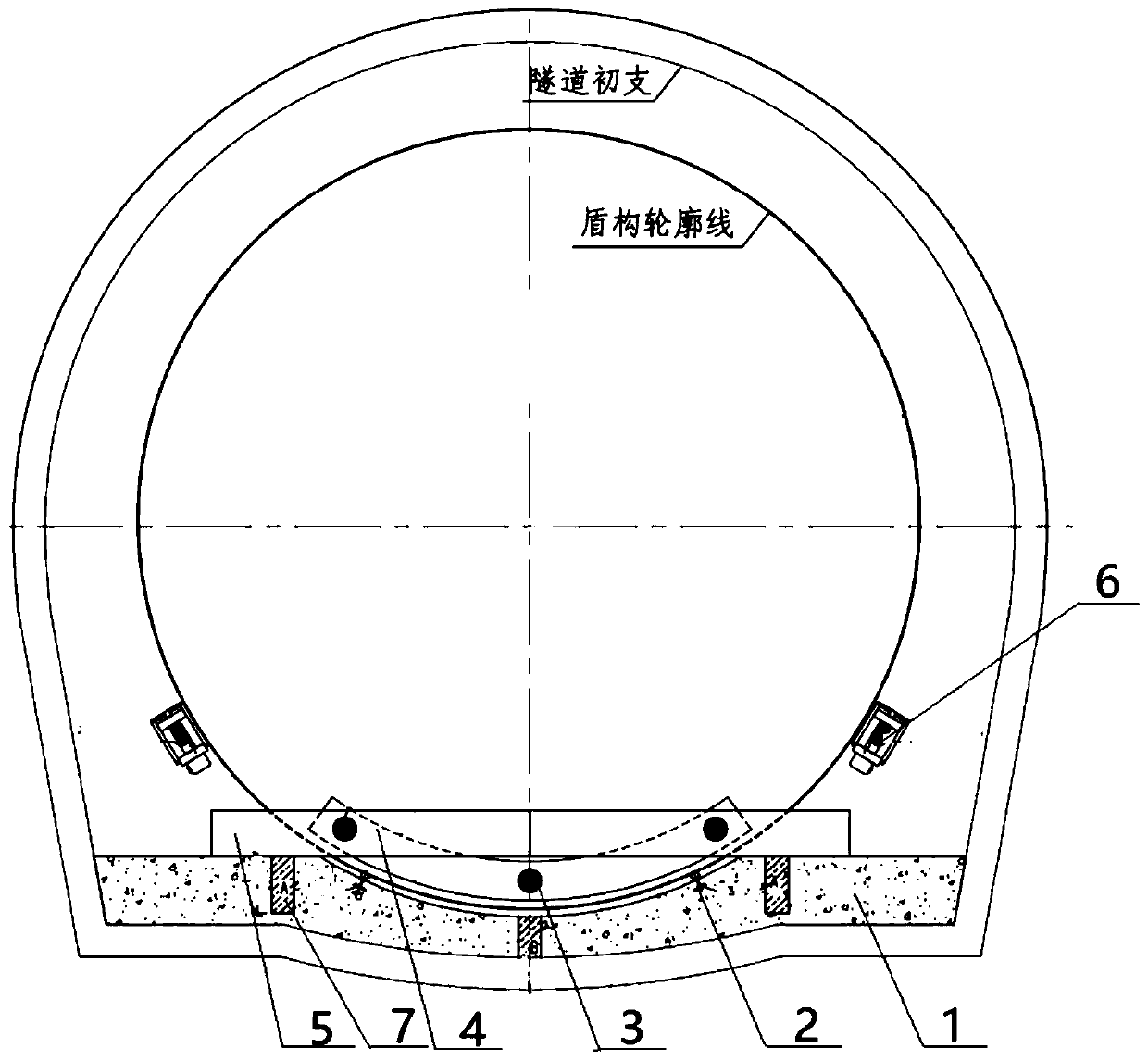

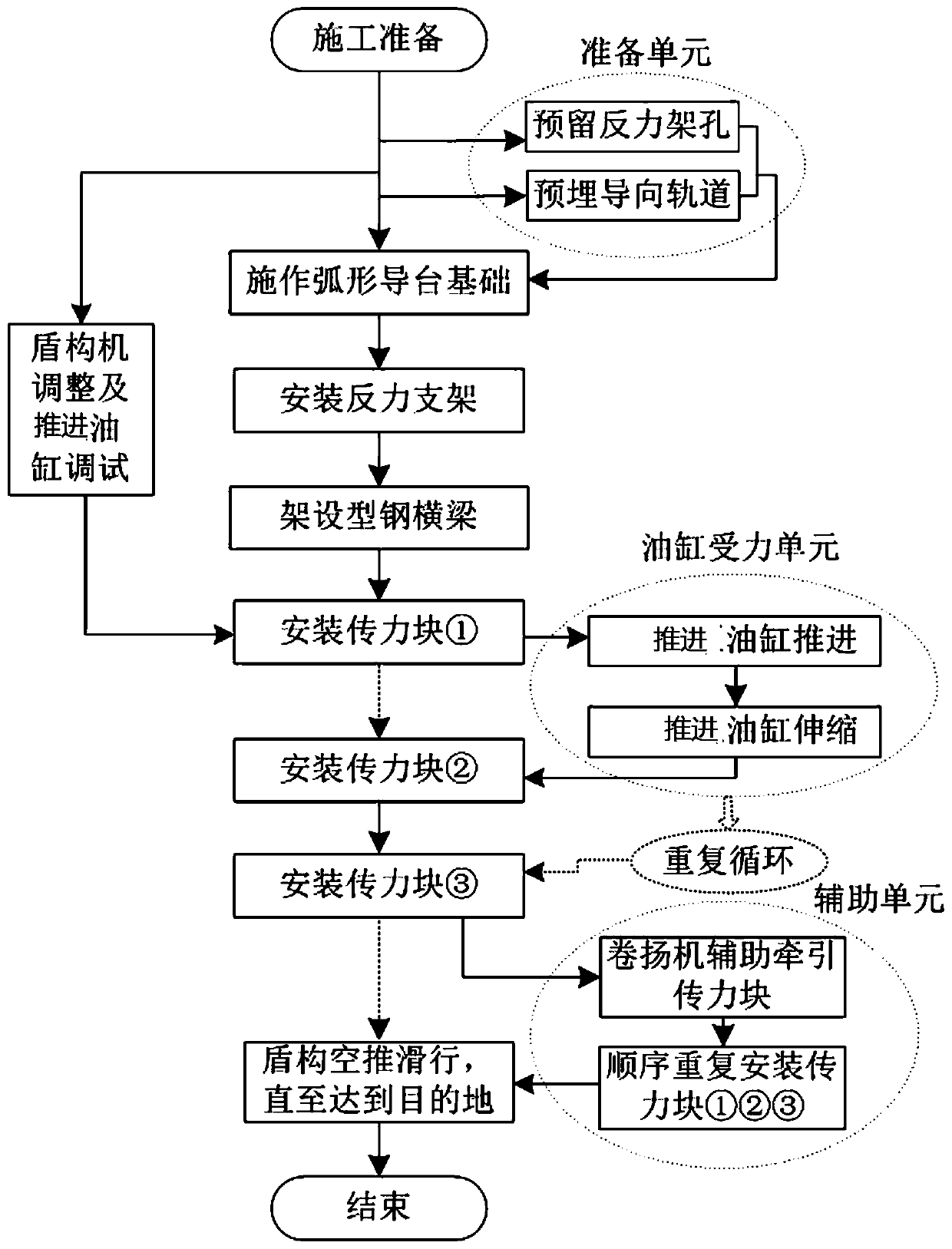

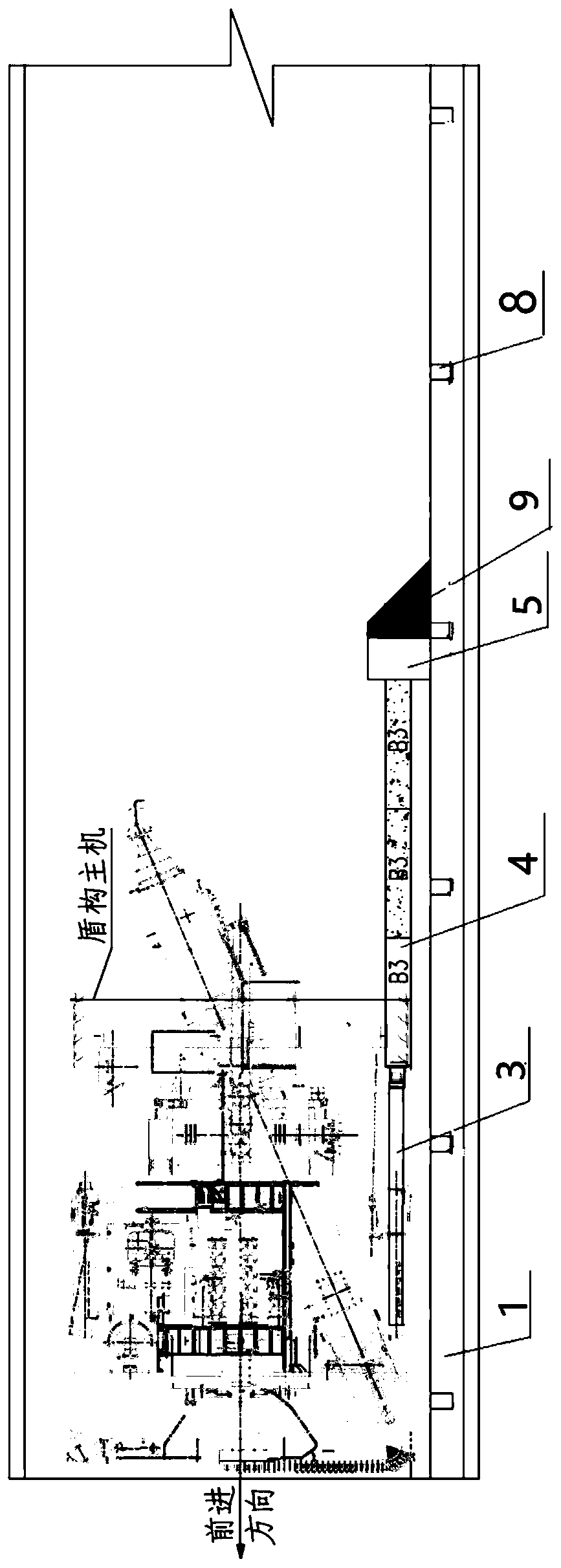

Device for shield plane sliding stepping in narrow space and construction method thereof

The invention discloses a device for shield plane sliding stepping in a narrow space. The device comprises an arc-shaped guide table and a guide rail, and further comprises a force transmission mechanism connected with thrust cylinders on a shield main machine and an auxiliary force transmission mechanism positioned on the shield main machine and used for pulling the force transmission mechanism,wherein the force transmission mechanism comprises a plurality of force transmission blocks connected with one ends of the thrust cylinders, a cross beam connected with the force transmission blocks and counter-force supports positioned on one side of the cross beam; and the bottoms of the counter-force supports are connected with the arc-shaped guide table, and the number of the counter-force supports is equal to that of the thrust cylinders. The device is simple and practical, existing resources such as standard block segments are utilized, the steel structure arc-shaped guide table does notneed to be independently machined, and cost is saved; plane sliding is achieved in the small space, the section size of a sliding channel does not need to be increased, and the safety risk of a shallow buried section tunnel is reduced; and a supporting stress structure adopts the H-shaped steel cross beam to increase the supporting stress area, the cross beam and the counter-force supports transmit force in a balanced and symmetrical mode, operation is easy and convenient, and use is safe.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

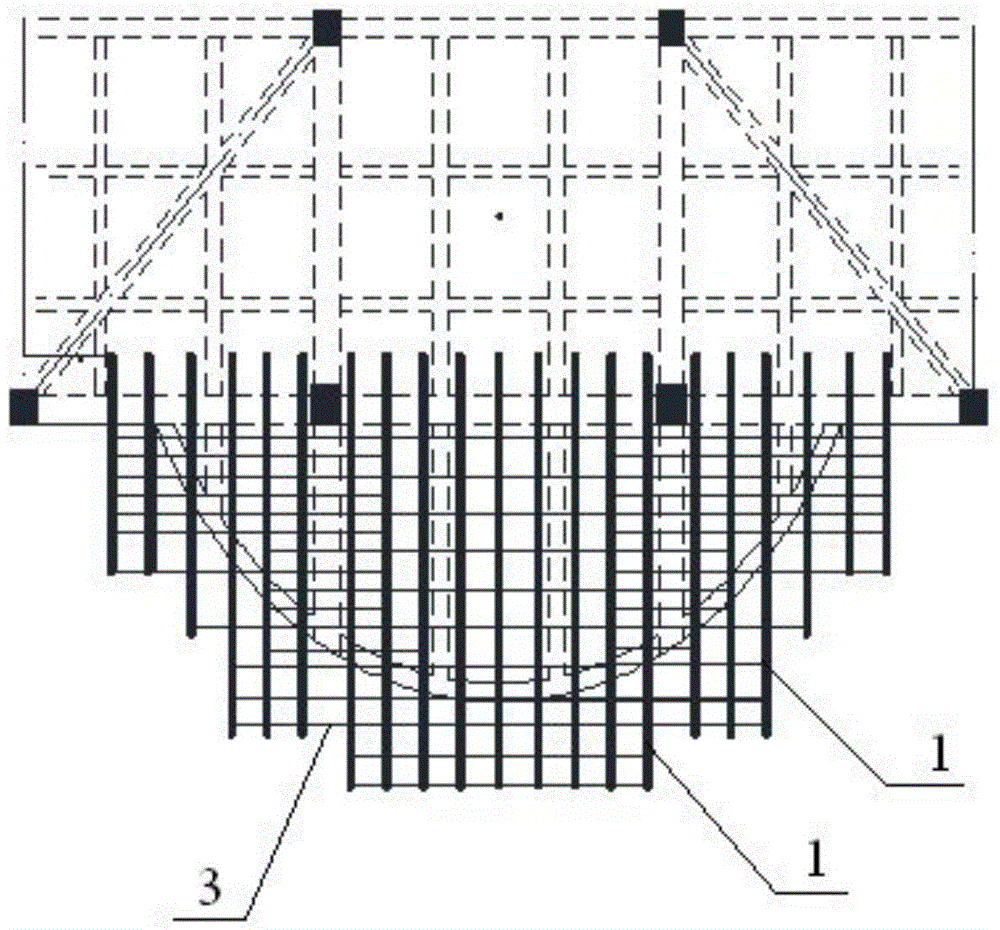

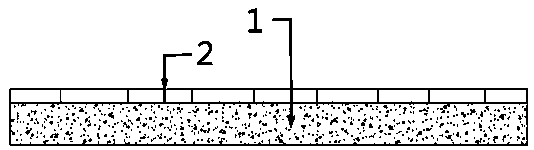

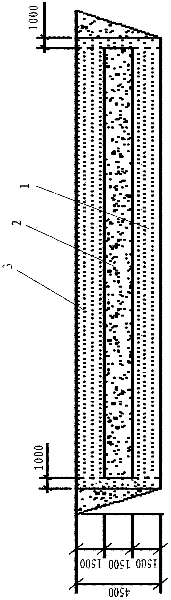

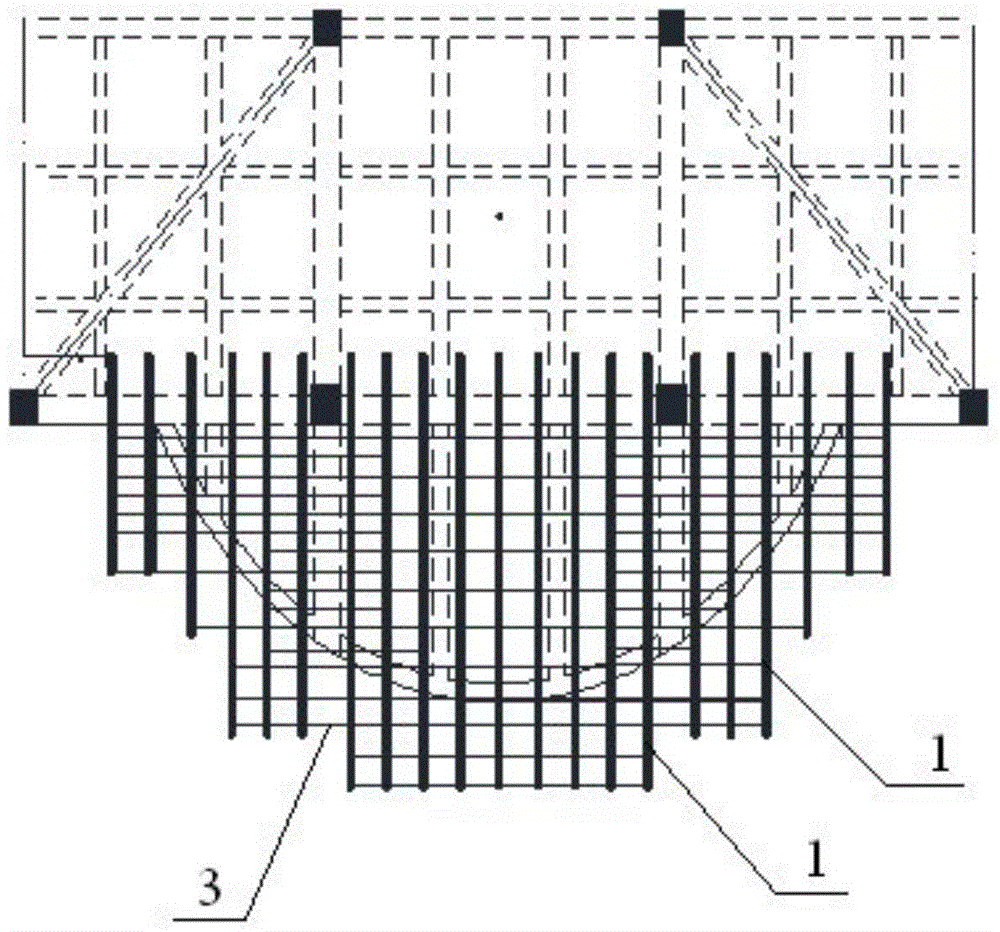

Construction method for decomposing grading high-rise pile cap

InactiveCN101446087ASolve the difficulty of constructionShorten the construction periodEmbankmentsDecomposerAluminium industry

The invention discloses a construction method for decomposing a grading high-rise pile cap. A pipe (1) based on a decomposer is constructed up to the ground elevation of a bearing platform at a time. The bearing platform (2) of the pile foundation is constructed in advance before secondary backfill is made, and then back fill (3) under the ground elevation of field plating is treated. The method has simple configuration, low cost, easy implementation, can solve greatly construction difficulty when being applied to aluminium industry fractional decomposition, shortens duration of a project, and reduces the investment.

Owner:GUIYANG AL-MG DESIGN & RES INST

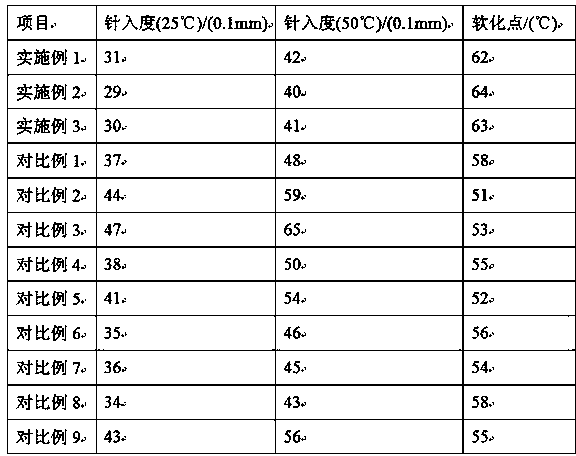

Weather-proof modified asphalt

InactiveCN109504108AImprove stress resistanceImprove wear resistanceBuilding insulationsFatigue damageGraphene

The invention mainly relates to the technical field of construction and discloses a weather-proof modified asphalt. The weather-proof modified asphalt is prepared from the following raw materials: 95-100 parts of matrix asphalt, 2.2-2.4 parts of water, 2.1-2.3 parts of nanometer titanium dioxide, 1.7-1.9 parts of SBS asphalt modifier, 1.1-1.3 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 0.3-0.5 part of asphalt stabilizer and 0.5-0.7 part of graphene. The weather-proof modified asphalt provided by the invention has the advantages of extensive source of raw materials, simple preparation, low cost, high weather fastness, ageing delaying effect, high fatigue damage resistance and anti-rutting performance under high-temperature and rainy conditions, capability of avoiding embrittlement and cracking under low temperature, high stability and capability of prolonging service life of road. Nanometer titanium dioxide and SBS asphalt modifier are added after matrix asphalt is heated and molten, so that fluidity and weather fastness of asphalt can be promoted and construction difficulty can be reduced.

Owner:魏林涛

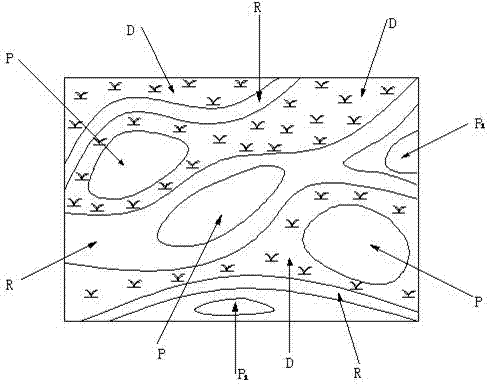

Construction method for reforming overall topography by determining elevations by adopting garden path foundation trench excavation

InactiveCN103757999ALow retrofit costReduce handlingRoadwaysSoil preservationMaterial resourcesEngineering

The invention discloses a construction method for reforming the overall topography by determining elevations by adopting garden path foundation trench excavation. The construction method is characterized by comprising the following steps: (1) accurately calibrating the garden construction range; (2) surveying the construction range, cleaning the surface and removing barriers; (3) equipping construction and measuring personnel and machinery; (4) carrying out construction measurement and setting out on the garden paths and determining the elevation of each construction site; (5) excavating garden path foundation trenches and splitting green plots; (6) measuring and setting out each green plot and determining the topography reforming elevation point; (7) balancing earthwork for the first time and transporting earthwork inward; (8) reforming the topography, namely making slopes or reshaping; (9) balancing earthwork for the second time and stacking, filling or transporting earthwork outward; (10) carrying out inspection and acceptance and follow-up treatment on the construction sites. The method for reforming the topography along the foundation trenches is adopted and has the beneficial effects that earthwork moving is reduced; the topography reforming cost is saved; the construction difficulty is reduced; the earthwork is stacked neatly; earth is filled conveniently; construction is carried out orderly; the construction progress can be accelerated; the manpower and material resources can be saved; the garden reforming efficiency and quality are improved.

Owner:FLOWER KING ECO ENG CO LTD

Wireless indoor fan coil control system

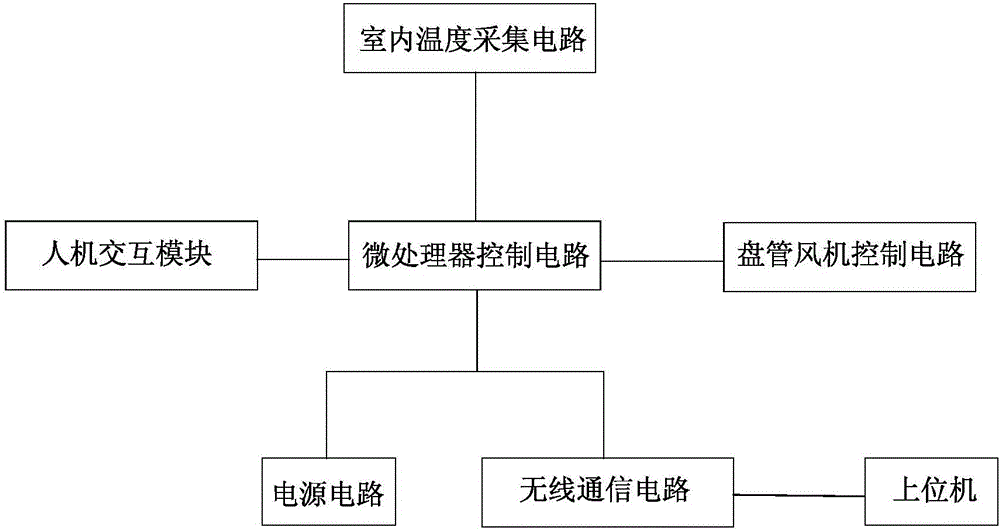

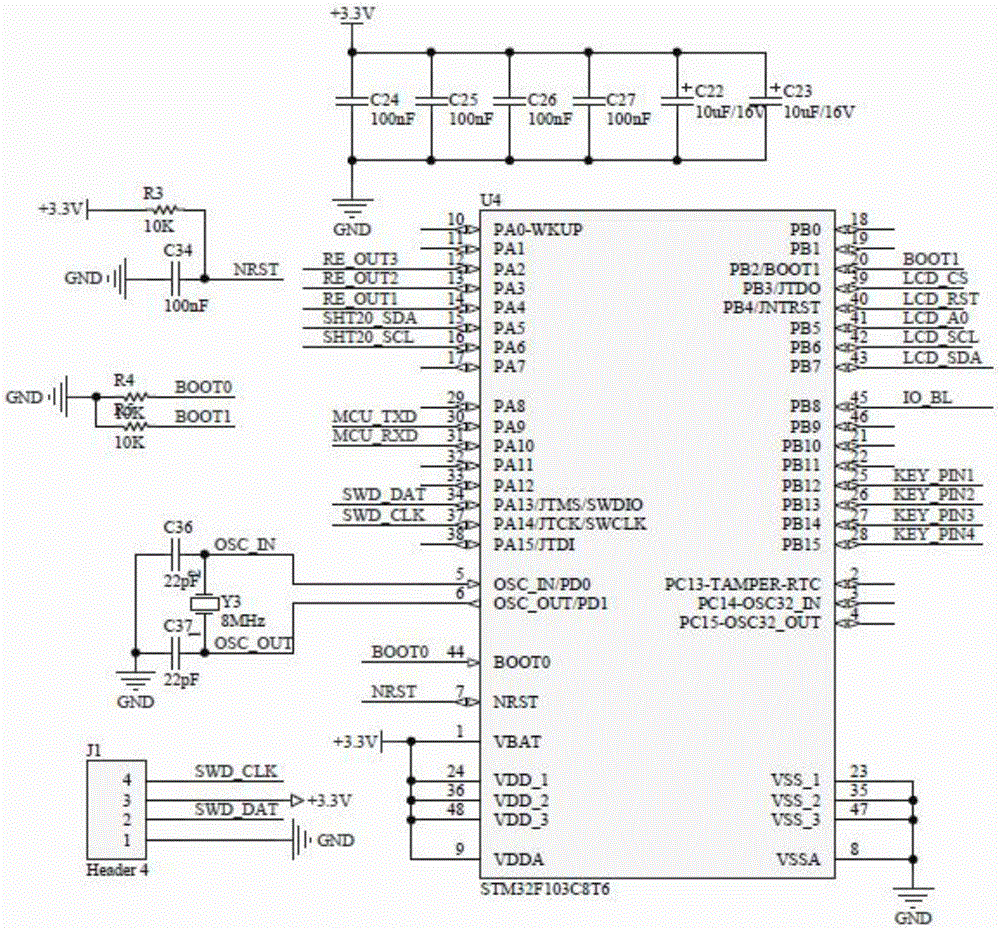

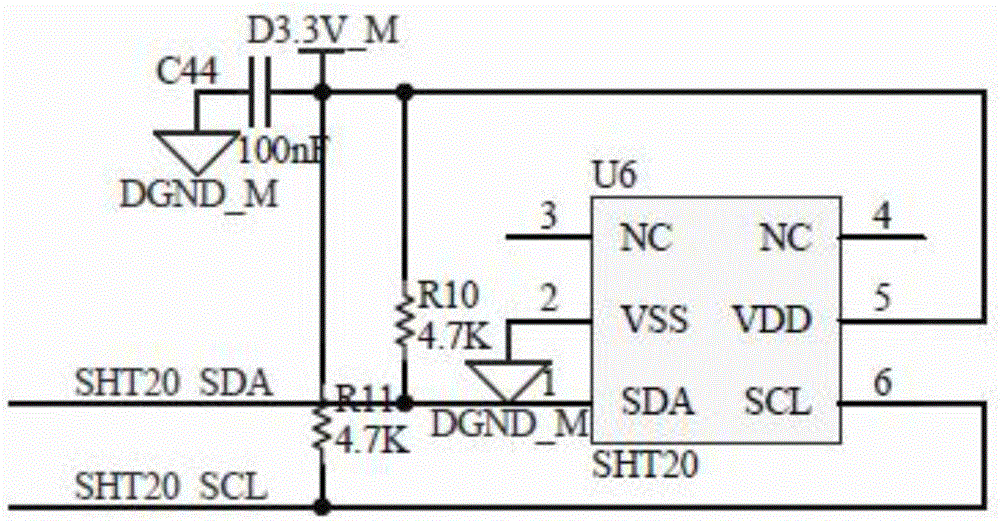

PendingCN106647487ARealize remote wireless controlRealize functionProgramme controlComputer controlTransceiverControl system

The invention discloses a wireless indoor fan coil control system comprising a microprocessor control circuit, an indoor temperature acquisition circuit, a wireless communication circuit, a coil fan control circuit, a power supply circuit and a man-machine interaction module; the indoor temperature acquisition circuit output end is connected with a temperature data input end of the microprocessor control circuit; a fan signal input end of the microprocessor control circuit is connected with a data transceiver end of the wireless communication circuit; a remote data transceiver end of the wireless communication circuit is wireless connected with a host; the coil fan data input end of the microprocessor control circuit is connected with the output end of the coil fan control circuit; the power supply circuit and the man-machine interaction module are respectively connected with the microprocessor control circuit.

Owner:山东金洲科瑞节能科技有限公司

Support-free steel structure spiral staircase

The invention discloses a support-free steel structure spiral staircase, which comprises a reinforced platform (1), stair steps (2), skirting waistline (3), railing handrails (5), the skirting waistline (3) The lower corner is welded to a reinforced platform (1); the stair steps (2) are welded to the skirting waistline (3), and multiple support columns (6) are arranged on both sides of the stair steps (2); The supporting column (6) is embedded in the skirting line (3) and fixed by welding, the supporting column (6) and the skirting line (3) are provided with grooves, the glass guardrail (4) is embedded in the groove, and the railing handrail (5) Fix it on the glass guardrail (4) through the connector. The invention can ensure the load bearing and force requirements, realize the feasibility of support-free technology, reduce the construction period, and reduce the construction difficulty; and can effectively prevent the occurrence of common quality problems caused by unbalanced force and fracture, and control the problem of serious material loss.

Owner:GOLD MANTIS CONSTR DECORATION

Cement fly ash foaming composite heat insulation material

InactiveCN101906826ASolve the pollution of the environmentAvoid construction difficultyRoof covering using slabs/sheetsClimate change adaptationThermal insulationSlurry

The invention relates to a cement fly ash foaming composite heat insulation material, which comprises a cement fly ash foaming heat insulation outer layer, a sandwich composite layer and a cement fly ash foaming heat insulation inner layer, wherein the sandwich composite layer is positioned between the cement fly ash foaming heat insulation outer layer and the cement fly ash foaming heat insulation inner layer; the cement fly ash foaming heat insulation inner layer is connected with a building concrete body; and the sandwich composite layer is prepared from a polyphenyl board (ERS board), an extruded toluene board (XPS board), hard foam polyurethane and polyphenyl granular slurry. The heat insulation material has the advantages that: the problem that the fly ash of a power plant pollutes the environment is solved; the industrial waste is prepared into the building energy-saving heat insulation material so as to solve the problem of waste consumption for the state, save the energy and change waste into valuable; the heat insulation material is a multi-purpose energy-saving heat insulation material, and can be used for heat insulation of a building peripheral structure; and the construction difficulty is solved, and the construction quality is ensured.

Owner:WUHAN CHANGHONGWEI TECH

Anchor rod for underground engineering anti-floating system construction and construction method

ActiveCN106013143AAvoid construction difficultyLow efficacyProtective foundationBulkheads/pilesEconomic benefitsArchitectural engineering

The invention relates to an anchor rod for underground engineering anti-floating system construction and a construction method. The anchor rod comprises an anchor rod framework, wherein an anchor head with a backing plate is fixedly mounted at the top of the anchor rod framework; the anchor rod framework comprises a guide pipe; a grout pipe I is arranged inside the guide pipe; and a grout pipe II is fixedly mounted at an external part of the guide pipe. The anchor rod has the benefits as follows: a traditional support type anchor rod construction machine is adopted, so that the defects that the construction difficulty is high and the efficiency is low, the construction period is long, the input cost is high, both excavation and structure construction processes cannot be effectively joined due to slow progress of a traditional process when an anti-floating pile is constructed in high-strength hard rock are overcome; and the fast progress and good quality are realized, and greater economic benefits are brought to enterprises.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU

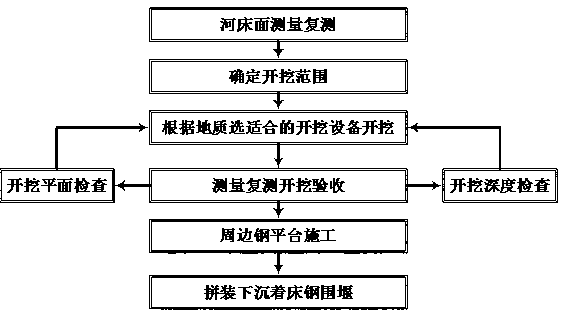

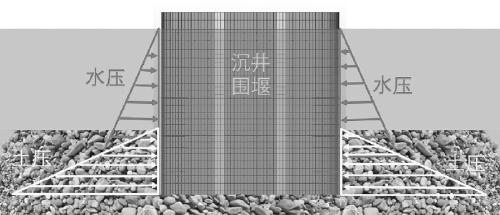

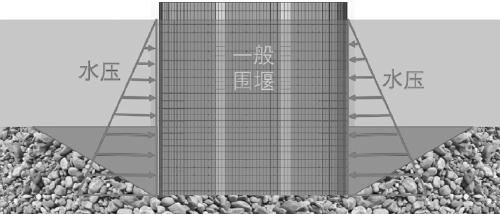

Construction method for underwater deeply-buried structure

The invention discloses a construction method for an underwater deeply-buried structure. The technological process comprises the step I of selecting proper underwater excavation equipment that can reach in waters according to the project geological exploration data; the step 2 of resurveying an underwater terrain, and designing a proper underwater excavation method and an excavation step-slope form according to design drawings and geological and hydrological data; the step 3 of performing surveying and setting out over water, and installing excavation monitoring equipment on the excavation equipment; the step 4 of performing underwater stepped excavation, and implementing necessary construction of an auxiliary construction platform after completion of excavation; the step 5 of constructingsinking cofferdam, and regulating implantation to a design attitude; the step 6 of pouring sandwich concrete and bottoming concrete of the cofferdam, and finishing cofferdam construction; and the step 7 of pumping water for dry construction of an underwater structure. According to the construction method, underwater excavation is implemented firstly, and then a water-surrounding auxiliary structure is constructed, so that dry construction environment of the structure is ensured; and the underwater construction problem of the deeply-buried structure below a complex geological riverbed can be solved in a high-quality mode quickly, efficiently and safely.

Owner:SICHUAN ROAD & BRIDGE GRP

Shell softening processing technology

InactiveCN108032666ASolve the process that cannot be bentSolve physical exhaustionSpecial ornamental structuresSurface cleaningEngineering

The invention discloses a shell softening processing technology which comprise the following steps: cleaning shell raw materials: pouring aired shells on an open place and manually picking one by one;roasting according to different sizes and thicknesses of the shells; cooling, soaking and drying; utilizing a bonding bottom material and glue to manually stick the shells one by one, cleaning the glue on the surfaces and drying the shells; cold pressing the bonded shells, surface cleaning and airing and performing surface brightening treatment. The shell softening processing technology disclosedby the invention has the advantages that 1, a technology that the shells can not bent and processed is solved; 2, a shell decoration plate which has the advantages of light weight, bright colors andgood decoration effect is provided; 3, construction difficulty in installing traditional tiles, stone materials and face boards and the physical power exhaustion situation caused by self weight of products to constructors in construction are solved; 4, the bottom material is multiply converted and can be compounded to the surfaces of a plurality of base materials; 5, high price of traditional natural materials is broken through.

Owner:江西兆骏实业有限公司

Drainage structure system underdrain and underdrain structuring method of drainage structure system

PendingCN109098258AOvercoming the disadvantages of poor sanitationSolve the shortcomings of poor sanitationSewerage structuresSewer pipelinesEngineeringSoil horizon

The invention provides a drainage structure system underdrain applied to the technical field of drainage structure systems. The invention also relates to an underdrain structuring method of a drainagestructure system. According to the drainage structure system underdrain, the underdrain channel (2) of every underdrain module (1) is in a U-shaped cross-sectional structure, the upper portion of every underdrain module (1) is connected in a fastened mode with an underdrain cover plate (3), the underdrain channels (2) of a plurality of the underdrain modules (1) form a drainage channel, underdrain parts are arranged inside arranging pits (7) formed in the ground (6), and a covering soil layer (8) is arranged above the underdrain cover plates (3). The drainage structure system underdrain and the underdrain structuring method of the drainage structure system can effectively combine the advantages of ditch drainage and pipe drainage, overcome the shortcoming of poor sanitary conditions of traditional drains, facilitate drain dredging, solve the problem of underdrain dredging inconvenience and reduce the construction difficulty.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

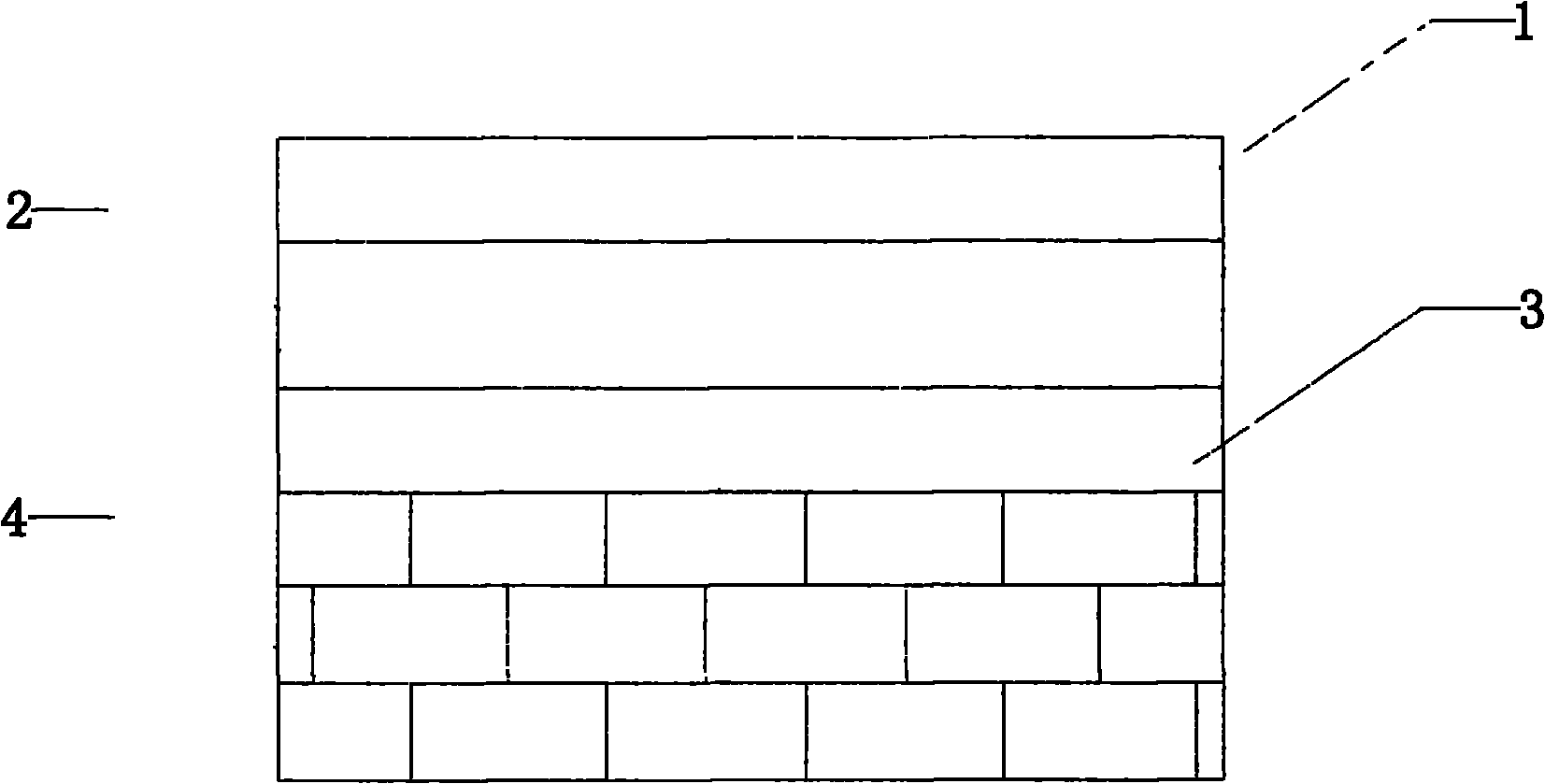

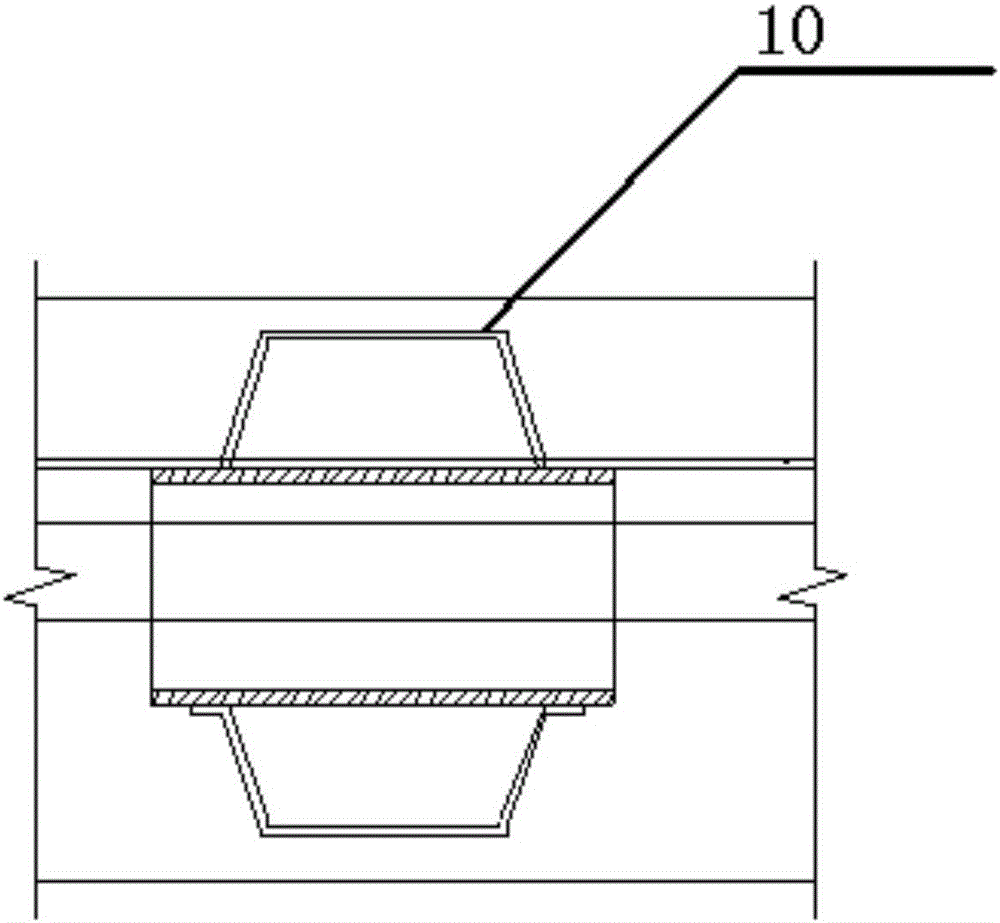

Blast furnace slag replacement method for high-fill steel slag foundation

ActiveCN102518111ASolve the problem of thermal expansionResolve lateral pressureEmbankmentsSoil preservationSlagThermal expansion

The invention discloses a blast furnace slag replacement method for high-fill steel slag foundation, which comprises the following steps of: superimposing a first blast furnace slag cushion layer (1), a graded gravel cushion layer (2) and a second blast furnace slag cushion layer (3) sequentially from bottom to top in a steel slag foundation pit, respectively compacting the first blast furnace slag cushion layer, the graded gravel cushion layer and the second blast furnace slag cushion layer, setting up a through groove around the first blast furnace slag cushion layer, the graded gravel cushion layer and the second blast furnace slag cushion layer, and filling blast furnace slag into the groove. By adopting the blast furnace slag replacement method, the problem of thermal expansion of the high-fill steel slag foundation can be solved. The invention has the advantages that the method can be easily mastered and has practicality, the quality requirements can be satisfied, the construction period can be shortened, and the construction cost can be reduced. Therefore, the method has good promotion prospects.

Owner:PANGANG GRP ENG TECH

High-altitude large cantilever concrete structure steel support platform

ActiveCN104453197BAvoid construction difficultyEasy to operateBuilding support scaffoldsComponent LoadFalsework

Owner:SHANGHAI ZHONGJIN CONSTR GRP

Portable nail hole rust prevention device

ActiveCN112360175AEasy to operateMeet the needs of the painting situationBuilding repairsBuilding insulationsMining engineeringStructural engineering

The invention provides a portable nail hole rust prevention device. The device comprises a paint pipe, a supporting pipe, a driving pipe and a connecting pipe. A paint storage tank for placing antirust paint is arranged in the paint pipe; a permeable layer is arranged at the opening side of the paint storage tank in the paint pipe; the supporting pipe is arranged and connected with the closed sideof the paint pipe; the driving pipe is arranged in the supporting pipe in a sliding and penetrating mode; the first end of the driving pipe is arranged in the paint storage tank; a paint jacking partis arranged at the first end of the driving pipe; the second end of the driving pipe extends out of the supporting pipe and is connected with the connecting pipe; and an elastic element is arranged on the outer wall of the driving pipe and located between the supporting pipe and the connecting pipe in a sleeving mode. The portable nail hole rust prevention device meets the requirements of nail hole antirust paint brushing on an architectural decoration site, solves the practical requirements, reduces the construction difficulty, is clean and sanitary in the construction process, and providesconvenience for the architectural decoration site.

Owner:上海宝冶建筑装饰有限公司 +1

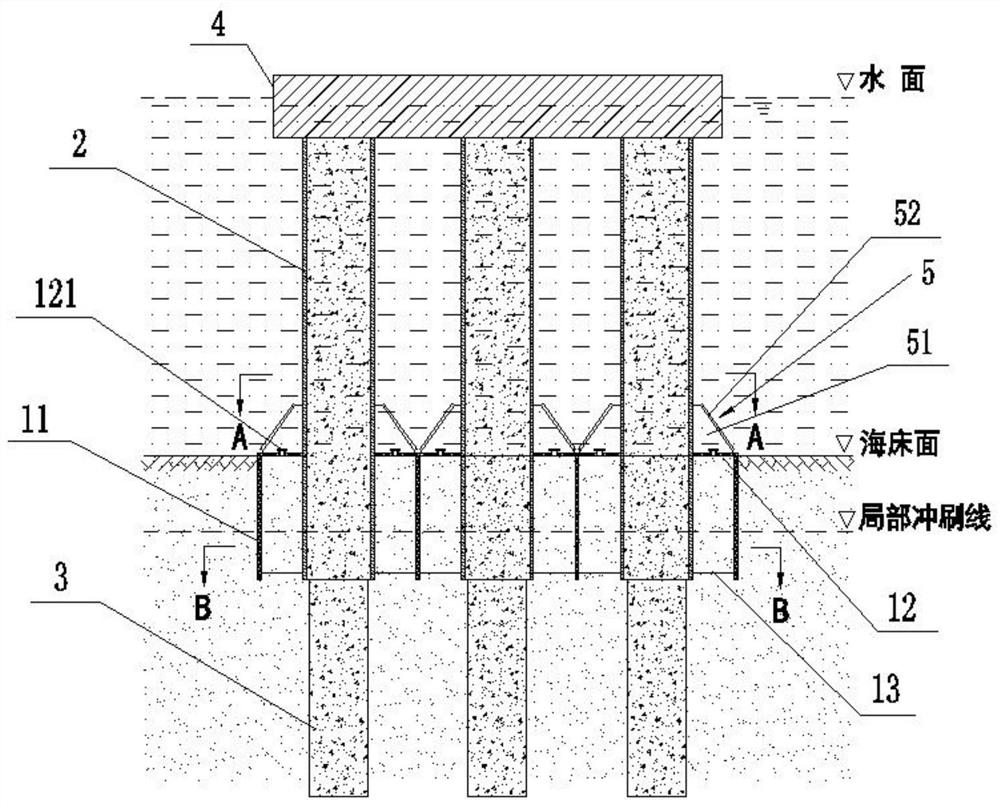

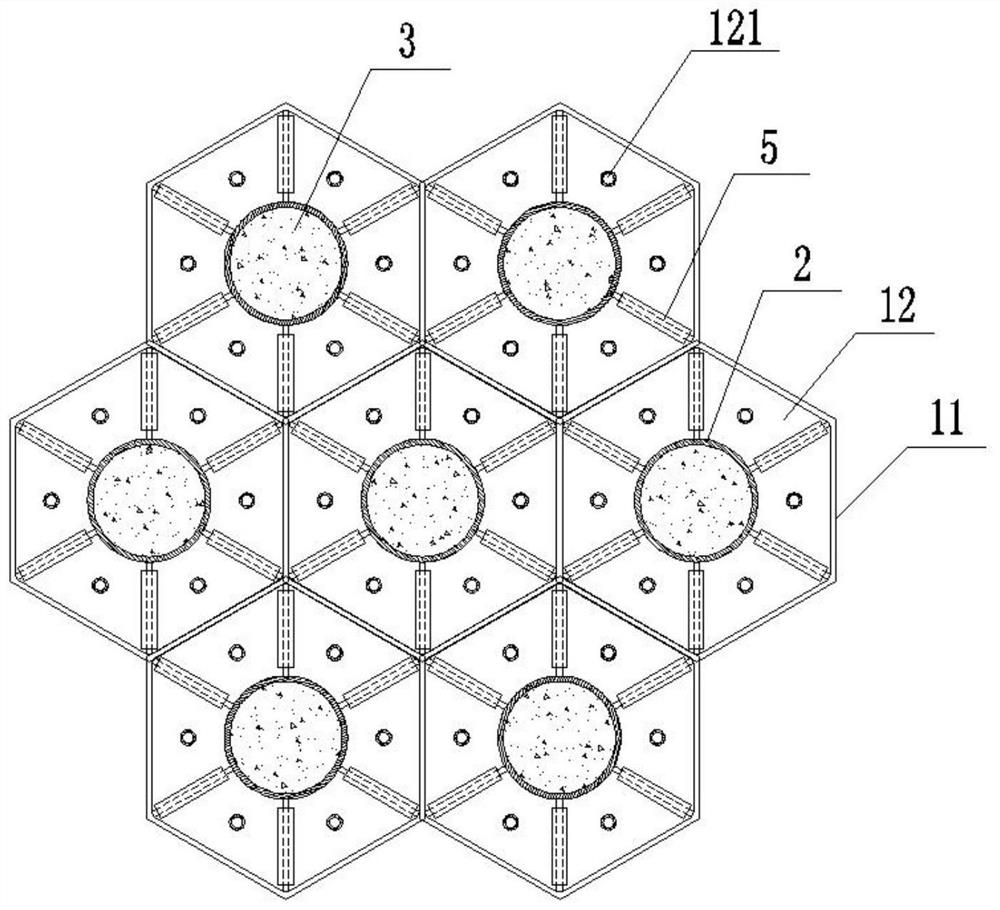

An integrated deep water foundation and its construction method

ActiveCN111636465BShorten the construction periodImprove carrying capacityArtificial islandsUnderwater structuresSuction forceSteel columns

This application relates to an integrated deep-water foundation and its construction method, and relates to the technical field of bridge deep-water foundations, including multiple suction single wells, multiple steel pipe columns, multiple bored piles and caps. The steel casing used for bored pile construction, and the steel pipe column and the single suction well are an integrated structure prepared in advance. After the drainage operation of the single suction well, the steel pipe column and the single suction well can sink to the design elevation. There is no need to erect a large jacket platform and carry out processes such as hoisting, turning over, and sinking of steel casings in the marine environment with harsh swell conditions, and the suction well base and steel pipe columns can participate in the stress of the deep water foundation during the bridge use stage Among them, the free length of the single pile can be effectively reduced, and the horizontal and vertical bearing capacity of the pile body can be improved. Therefore, the application can not only reduce the construction risk, difficulty and cost, but also shorten the construction period and improve the horizontal bearing capacity and vertical bearing capacity of the pile body.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

A jacking process for an underwater cable-stayed floating tunnel

ActiveCN111254982BReduce security risksAvoid construction difficultyArtificial islandsUnderwater structuresWind waveOffshore construction

The invention discloses a jacking process for an underwater cable-stayed floating tunnel. It includes prefabricating all the pipe joints of the underwater floating tunnel in the land prefabrication field, and then transporting them to the shore structure on the pushing side through the land slope tunnel, followed by secondary outfitting, docking with the subsequent pipe joints and sealing them into the water, and then putting them into the water. The pipe joints are pushed up section by section to the shore structure on the receiving side; the stay cables are installed on the pipe joints one by one along with the jacking and pulled into the cable anchorage pier; The concrete on the outer surface of the pipe joints at both ends of the floating tunnel in the water is poured in the shore structure to complete the consolidation of the pipe joints at both ends of the floating tunnel in the water. Adjust the cable force of the stay cables on the anchorage pier and seal the anchor. The jacking process of the present invention is less affected by wind, waves, currents, and ship waves, which greatly reduces the risk of man-machine safety in offshore construction, and has extremely high construction efficiency and short construction period.

Owner:CCCC THIRD HARBOR ENG +1

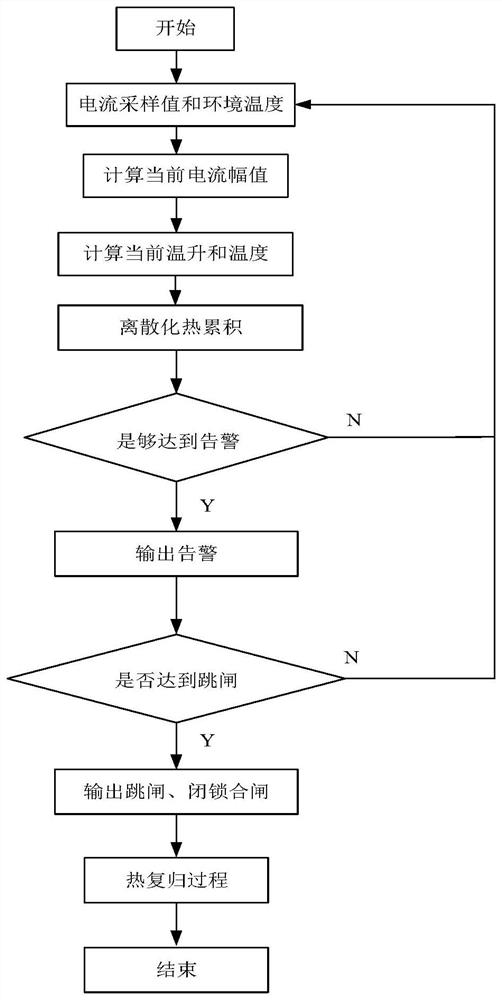

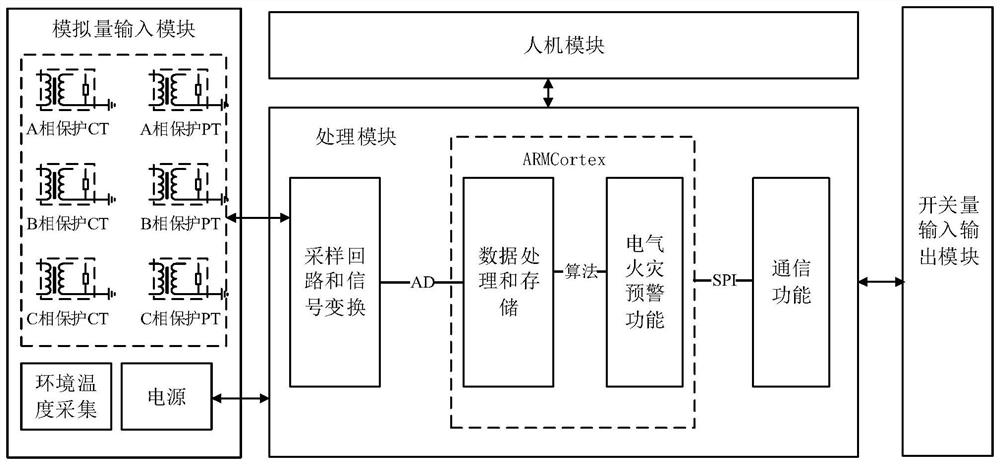

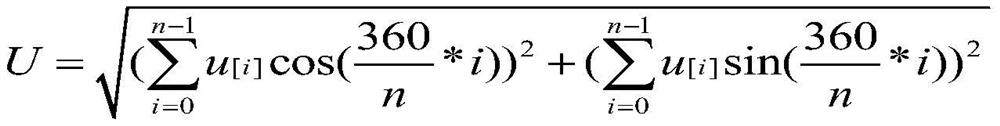

Fire early warning method based on logarithmic inverse time limit principle

PendingCN114202875ASolve the difficulty of getting electricityHigh economy and practicalityEmergency protection detectionFire alarm electric actuationThermodynamicsElectrical current

The invention discloses a fire early warning method based on the logarithmic inverse time limit principle, and the method comprises the steps: collecting the load current of an operation line through the environment operation state and the parameters of a power supply cable; the real-time temperature rise of the current power supply cable is estimated, the current cable temperature is estimated according to the environment temperature, and when the temperature is higher than the safe operation level, a fire early warning prompt is given; and performing a thermal accumulation process on the real-time load current by applying a logarithmic discretization inverse time limit algorithm, tripping and starting a thermal reset timing process when the running limit of cable heating is reached, and forbidding the line to be switched on and put into operation before thermal reset zero clearing in the thermal accumulation process. According to the method, the temperature and the heat accumulation time of the running line cable can be quickly estimated and judged without depending on an external cable temperature sensor, the running safety of the power cable is guaranteed, fire accidents caused by cable overheating are avoided, and the life and property safety of people is guaranteed.

Owner:江苏业力科技有限公司

Concrete filling and pouring method for connecting upper column section and lower column section of prefabricated steel reinforced concrete column

InactiveCN112982831AImprove bindingGuaranteed bondingStrutsPillarsReinforced concrete columnArchitectural engineering

The invention discloses a concrete filling and pouring method for connecting an upper column section and a lower column section of a prefabricated steel reinforced concrete column. The method is characterized in that filament sleeves and lug plates are used for connecting steel bars and a profile steel framework in upper and lower prefabricated steel reinforced concrete columns into a whole; a pisolite type grouting material is used for pouring a connecting area of the upper and lower columns to form an assembly type integral structure column; the filament sleeves are arranged on the reinforcing steel bars at the two ends of the upper and lower prefabricated steel reinforced concrete columns and are in screwed connection with the reinforcing steel bars; and floor steel beams welded with the profile steel framework are arranged at the upper parts of the upper and lower prefabricated profile steel concrete columns. Compared with the prior art, the concrete filling and pouring method for connecting the upper column section and the lower column section of the prefabricated steel reinforced concrete column has the advantages that joint connection is moved to the middle of the column, beam-column joints with complex structures are avoided, construction quality and stress safety are guaranteed, factory production of the prefabricated steel reinforced concrete column is achieved, production efficiency is high, quality is more controllable, and the problem that an existing steel reinforced concrete column structure is difficult to construct on site is well solved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

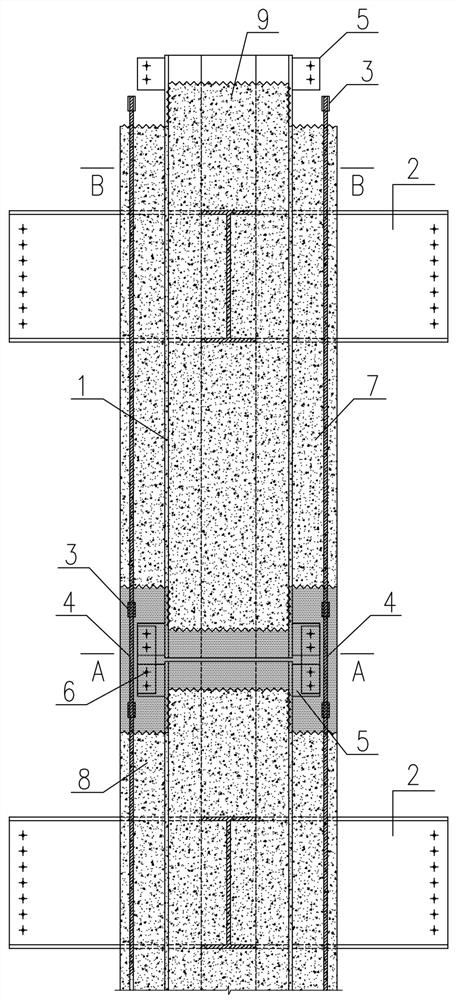

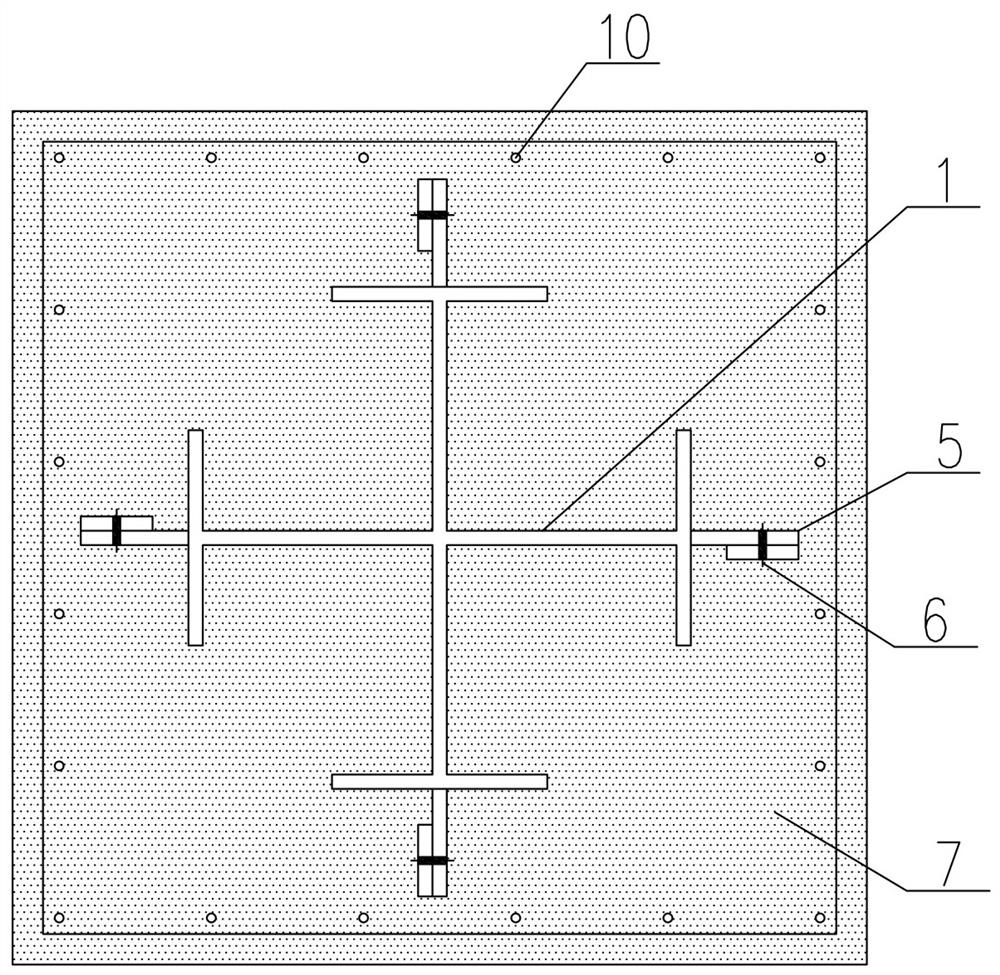

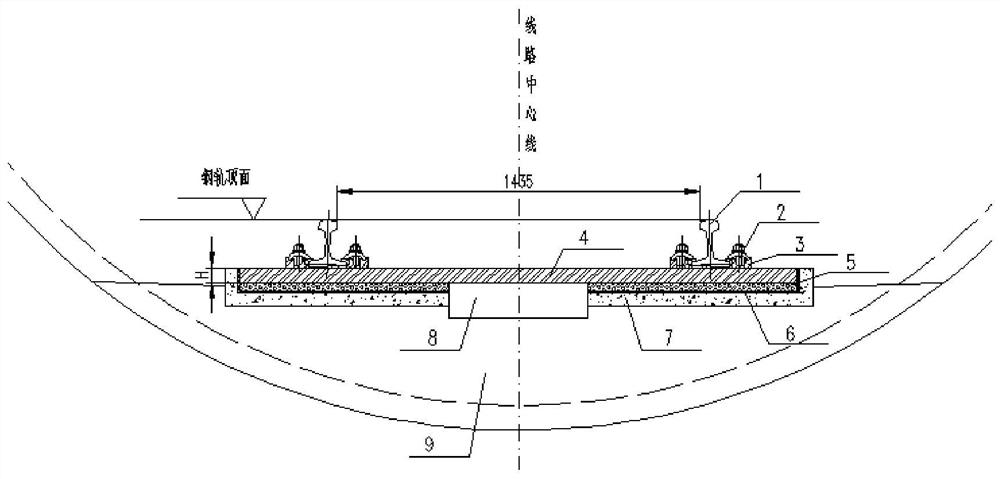

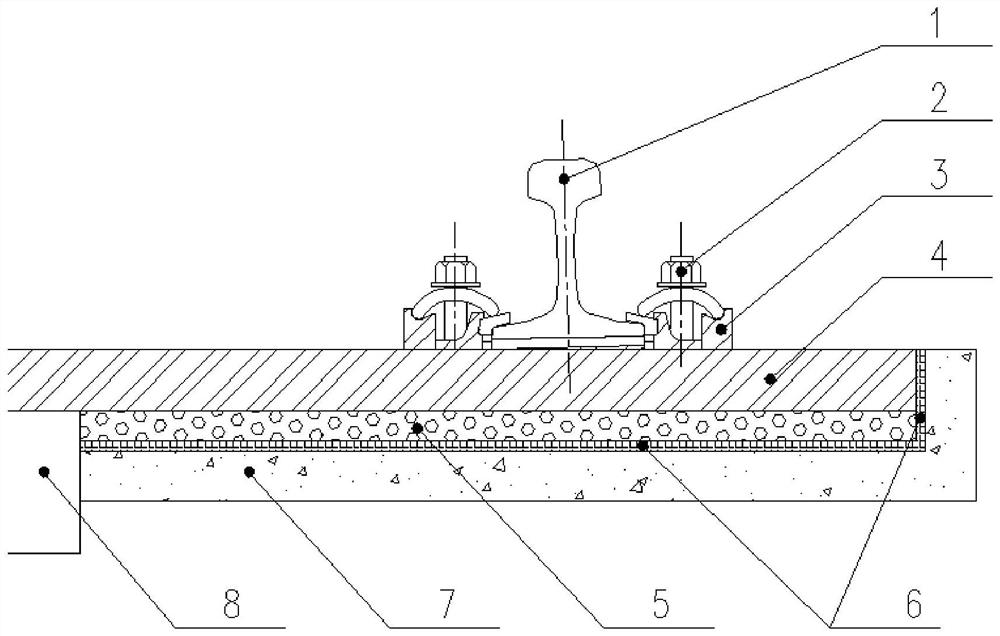

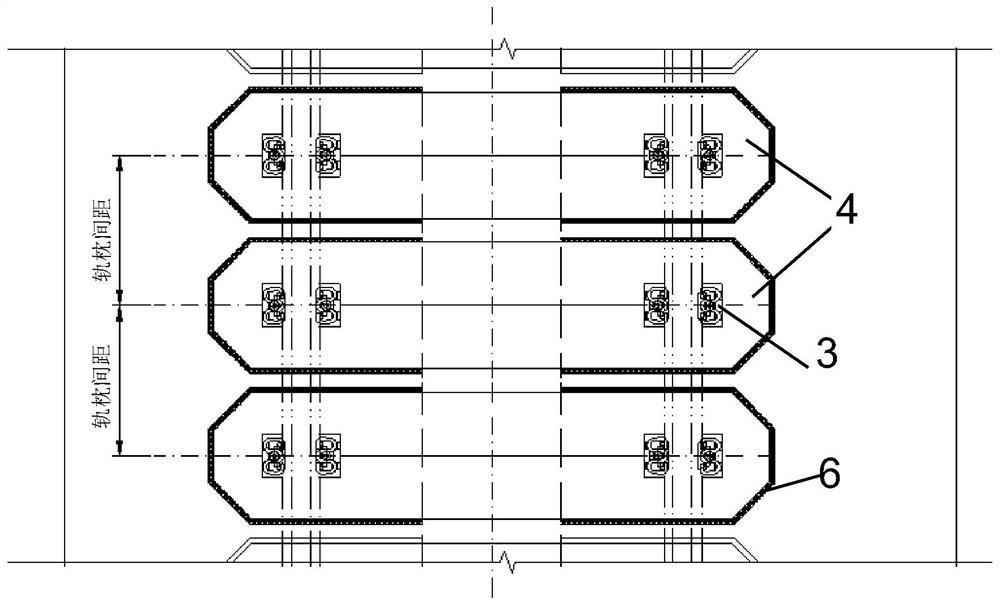

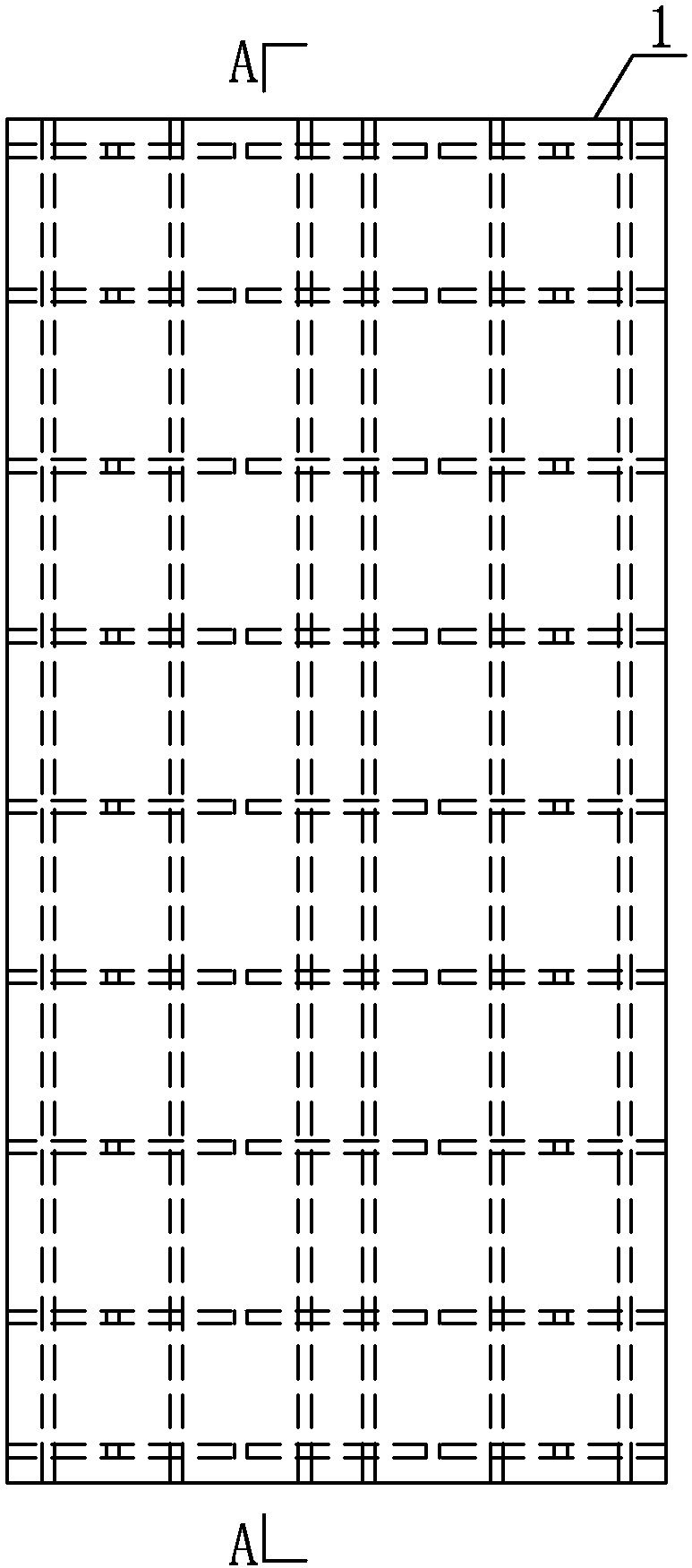

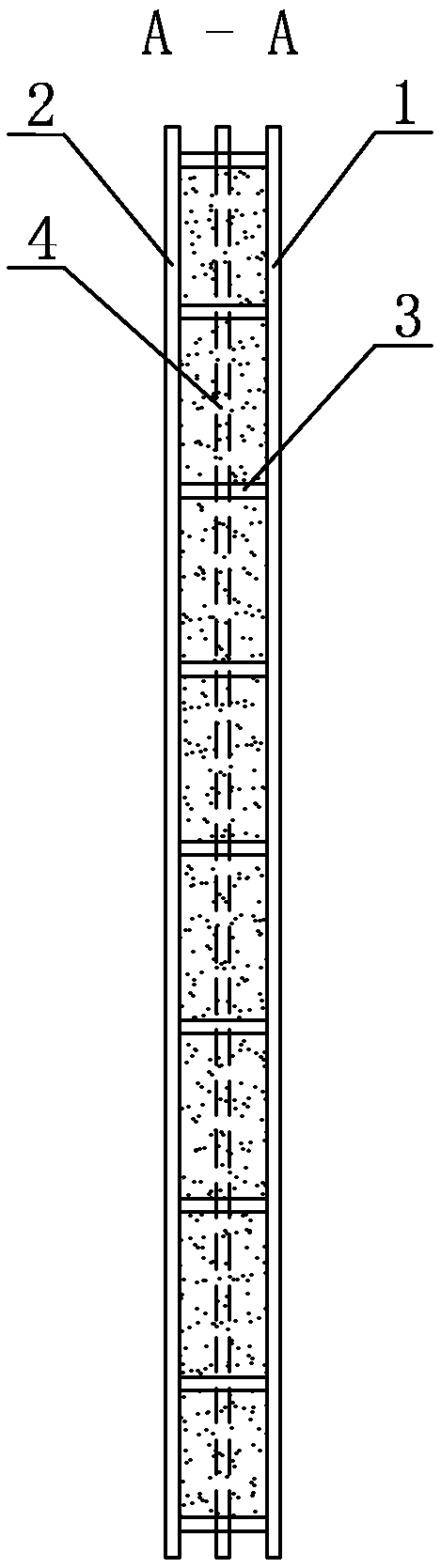

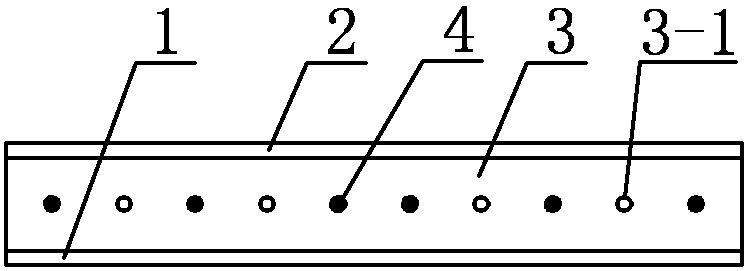

Rubber cast iron sleeper plate type vibration reduction system

A rubber cast iron sleeper plate type vibration reduction system comprises a steel rail, a fastener, a fastener base plate, a sleeper and a ballast bed. The sleeper is a cast iron sleeper, and the fastener base plate and the cast iron sleeper are integrally formed. Rubber vibration reduction pads are symmetrically arranged on the bottom surface of the sleeper, and the sleeper is provided with a rubber sheath which wraps the bottoms of the rubber vibration reduction pads and extends upwards to wrap the side surface of the sleeper. The ballast bed is arranged below the rubber sheath; the ballastbed is composed of a self-compacting mortar cushion layer or a common reinforced concrete cushion layer; and the self-compacting mortar cushion layer or the common reinforced concrete cushion layer is filled below the rubber sheath and around the side surface of the rubber sheath. Under a condition of the same mass, a volume of the vibration mass can be greatly reduced so that a purpose of greatly reducing a height of a track structure is achieved.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Construction method of staggered assembled steel plate-rpc anti-blast door

ActiveCN105781364BImprove finenessHigh reactivityCeramic shaping apparatusWar-like protectionEngineeringRebar

The invention discloses a staggered splicing type steel plate-RPC anti-detonation door and a construction method thereof. According to the anti-detonation door, a cavity formed by a door leaf front side steel plate, a door leaf reverse side steel plate and a plurality of inner ribbed beams is filled with an RPC inner core. The construction method of the anti-detonation door comprises the steps that firstly, the door leaf front side steel plate, the door leaf reverse side steel plate and the inner ribbed beams are manufactured according to the size; secondly, the number of needed steel bars is calculated; thirdly, steel bar holes are formed in the inner ribbed beams in the length direction; fourthly, the door leaf front side steel plate is welded to the odd-number inner ribbed beams, and the door leaf reverse side steel plate is welded to the even-number inner ribbed beams; fifthly, the door leaf front side steel plate and the door leaf reverse side steel plate are spliced in a staggered manner, and the steel bars penetrate the steel bar holes; sixthly, reactive powder concrete is poured in the cavity formed by the door leaf front side steel plate, the door leaf reverse side steel plate and the multiple inner ribbed beams and is standing for 48 h; seventhly, the anti-detonation door is conveyed into a steam curing room at the temperature of 90 DEG C to be cured for 72 h; and eighthly, after 28 days, the RPC and the steel plates are effectively bonded to form the steel plate-RPC anti-detonation door. The staggered splicing type steel plate-RPC anti-detonation door and the construction method thereof are applied to anti-detonation protection projects.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com