Hoisting method of large support equipment for basement

A technology of supporting equipment and hoisting method, applied in the directions of transportation, packaging, cranes, etc., can solve the problems of difficult construction, large supporting equipment cannot be directly transported to the basement room, etc., and achieve the effect of low operation cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

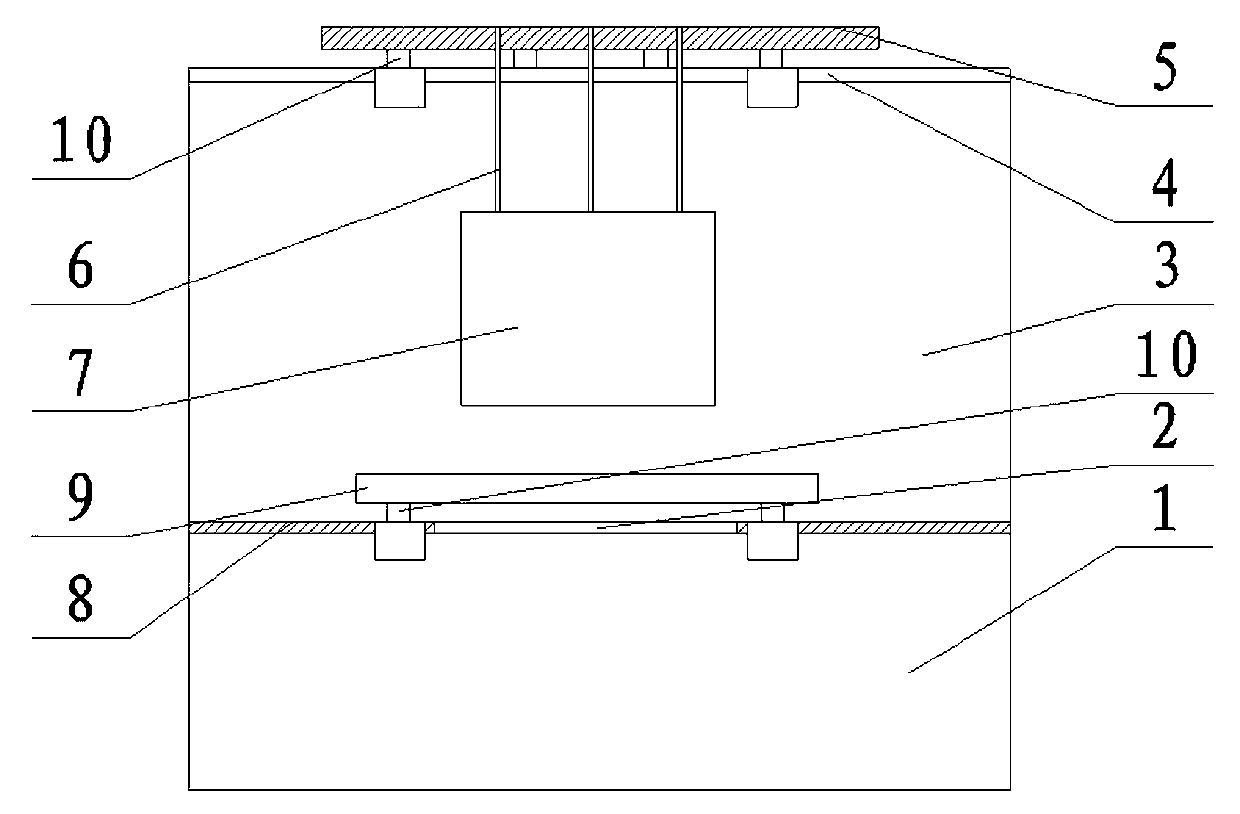

[0011] The hoisting method of large supporting equipment in the basement includes the following steps:

[0012] (1) On the top plate of the basement machine room 1, open a hoisting opening 2 connected to the first floor 3; on the second floor 4 above the ground floor 3, which is located directly above the hoisting opening 2, place several parallel upper channel steels 5 According to the structure of the pre-installed large-scale supporting equipment 7, select a hoisting point located directly above the hoisting port 2 and directly below the upper channel steel 5 on the second-floor floor 4, and drill hoisting holes; Parallel to the lower channel steel 9 with both ends supported on the floor 8 above the ground, it is used to temporarily support and protect the pre-installed large supporting equipment 7;

[0013] (2) Fix one end of the guide chain 6 on the top of the large-scale supporting equipment 7 near the hoisting port, and the other end passes through the hoisting hole and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com