Rubber cast iron sleeper plate type vibration reduction system

A technology of vibration reduction system and sleeper, which is applied in the field of track engineering, and can solve problems such as high track height and inability to meet vibration reduction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

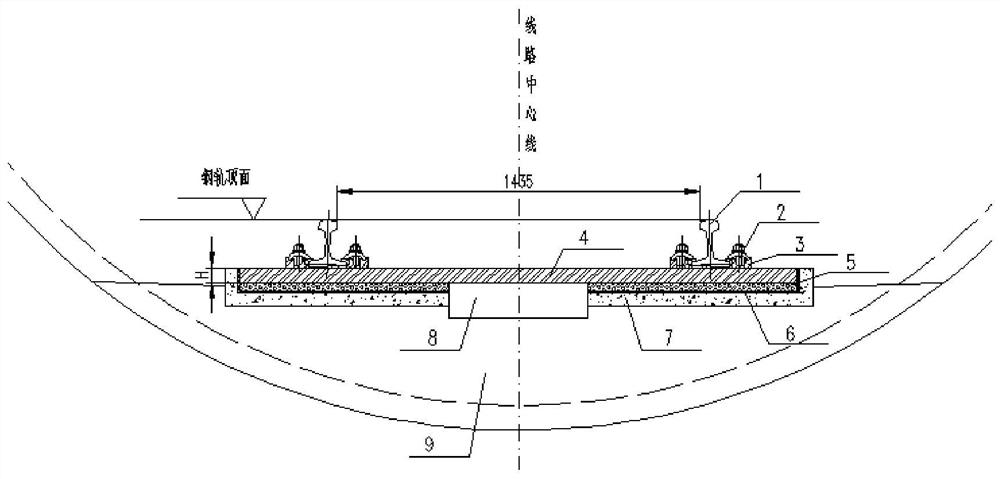

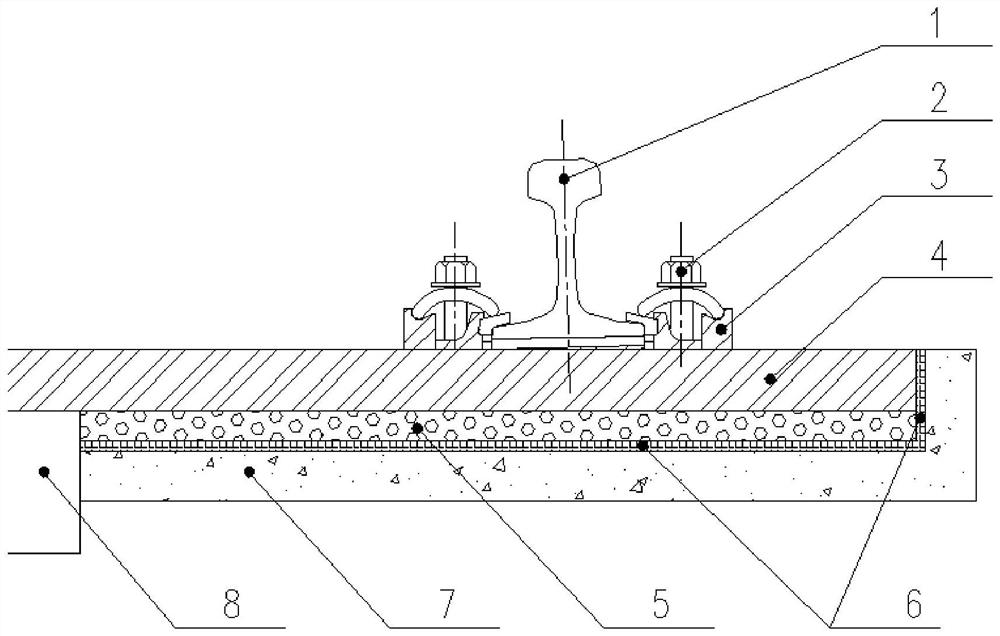

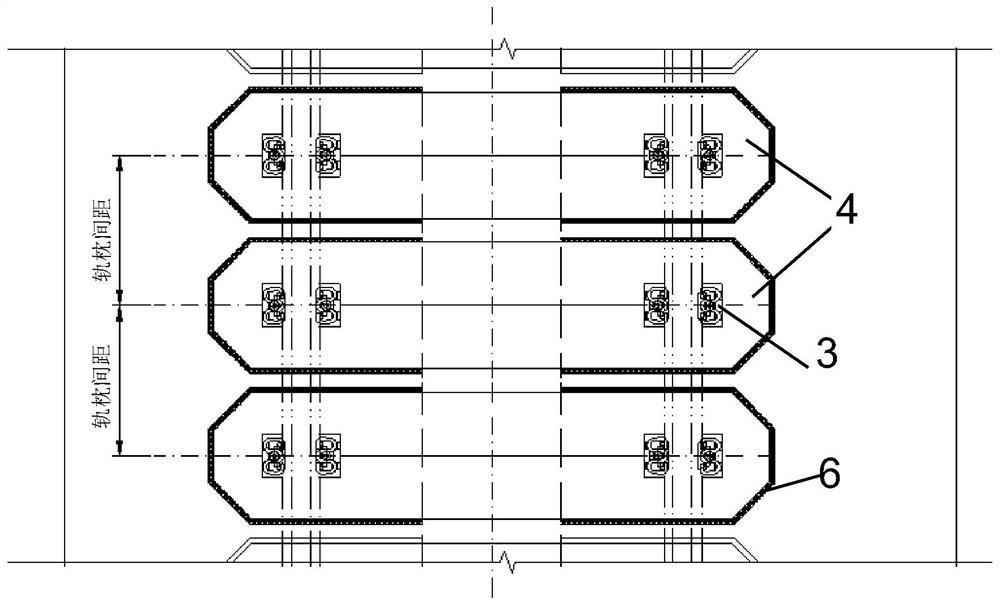

[0020] see Figure 1-2 As shown, a rubber cast iron sleeper plate type vibration damping system of the present invention includes a steel rail 1, a fastener 2, a fastener backing plate 3, a sleeper 4, and a track bed. The sleeper 4 is a cast iron sleeper, and the density of the cast iron is 7800kg / m3 , the fastener backing plate 3 is integrally formed with the cast iron sleeper; the bottom surface of the sleeper 4 is symmetrically provided with a rubber damping pad 5, and the sleeper 4 is provided with a rubber sheath 6 to wrap the rubber damping pad 5 The bottom extends upwards to wrap the side of the sleeper 4; the rubber sheath 6 is provided with the ballast bed, and the ballast bed is composed of a self-compacting mortar cushion or an ordinary reinforced concrete cushion 7; the self-compacting mortar Cushion-like or ordinary reinforced concrete cushion is filled below the rubber sheath 6 and around the sides.

[0021] The fastener backing plate 3 is made of the same mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com