Patents

Literature

56results about How to "Solve the difficulty of construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

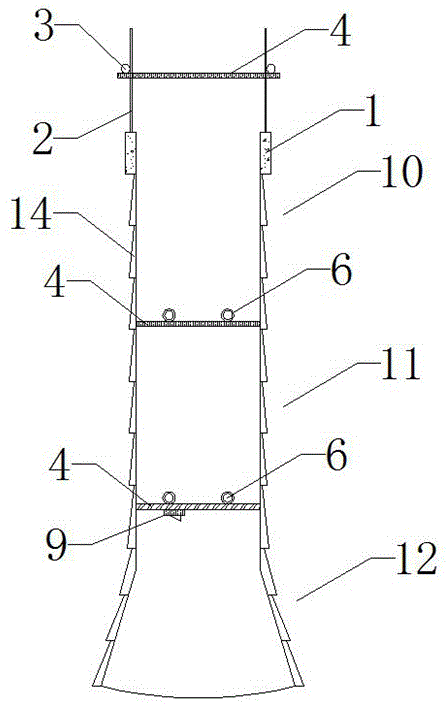

Offshore wind turbine single pile-suction cylinder combined foundation and construction method thereof

The invention provides an offshore wind turbine single pile-suction cylinder combined foundation and a construction method thereof. The combined foundation comprises a single pile and a suction cylinder which are connected with each other vertically, a partition plate is arranged in the suction cylinder and divides the suction cylinder into an upper cylinder body and a lower cylinder body, the upper cylinder body is generally located above a seabed mud surface, and if the scouring depth is considered, the upper cylinder body can be sunken below the seabed mud surface when the calculated scouring depth is large, and a cover plate of the upper cylinder body is flush with the mud surface. The lower cylinder body is opened downwards and penetrates into a rock soil covering layer; and the bottom end of the single pile penetrates through the upper cylinder body and abuts against the partition plate. According to the method, the suction cylinder penetrates into a designated elevation throughintegral self-weight sinking of the single pile and the suction cylinder and suction cylinder negative pressure sinking, the inclination of the suction cylinder is monitored in the sinking period, leveling is conducted in time through a suction system, the problems of large-amplitude inclination, shaking and the like are avoided, and the problems that single pile rock-socketed construction is large in difficulty, long in construction period and high in cost are solved.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

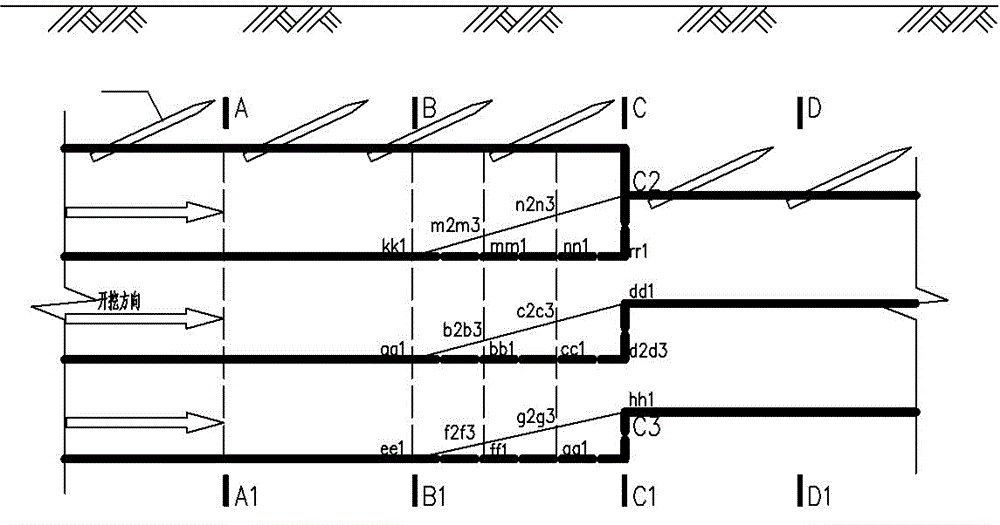

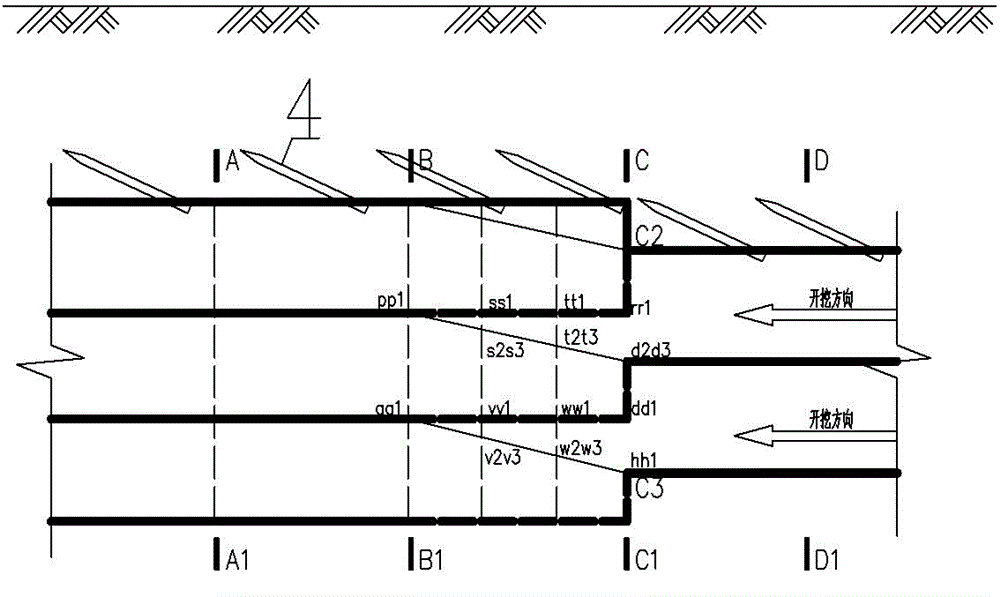

Method of constructing shallow tunnel underground passage variable-cross section cross mid-partition wall

ActiveCN103334761AAvoid duplicationAvoid occupying spaceUnderground chambersTunnel liningRebarMechanical engineering

The invention provides a method of constructing a shallow tunnel underground passage variable-cross section cross mid-partition wall. The method is characterized by comprising the following steps of 1) dividing a first cross section of a passage into a plurality of guide holes along a tunneling direction; 2) finishing primary supporting for the first cross section to the third cross section by the CRD method; 3) dividing a fourth cross section into a plurality of guide holes; 4) respectively replacing the supporting of each temporary inverted arch surface of the upper layer, the middle layer and the lower layer among the second cross section to the fourth cross section with new temporary inverted arches; 5) paving and firmly welding longitudinal reinforcing steel bars on the third new temporary inverted arch surface according to requirements; 6) finishing underground passage primary supporting for the fourth cross section to the fifth cross section by the CRD method by taking the two new temporary inverted arch surfaces of the middle layer and the lower layer as construction walking passages; and 7) detaching the temporary inverted arch supports section by section, and meanwhile lining the underground passage for the second time section by section, so that the main body structure is formed. Due to the fact that the procedure conversion of variable-cross section passage support change is adopted, the CRD method can be used for continuously operation according to the requirements all the way, the cost can be saved, and the efficiency is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

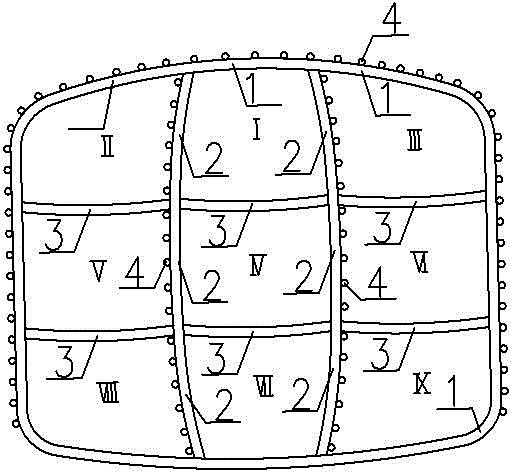

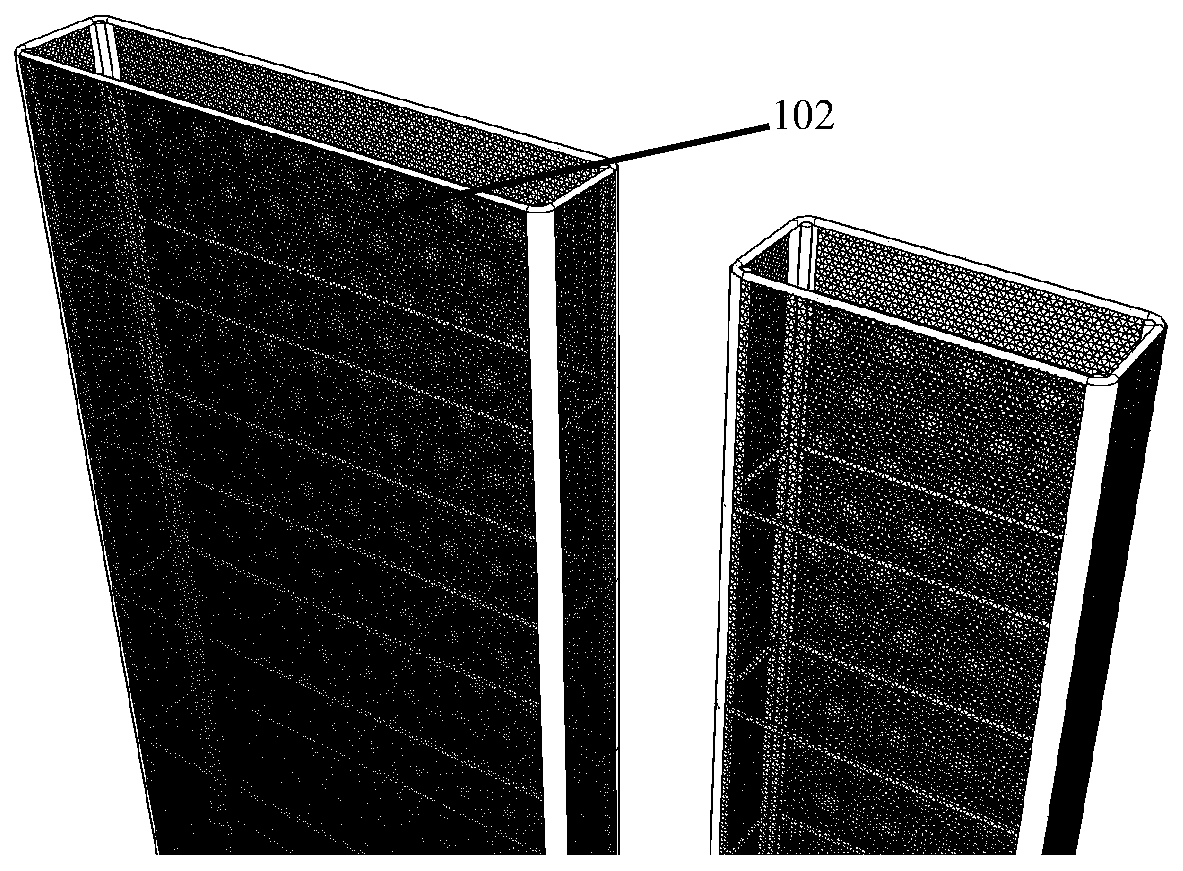

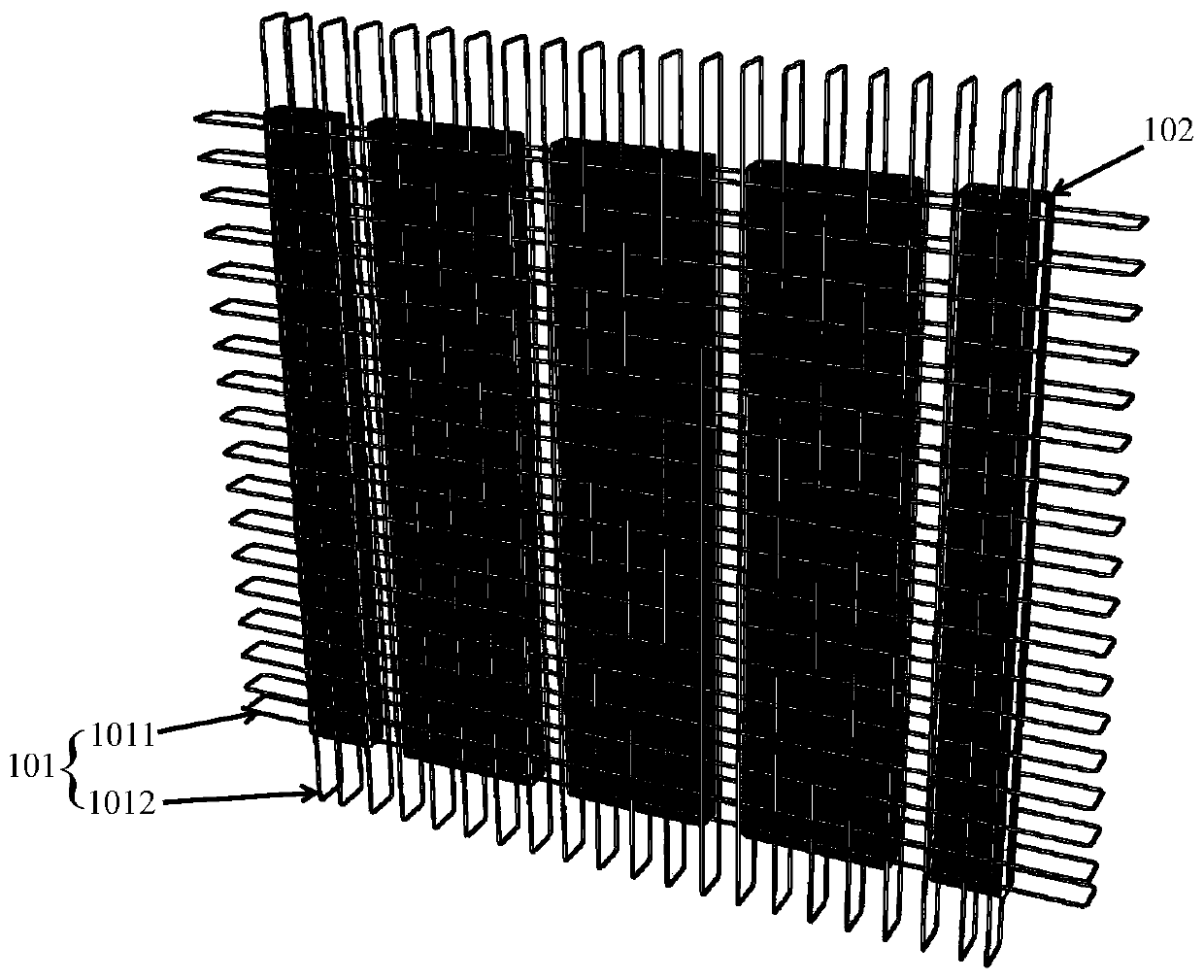

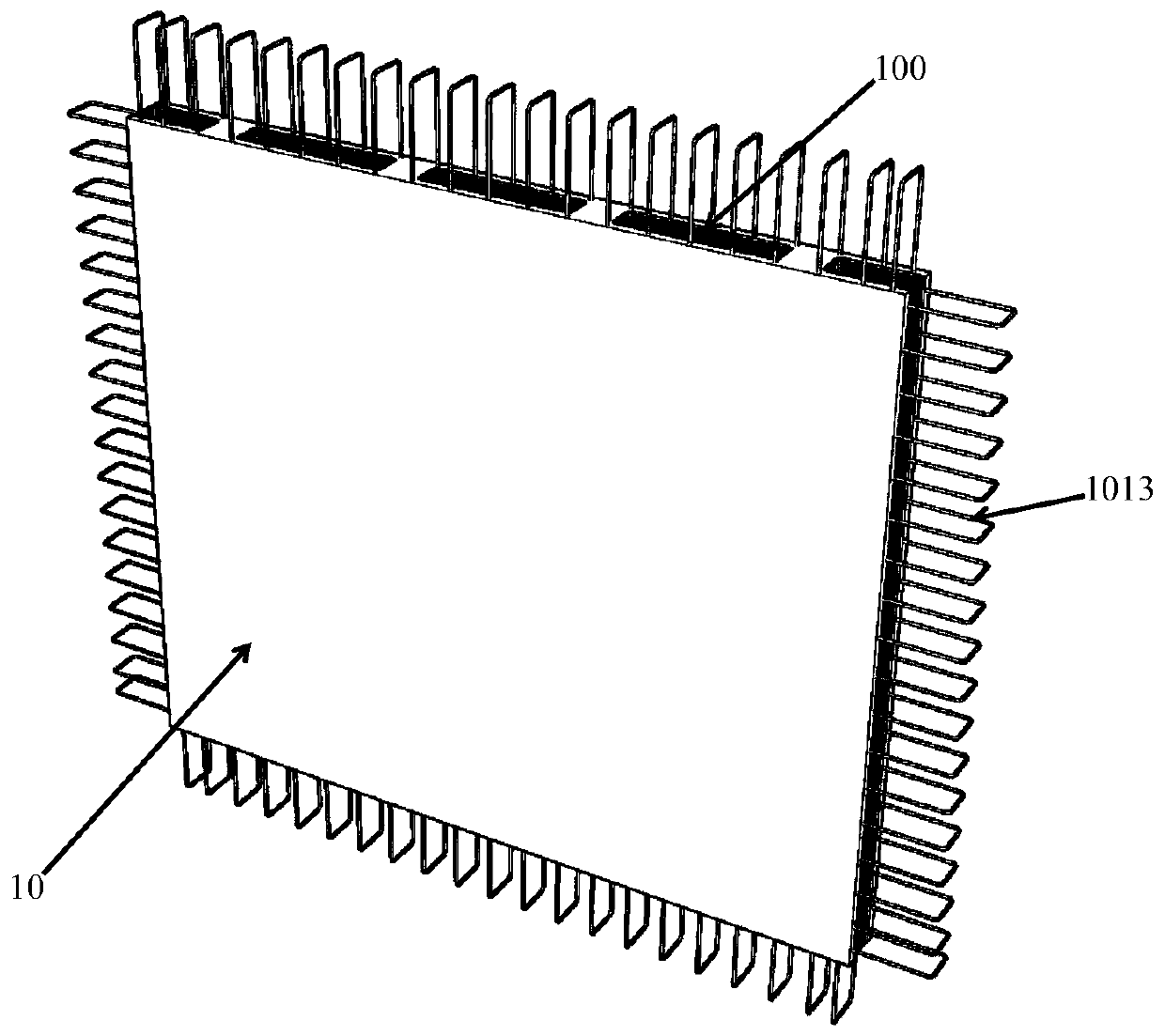

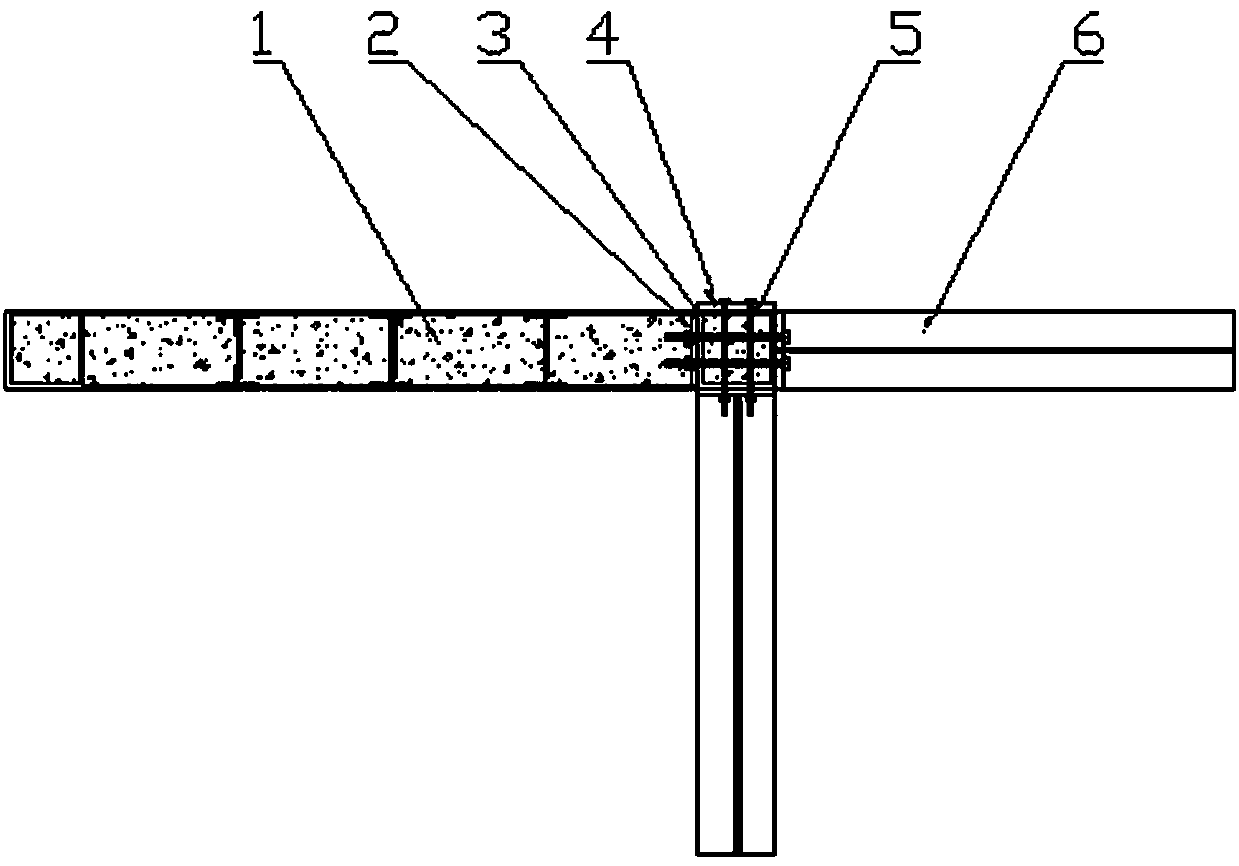

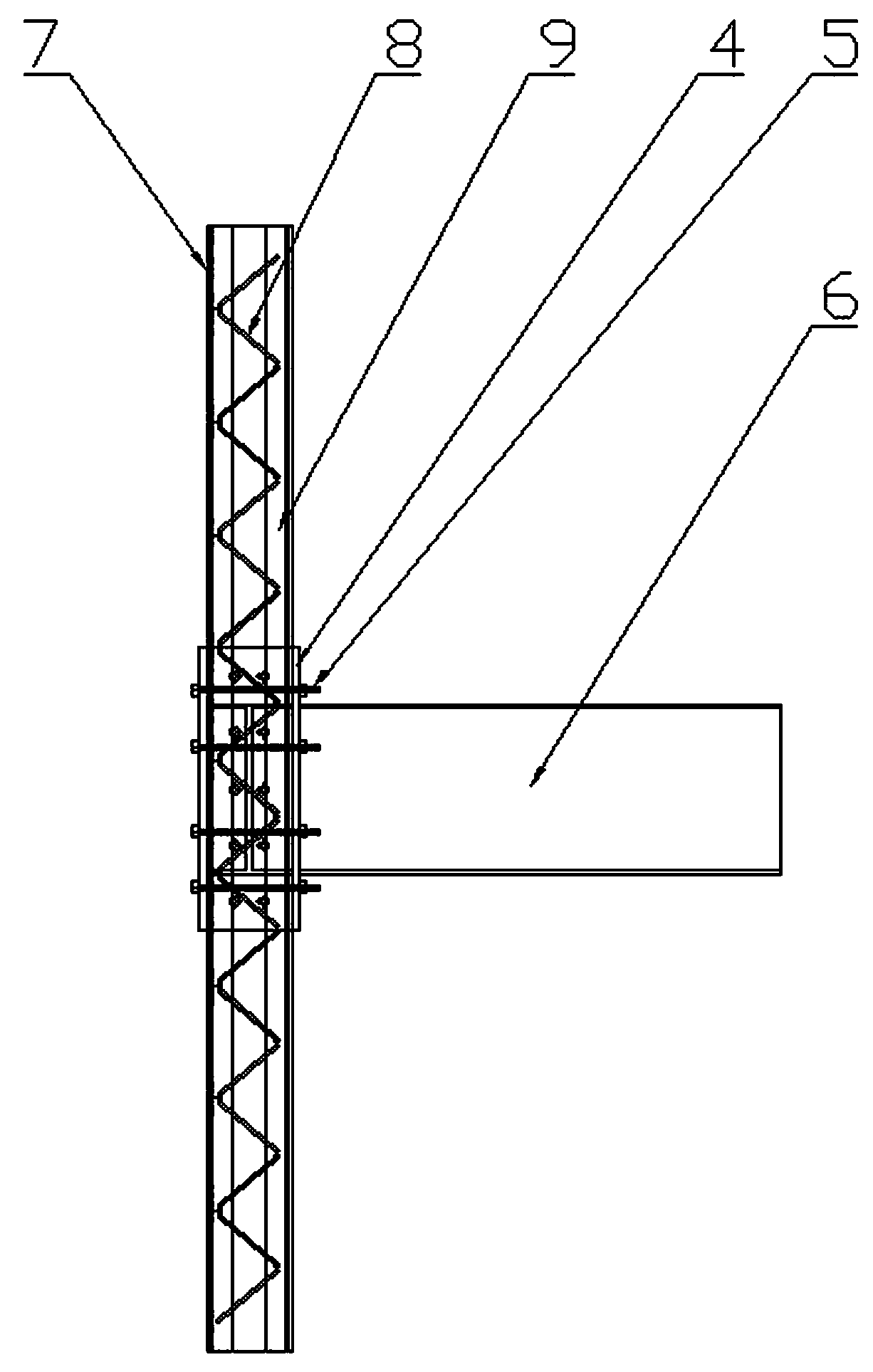

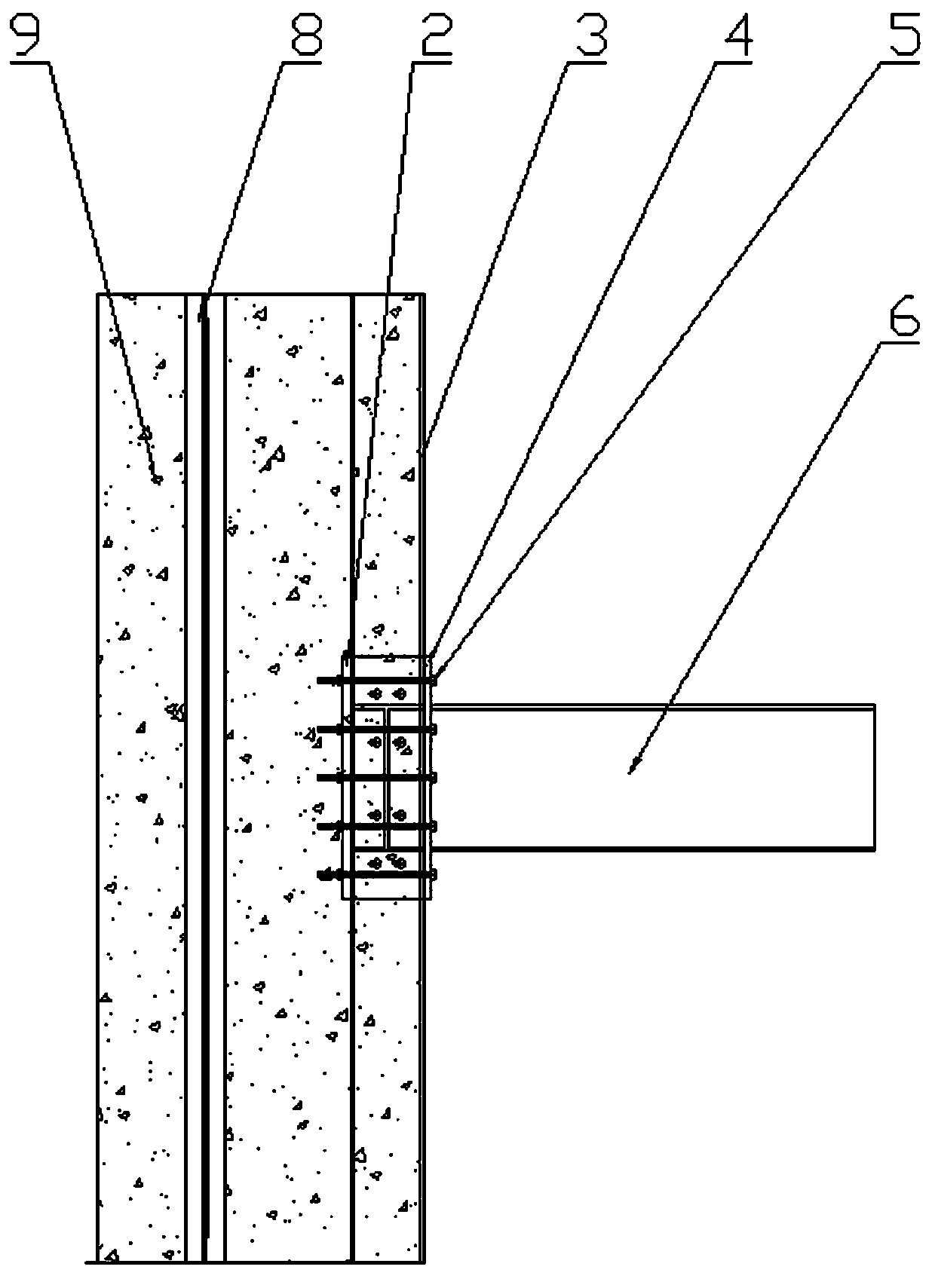

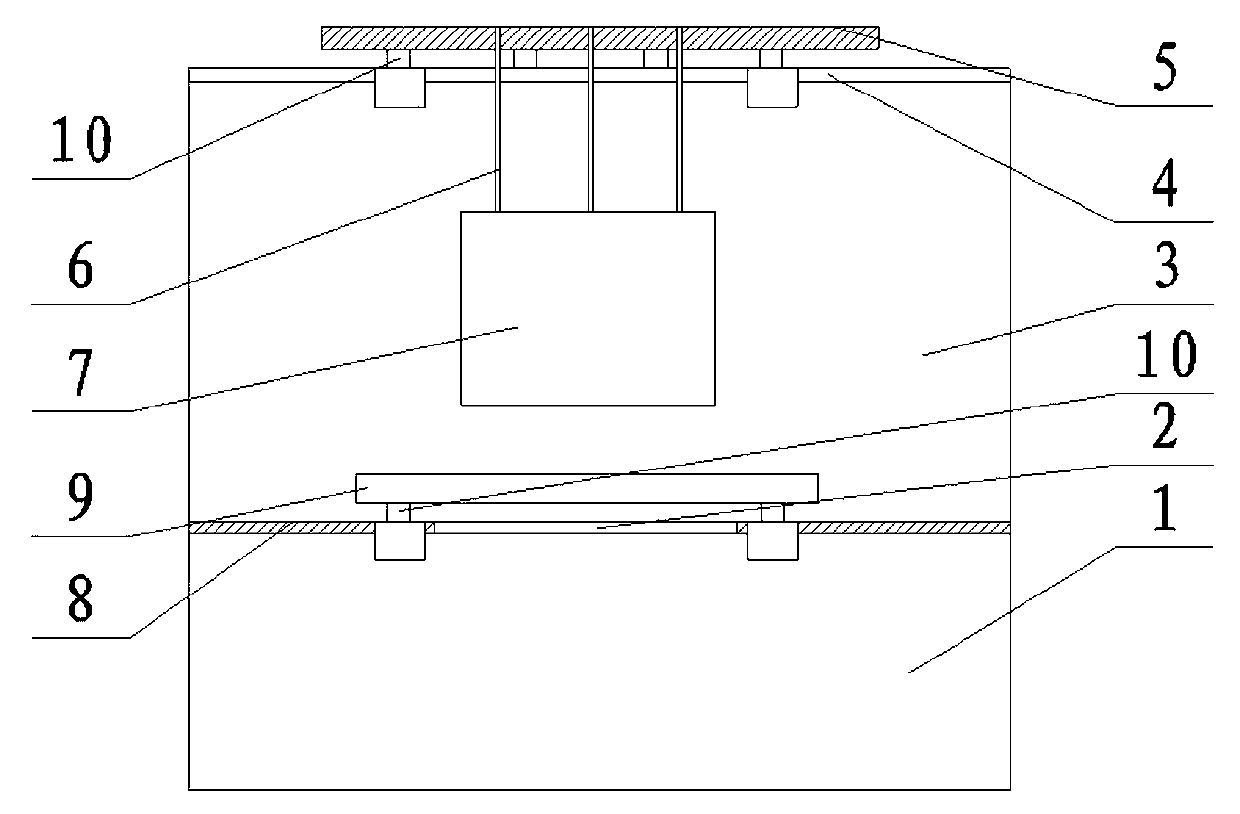

Fabricated core-grouting wall body, construction method of fabricated core-grouting wall body and frame for preparing wall body

PendingCN110185174ASolve the difficulty of constructionHigh knot strengthConstruction materialWallsDie swellRebar

The invention discloses a fabricated core-grouting wall body, a construction method of the fabricated core-grouting wall body and a frame for preparing the wall body. A longitudinal first cavity is formed in a prefabricated wallboard for grouting concrete at a construction site, and the problem that the construction difficulty of grouting to horizontal seams in the prior art is high is effectivelysolved; the tension intensity between inner and outer leaf wallboards is further effectively enhanced, risks of die expansion of the existing double-side composite wall and die shell shear wall are overcome, so the inner and outer leaf wallboards can be made thinner. A die shell is bounded and fixed in a steel cage in advance, the die shell is not disassembled after completing concrete sproutingbut left in a prefabricated part to form the first cavity, and the problems that the die shell cannot be stressed in the process of using during later periods in the prior art, and due to the fact that a building transforms in the process of using, and hidden cracks are produced between the die shell and internal post-grouting concrete shear wall can be effectively solved; and the die shell is bounded and fixed in the steel cage, the die shell can be stressed in the process of using during the later periods, and the intensity of the prefabricated wallboard is further improved.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

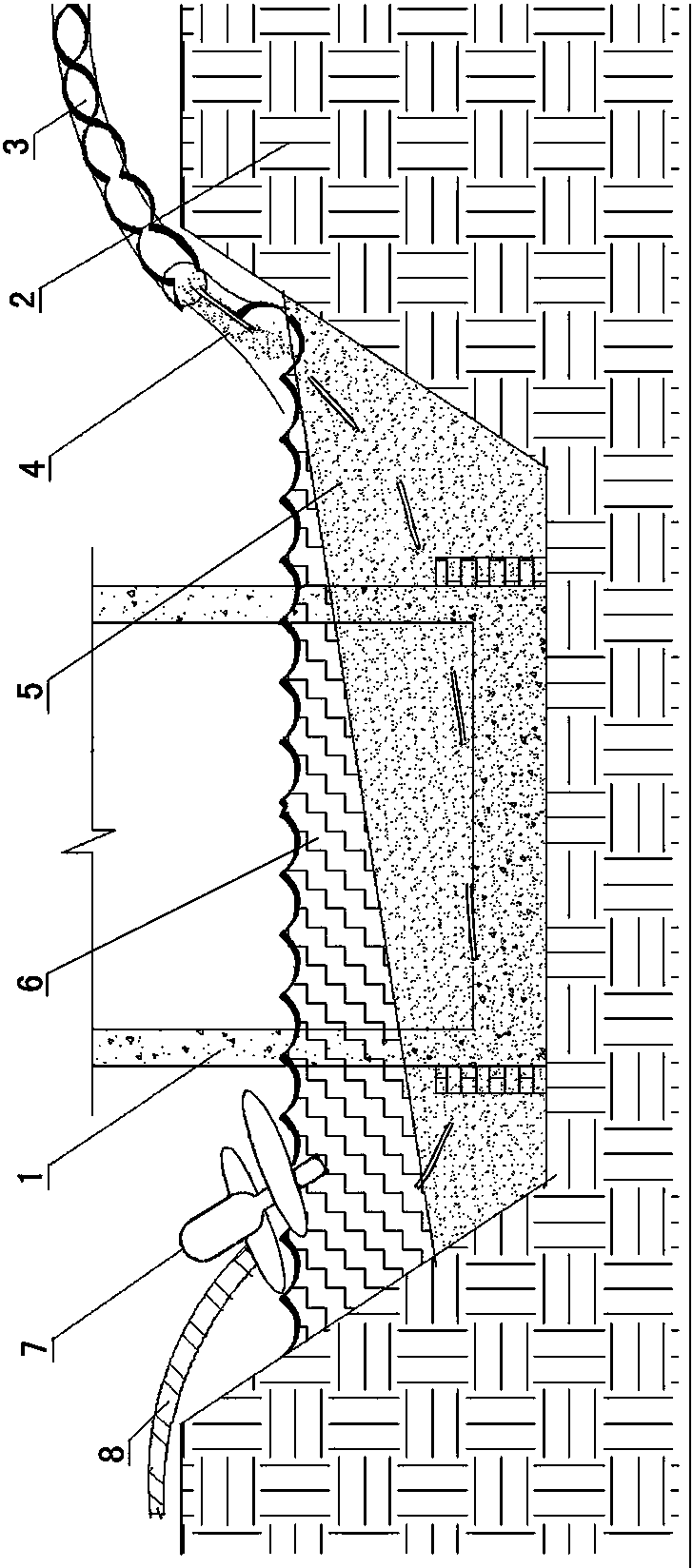

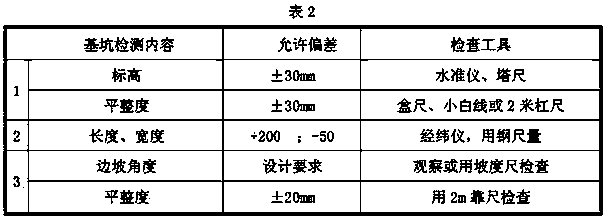

Construction method of sludge soil texture deep foundation pit excavation and pumping sand compacted backfilling

InactiveCN103510522AShorten construction timeReduce investmentEmbankmentsExcavationsSludgeWater table

A construction method of sludge soil texture deep foundation pit excavation and pumping sand compacted backfilling comprises the following steps: first, measuring and positioning are conducted; second, a small foundation pit is artificially excavated in the middle of a deep foundation pit to be excavated; third, a suspension type sewage pump used for draining slurry is placed in the small foundation pit; fourth, deep foundation pit excavation construction is carried out; fifth, after the deep foundation pit excavation construction is completed, a section chief assigns unified inspection and acceptance of the position, size and slope of the deep foundation pit to a quality inspector, a technician and a surveyor; sixth, pumping sand compacted backfilling construction is carried out. The construction method of sludge soil texture deep foundation pit excavation and pumping sand compacted backfilling is quite convenient and rapid to use, solves various adverse factors and construction problems of conventional excavation and backfilling of a pile plus sludge soil texture deep foundation pit, is applicable to excavation and backfilling of deep foundation pit engineering of all projects along the coast or in wet land mucky soil or with a high underground water level, and ensures normal construction of the engineering.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

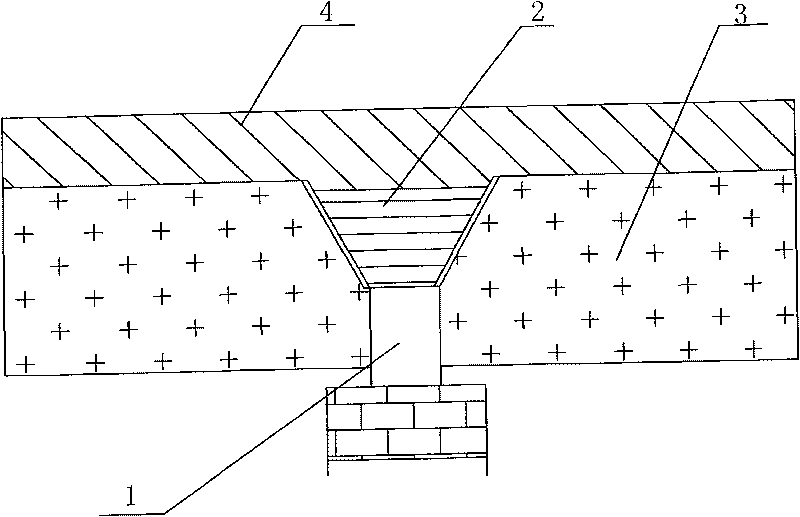

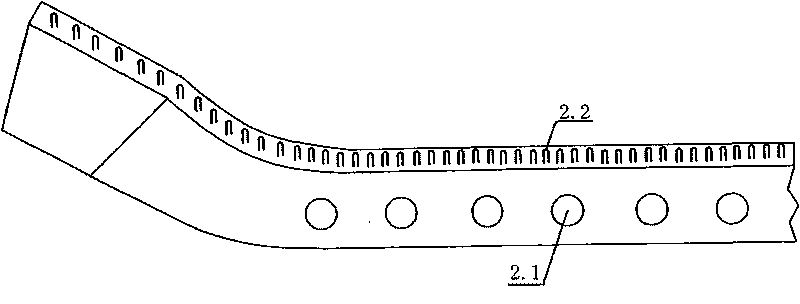

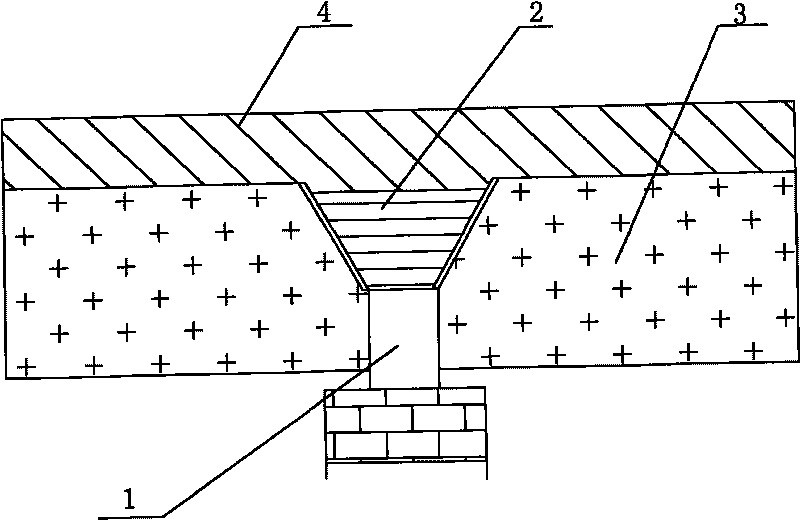

Bridge expansion joint structure

InactiveCN101701448ASolve the difficulty of constructionExtended service lifeBridge structural detailsEngineeringExpansion joint

The invention relates to a bridge expansion joint structure comprising two adjacent bridge bodies (3). The upper parts of the connection ends of the two adjacent bridge bodies (3) are provided with mutually symmetric inclined planes and the lower parts are provided with vertical planes, so that a bridge expansion joint (1) formed between the two adjacent bridge bodies (3) is divided into an upper part and a lower part, wherein the cross section of the upper part is an inverse trapezoid, with wide top and narrow bottom, and the cross section of the lower part is a rectangle with identical upper and lower width; and a rubber belt (2) is embedded on the inverse trapezoid of the bridge expansion joint (1) and the section of the rubber belt (2) is in the shape of a triangular belt. Asphalt concrete (4) is directly paved on the whole bridge deck, thus the rubber belt (2) of the bridge expansion joint is closely connected with the asphalt concrete (4) on the bridge deck into a whole. The side wall of the rubber belt (2) is provided with a plurality of pores (2.1) and the surface of the rubber belt (2) is provided with a plurality of small convex columns (2.2). The structure can slow down premature damage of the bridge expansion joint, prolong the service life, ensure the vehicles to pass safely, smoothly and swiftly, simultaneously lower the maintenance cost, save the raw materials and accelerate the construction progress.

Owner:潘志洪

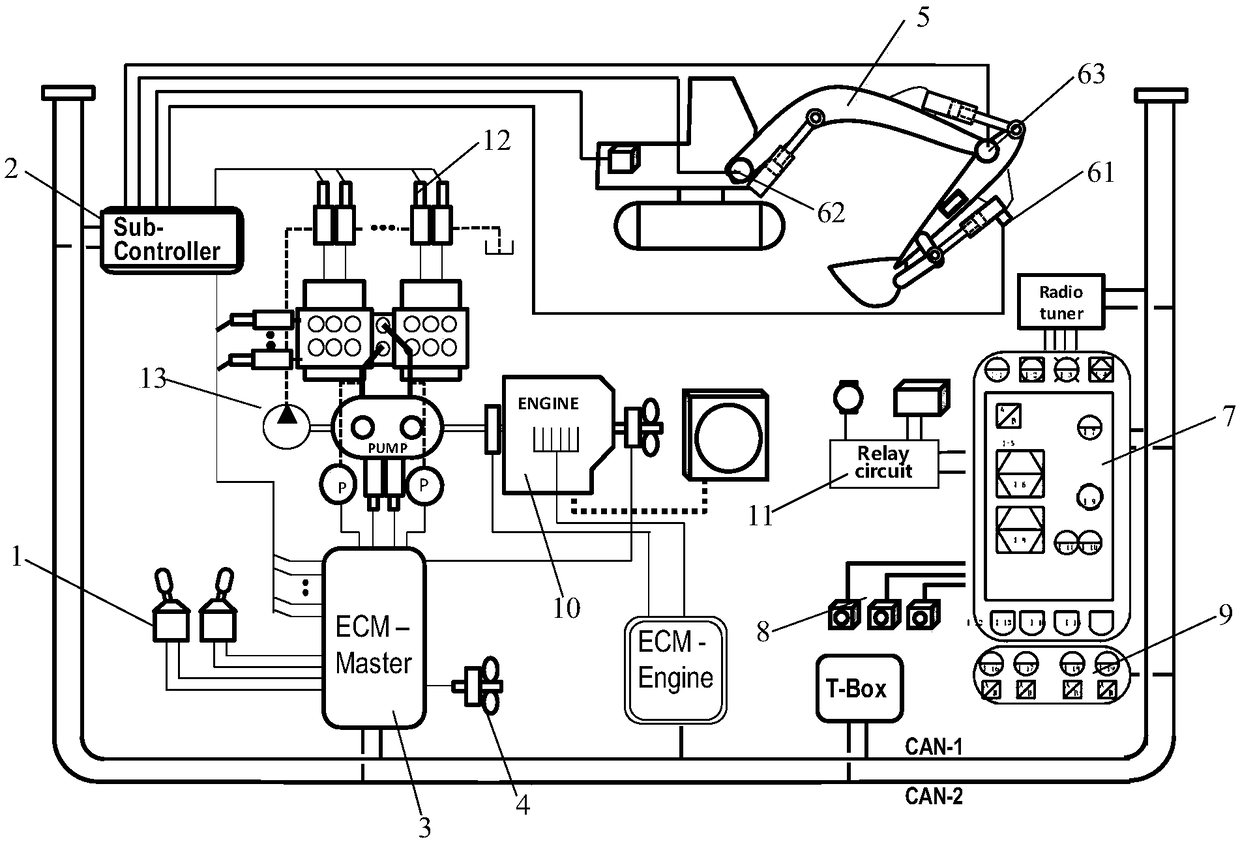

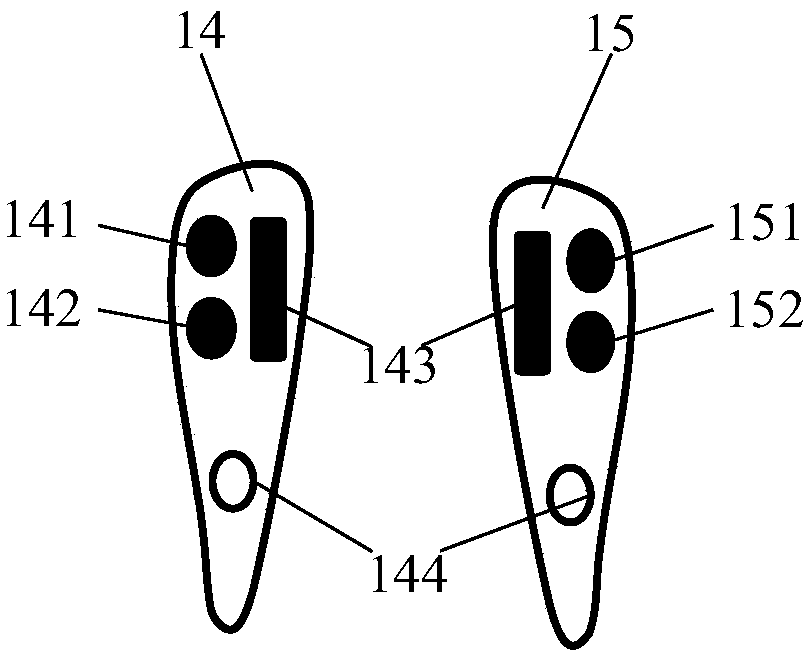

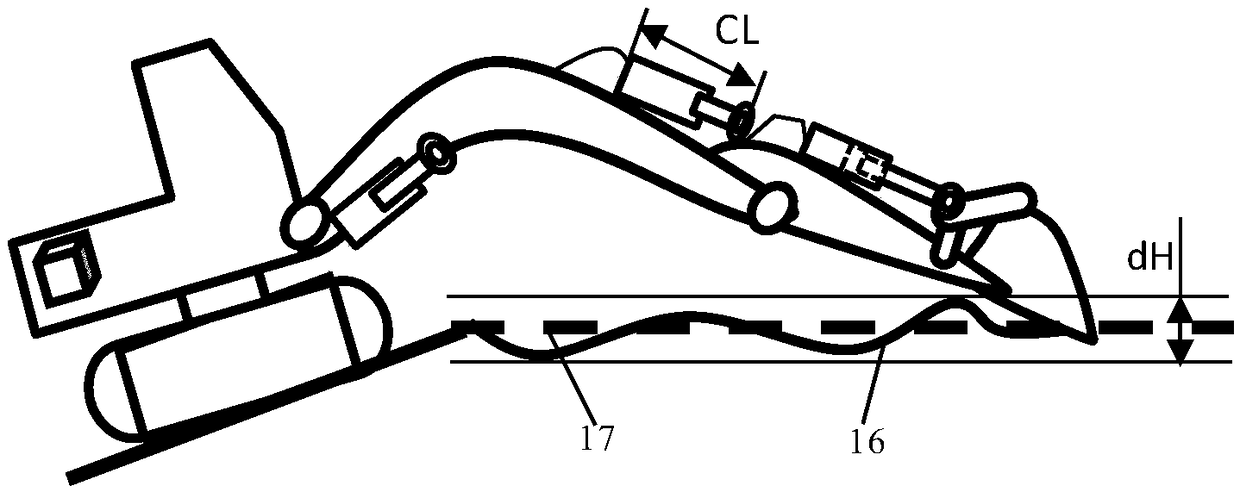

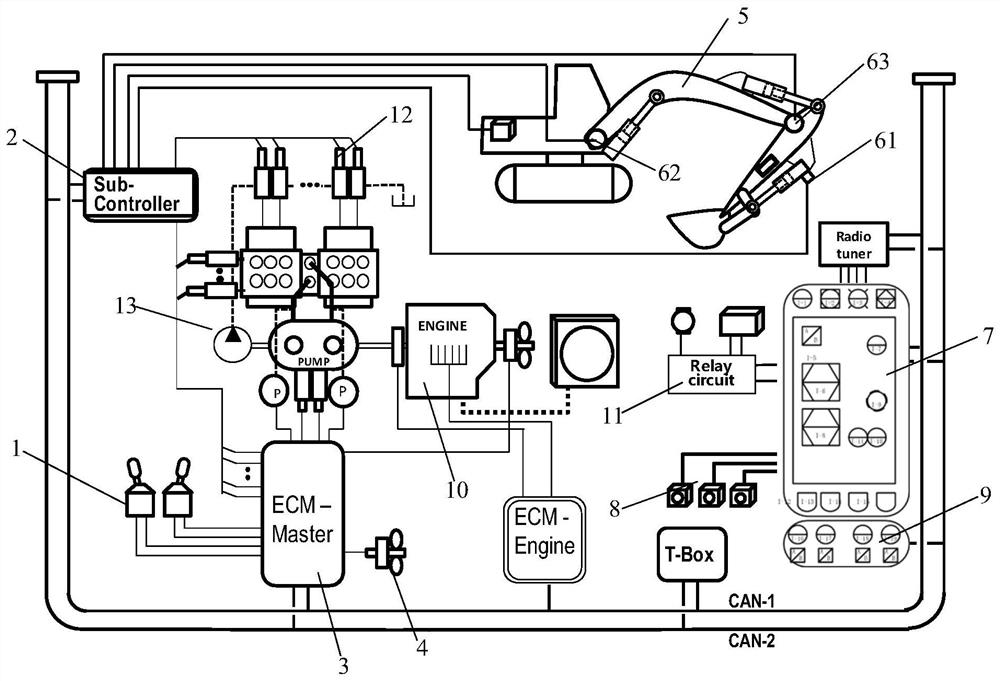

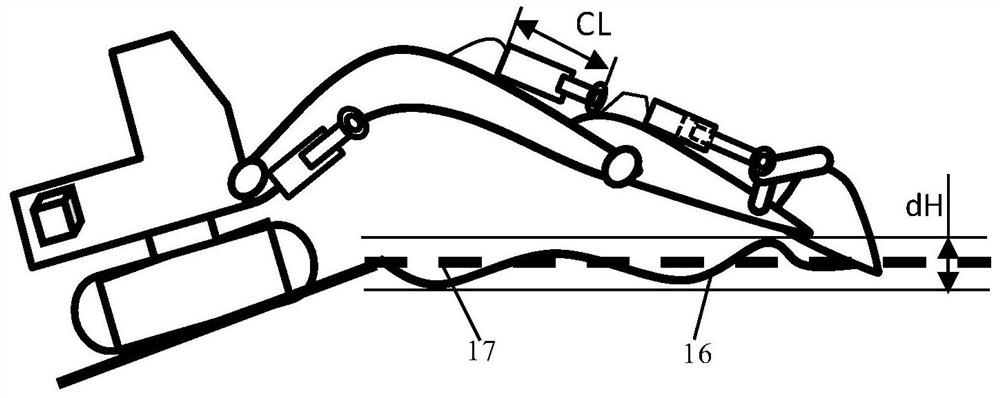

Semi-automatic construction control system and method for excavator

ActiveCN109024751ALow operator skill level requirementsSave fuelSoil-shifting machines/dredgersAutomatic Generation ControlAutomatic train control

The invention discloses a semi-automatic construction control system and method for an excavator. The semi-automatic construction control system and method solve the technical problems of low construction efficiency and low construction precision in the operation process of using the excavator for leveling and slope repairing, and the control system comprises a sensor module, a control module, a measuring module and an operating module; and the measuring module inputs measuring data into the control module, and the control module realizes calculation of the elevation, the flatness and the slope by establishing a coordinate system, meanwhile, the sensor module feeds back the condition of the excavator equipment to the control module, engineering design data are manually input into the control module, the control module transmits correction output signals which are fed back to the operating module, and the excavator enters a two-linkage semi-automatic state to complete the construction.The control system and the control method also have the advantages of low technical requirements for an excavator operator, high construction precision, no need for secondary measurement and the like.

Owner:QINGDAO LOVOL EXCAVATOR

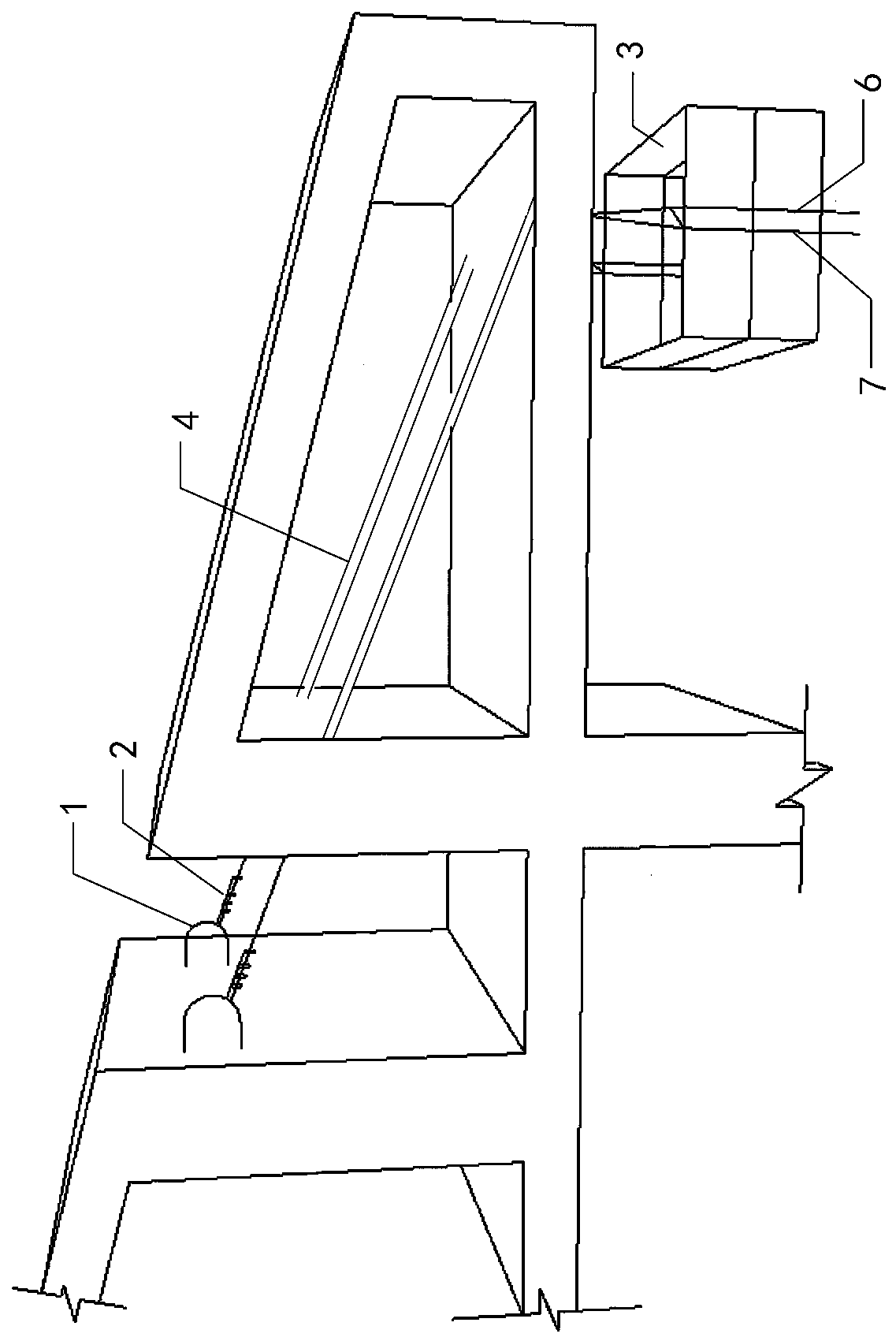

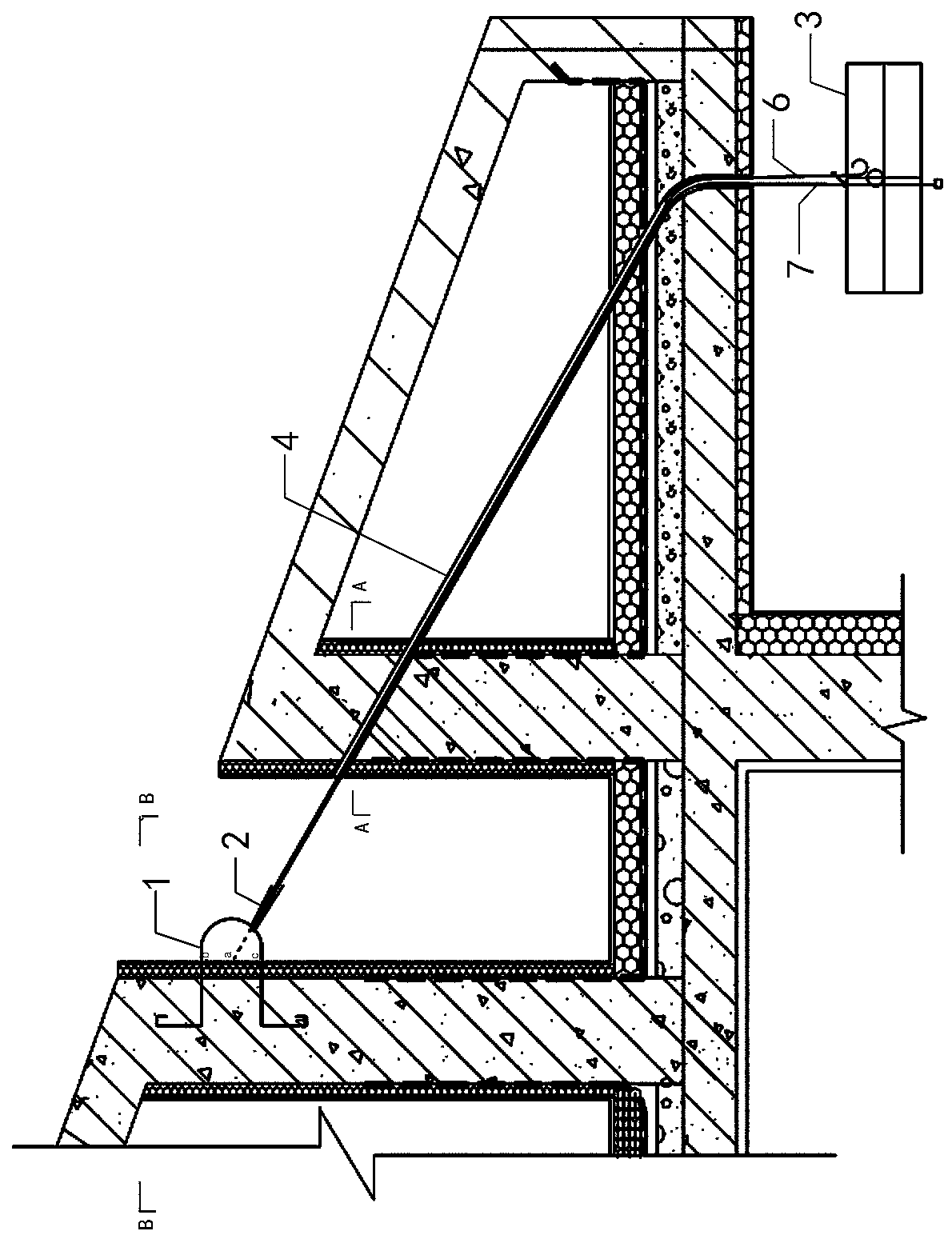

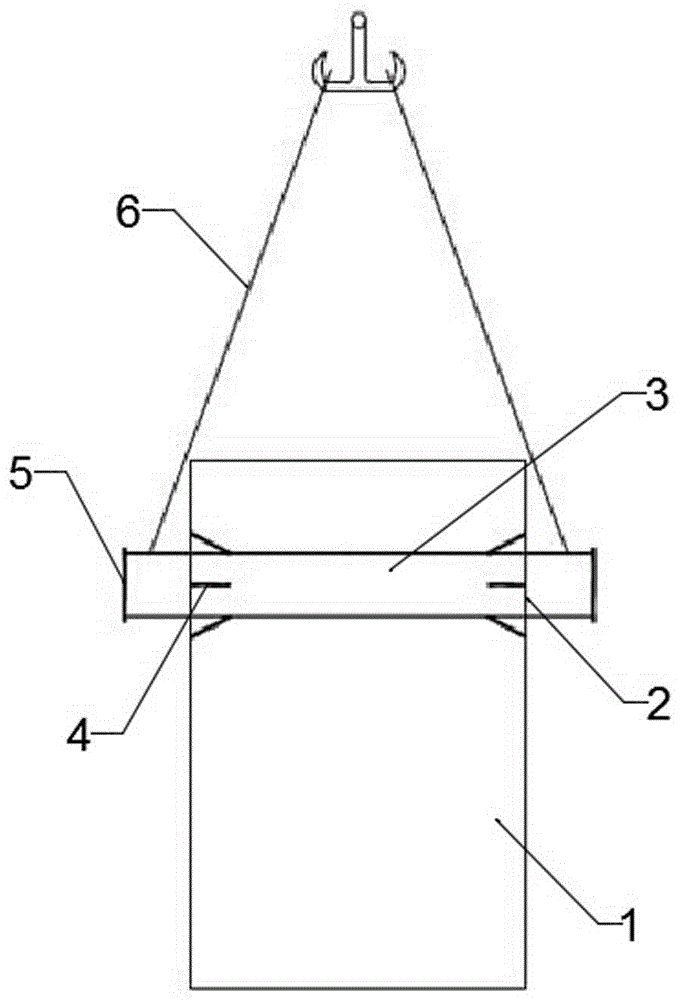

Support-free balance-weight-free hanging basket hanging structure and construction method thereof

PendingCN110158937AAvoid destructionAvoid damageBuilding support scaffoldsEavesArchitectural engineering

The invention discloses a support-free balance-weight-free hanging basket hanging structure and a construction method thereof, and relates to the field of building structure construction. The support-free balance-weight-free hanging basket hanging structure is used for a roof structure with an inclined roof and the periphery with overhanging eaves, the system comprises two hanging systems arrangedin a spaced manner, each hanging system comprises an anchorage ring embedded in the roof wall, a steel casing pipe embedded between the parapet wall and an overhanging plate, an anti-friction hose inserted in the steel casing pipe, a lifting steel wire rope and a safety rope, and the lifting steel wire rope and the safety rope are inserted into the anti-friction hose in a penetrating manner. Theproblems that a hanging basket for hanging outer eave decoration needs to erect a frame or need a balance weight when the roof is the inclined roof and the periphery is provided with the outer overhanging eaves, the structure is complex, the construction is tedious, and the construction difficulty is large are solved.

Owner:BEIJING FOURTH CONSTR & ENG

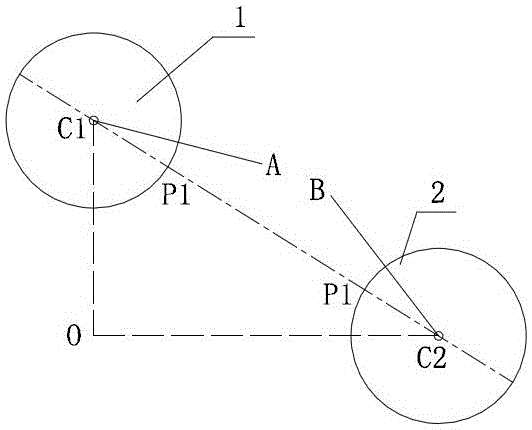

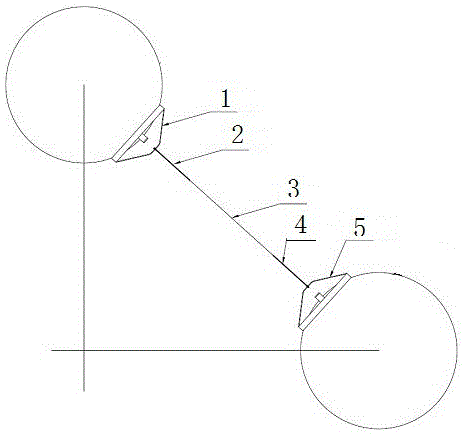

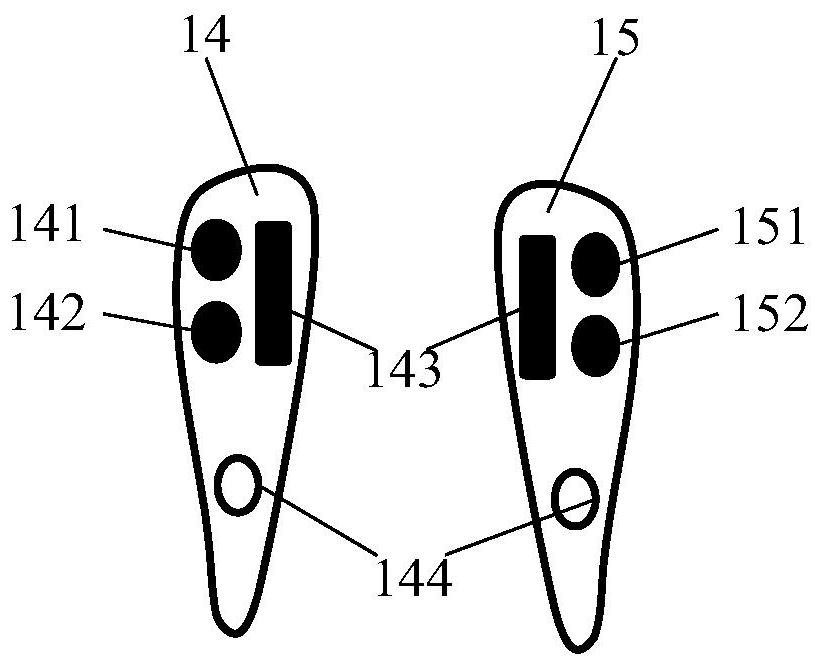

Shielding ball holing position positioning method and positioning device

ActiveCN105066819AIncrease project costSolve the difficulty of constructionMechanical measuring arrangementsEngineeringTransformer

The invention relates to the technical field of a transformer station used for power supply and distribution, particularly relates to a shielding ball holing position positioning method and positioning device, and aims at solving problems of high project field construction difficulty, low construction efficiency and high project cost caused by the fact that a holing position is accurately found after multiple times of testing in field installation of shielding balls. In order to solve the problems, the invention provides the simple positioning method. In order to implement the method, the invention provides the preferable positioning device. The positioning device comprises positioning covers which comprise positioning surfaces of which the central axes constantly pass through the centers of spheres of the shielding balls. Internal diameter of the positioning surfaces is identical to diameter of a tubular bus requiring installation. The positioning covers are fixedly provided with pointing devices of which extension direction is overlapped with the central axes of the positioning surfaces. In field installation of the shielding balls, the two positioning covers arranged on the surfaces of the two shielding balls are moved and the two pointing devices are enabled to point to one straight line so that the position of the positioning surfaces is the position requiring holing.

Owner:PINGGAO GRP +1

Wide self-adhesive high-polymer composite waterproof coiled material and production process thereof

InactiveCN102797482AImprove quality requirementsSolve the difficulty of constructionUnderground chambersProtective foundationProduction lineMaterials preparation

The invention discloses a wide self-adhesive high-polymer composite waterproof coiled material and a production process thereof. The coiled material consists of three or four layers, namely an isolating membrane layer, a self-adhesive layer, a waterproof plate layer or the isolating membrane layer, the self-adhesive layer, the waterproof plate layer and a geotextile composite layer from top to bottom; the production process comprises the following steps of material preparation, mixing, extrusion, rolling and compounding, storage, self-adhesive layer coating, storage and coiling; the coiled material solves problems that the difficulty is high in the processes of production of the conventional geotextile waterproof material and engineering construction, the requirement on quality of constructors and the cost are high, the construction quality is not stable, the construction progress is slow, the conventional geotextile waterproof material with a self-adhesive function is relatively narrow and inconvenient to construct, a large number of joints are generated because the geotextile waterproof material is frequently welded, the probability that quality problems occur after the geotextile waterproof material is welded is high, a product is compounded in the later period, and the production cost is high; the largest width of the waterproof coiled material reaches 3.05m; the self-adhesive function is realized; waterproof coiled material forming and self-adhesive layer coating are performed on the same production line, so that the production cost is reduced; and the waterproof coiled material is favorable for construction during waterproof engineering such as tunnels, metros and culverts, and the construction quality is improved.

Owner:DEZHOU ORIENT GEOSYNTHETICS

Construction method for mixed structure of steel structure and reinforced concrete

InactiveCN109853964ASolve the difficulty of constructionBuilding material handlingSupporting systemReinforced concrete

The invention relates to a building construction method, and especially relates to a construction method for a mixed structure of a steel structure and reinforced concrete. The method includes the following operation steps: S1. a moulding bed is installed, including pre-embedding of an embedded part, and pouring of a bottom plate; S2. installation and construction of the steel structure are performed, including installation of core tube steel frames on both sides, the installation of an atrium conversion truss, and reinforcement of a core tube joint area that are performed in order; S3. unloading of a supporting moulding bed is performed; wherein, when the installation of the core tube steel frames on the both sides is performed, a temporary supporting moulding bed is installed, and afterconcrete is poured to a predetermined height, the temporary supporting moulding bed is dismounted layer by layer; and after the atrium conversion truss is installed, construction of lower reinforced concrete is carried out, and then the reinforcement of the core tube joint area is performed. Through the installation of the temporary supporting moulding bed, a supporting system and the steel structure itself, the construction method forms an independent stable structural system, which is "first the steel structure and then the reinforced concrete", and effectively solves the problem of large construction difficulty of the special mixed structure of the steel structure-the reinforced concrete.

Owner:成都建工第二建筑工程有限公司

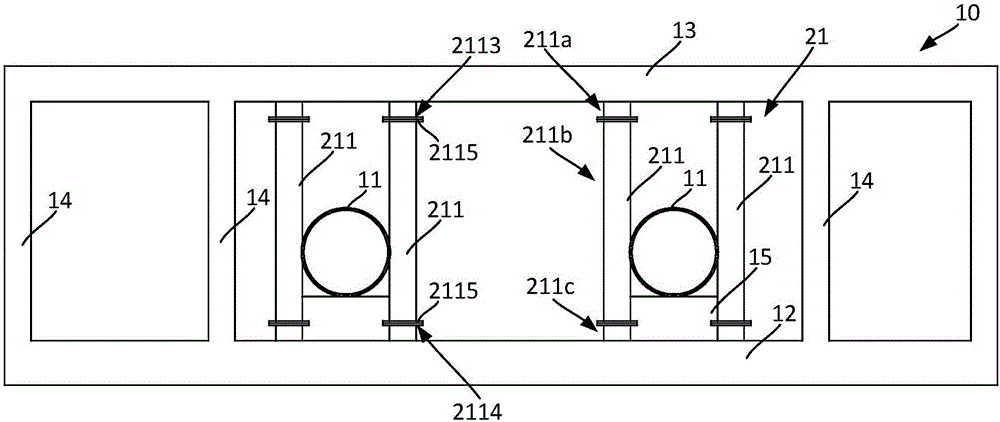

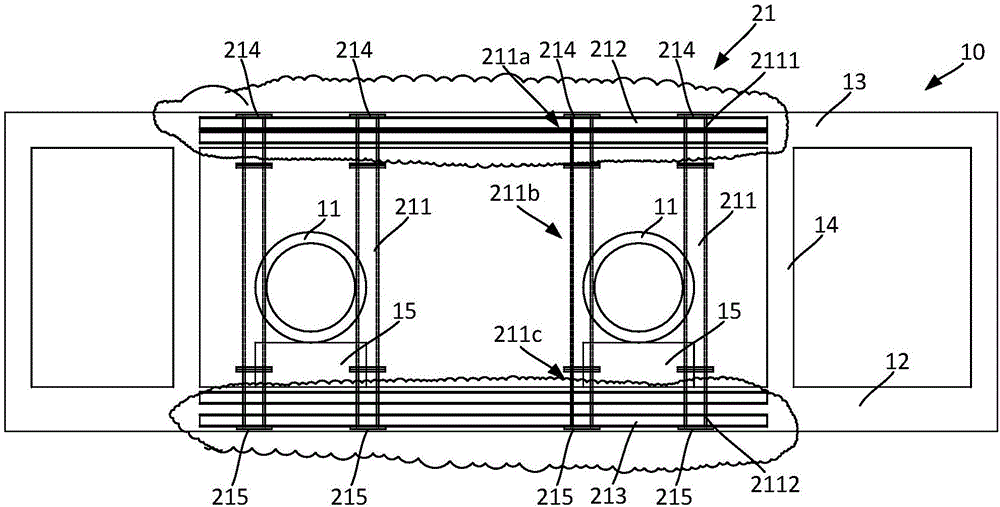

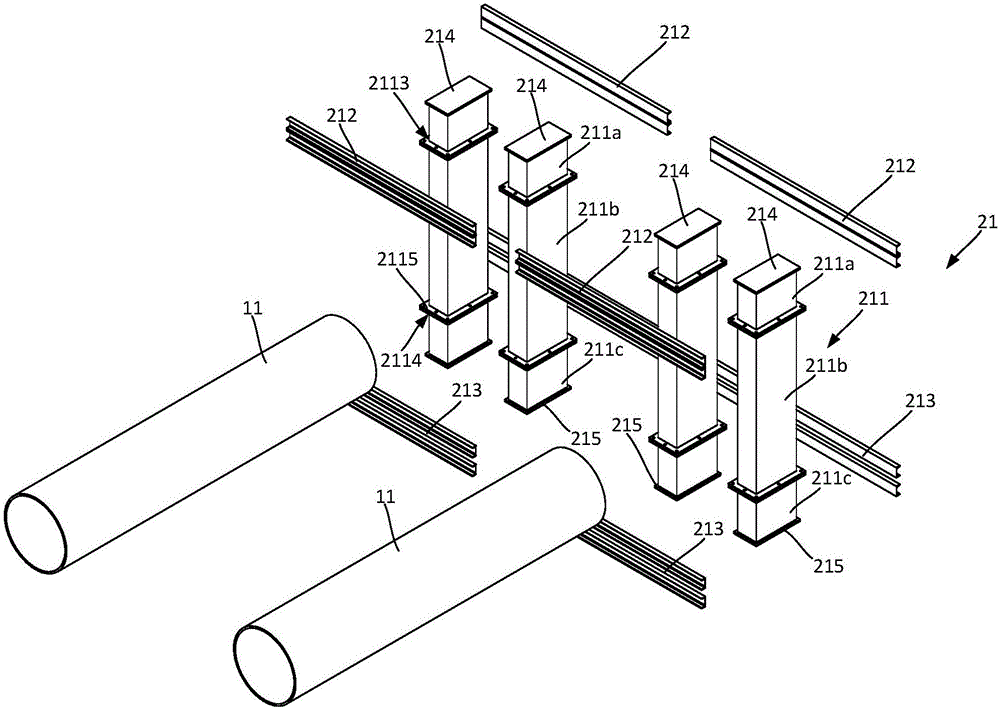

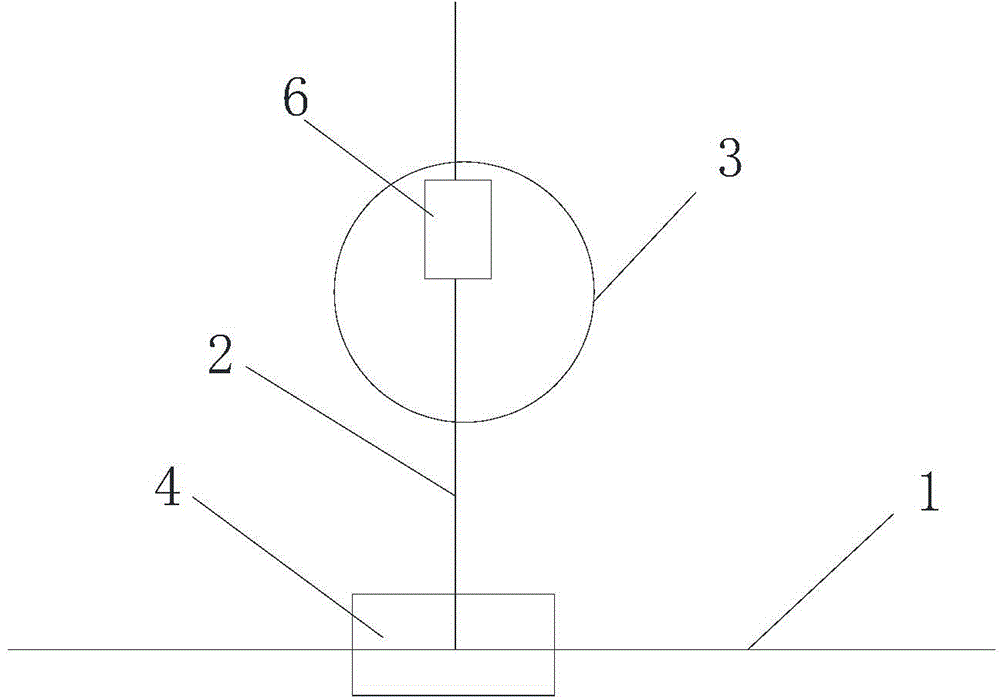

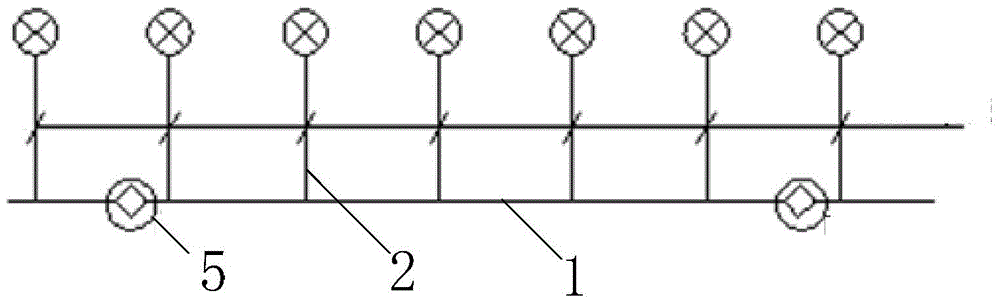

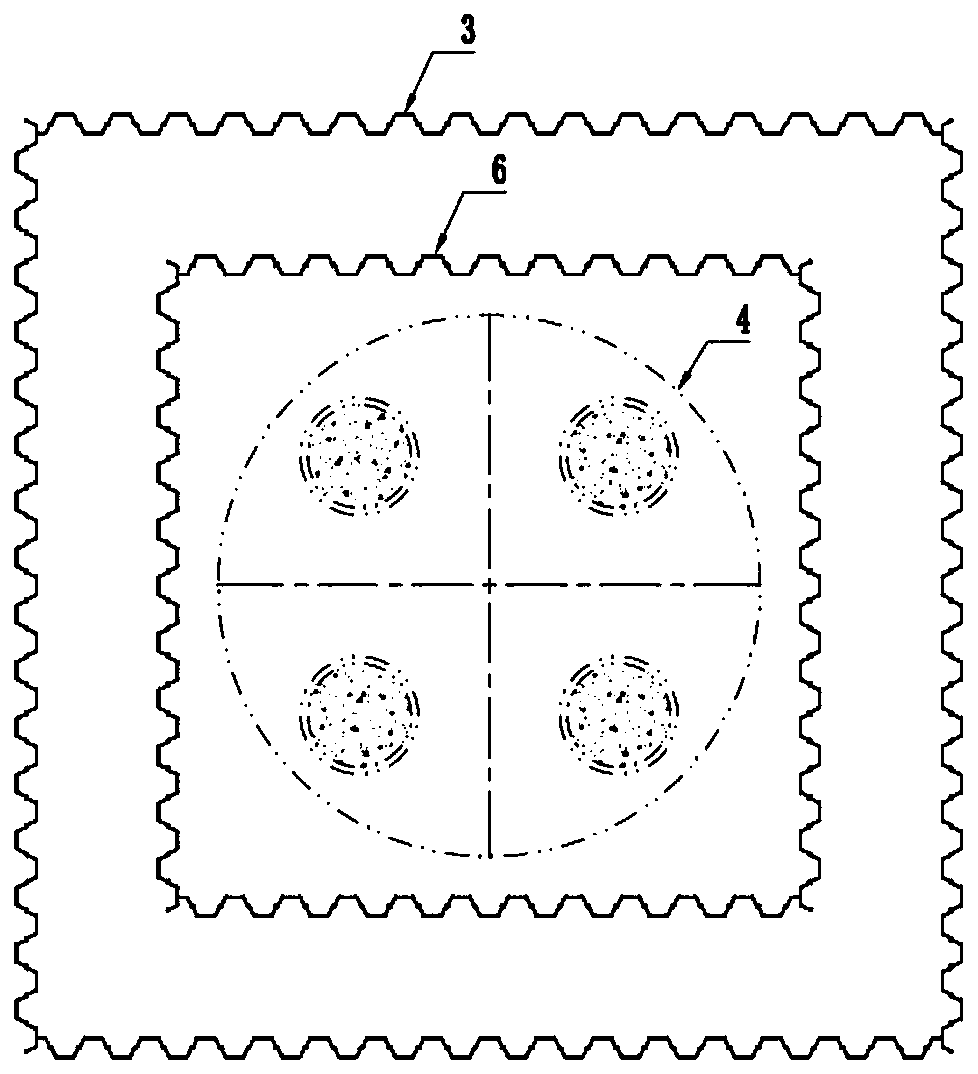

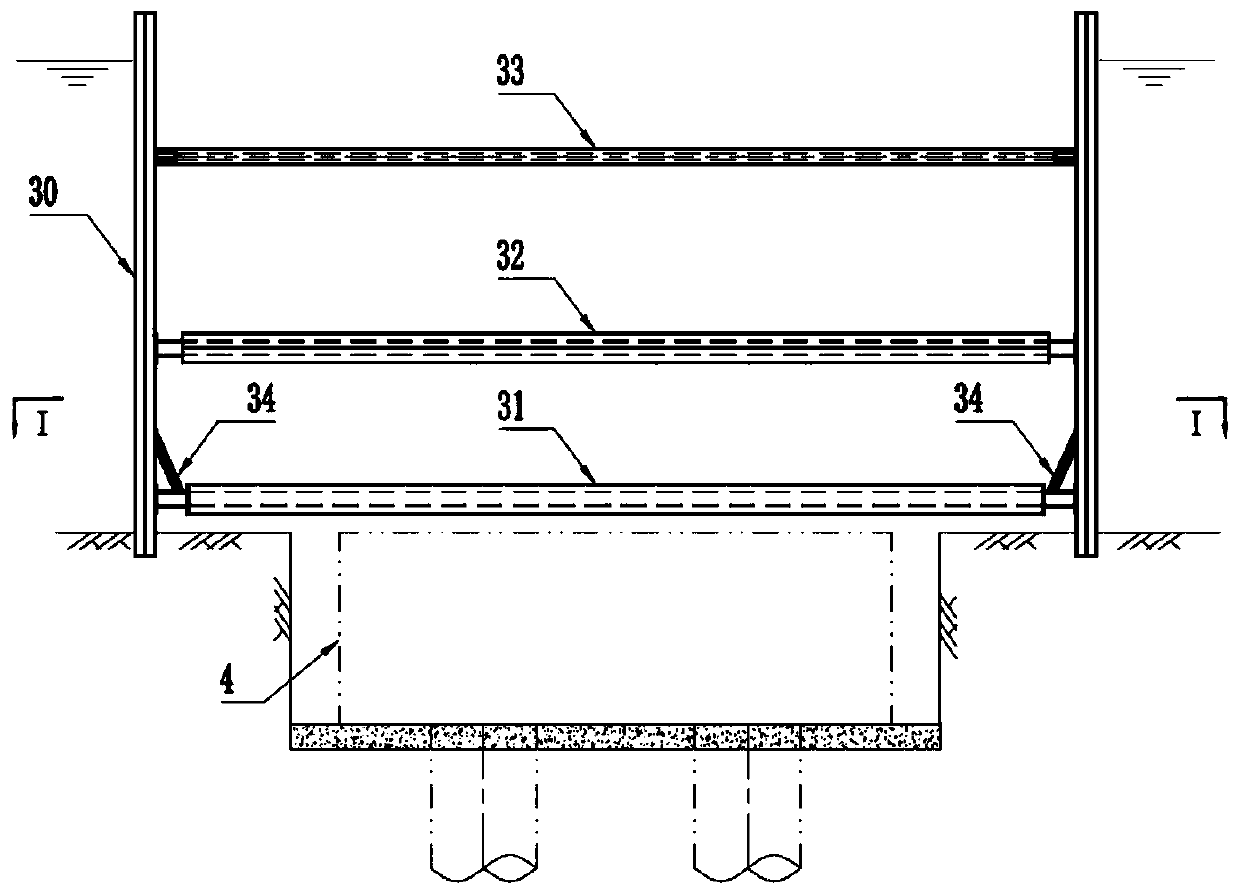

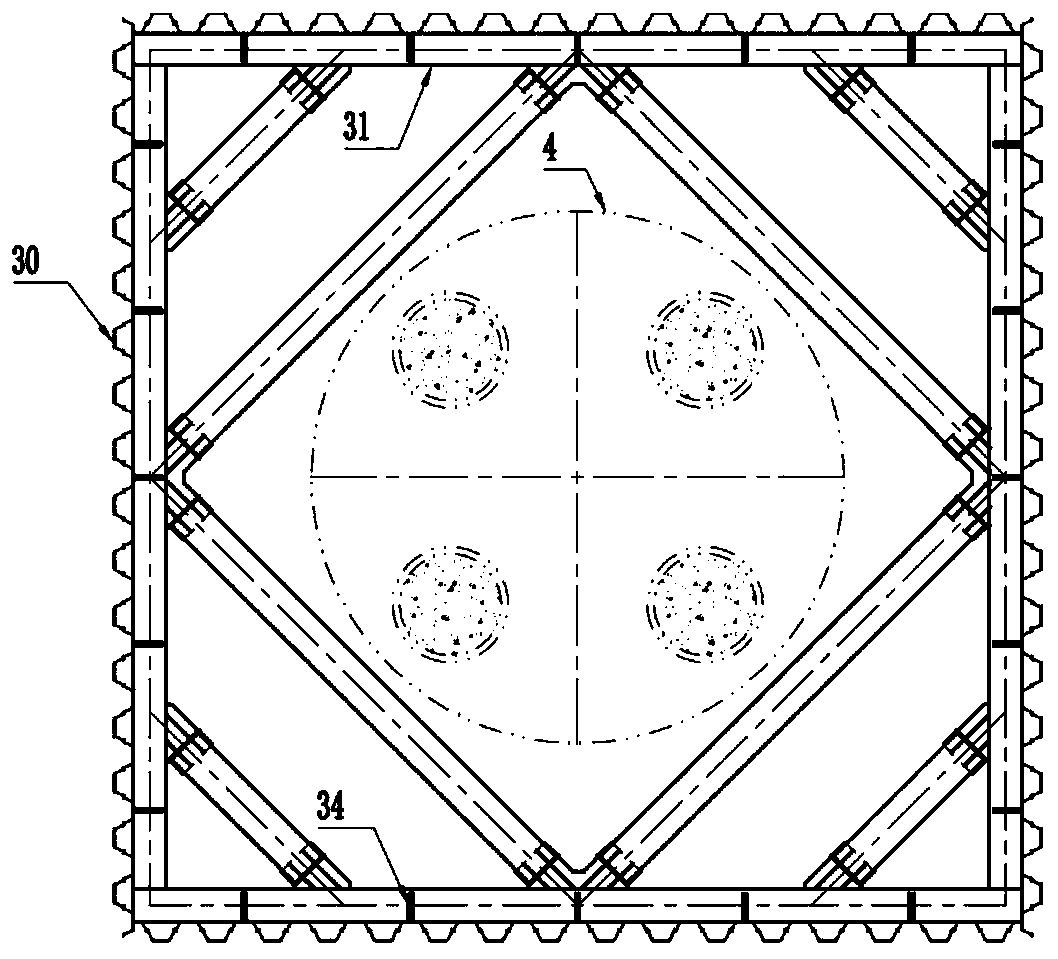

Bracket structures for heat distribution pipelines in utility tunnel and construction method of bracket structures

ActiveCN106704708AEasy constructionSolve the difficulty of constructionArtificial islandsPipe supportsArchitectural engineeringUtility tunnel

The invention relates to bracket structures for heat distribution pipelines in a utility tunnel and a construction method of the bracket structures. The bracket structures comprise stand columns which are arranged on the two sides of the heat distribution pipelines in a clamping mode and vertically arranged between a top plate and a base plate of the utility tunnel. The tops of the stand columns are embedded into the top plate to form first anchor-connecting sections, and the bottoms of the stand columns are embedded into the base plate to form second anchor-connecting sections. The heat distribution pipelines are fixed and supported through the stand columns arranged on the two sides of the heat distribution pipelines in the clamping mode, the tops of the stand columns are embedded into the top plate of the utility tunnel, the bottoms of the stand columns are embedded into the base plate of the utility tunnel, therefore the stand columns can effectively transmit longitudinal thrust of the heat distribution pipelines to the structure of the utility tunnel, and the thrust of the heat distribution pipelines is unloaded while the heat distribution pipelines are fixed. The utility tunnel and the earth form an integrated stress structure, the rigidity of the utility tunnel can be simplified to be infinite in the longitudinal section, and therefore a closed force transmission ring transmitting pressure of the heat distribution pipelines to the earth is formed, and the structural stability and safety can be ensured.

Owner:中建科技集团华北有限公司

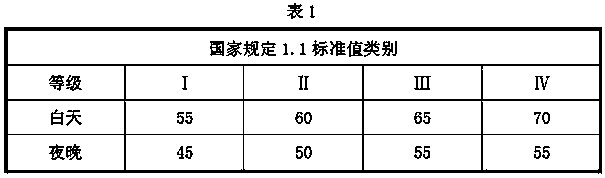

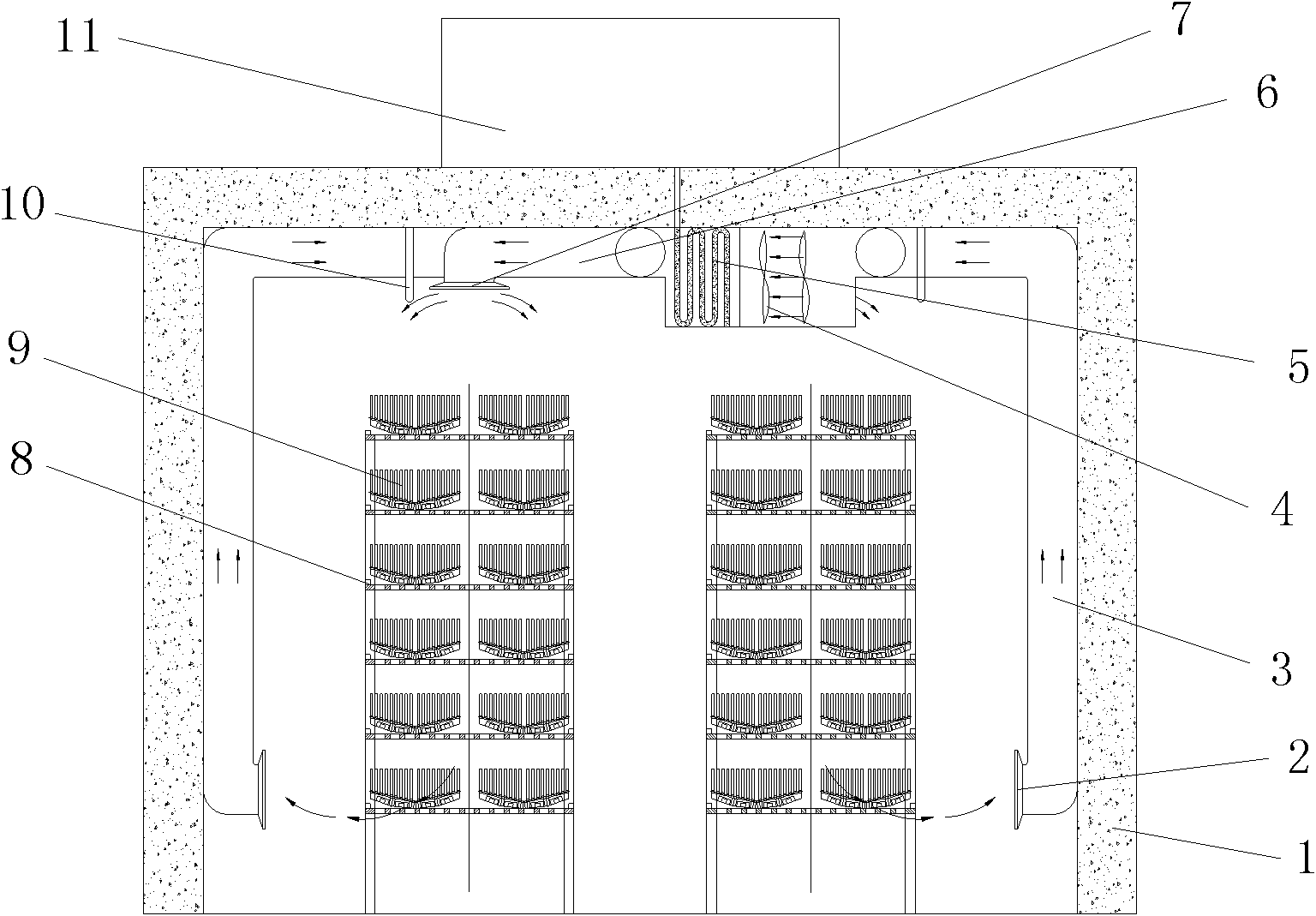

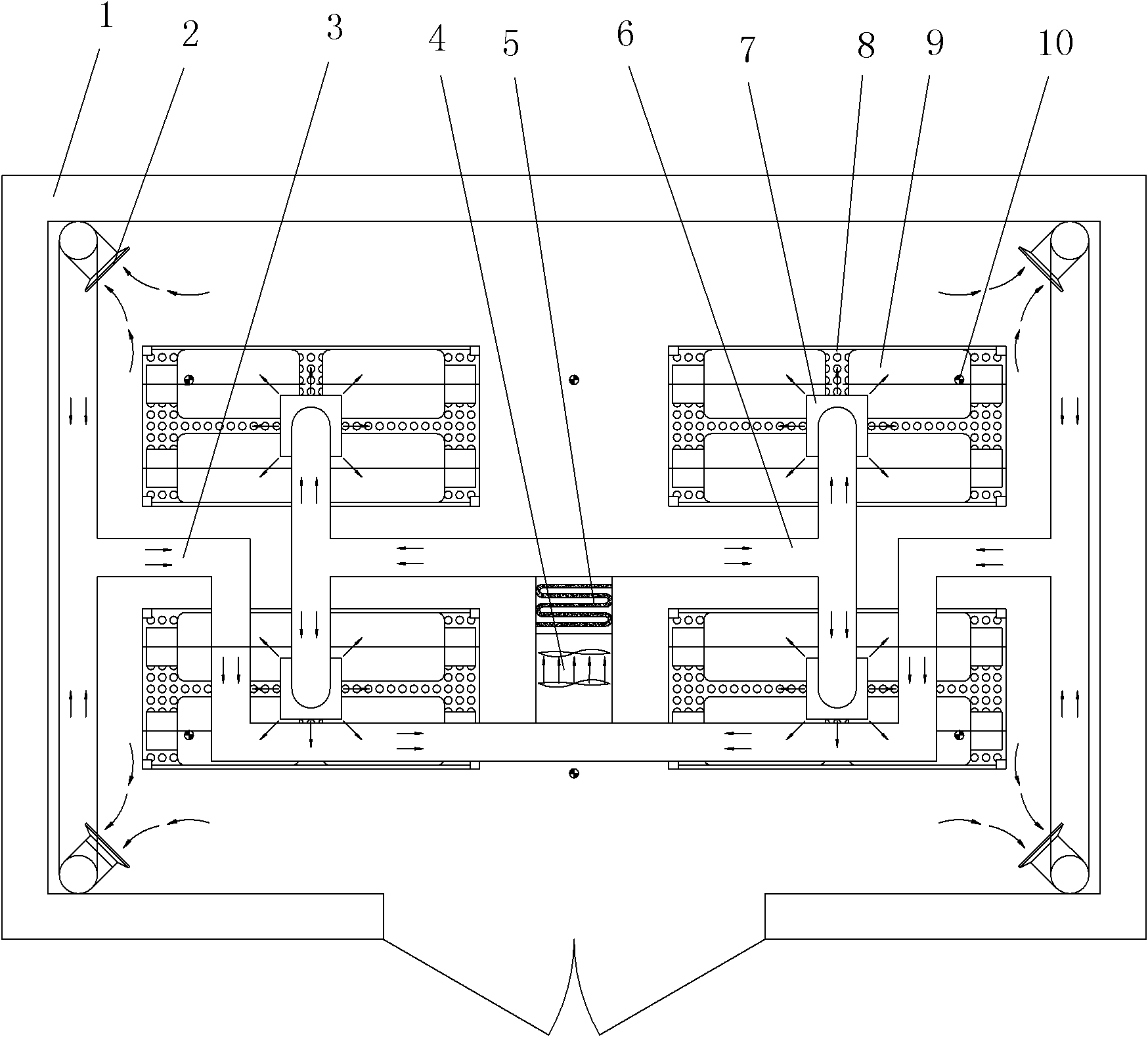

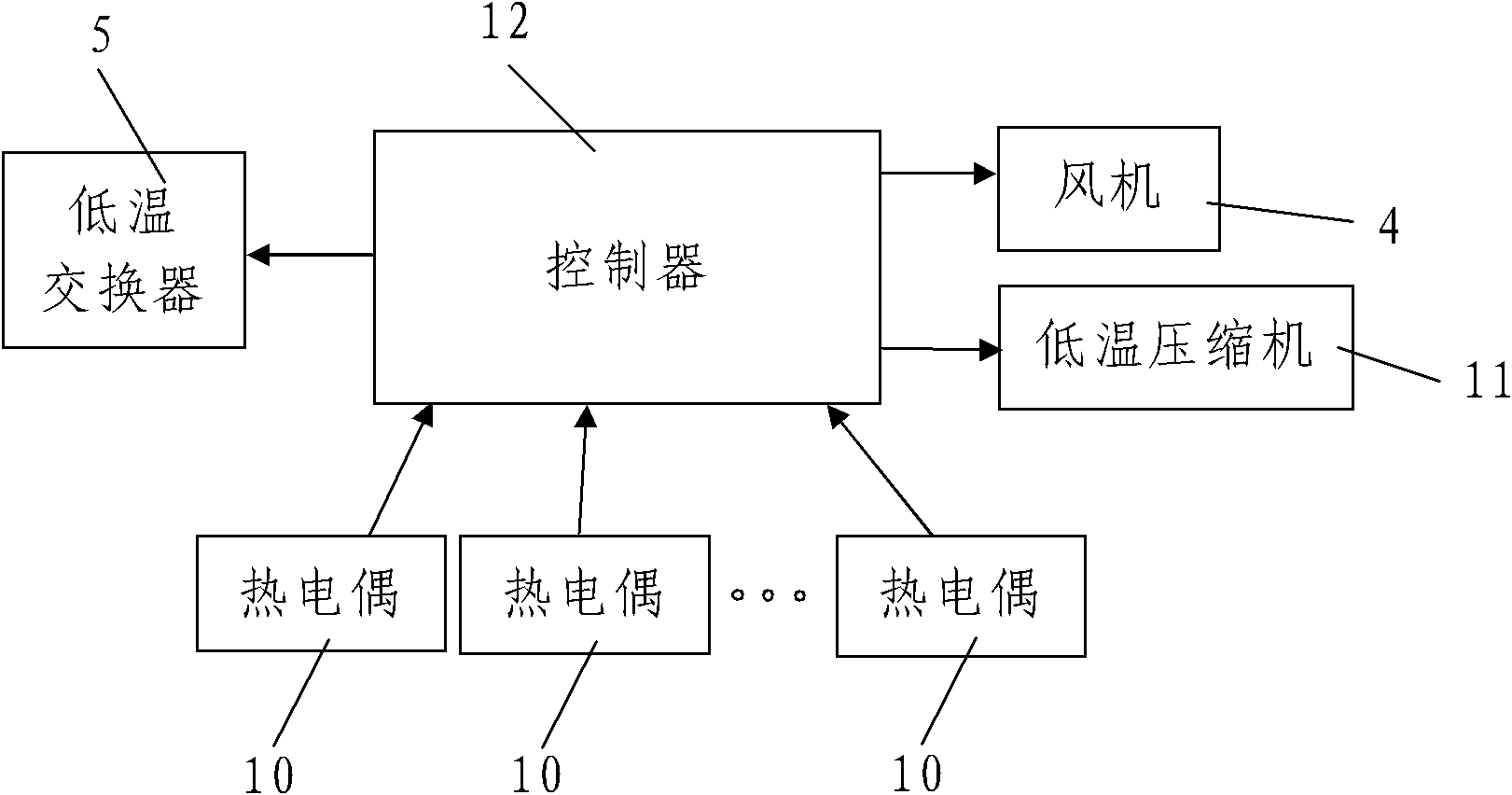

LED (light-emitting diode) street lamp low temperature environment aging room

InactiveCN102486321ASimple structureLow costDucting arrangementsSpace heating and ventilation safety systemsAirflowReturn channel

The invention discloses an LED (light-emitting diode) street lamp low temperature environment aging room. The LED street lamp low temperature environment aging room comprises an aging room body, an air-circulating channel which is used for continually circulating to introduce cold air to an aging region in the aging room body, a controller and multiple temperature-detecting devices, wherein the air-circulating channel comprises a low temperature exchanger, a low temperature compressor, a fan, a cold air inlet channel, and an air return channel, wherein the low temperature exchanger is arranged above the middle of the aging room body, the low temperature compressor is connected with a low temperature exchanger, the cold air inlet channel is used for leading cooling draft acquired by the low temperature exchanger after low temperature exchange to successively introduce the aging region through multiple cold air inlets, the air return channel is used for absorbing air in the aging region under the action of the fan to the side of the low temperature exchanger so as to carry out low temperature exchange through multiple air return ports, and the cold air inlet channel is communicated with the air return channel through a communicating pipe. The low temperature environment aging room provided by the invention has the advantages of simple structure, is easy to operate, is low in cost and has good using effects, and can be used for effectively solving a temperature maldistribution problem in the aging region through adjusting the refrigeration states of the low temperature exchanger and the low temperature compressor and the shutter states of air inlets and the air return ports.

Owner:XIAN DAYU PHOTOELECTRIC TECH

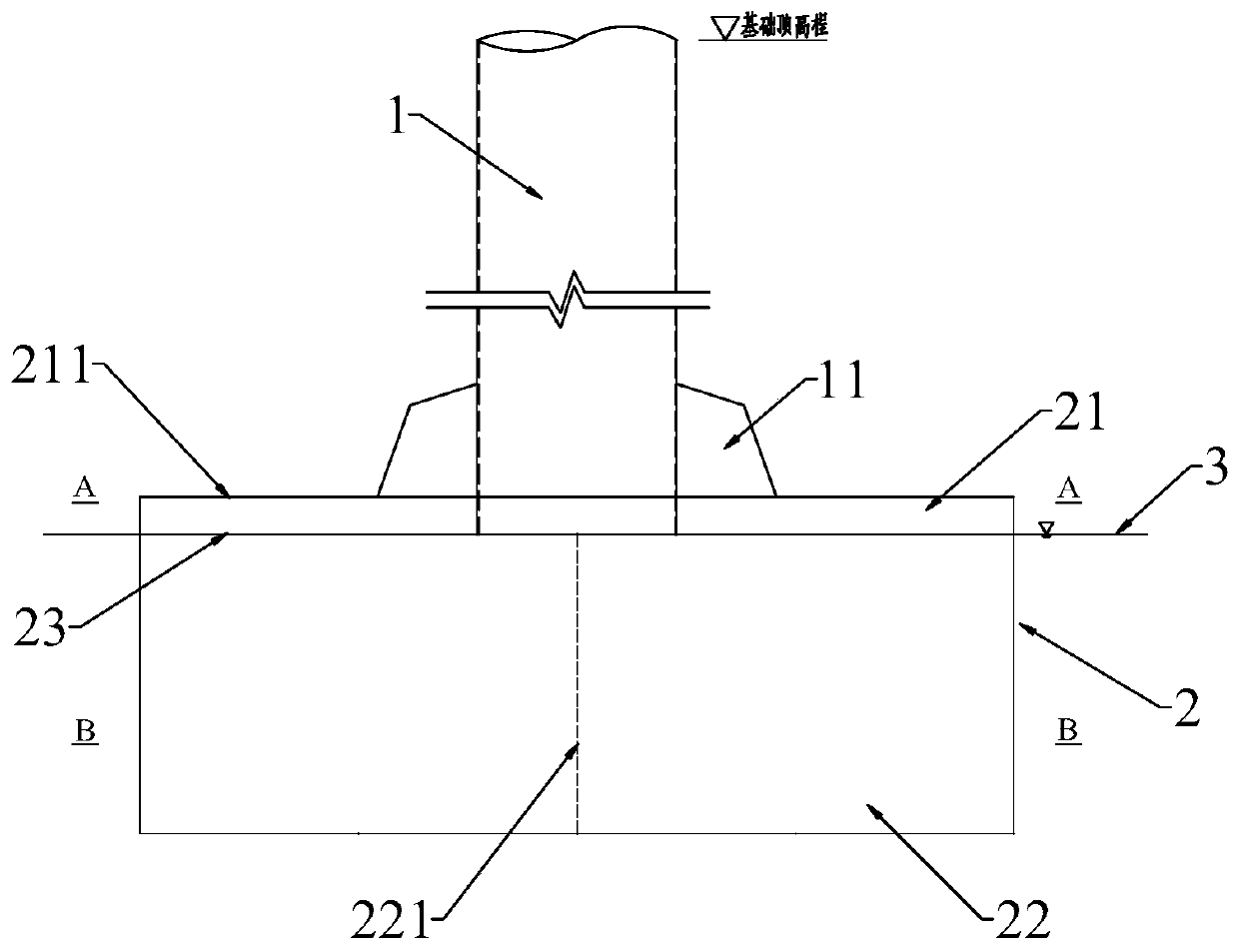

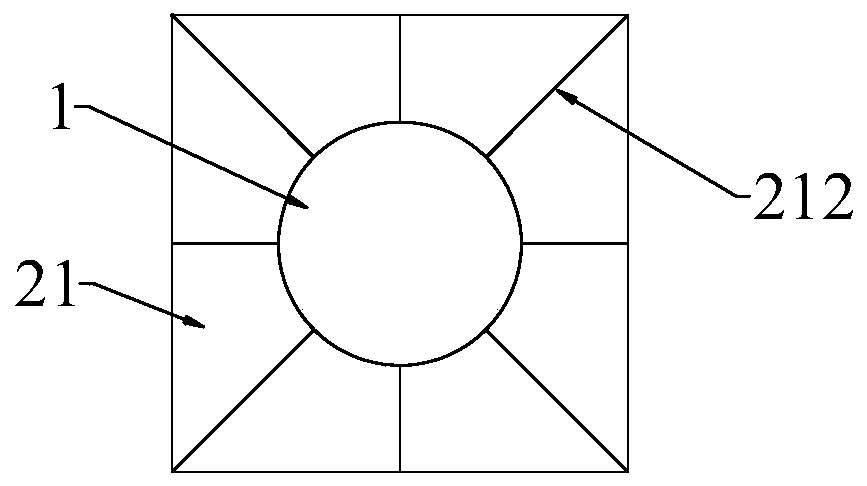

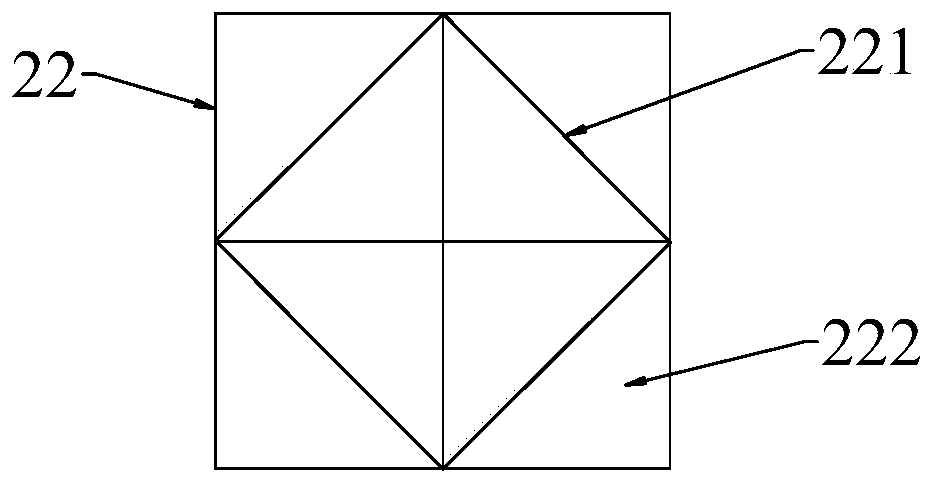

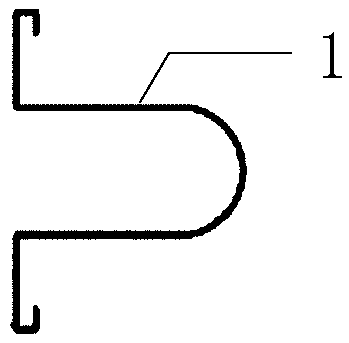

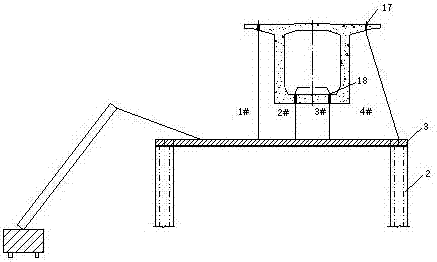

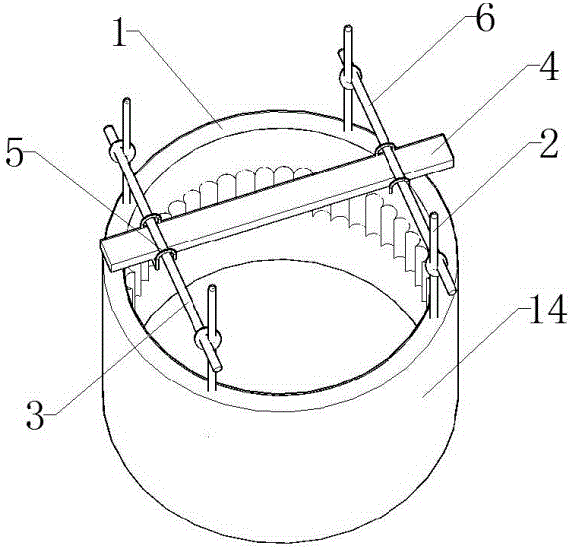

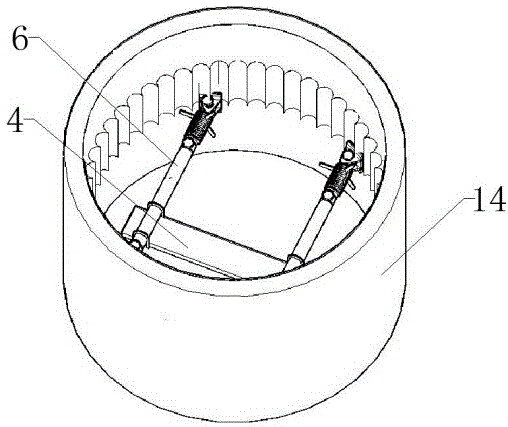

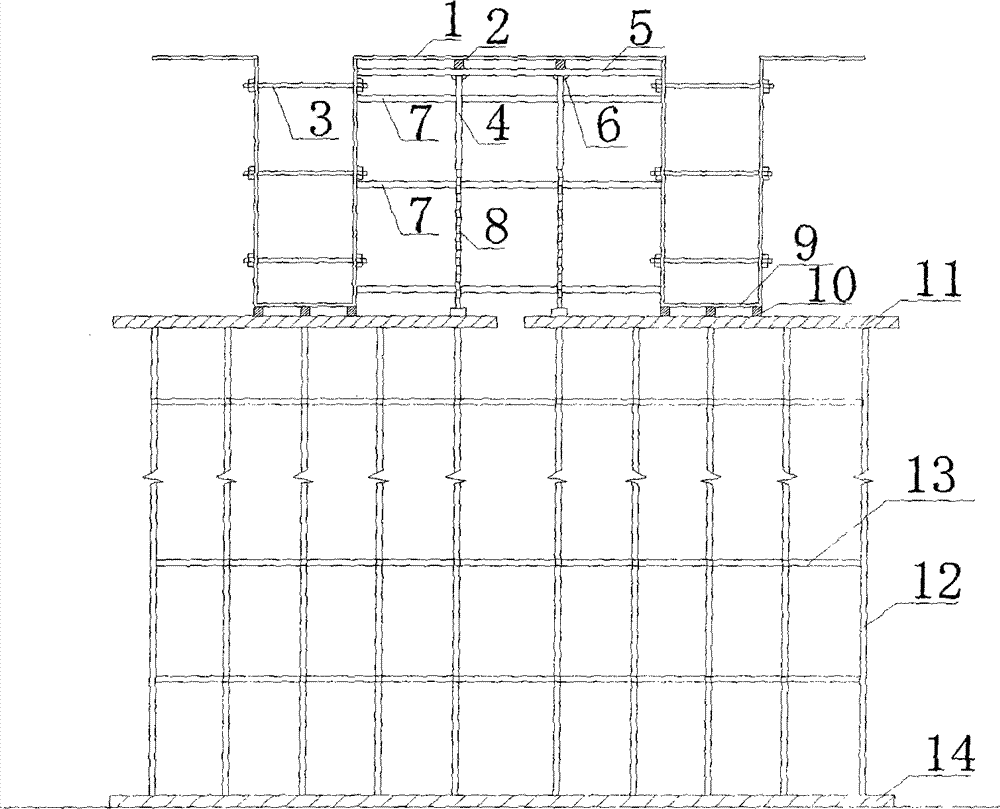

Construction method for decomposing grading high-rise pile cap

InactiveCN101446087ASolve the difficulty of constructionShorten the construction periodEmbankmentsDecomposerAluminium industry

The invention discloses a construction method for decomposing a grading high-rise pile cap. A pipe (1) based on a decomposer is constructed up to the ground elevation of a bearing platform at a time. The bearing platform (2) of the pile foundation is constructed in advance before secondary backfill is made, and then back fill (3) under the ground elevation of field plating is treated. The method has simple configuration, low cost, easy implementation, can solve greatly construction difficulty when being applied to aluminium industry fractional decomposition, shortens duration of a project, and reduces the investment.

Owner:GUIYANG AL-MG DESIGN & RES INST

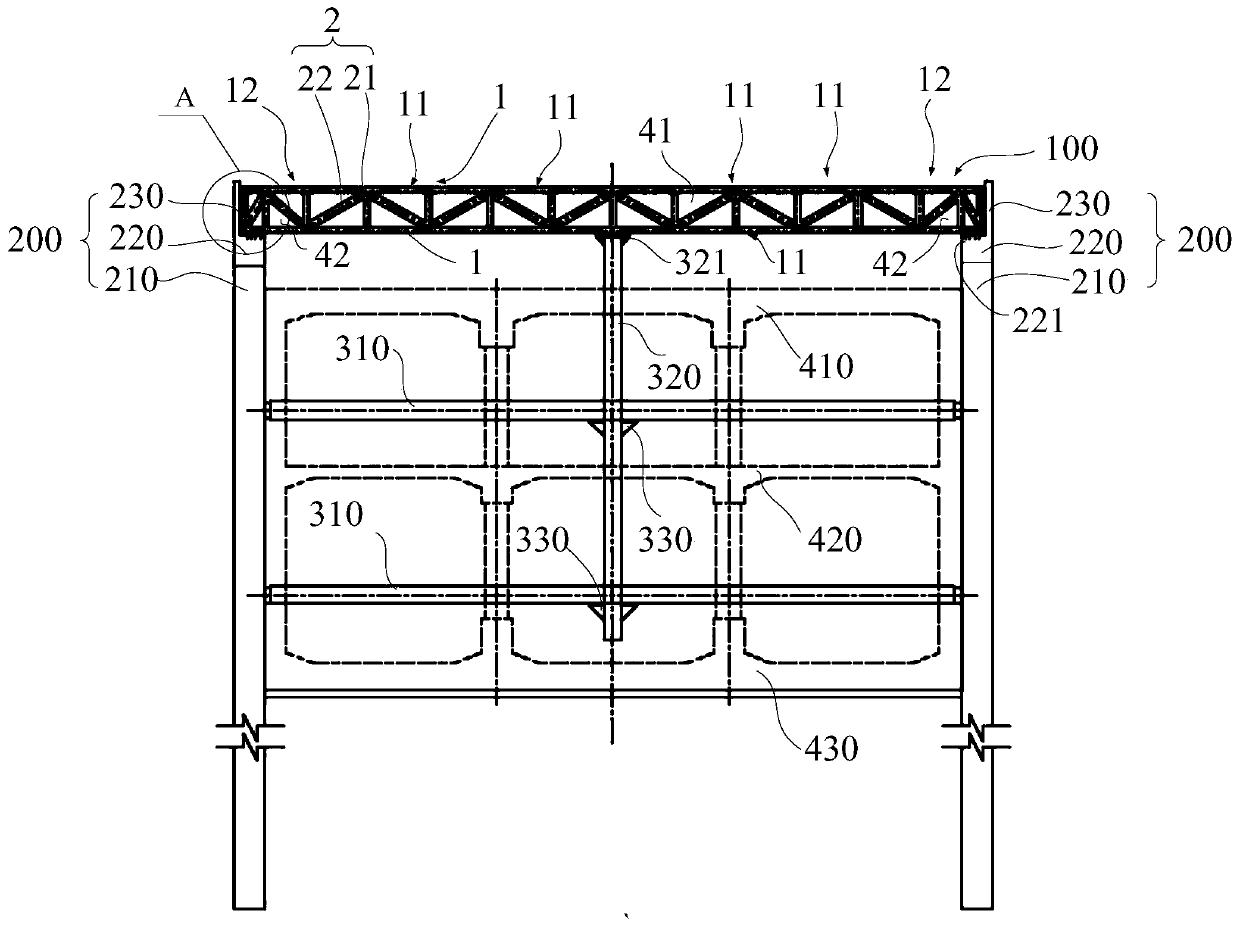

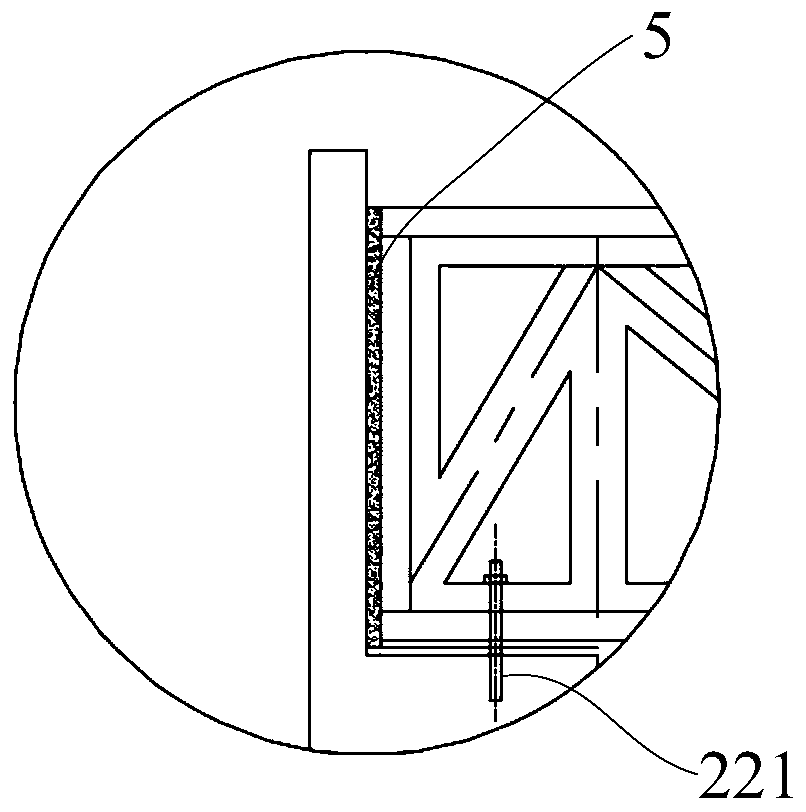

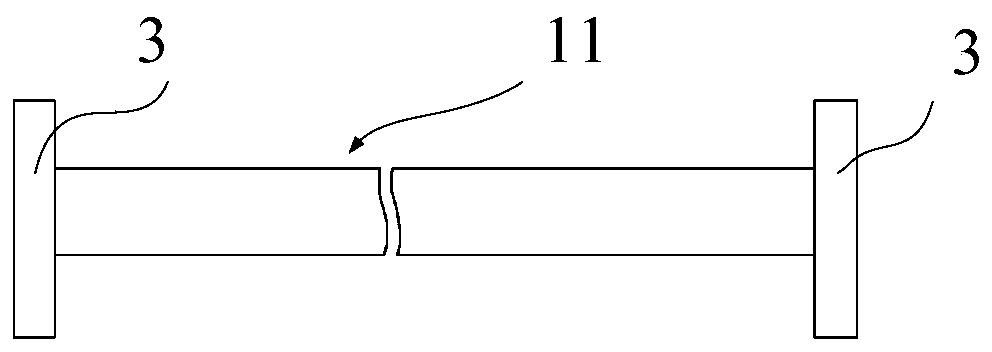

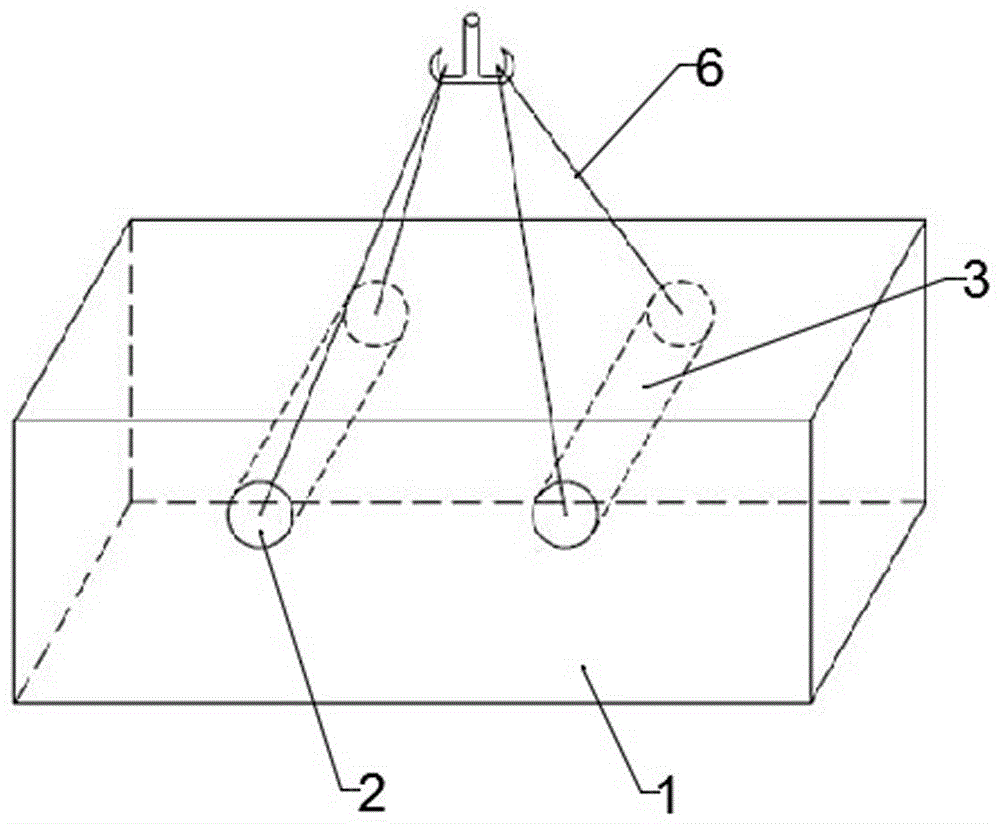

Supporting truss capable of being recycled, foundation pit supporting system and subway station construction method

PendingCN111270685AReduce the difficulty of disassemblyShorten the construction periodArtificial islandsExcavationsSupporting systemArchitectural engineering

The application provides a supporting truss capable of being recycled, a foundation pit supporting system and a subway station construction method. The supporting truss is used in the foundation pit supporting system of a construction subway station and comprises two chord members and a web member, the two chord members are arranged at interval and in an up and down mode, and the two ends of eachchord member are detachably connected to an enclosure body of the foundation pit supporting system; and the web member is connected between the upper chord member and the lower chord member. Accordingto the supporting truss, the supporting truss is spliced by using the prefabricated chord members and the web member, so that the construction process of cast-in-place concrete forming of the supporting truss is omitted, after the supporting work is completed, direct detaching can be conducted, the construction difficulty of the supporting truss is reduced accordingly, and meanwhile, the construction period is also shortened.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Construction method of condenser

InactiveCN105953599AShorten the construction periodImprove work efficiencySteam/vapor condensersWater pipeBuilding construction

The invention discloses a construction method of a condenser. The method comprises the following steps: S1, a foundation is constructed in the position where the condenser is mounted, and all components of the condenser in bulk are assembled in a shell while construction of the foundation is performed, before construction of the foundation or after construction of the foundation; S2, sleepers are laid beside the foundation; S3, rails are laid on the sleepers; S4, the shell assembled in S1 is lifted onto the rails; S5, a throat part of the condenser is welded onto the shell; S6, the condenser with the throat part welded in S5 is hauled onto the foundation; S7, penetration of cooling water pipes is performed. By adoption of the method, assembly of the condenser and construction of the foundation can be performed simultaneously, so that the construction period of the condenser is shortened, and the working efficiency is improved; the problem of high construction difficulty caused by narrow installation sites can be effectively solved; besides, a lifting auxiliary reinforcement measure is taken during lifting of the shell of the condenser, that is, through holes are formed in the shell and steel pipes penetrate through the through holes, the structure is simple, the method is easy to realize, and the cost is low.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Multi-cavity composite shear wall and H-shaped steel beam fabricated node and construction method thereof

PendingCN110725402AAvoid stress concentrationImprove stabilityWallsStress concentrationEarthquake resistance

The invention relates to a multi-cavity composite shear wall and H-shaped steel beam fabricated node and a construction method thereof, and belongs to the technical field of building engineering. Thenode comprise a pair of end posts, wherein a multi-cavity steel plate composite shear wall is arranged between the two end posts, an inner end plate is arranged between one side end post and the multi-cavity steel plate composite shear wall, the other three faces of each end post are provided with outer end plates which are welded on the corresponding end post in an attached mode, a plurality of pairs of pull screw rods which are arranged at equal intervals and penetrate through the end posts are arranged between the upper and lower end outer end plates, and between the side edge outer end plates and inner end plates, and steel beams welded on the outer end plates in a grooving mode are arranged on the side edge and lower edge outer end plates. The node has the characteristics of being high in structural strength, not prone to deform, strong in stability, good in anti-seismic performance and long in service period. The problem that the construction difficulty is large is solved. The stress concentration caused by direct welding of outer rib plates and outer cladding steel plates on the end posts is avoided.

Owner:浙江东南网架股份有限公司

Protective shed structure for continuous girder crossing on-active-duty highway and construction method of protective shed structure

InactiveCN107269013ASolve the difficulty of constructionSolve the problem of high safety factorBuilding material handlingBuilding construction

The invention discloses a protective shed structure for a continuous girder crossing an on-active-duty highway and a construction method of the protective shed structure. The protective shed structure comprises strip-shaped bases, stand columns and transverse load distributing girders, wherein the stand columns are fixedly arranged on the strip-shaped bases, and the transverse load distributing girders are set up on the stand columns; a set of longitudinal load distributing girders are arranged on each transverse load distributing girder, a waterproof board is arranged above the longitudinal load distributing girders, and steel pipe piles are fixedly arranged on the positions, at the two sides of the transverse load distributing girders, of the ground; and hawsers are arranged on the steel pipe piles, one ends of the hawsers are fixedly connected with the steel pipe piles, and the other ends of the hawsers are fixedly connected with the tops of the corresponding stand columns at the two sides of the transverse load distributing girders. The protective shed structure has the following characteristics and beneficial effects that the problem of large construction difficulty is solved by integrally hoisting and splicing the bases, the transverse girders and a longitudinal girder top layer, the problem of a high requirement for a safety factor is solved by building auxiliary facilities, and relatively good technical and economical benefits are achieved; and the transverse girders are removed by adopting the method of traction hoisting, and therefore the removing difficulty is reduced.

Owner:HANGZHOU JIANGRUN TECH LIMITED

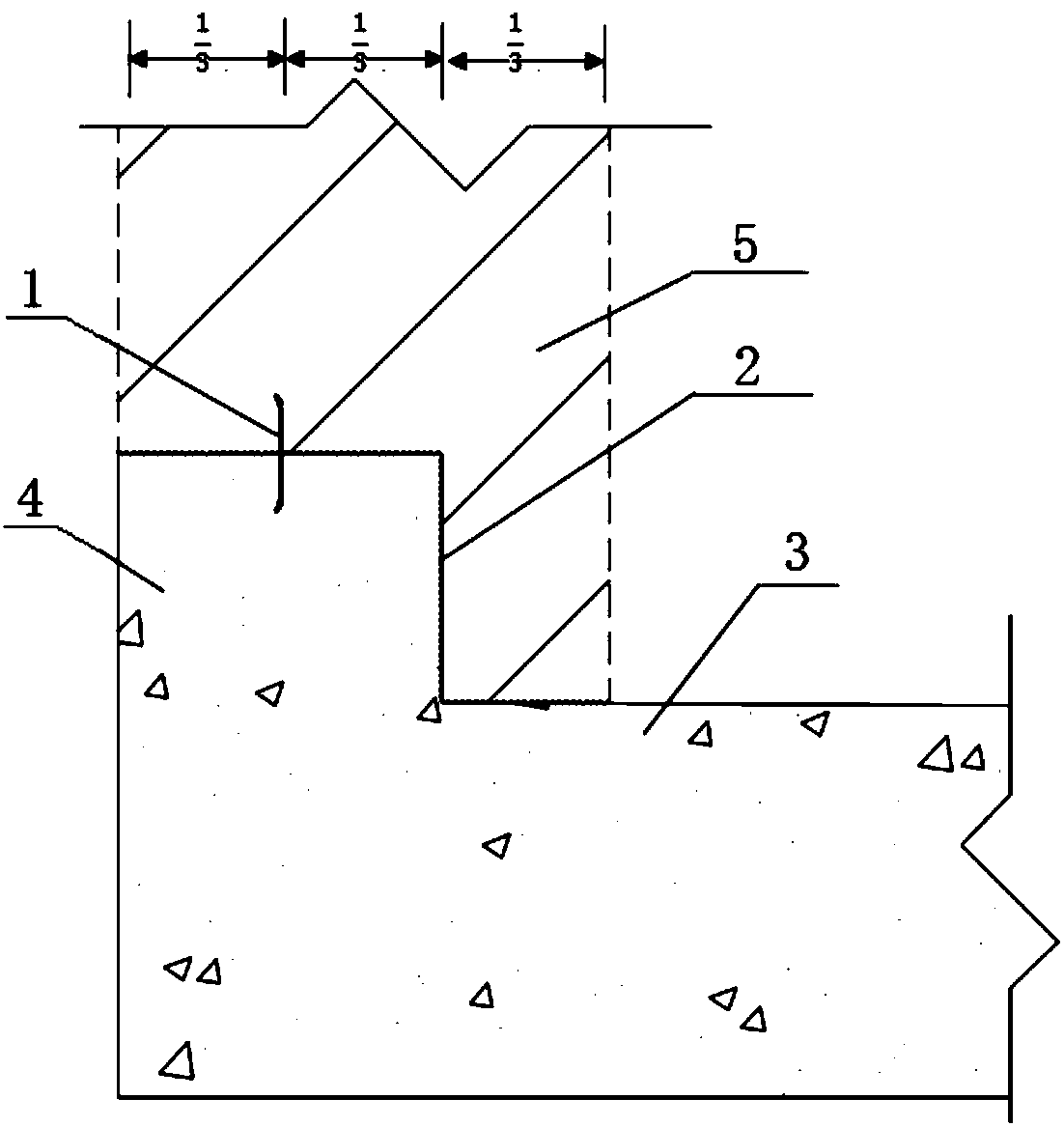

Preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer

ActiveCN108130889AReduce the difficulty of engineering constructionReduce construction difficultyHydraulic engineering apparatusMarine site engineeringBaseboardEngineering

The invention discloses a preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer. Under the circumstance that the flow channel layer is the special-shaped structure of gradient section and with the adoption of floor pouring technique, the height of the side wall of flow channel layer within two thirds of the width of the outboard of side wall is about 0.5m. The improved section of the side wall of flow channel layer is segmented by adopting overhanging model. By means of welding, a sealing plate is connected with a reticulate frame. After the floor pouring process is finished, the formed faulting is used as the stress release channel for the side wall of flow channel layer. The preparation method for baseboard of mainpipe and sluice and step-style construction joint for side wall of flow channel layer can reduce the difficulty in constructing baseboard, enlarge the pouring space of concrete base slab and improve the managing and controlling level and quality of the floor pouring of concrete base slab. The preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer can use the formed faulting in the floor pouring section as the release channel for the side wall of flow channel layer to reduce the restriction of the baseboard on the flow channel layer, which is beneficial to control the cracks caused by the temperature of concrete on the side wall of flow channel layer. The sealing plate, together with the floor pouring section, has a good water proofing effect. In one word, the preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer can obviously save the time forconstruction and accelerate the process of construction.

Owner:上海市水利工程集团有限公司

Method for constructing energy-saving building by using prefabricating method

InactiveCN105040981AGuaranteed temperature requirementsGuaranteed Humidity RequirementsBuilding material handlingComputer moduleBuilding design

The invention discloses a method for constructing an energy-saving building by using a prefabricating method. A drawing of a building to be constructed is designed by an architectural design unit, when the drawing is designed, the whole building is divided into a plurality of building modules according to a stress principle, and the designed drawing of the building modules is transmitted to a prefabricating unit so as to prefabricate the building modules. A prefabricating method of the prefabricating unit which prefabricates the building modules comprises the following steps of (1) arranging a prefabricating field in an open environment and setting up a prefabricated house of which parameters of an inner environment can be adjusted; (2) arranging a pedestal for prefabricating the building modules in the prefabricating house; (3) setting up prefabricated modules corresponding to the single building modules on the pedestal by using steel according to a drawing standard of the single building modules; (4) performing concreting on the constructed prefabricated modules; and (5) solidifying the building modules. The problem that difficulty of building construction in the prior art is high in cold days is solved.

Owner:CHENGDU DIANSHI CREATIVE TECH

Hoisting method of large support equipment for basement

ActiveCN103121629AEasy to operateSolve the problem that it cannot be directly transported to the basement computer room, resulting in difficult constructionCranesBasementIndustrial engineering

The invention relates to a hoisting method of large support equipment, and particularly to a hoisting method of large support equipment for a basement, solving the problem of large construction difficulty caused by incapability of directly conveying the existing large support equipment to a basement house. The hoisting method of the large support equipment for the basement comprises the following steps of: arranging a hoisting hole in the top of the basement house; placing a plurality of upper channel steels on an aboveground second-layer floor of a ground floor, selecting a hoisting point on the aboveground second-layer floor and drilling a hoisting hole; fixing one end of a guide chain on the top of the large support equipment near the hoisting hole and enabling the other end of the guide chain to pass through the hoisting hole; pulling the other end of the guide chain so as to hoist the large support equipment until the large support equipment is set right; and dismantling lower channel steels, and loosening the other end of the guide chain to ensure that the large support equipment downwards moves until the hoisting hole falls the basement house to be in place. The hoisting method provided by the invention is simple to operate, and can be widely applicable to hoisting of the large support equipment of the basement.

Owner:山西太行建设开发有限公司

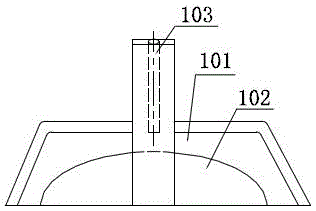

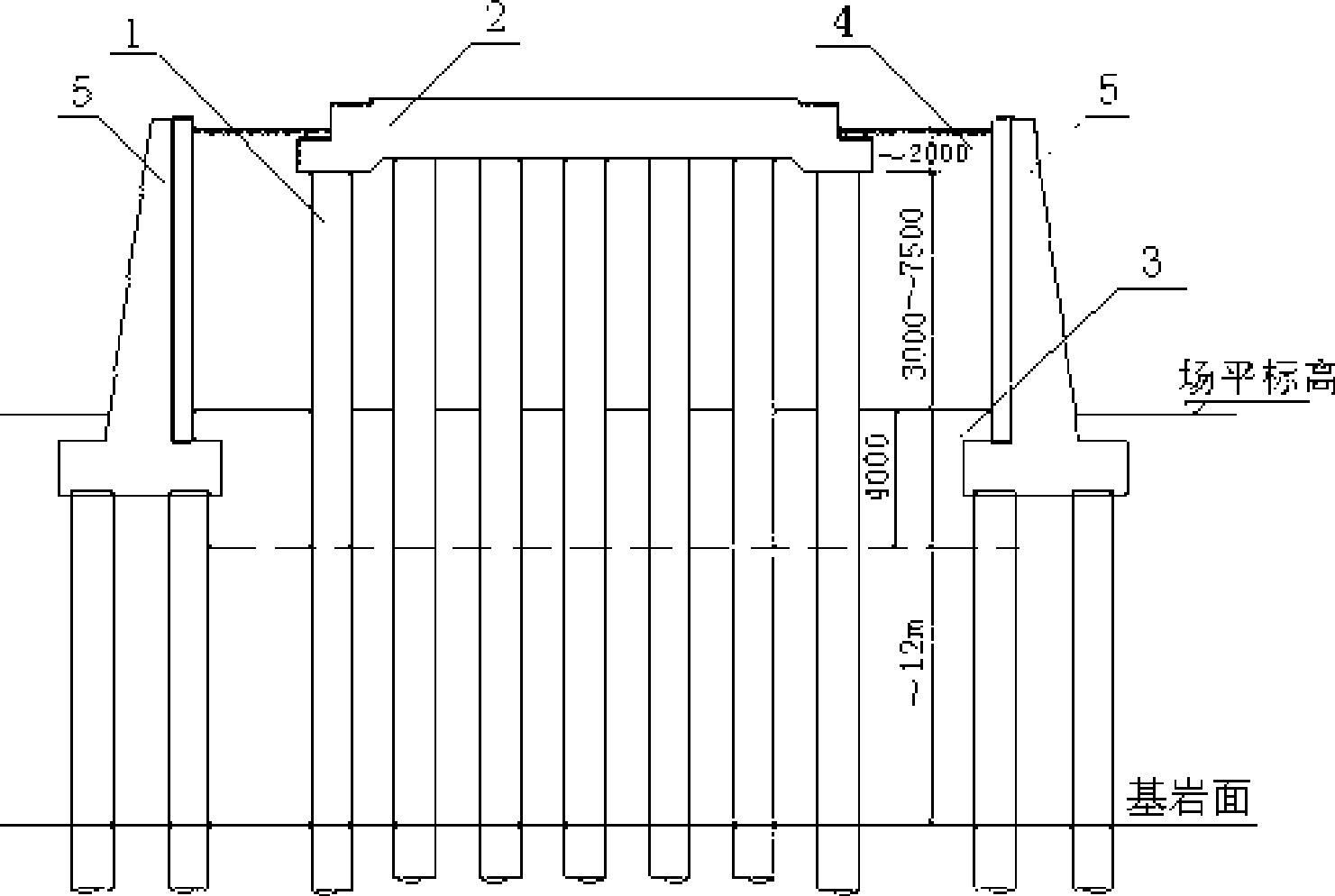

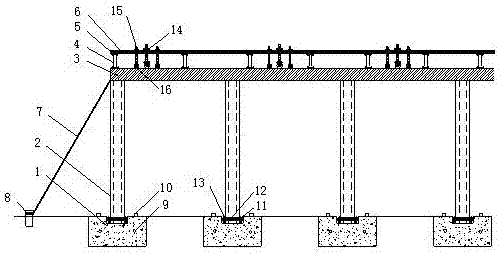

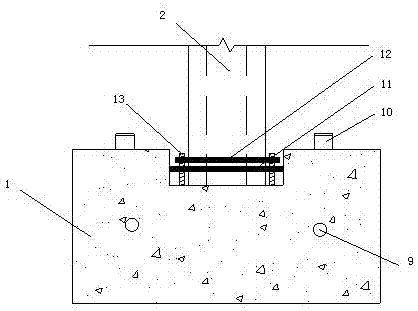

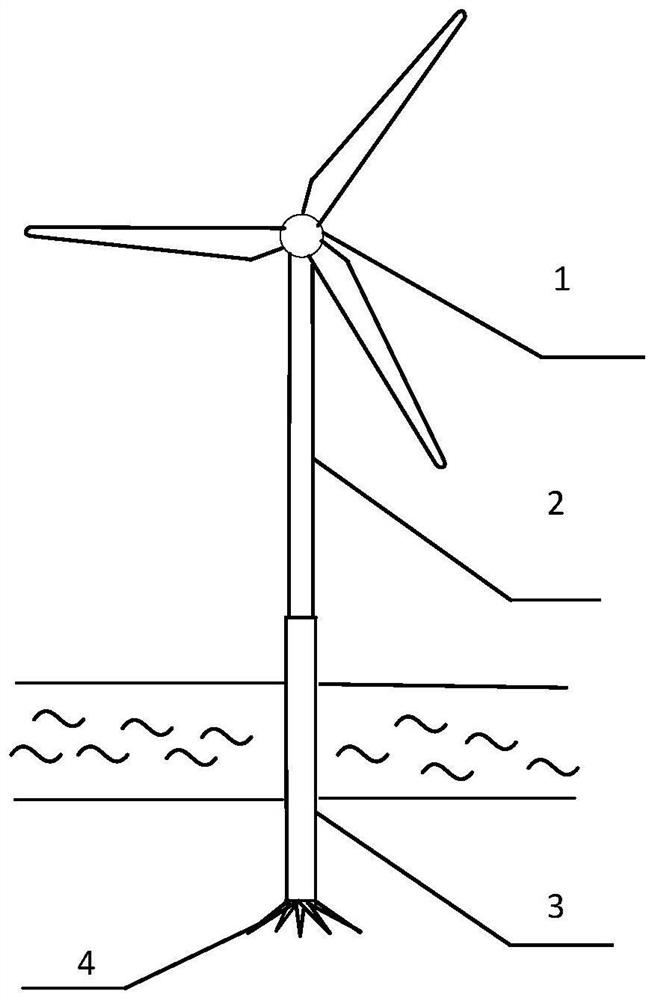

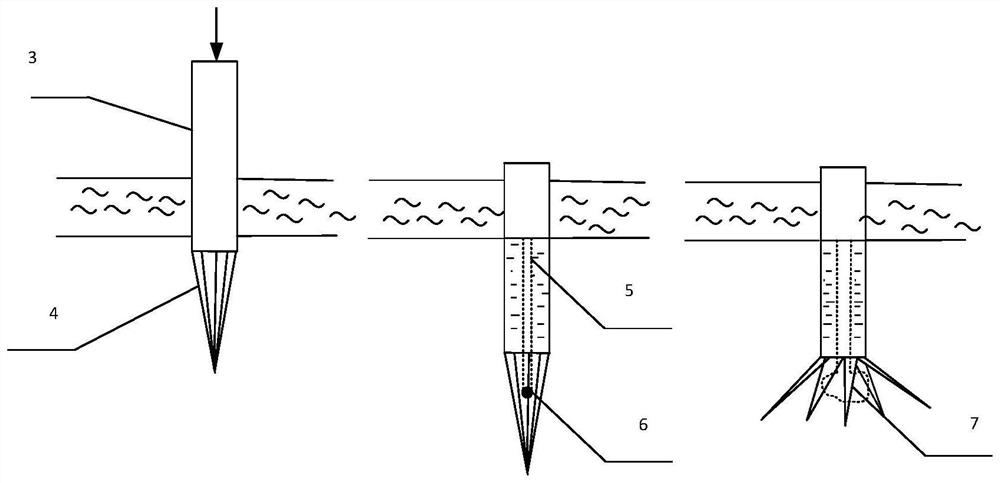

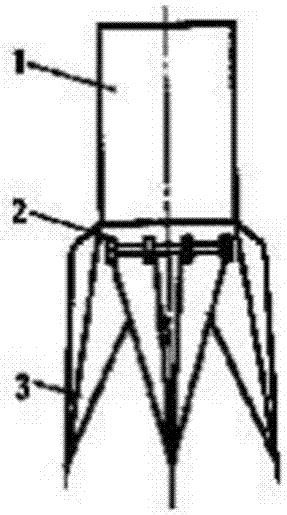

Single-pile foundation for offshore wind power and construction method thereof

PendingCN113513040ASolve the construction costSolve the difficulty of constructionFoundation engineeringTree rootArchitectural engineering

The invention provides a single-pile foundation for offshore wind power and a construction method thereof. The single-pile foundation comprises a single-pile foundation body, and the bottom of the single-pile foundation body is of a tree-root-shaped structure; the structure can meet the requirements of safety and stability without increasing the depth of the pile foundation; and the problems that the construction cost and the construction difficulty are obviously increased due to continuous increase of the depth of the offshore wind power single-pile foundation in the future are solved.

Owner:HUANENG CLEAN ENERGY RES INST +1

Uplift pile construction method without rock blasting

ActiveCN104805830ASolve the difficulty of constructionHigh speedBulkheads/pilesDrilling machines and methodsAutomationRock core

The invention discloses an uplift pile construction method without rock blasting which comprises the construction processes of burying a reaction frame of an orifice section, extracting rock cores of the orifice section in a layering manner, and cleaning and chiseling the rock surfaces of the orifice section; erecting a reaction frame of a standard section, extracting rock cores of the standard section in a layering manner, and cleaning and chiseling the rock surfaces of the standard section; erecting a reaction frame of an expanding section, extracting rock cores of the expanding section in a layering manner, and cleaning and chiseling the rock surfaces of the expanding section, and the like. The beneficial effects of the method is that the whole construction work of the orifice section, the standard section and the expanding section can be completed and the big difficulty in expanding section construction is overcome; the speed is fast and the average excavation construction speed of the whole rock stratum can reach 1.2m per day; machinery automation is high; the universality is high; the operation is convenient; the safety, energy conservation and environment protection are realized.

Owner:YSD RAIL TRANSIT CONSTR CO LTD +2

Method for erecting slab form with ribbed beam

ActiveCN104328909AImprove stabilitySolve the difficulty of constructionForms/shuttering/falseworksSupporting systemFloor slab

The invention discloses a method for erecting a slab form with a ribbed beam. The method is characterized by comprising the following steps of A, erecting a ribbed beam form support system; B, overhanging a ribbed beam main channel batten at the bottom of the ribbed beam, and erecting a plate support system on the ribbed beam key keel batten, wherein the lower end of a support rod consisting of a vertical steel pipe and an adjustable support is supported on the ribbed beam key keel batten, a horizontal steel pipe is horizontally fastened to the upper end of the vertical steel pipe through a bowl type fastener, a plate keel batten is supported on the horizontal steel pipe and is intersected with the horizontal steel pipe and a form is erected on the plate keel batten. The method has the characteristics of convenience in operation and high practicability.

Owner:海南万泰建筑工程有限公司

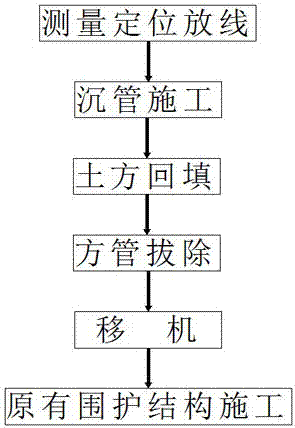

Pile-sinking construction method for deep riprap unfavorable geologic region

InactiveCN107268625ASolve the difficulty of constructionEasy constructionBulkheads/pilesEngineeringFine grain

The invention discloses a pile-sinking construction method for a deep riprap unfavorable geologic region, and the pile-sinking construction method firstly performs earthwork replacing operation of a vertical enclosure structure area, and performs vertical pile construction or steel plate pile enclosure structure construction in an area in which replacement is completed. The pile-sinking construction method is characterized in that the earthwork replacing operation comprises the following steps: (1) measuring, paying off and positioning; (2) defining one group by a plurality of pile tubes which are arranged in parallel and are provided with movable pile tips, and performing pipe-sinking construction; (3) backfilling fine grained soil into one group of immersed tubes which are constructed; (4) after earthwork backfilling is completed, reserving the last pile tube as the first one of a next group, pulling off the rest of the pile tubes, thereby forming a cob wall; and (5) repeating steps (2) to (4), and performing pipe-sinking backfilling operation of the next group of pile pipes until earthwork of the vertical enclosure structure area is replaced. The pile-sinking construction method is convenient in construction, is high in pile sinking efficiency, is low in construction cost, and can strength the water-stop effect of the vertical enclosure structure.

Owner:ZHONGYIFENG CONSTR GRP

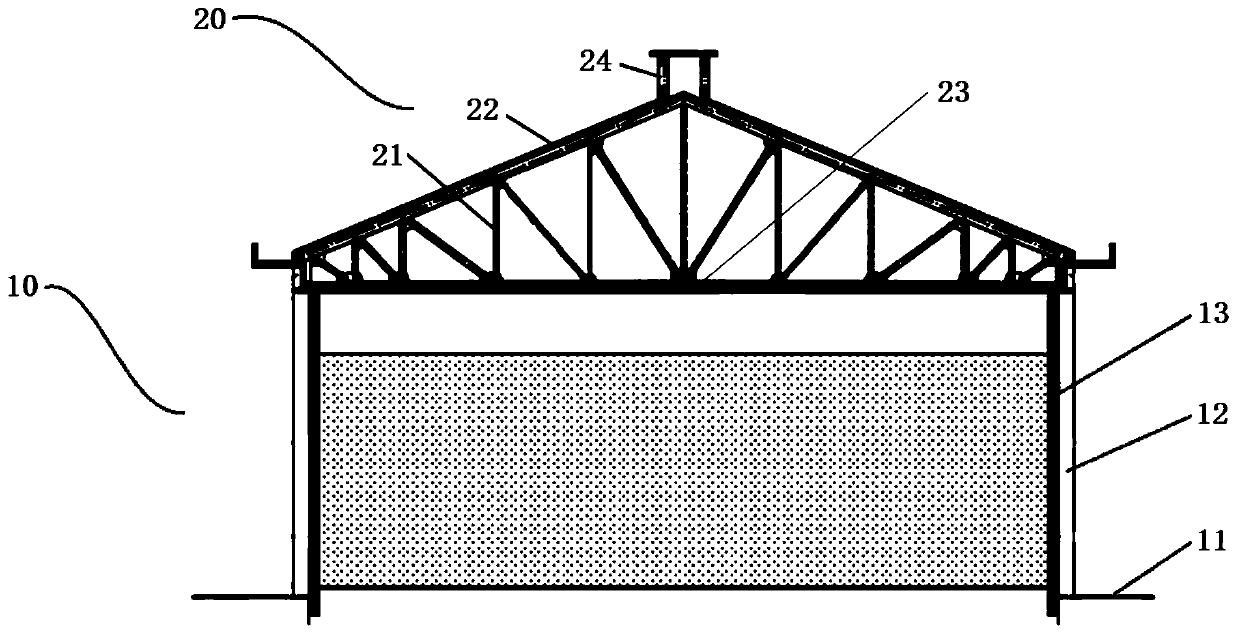

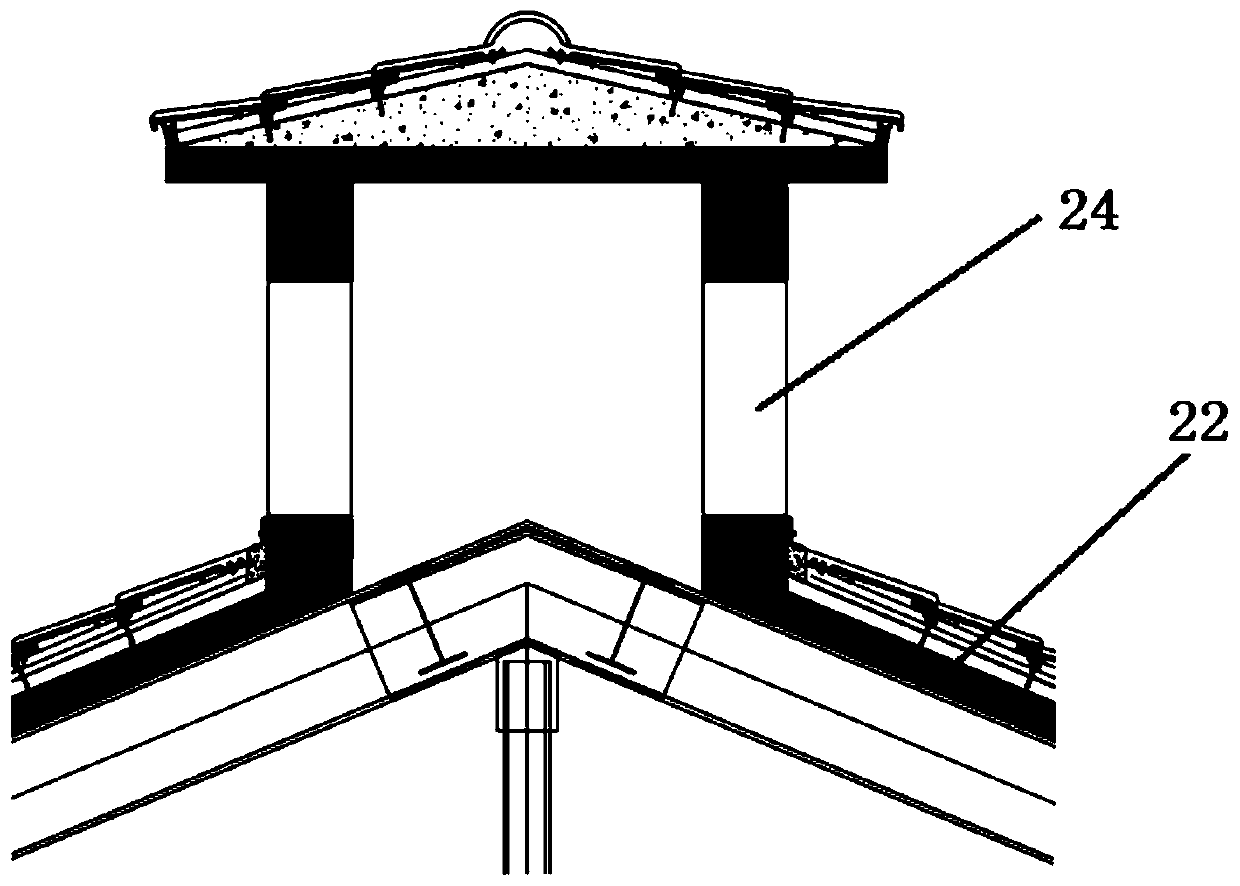

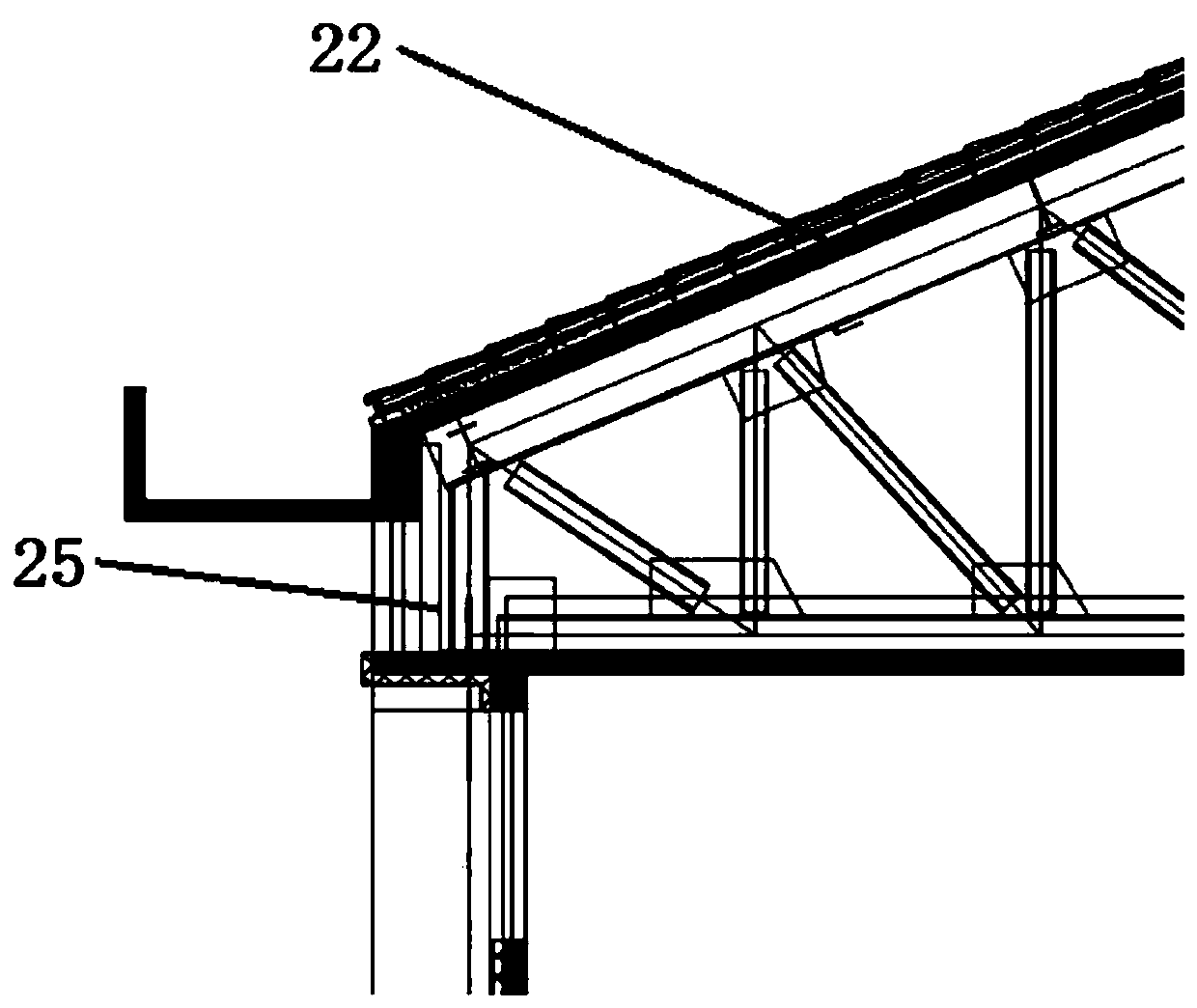

Full-cast-in-place self-ventilation dour-layer roof granary structure and construction method

PendingCN110725596ASolve poor heat insulation effectLow temperature protectionBuilding roofsClimate change adaptationArchitectural engineeringMesh reinforcement

The invention provides a full-cast-in-place self-ventilation dour-layer roof granary structure and a construction method. The structure comprises a square granary body, and a granary roof arranged atthe top of the granary body; the granary body comprises a foundation, stand columns and walls formed through cast-in-place concrete; the granary roof comprises a trapezoidal steel roof truss, an upper-layer roof panel and a lower-layer roof panel; the foundation, the stand columns, the walls and the granary roof are integrally formed through casting of concrete on reinforcement nets in place; thesteel roof truss is connected with the columns and the walls; the foundation, the stand columns, the walls and the lower-layer roof panel form whole closed space; and the steel roof truss between theupper-layer roof panel and the lower-layer roof panel forms self-ventilation heat adjusting space. The structure can effectively stop the heat transfer to protect low temperature in the granary, and achieves environmental protection, energy conservation and good airtight performance in the granary.

Owner:北京粮猫科技有限公司

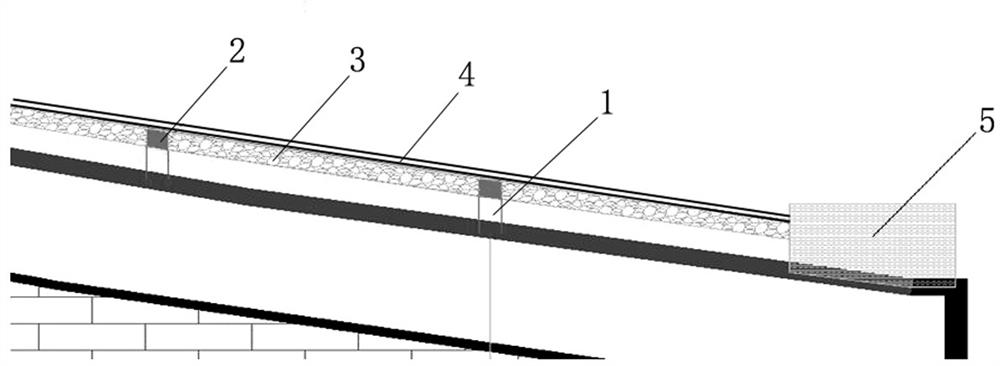

Construction method of sloping roof using large-span hyperbolic high-wave pressure steel plate

ActiveCN109577565BSolve the difficulty of constructionReach the costRoof covering using slabs/sheetsRoof toolsSocial benefitsDesign standard

The invention discloses a slope roof construction method adopting a long-span hyperbola high-wave profiled steel sheet. The method comprises the technological steps of performing radian paying-off, placing a pre-embedded plate, placing and fixing a welding stand column and a purline, performing stand column joint water resistance, installing the high-wave profiled steel sheet, and installing an aluminum buckle plate. The construction method is the technology construction method combining a profiled steel slope roof and a traditional roof, and one layer of high-wave profiled steel sheet coversan existing structure roof. The construction method performs secondary protection design on the roof, and on the premise of not lowering the design standard, the effects of attractive appearance, heatpreservation, fire resistance, environment protection, corrosion resistance, secondary water resistance and the like are achieved. The construction method is advanced in technology and scientific indesign and facilitates construction, on the premise that the construction quality is ensured, the project manufacturing cost is lowered to the maximum extent, the construction purposes of low cost andhigh quality are achieved, and good economic and social benefits are achieved.

Owner:SHANXI WUJIAN GRP CO LTD

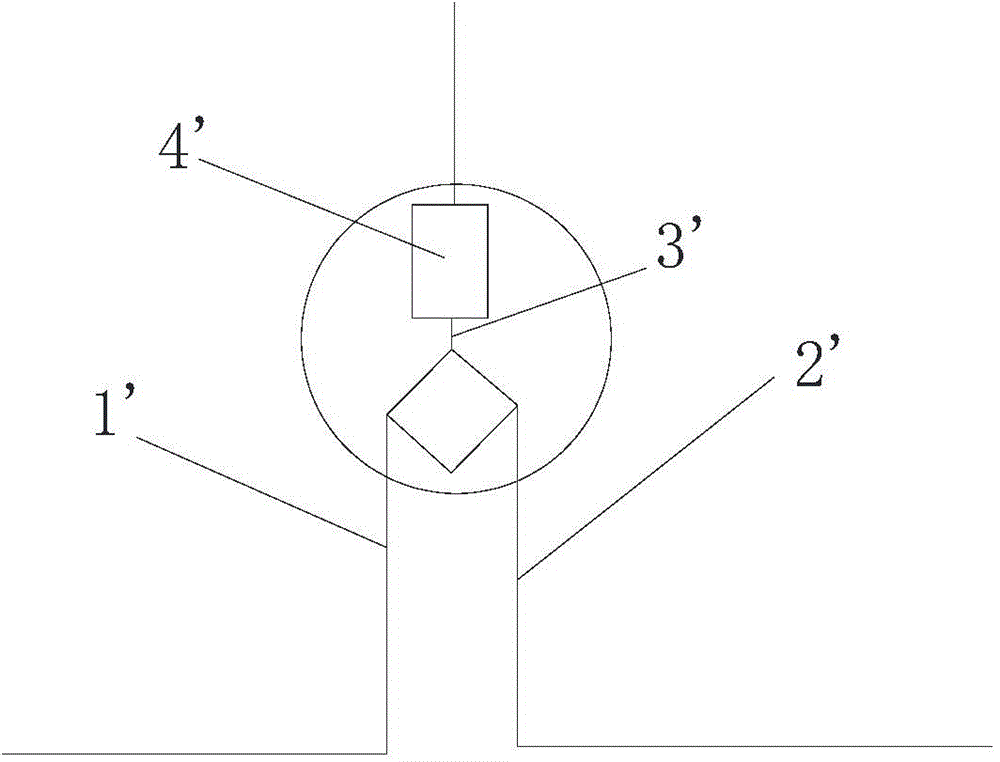

Street lamp connecting structure

InactiveCN104456480AAvoid formingSolve small spaceMechanical apparatusElectric circuit arrangementsEngineering

The invention provides a street lamp connecting structure. The street lamp connecting structure comprises a street lamp main wire harness which is arranged along a road, and a street lamp post branch which is connected to the street lamp main wire harness and extends into a middle cavity of the street lamp post. According to the technical scheme adopted by the invention, the street lamp main wire harness is paved along the road, and the street lamp post branch is connected to the street lamp main wire harness and extends into the middle cavity of the street lamp post to supply power for the street lamp, so that a joint is prevented from forming in the street lamp post. Therefore, the problems of narrow street lamp post space and difficulty in enabling a cable to enter the street lamp post to construct in the prior art are solved.

Owner:STATE GRID CORP OF CHINA +1

Construction method of steel sheet pile cofferdam of water area no-covering-layer low pile cap

ActiveCN111456049ASolve the difficulty of constructionReduce construction costsFoundation engineeringPile capCofferdam

The invention discloses a construction method of a steel sheet pile cofferdam of a water area no-covering-layer low pile cap. The method comprises the following steps that the part, at the design position of the steel sheet pile cofferdam, of a riverbed surface is cleaned; according to the design position, a guiding device is arranged at the corresponding position on a water surface, and the guiding device is welded to brackets of steel pipe piles; groove milling does not need to be conducted on the part, at the design position, of a rock stratum, the steel sheet piles are inserted and driveninto the design position in the outer wall direction of the guiding device, and the steel sheet piles are sequentially connected end to end to form the steel sheet pile cofferdam; a bottom-layer innersupport is lowered into the steel sheet pile cofferdam, and the bottom layer inner support and the steel sheet pile cofferdam are welded and fixed through pulling rods; a middle-layer inner support and a top-layer inner support are sequentially lowered into the steel sheet pile cofferdam and fixed; and high-pressure grouting is conducted on the part, in the steel sheet pile cofferdam, of the rockstratum through a grouting device, so that the part, in the steel sheet pile cofferdam, of the rock stratum is impermeable. According to the method, the characteristics of self-strength and stabilityof the rock stratum are fully utilized, so that the design length of the steel sheet piles is effectively reduced.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

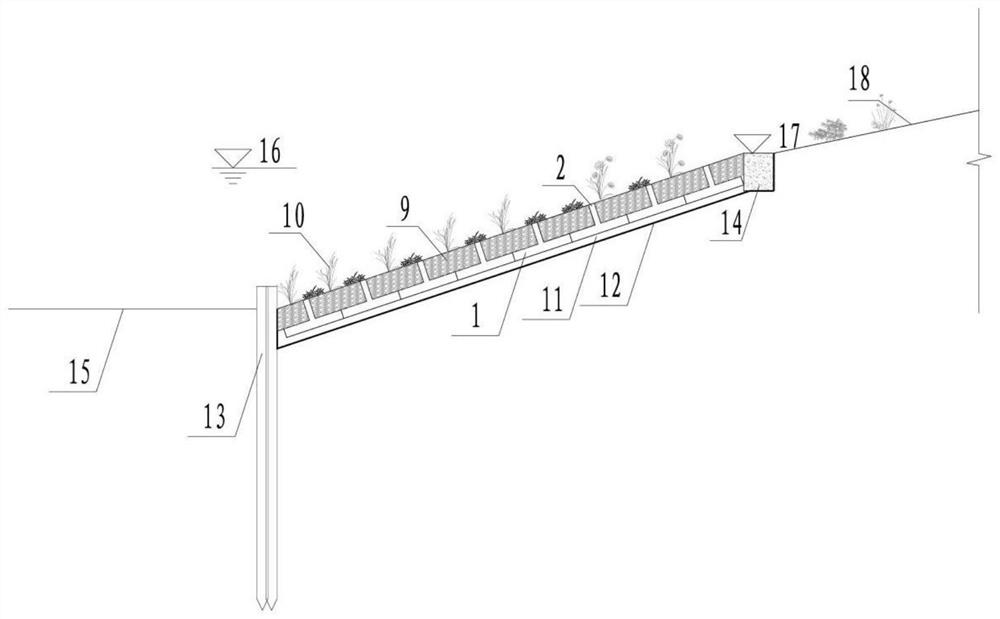

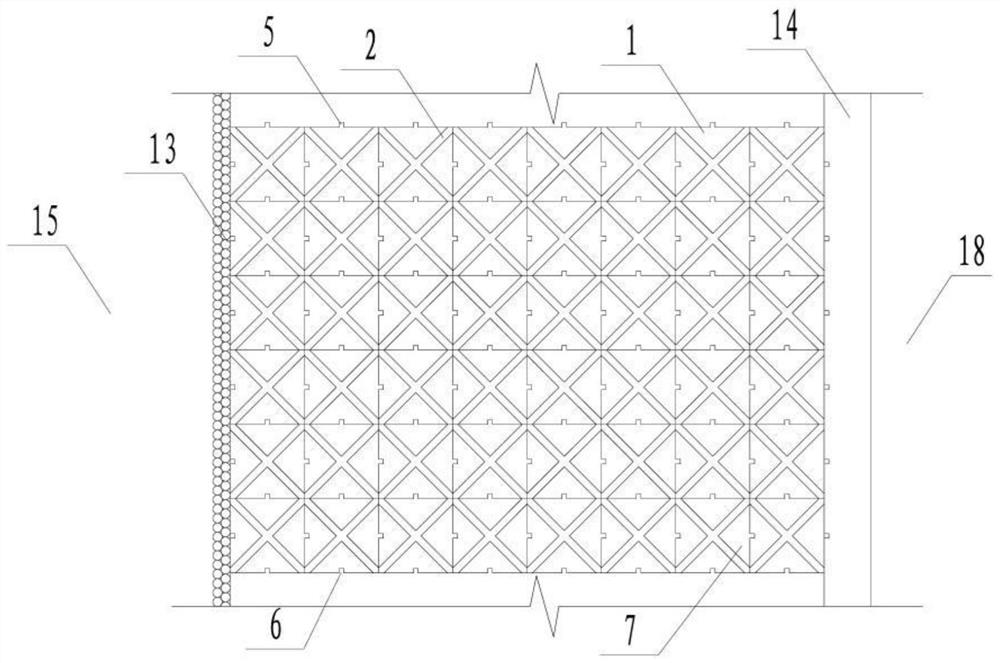

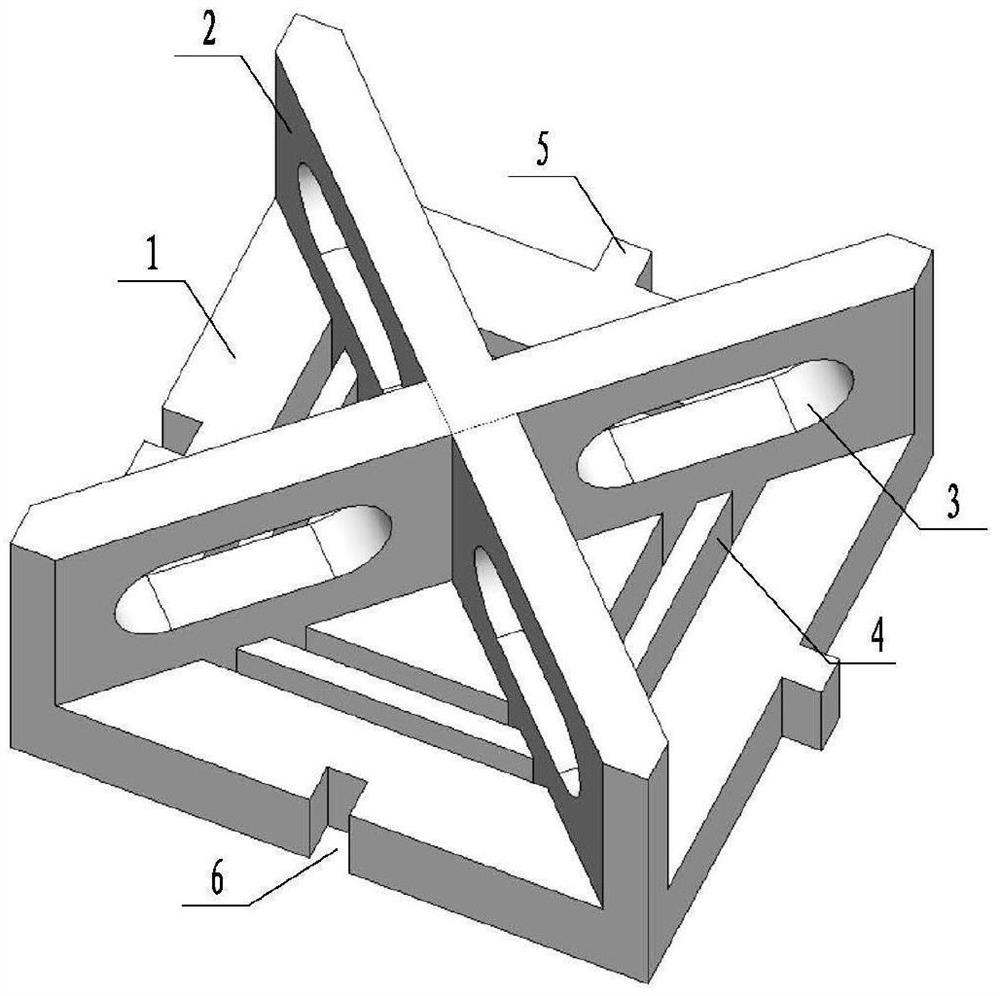

Slope protection building block, ecological slope protection suitable for rain source type river channel and construction method thereof

PendingCN113356140AMeets washout protection requirementsAddressing bare aestheticsCoastlines protectionReceptacle cultivationEnvironmental resource managementRiver routing

The invention relates to a slope protection building block, an ecological slope protection suitable for a rain source type river channel and a construction method thereof. The slope protection building block comprises a building block base, clamping heads or / and clamping grooves are arranged on all the side faces of the building block base, a building block framework is arranged on the upper end face of the building block base, and the ecological slope protection comprises a plurality of slope protection building blocks; the plurality of slope protection building blocks are spliced to form a slope protection building block layer, a plurality of building block bases are spliced to form a lower-layer slope protection of the slope protection building block layer, a plurality of building block frameworks are spliced to form an upper-layer frame grid of the slope protection building block layer, and the upper-layer frame grid is filled with planting soil for planting plants. According to the slope protection building block, the ecological slope protection suitable for a rain source type river channel and the construction method thereof, the problem that flood control safety and the ecological landscape function cannot be both considered in the prior art is solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A kind of semi-automatic construction control system and control method of excavator

ActiveCN109024751BLow operator skill level requirementsSave fuelSoil-shifting machines/dredgersControl systemControl engineering

The invention discloses an excavator semi-automatic construction control system and control method, which solves the technical problems of low construction efficiency and low construction precision existing in the operation process of excavator leveling and slope repairing. The control system includes a sensor module and a control module , measurement module and operation module. The measurement module inputs the measurement data into the control module. The control module realizes the calculation of elevation, flatness and slope by establishing a coordinate system. At the same time, the sensor module feeds back the condition of the excavator equipment to the control module, which is manually input into the engineering design. The data is sent to the control module, and the control module transmits the feedback correction output signal to the operation module, and the excavator enters the two-linkage semi-automatic state to complete the construction. The control system and control method provided by the invention also have the advantages of low requirements on the technical level of excavator operators, high construction precision, and no need for secondary measurement.

Owner:QINGDAO LOVOL EXCAVATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com