Concrete filling and pouring method for connecting upper column section and lower column section of prefabricated steel reinforced concrete column

A technology of concrete and section steel, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as construction difficulties, and achieve the effects of solving construction difficulties, reducing construction difficulty, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

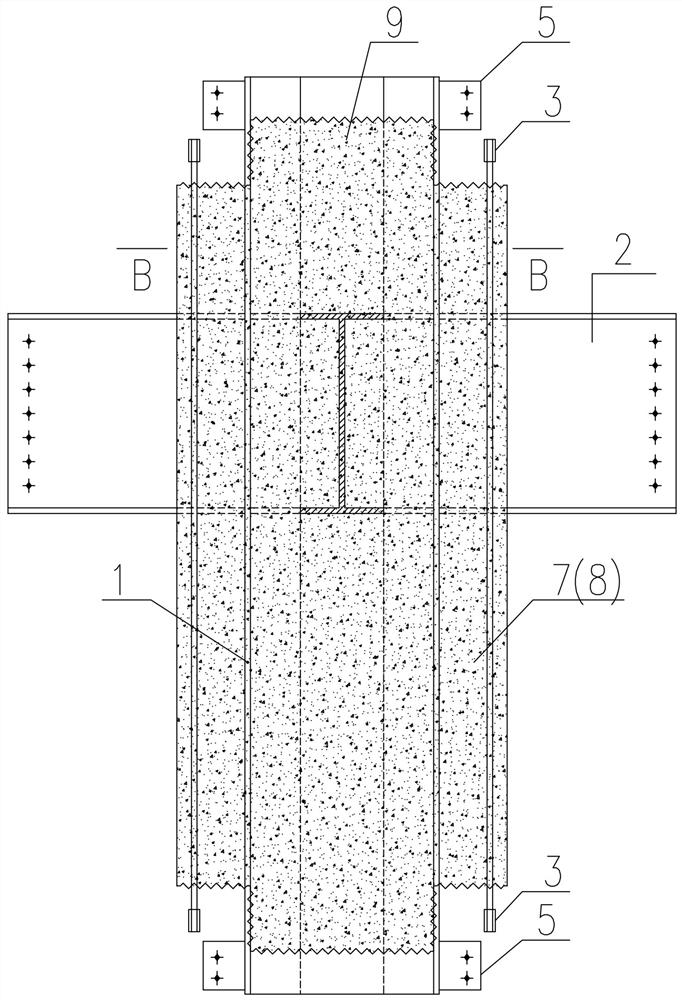

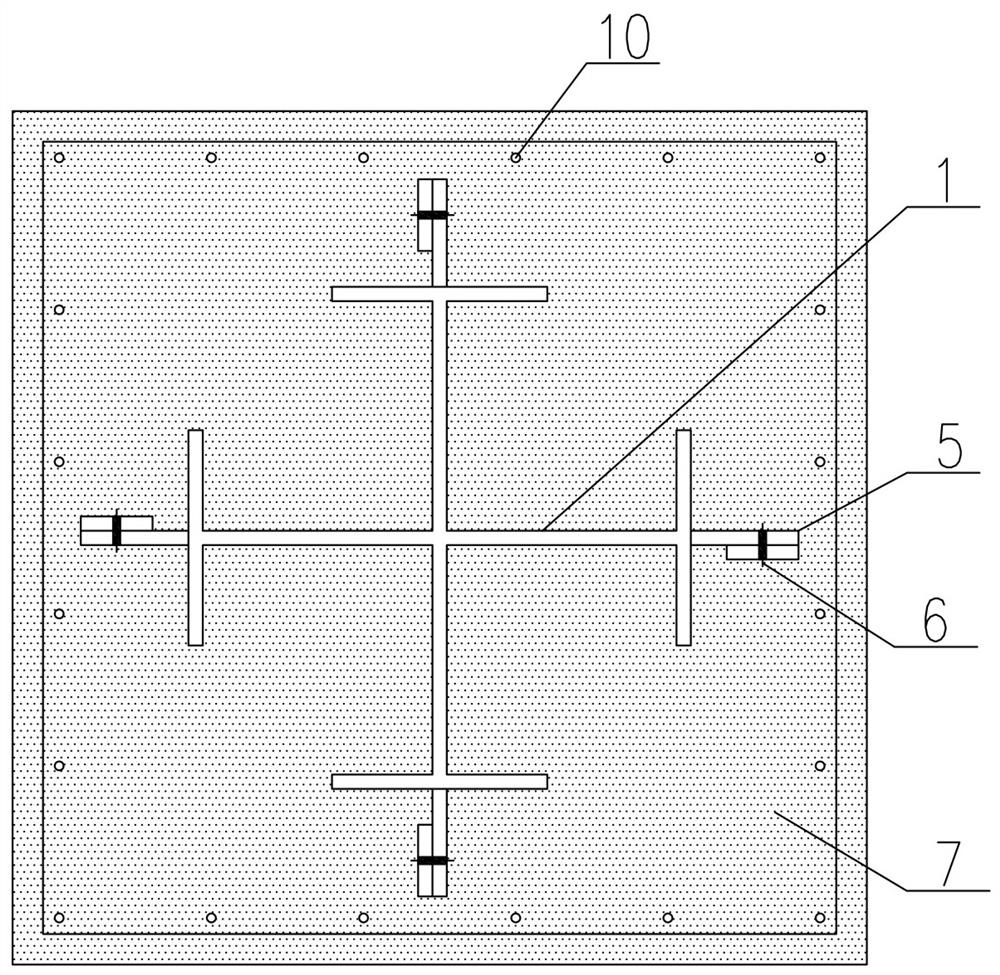

[0015] See attached figure 1 , the prefabricated steel-concrete column unit structure of the present invention includes the upper prefabricated steel concrete column 7 (or the lower prefabricated steel concrete column 8 of the steel bar 10 and the steel skeleton 1, and the two ends of the upper prefabricated steel concrete column 7 are provided with the steel skeleton 1 The enveloping concrete boss 9, the steel bar 10 is provided with a threaded sleeve 3, and the upper part of the upper prefabricated steel concrete column 7 (or the lower prefabricated steel concrete column 8) is provided with a steel frame 1 for welding. The floor steel beam 2; the floor steel beam 2 is symmetrically arranged on both sides of the upper prefabricated steel concrete column 7 (or the lower prefabricated steel concrete column 8); Welded lugs5.

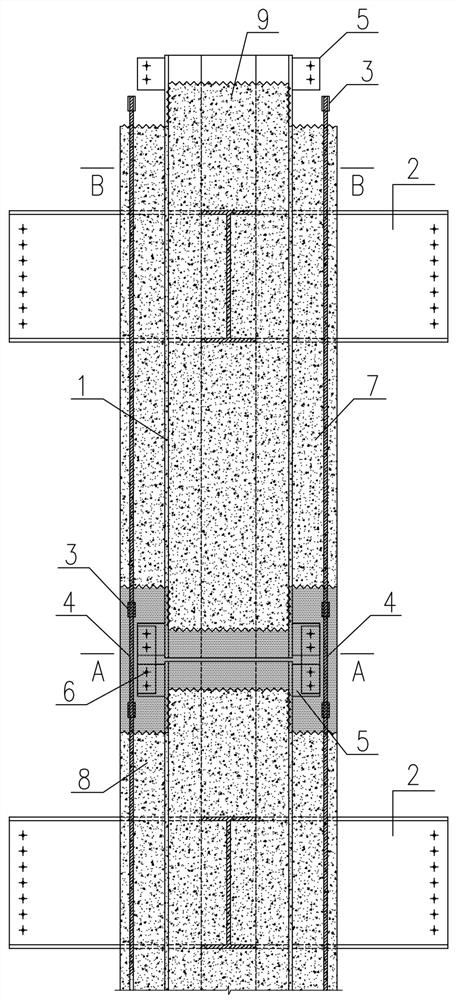

[0016] See attached Figure 2~Figure 3 , the upper prefabricated steel concrete column 7 is set on the lower prefabricated steel concrete column 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com