Pile-embedding method for hollow pile and auger drill for implementing same

A hollow pile and auger technology, which is used in the field of building pile foundation construction piles and augers, can solve the problems that endanger the stability and safety of surrounding buildings and underground pipeline facilities, adversely affect project cost and progress, interfere with normal work of residents and Life and other problems, to achieve the effect of reducing the rise of super-void water pressure, reducing soil uplift and displacement, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

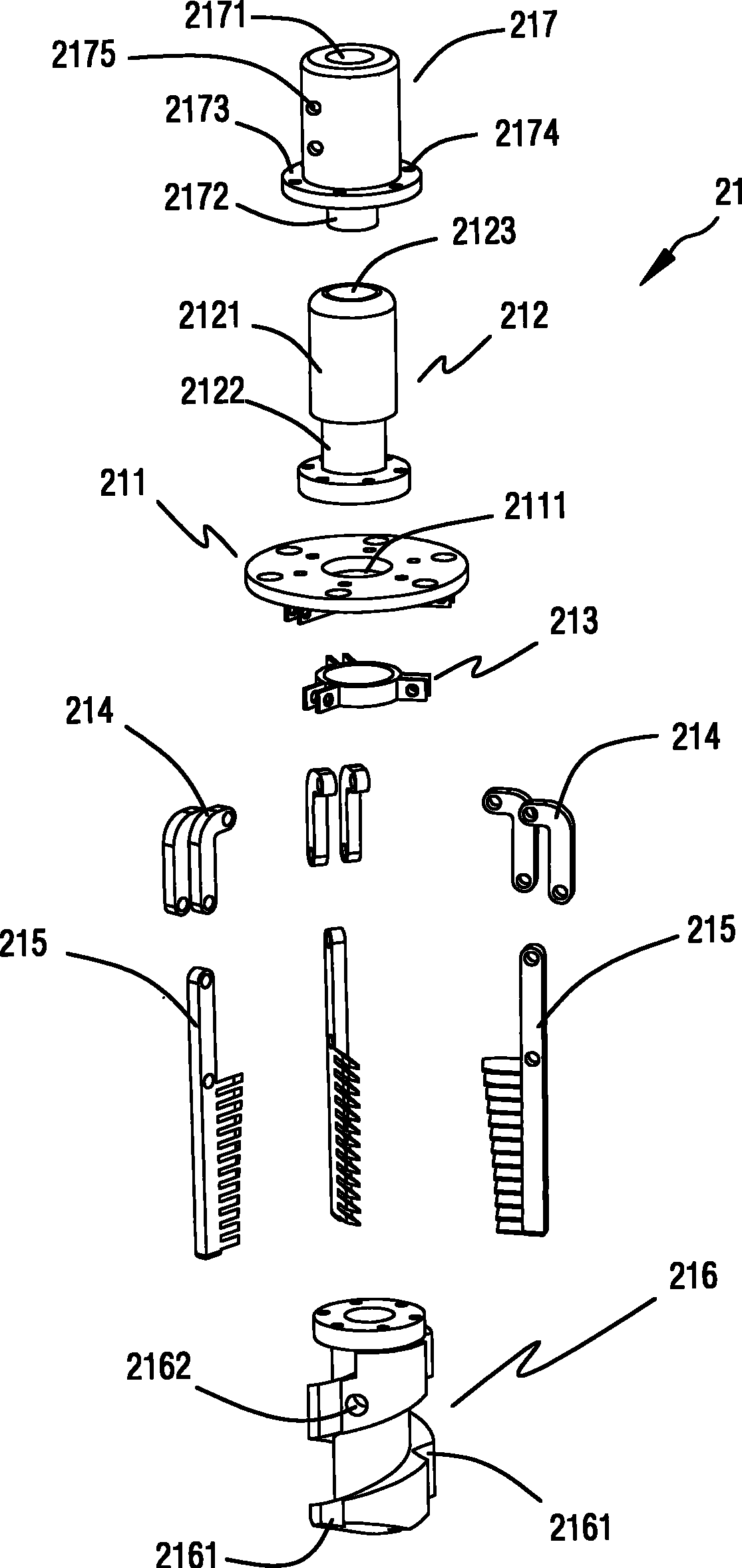

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

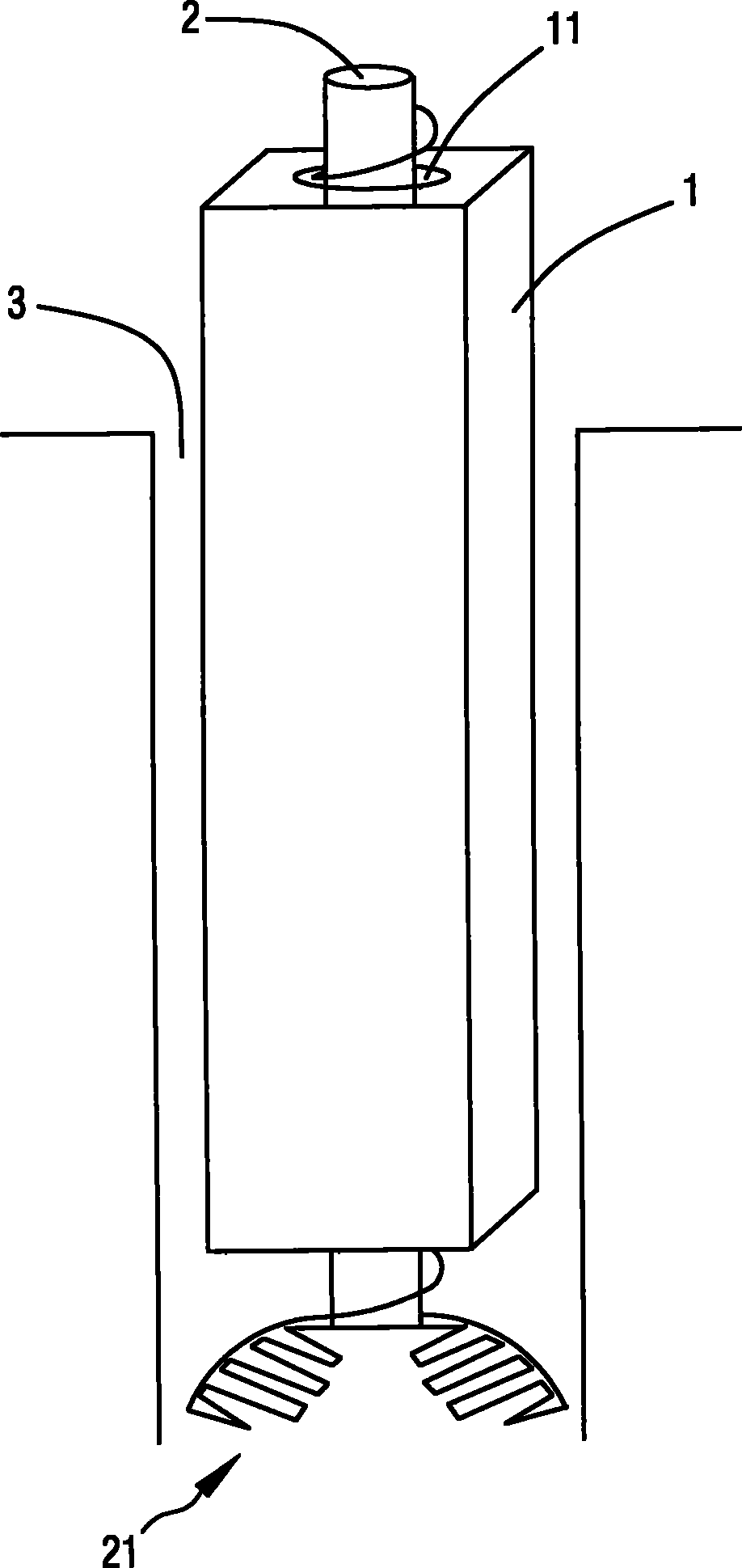

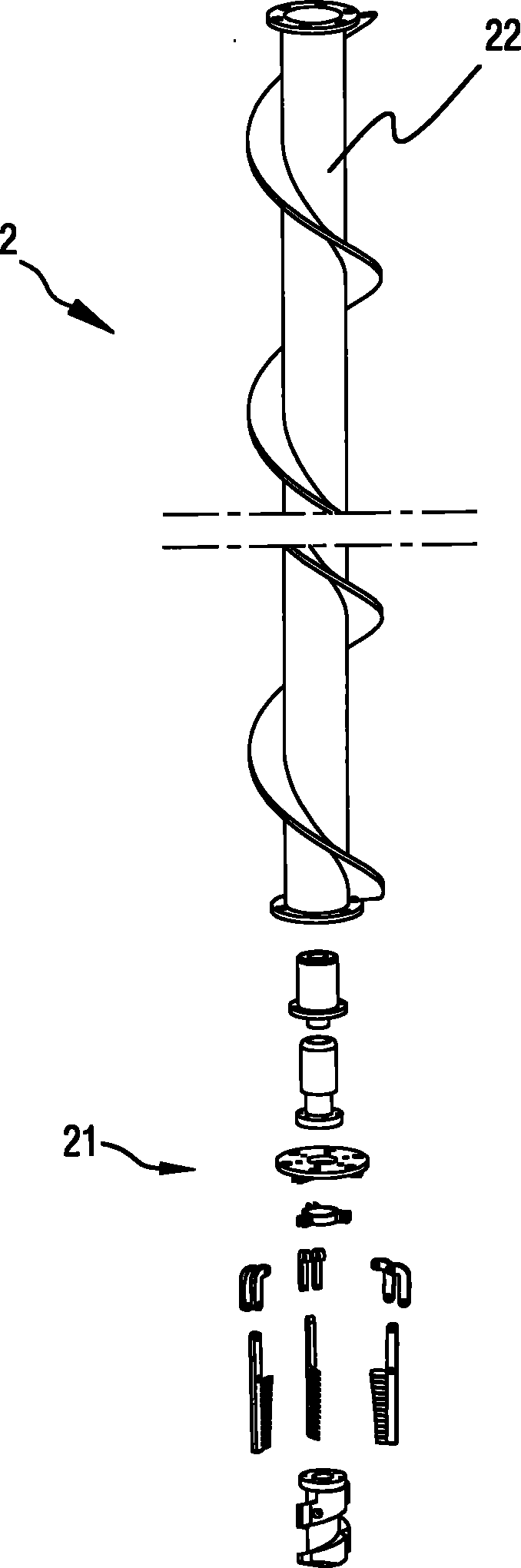

[0049] figure 1 What is shown is a schematic diagram of the implementation of a hollow pile planting method according to a specific embodiment of the present invention. As shown in the figure, the pile planting method according to the present invention is mainly implemented for hollow piles, wherein the hollow pile 1 along Its length direction has a central through hole 11, and the hollow pile 1 shown in the figure is a hollow square pile. Of course, those skilled in the art should understand that the hollow pile 1 can also be a kind of pipe pile, or can be any cross section Form hollow piles, such as special-shaped hollow piles, etc.

[0050] Pile planting method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com