Construction method of condenser

A construction method and condenser technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of difficult construction and achieve the effects of shortening the construction period, preventing shell deformation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

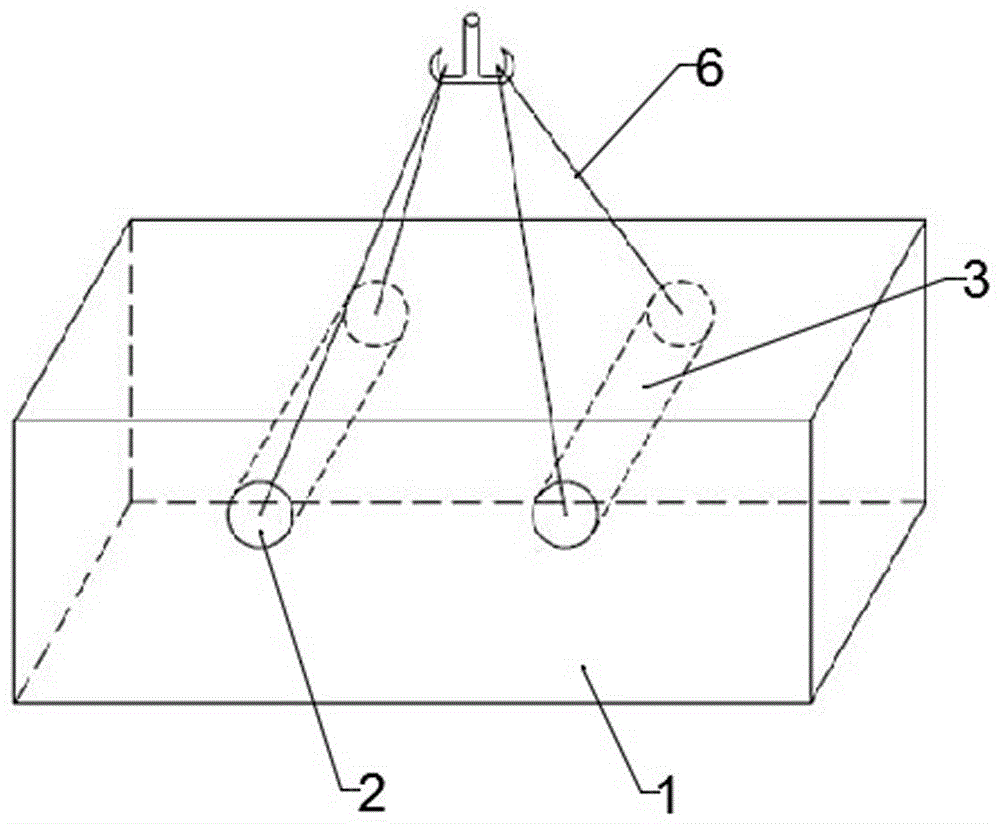

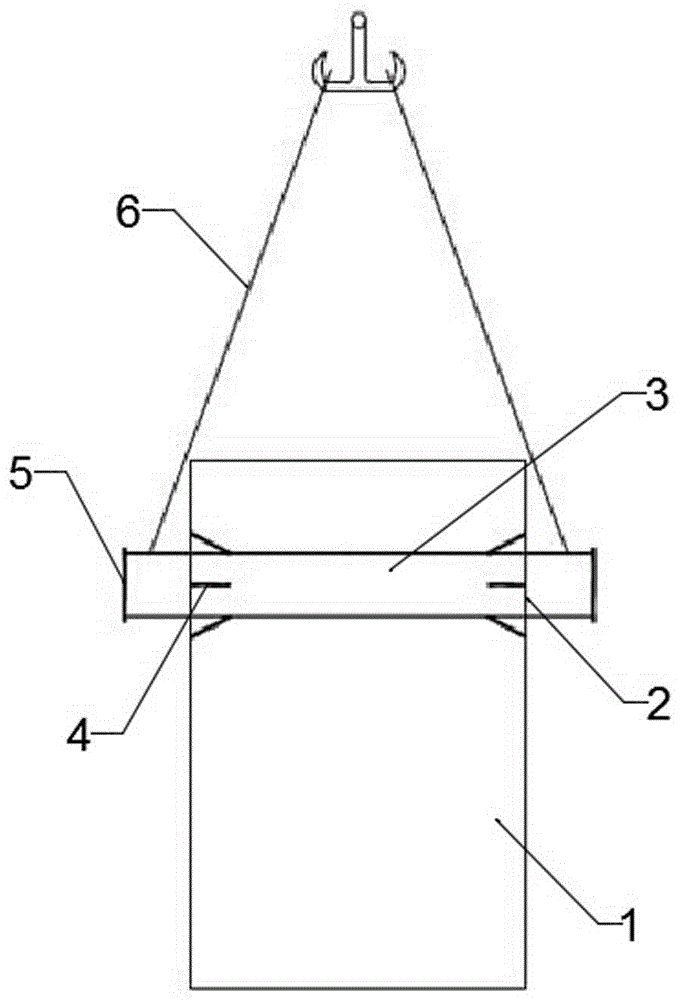

[0031] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

[0032] The construction method of condenser of the present invention comprises steps as follows:

[0033] S1. Carry out foundation construction at the position where the condenser is installed, and assemble the various components of the condenser in bulk into the shell 1 at the same time as the foundation construction. Body combination installation, clapboard in place, exhaust pipe joint hoisting, neck joint installation, clapboard alignment.

[0034] S2. Lay the trails next to the foundation to ensure that the trails are parallel to the horizontal plane.

[0035] S3. After laying the track log, lay the track on the track log to ensure that the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com