Bridge expansion joint structure

A technology for expansion joints and bridges, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of complex construction process, damage to expansion joints, complex materials, etc., to simplify the construction process, save investment costs, and reduce maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

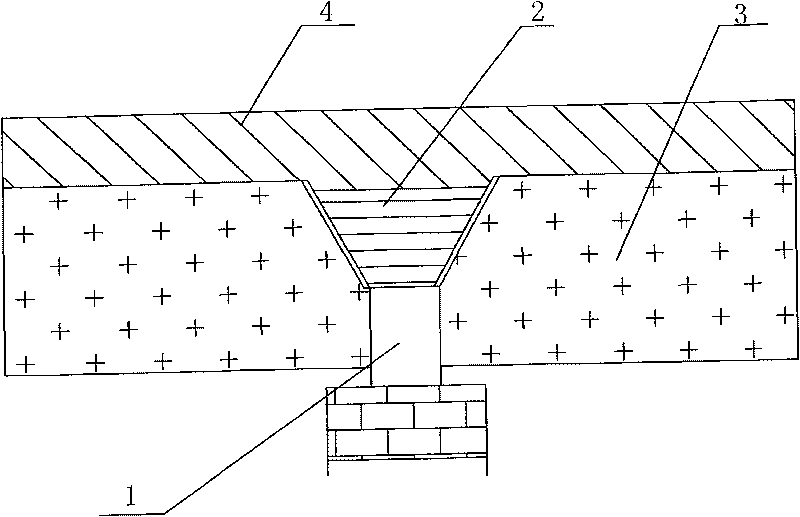

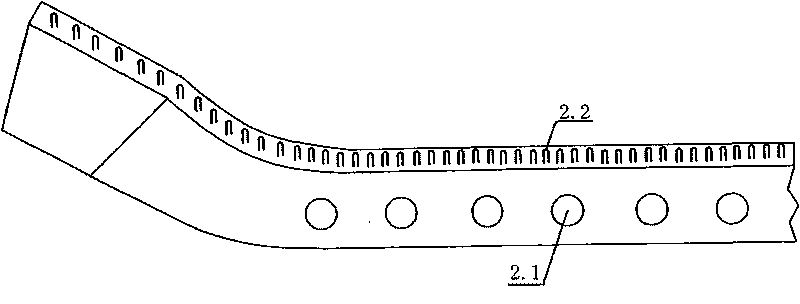

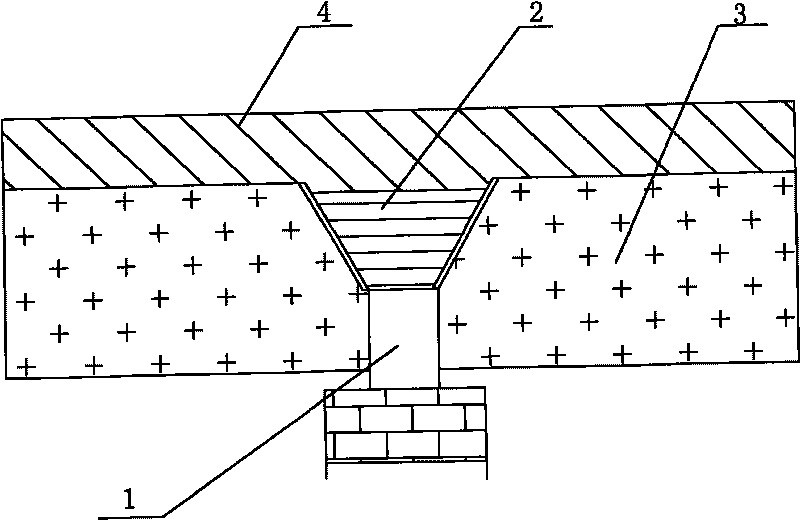

[0016] see figure 1 , figure 1 It is a schematic diagram of the overall structure of the bridge expansion joint structure of the present invention. Depend on figure 1 It can be seen that the bridge expansion joint structure of the present invention includes two adjacent beam bodies 3, the upper parts of the interface ends of the adjacent two beam bodies 3 are arranged as mutually symmetrical inclined planes, and the lower parts are all arranged as vertical planes, so that the adjacent two beam bodies The bridge expansion joint 1 formed between 3 is divided into upper and lower parts: the cross-section of the upper part is an inverted trapezoid with a wide top and a narrow bottom, and the cross-section of the lower part is a rectangle with the same width up and down. A rubber belt 2 is embedded in the inverted ladder-shaped place with a wide top and a narrow bottom. The cross section of the rubber belt 2 is in the shape of a triangular belt, and finally the asphalt concrete 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com