Construction method of staggered assembled steel plate-rpc anti-blast door

A construction method and technology for anti-explosion doors, applied in the field of anti-explosion doors, can solve the problems of difficulty in guaranteeing the quality of welding seams, high cost, and many welding seams, and achieve the effects of ensuring quality, good fire resistance and small thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

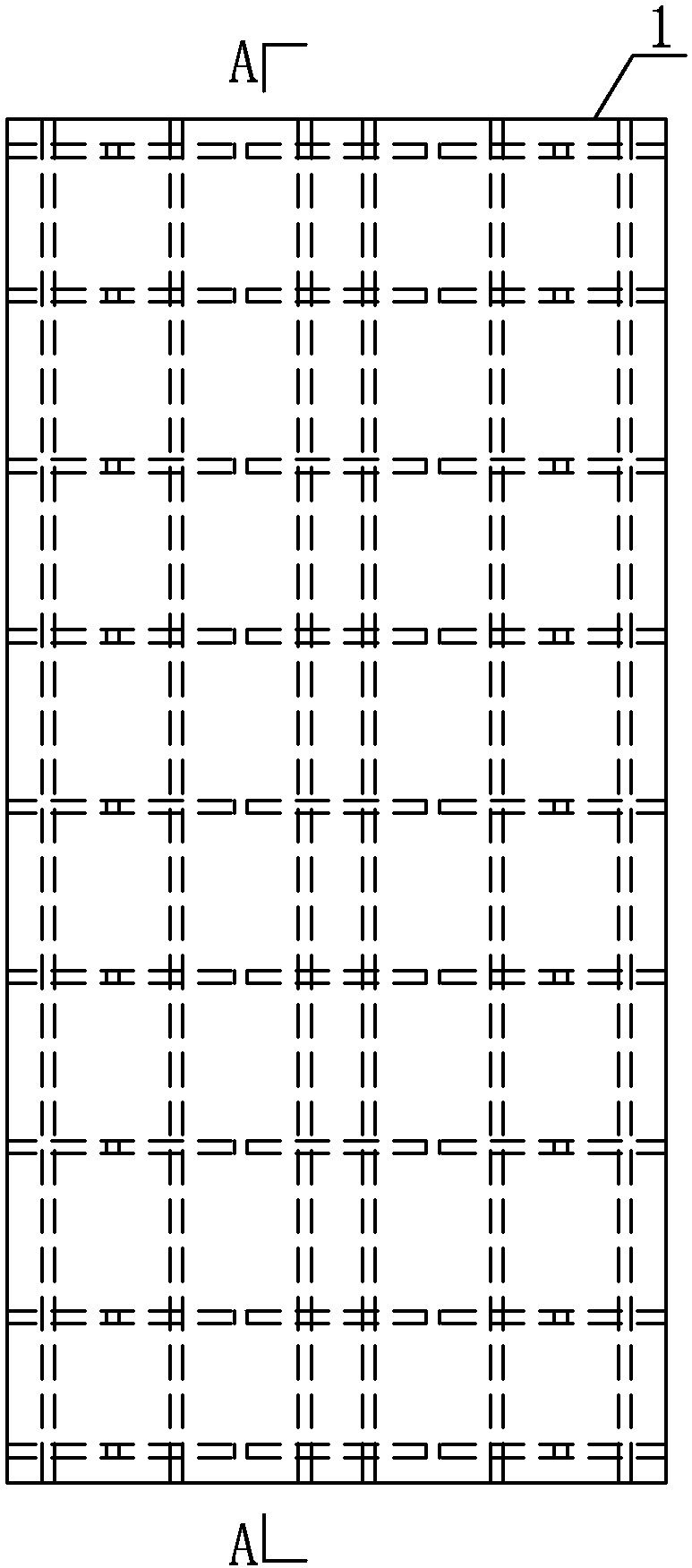

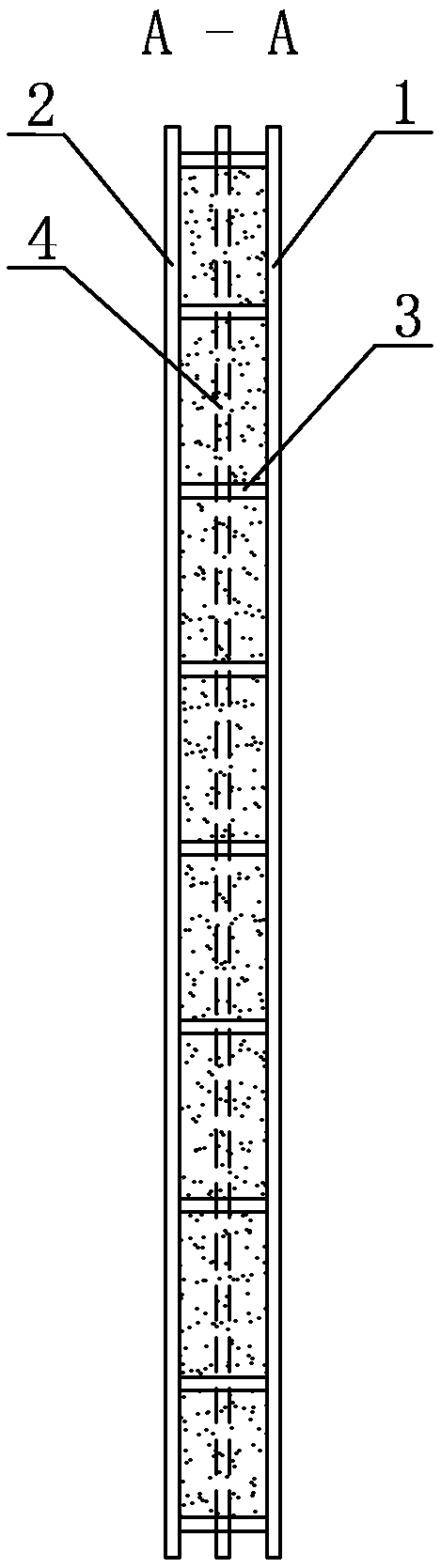

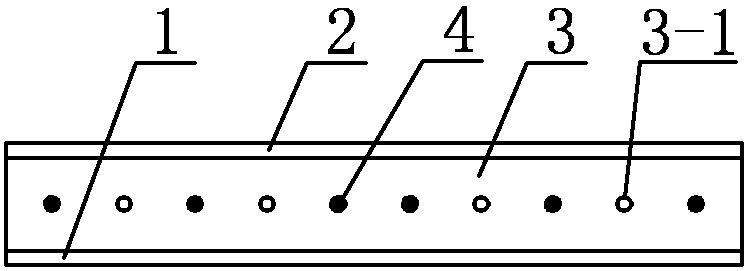

[0030] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment comprises door leaf front steel plate 1, door leaf back steel plate 2, several inner rib beams 3, several steel bars 4 and RPC inner core 5, door leaf front steel plate 1 and door leaf back steel plate 2 are arranged in parallel, several The inner rib beams 3 are arranged horizontally between the front steel plate 1 of the door leaf and the back steel plate 2 of the door leaf, several inner rib beams 3 are arranged at equal intervals along the height direction of the door leaf, and each inner rib beam 3 is provided with several reinforcement holes 3-1 along the length direction , several steel bar holes 3-1 are arranged at equal intervals along the same straight line, one steel bar 4 runs through one longitudinal steel bar hole 3-1 in several internal rib beams 3, the number of steel bar holes 3-1 is greater than the number of steel bars 4, The cavity formed by the f...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the thickness of the door leaf front steel plate 1 and the door leaf back steel plate 2 of this embodiment is the same, can choose 45# carbon steel for use. Other connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 2 The present embodiment will be described. The thickness of the inner rib beams 3 in this embodiment is 3 mm to 5 mm, and the distance between two adjacent inner rib beams 3 is 200 mm to 500 mm. Other connections are the same as those in the first or second specific embodiment.

[0033] Specific implementation mode four: combination figure 2 Describe this embodiment, the thickness of the inner rib beam 3 of this embodiment is 4mm, and the distance between two adjacent inner rib beams 3 is 350mm. Other connections are the same as those in the third embodiment.

[0034] Specific implementation mode five: combination figure 2 This embodiment will be described. The steel bar 4 of this embodiment is a steel bar of HRB500 grade. This grade of steel bars can meet the requirements of the blast door bearing capacity. Other connections are the same as those in the third embodiment.

[0035] Specific implementation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com