Construction method of steel sheet pile cofferdam of water area no-covering-layer low pile cap

A steel sheet pile cofferdam, no covering layer technology, applied in basic structure engineering, construction and other directions, can solve the problems of restricted construction period, high construction unit price, high technical personnel ability requirements, etc., to solve the construction difficulty, reduce construction costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

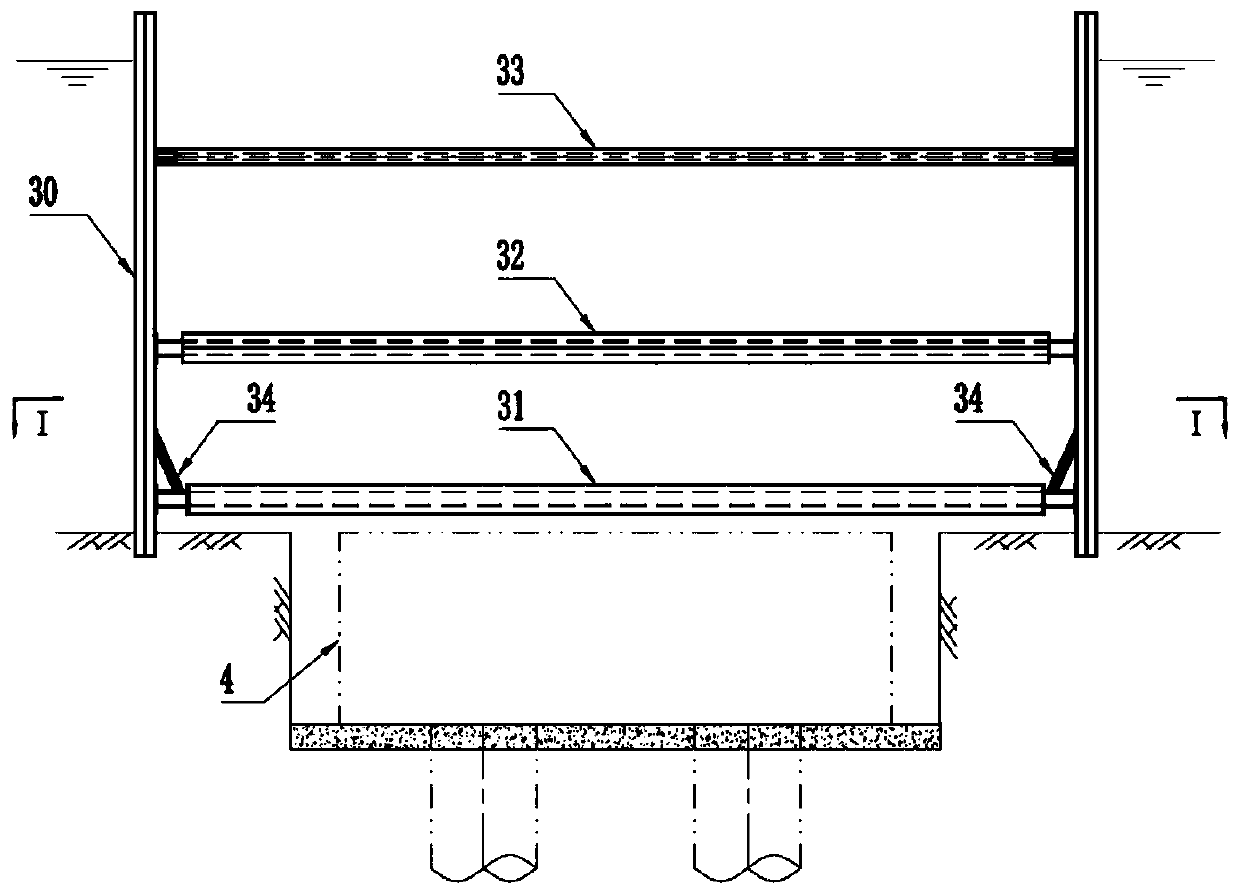

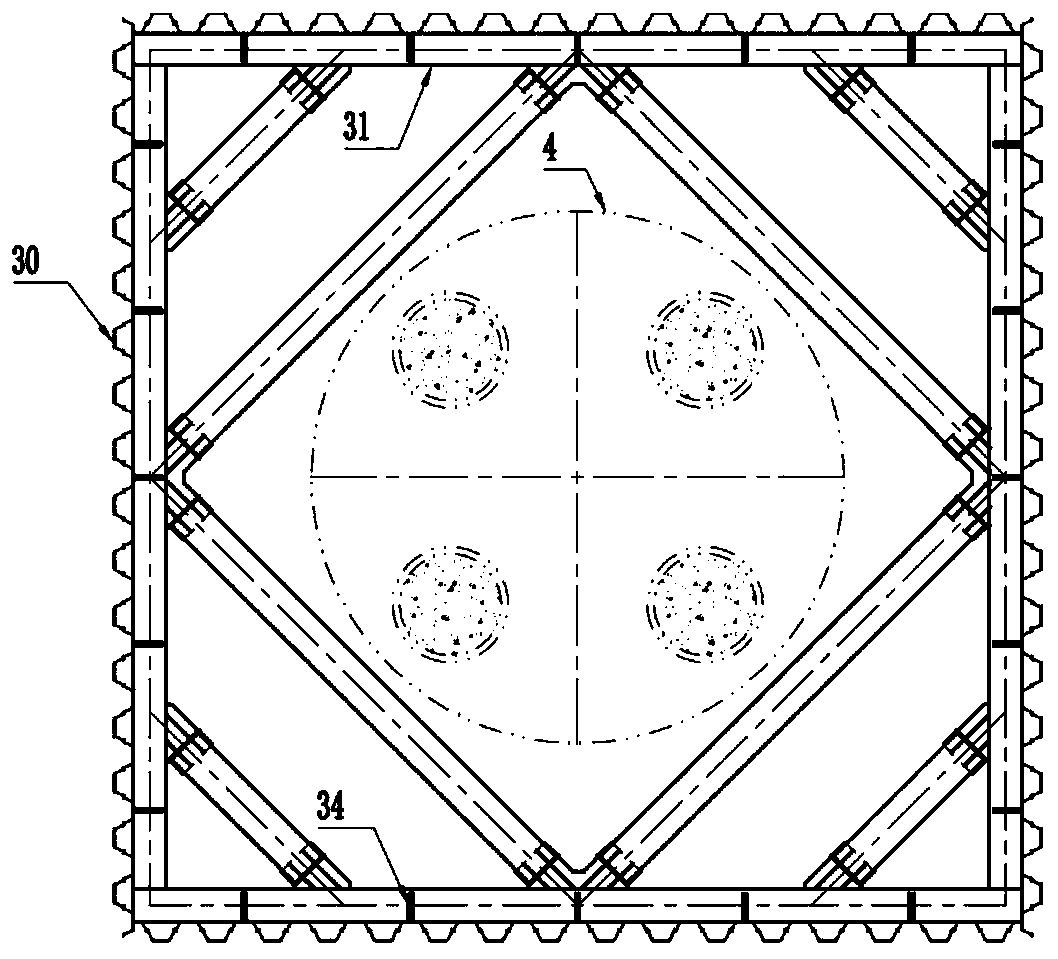

[0037] see figure 2 and image 3 As shown, the embodiment of the present invention provides a construction method of a steel sheet pile cofferdam with no covering layer and low pile cap in water area, including the following steps:

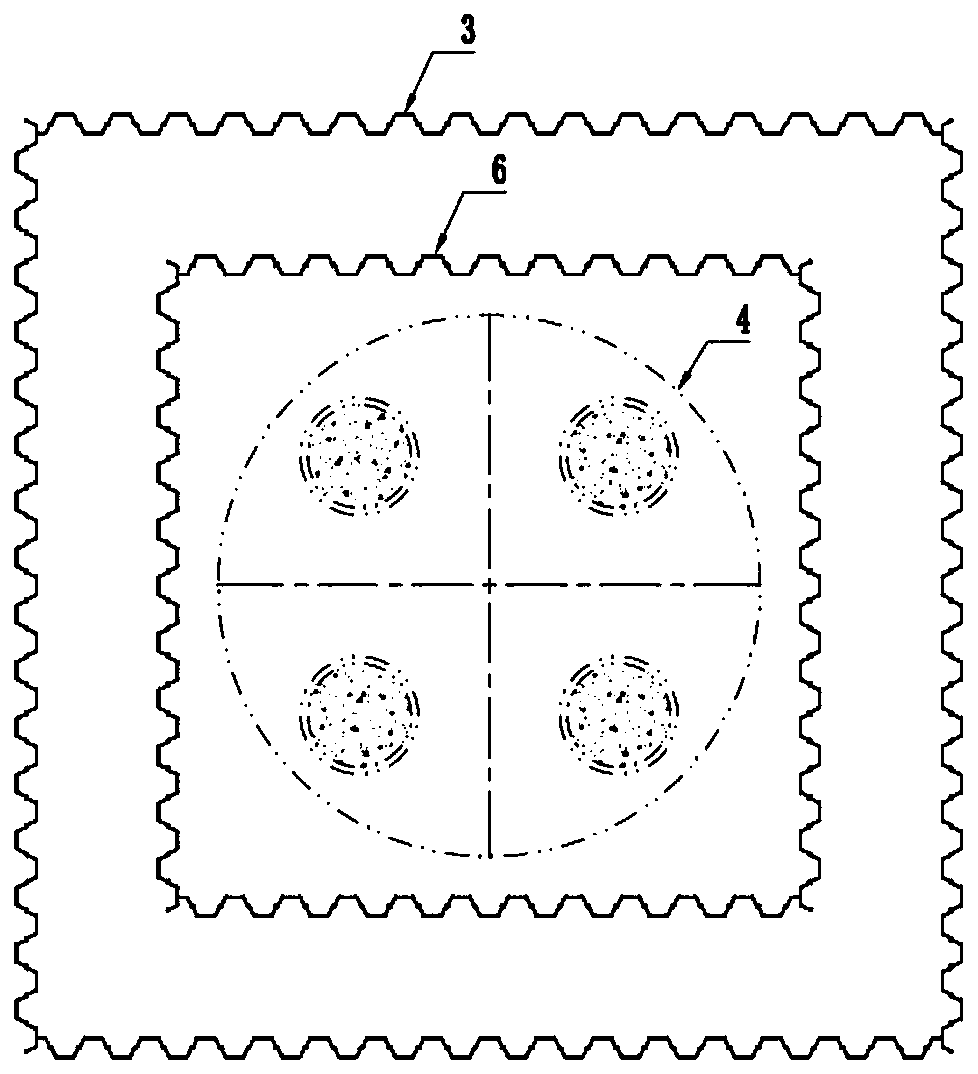

[0038] S1: if figure 1 As shown, when the steel sheet pile cofferdam 3 of the present invention is designed, the cap is a circular cap with a diameter of 11.5m, the length and width of the conventional steel sheet pile cofferdam are 13.2m and 13.2m, and the conventional steel sheet pile cofferdam The center of the weir and the center of the cap are basically coincident, while the length and width of the steel sheet pile cofferdam 3 of the present invention are 19.2m and 19.2m, and the center of the steel sheet pile cofferdam 3 of the present invention is also basically coincident with the center of the cap The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com