Wide self-adhesive high-polymer composite waterproof coiled material and production process thereof

A technology of waterproofing membrane and production process, which is applied in basic structure engineering, protection device, wellbore lining and other directions to achieve the effect of reducing production cost and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

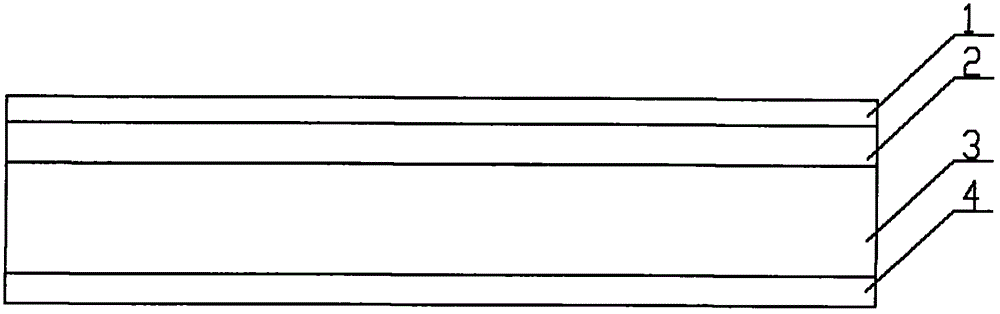

Image

Examples

Embodiment 1

[0018] The first step, ingredients: the formula is polyvinyl chloride (PVC) or polyethylene (PE) + 5% moisture absorbing agent + 2.5% color masterbatch;

[0019] The second step, mixing: the main equipment is a screw, and the auxiliary equipment is a feeding device. Mix the ingredients evenly, enter the screw through the feeding device, and then fully melt and mix under the action of the high-temperature screw;

[0020] The third step, extrusion: the main equipment is a flat extrusion die, which evenly extrudes the plate-shaped molten material from the melted and mixed raw materials;

[0021] The fourth step, calendering and compounding: the main equipment is three calender rolls, the plate-shaped molten material enters the three calender rolls, and the plate-shaped molten material is calendered, cooled and formed to form a waterproof sheet;

[0022] The fifth step, storage: the equipment is an elastic storage rack, which buffers the slight asynchronous production speed of the...

Embodiment 2

[0028] The first step, ingredients: the formula is polyvinyl chloride (PVC) or polyethylene (PE) + 5% moisture absorbing agent + 2.5% color masterbatch;

[0029] The second step, mixing: the main equipment is a screw, and the auxiliary equipment is a feeding device. Mix the ingredients evenly, enter the screw through the feeding device, and then fully melt and mix under the action of the high-temperature screw;

[0030] The third step, extrusion: the main equipment is a flat extrusion die, which evenly extrudes the plate-shaped molten material from the melted and mixed raw materials;

[0031] The fourth step, calendering and compounding: the main equipment is three calendering rollers, the plate-shaped molten material enters the three calendering rollers, and the geotextile composite layer sent from the geotextile unfolding device is compounded, calendered, and cooled by the three calendering rollers Forming, it becomes a composite waterproof board;

[0032] The fifth step, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com