Non-support steel-structure spiral staircase

A spiral and steel structure technology, applied in the direction of stairs, ladder-like structures, building structures, etc., can solve the problems of technical failure to meet the requirements, difficult construction, serious material loss, etc., and achieve the feasibility and prevention of support-free technology The effect of unbalanced force fracture and severe material loss control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

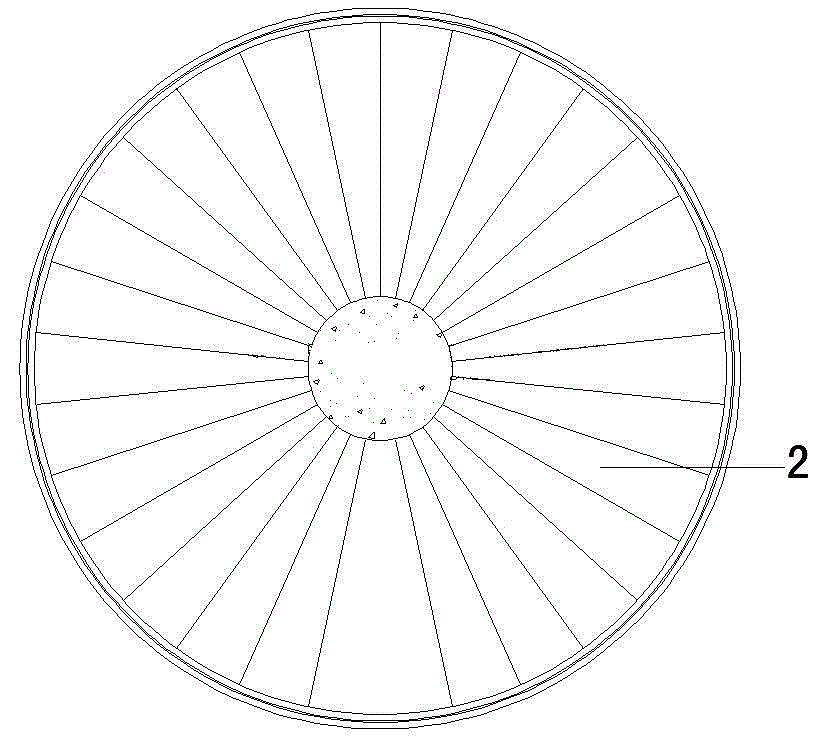

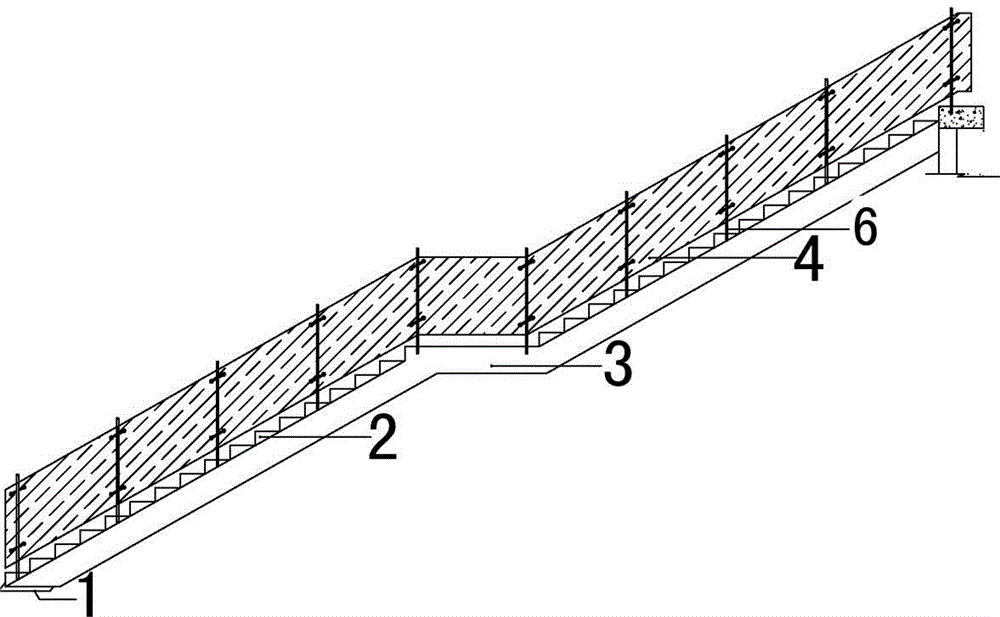

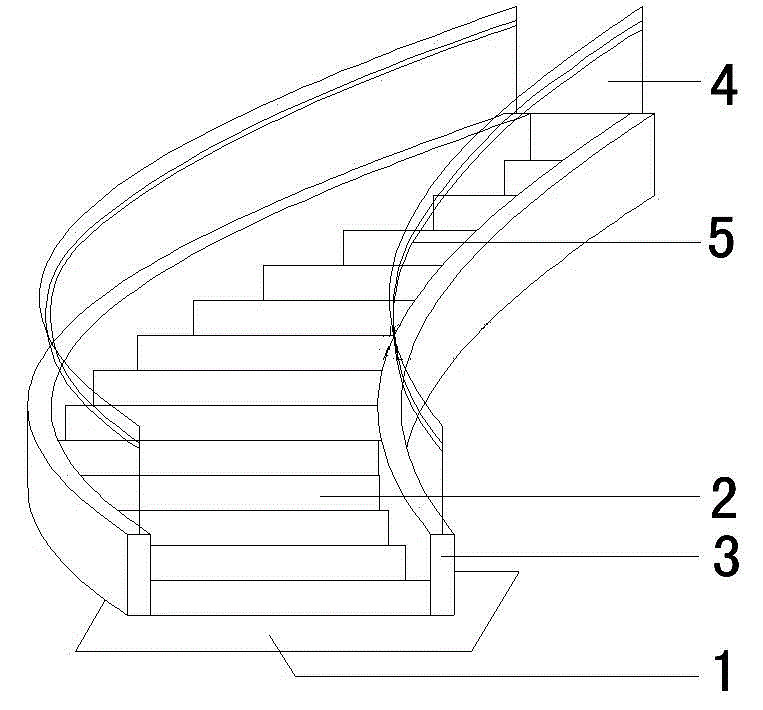

[0031] Example: such as figure 1 , figure 2 , image 3 Shown: a support-free steel structure spiral staircase, which includes a reinforced platform 1, stair treads 2, skirting waistline 3, glass guardrail 4, railing handrail 5, support column 6.

[0032] Such as Figure 4 , Figure 5 As shown, one layer of reinforced platform 1 includes 15mm thick steel plate 1 and L50 angle steel. The angle steel is welded horizontally and vertically to form a mesh layer, and the angle steel spacing is 300mm (300*300mm horizontally and vertically). The lower layer of the angle steel mesh layer is equipped with a woodworking board, and the upper layer is welded with a 10mm thick steel plate 2. On the second layer of the steel plate, a cement mortar leveling and pasting layer is laid. Anchor bolts are reinforced and welded with L50 angle steel to ensure the force support of the bearing point. The upper part of the steel plate is a cement mortar leveling adhesive layer, and the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com