Full-cast-in-place self-ventilation dour-layer roof granary structure and construction method

A self-ventilating, granary storage technology, applied in the field of granary construction, can solve problems such as poor roof insulation performance, environmental protection and energy saving, poor waterproof performance of terracotta tiles, etc., to achieve airtight performance guarantee, solve environmental problems, and block heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

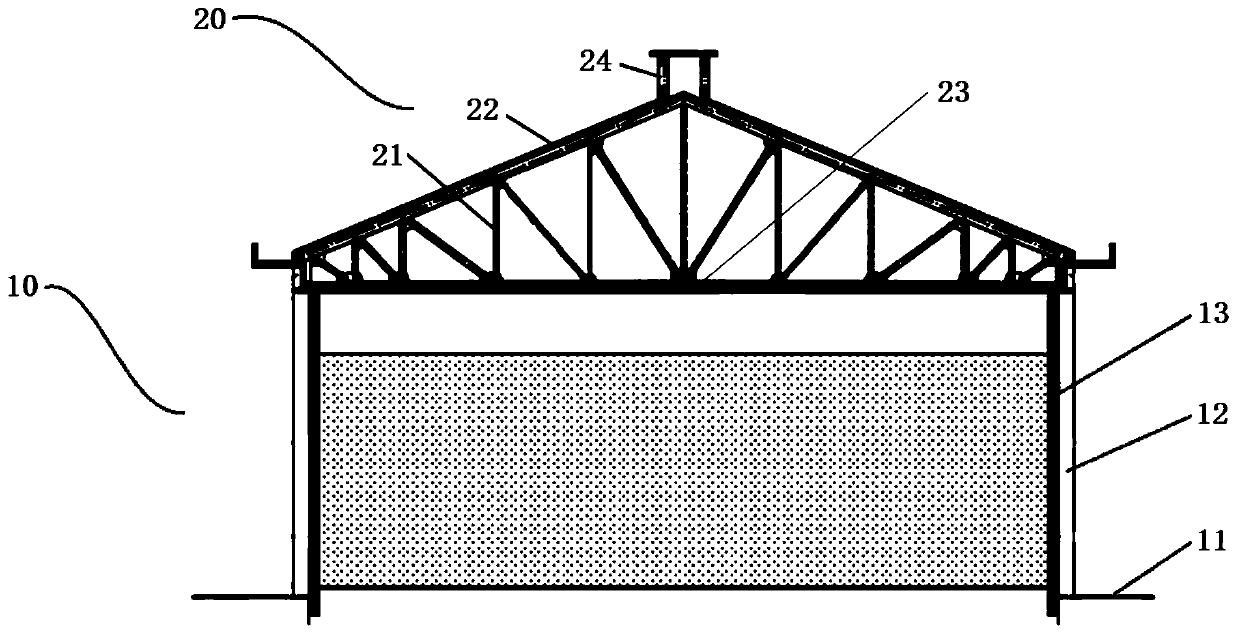

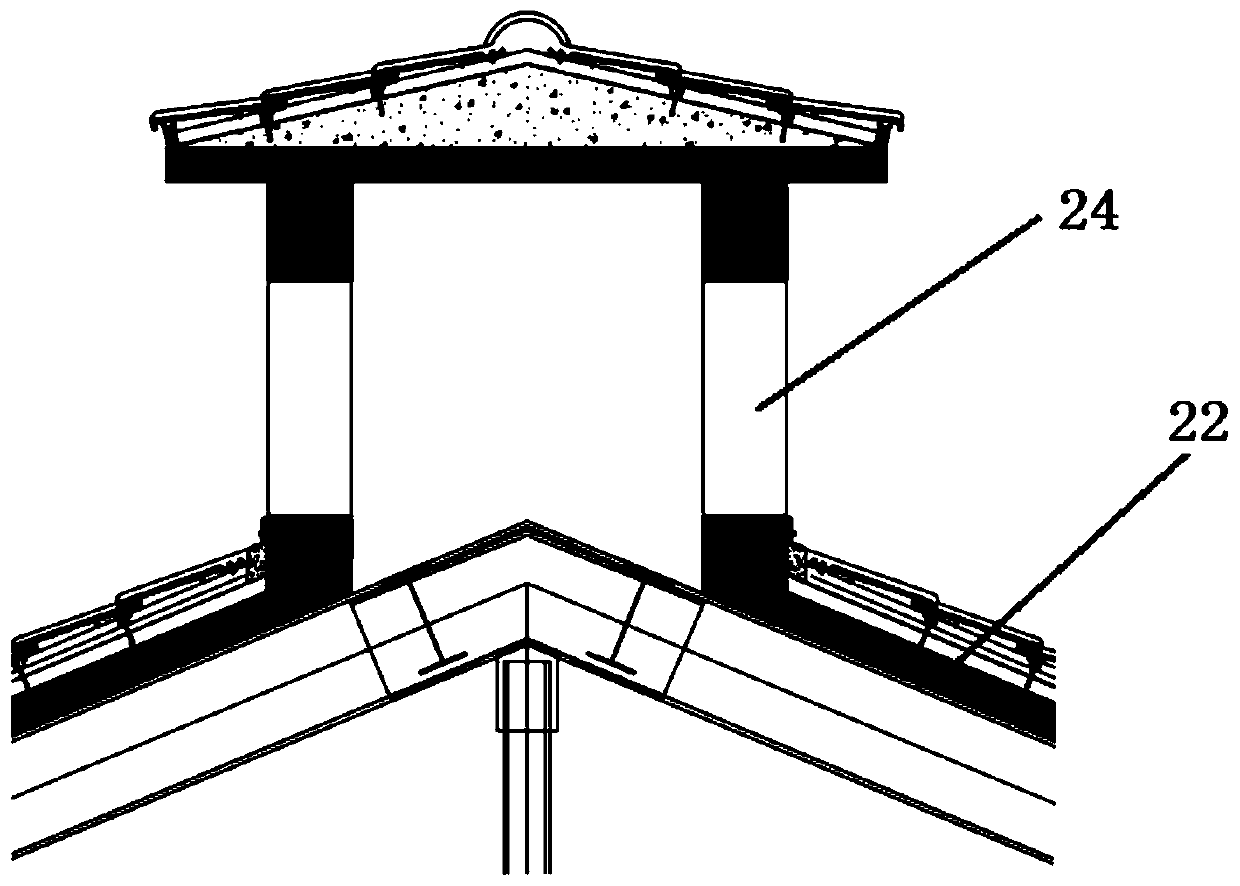

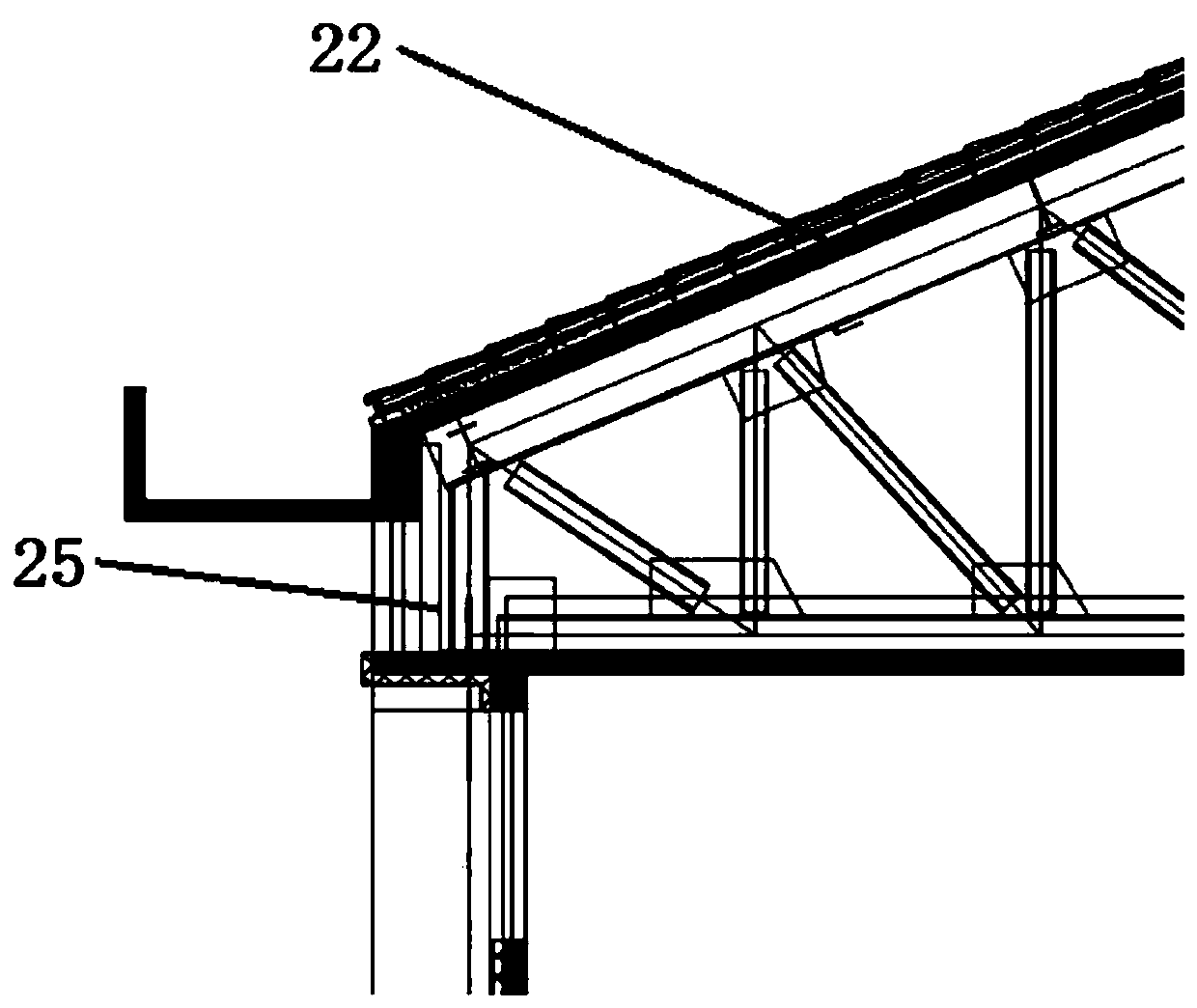

[0050] Such as Figure 1~3 As shown, the fully cast-in-situ self-ventilated double-roofed granary storage silo of the present invention includes a square silo body 10 and a silo roof 20 arranged on the top of the square silo body 10. The silo body 10 includes a foundation formed by pouring concrete on a steel mesh 11. Column 12 and wall 13; the warehouse roof 20 includes a trapezoidal steel roof truss 21 and a double-layer roof panel. The trapezoidal steel roof truss 21 is tightly connected with the column 12 and the wall 13 and the double-layer roof panel includes the upper roof panel 22 and The lower roof panel 23, the upper roof panel 22 are reinforced concrete slabs formed by pouring concrete on the upper chord surface of the trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com