Coated glass and preparation method thereof

A technology of coated glass and glass, which is applied in the direction of chemical instruments and methods, glass/slag layered products, laminating devices, etc., can solve the problems of cleaning glass, such as large manpower and material costs, no discoloration function, and loss of protection function. Achieve the effect of saving manpower and material resources, excellent heat insulation effect, and good compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

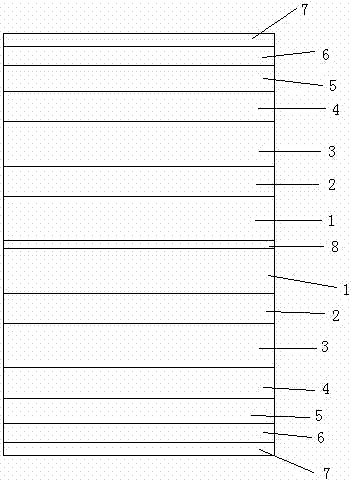

[0031] Such as figure 1 As shown, a coated glass includes a glass substrate and a film layer arranged on one side of the glass substrate. The film layers are distributed from the glass substrate to the outside in sequence: a first composite layer 1, a first functional layer 2, a second composite layer 3, The second functional layer 4 , the protective layer 5 , the discoloration layer 6 , and the antifouling layer 7 . Among them, the first composite layer 1 and the second composite layer 3 are made of 20% ZnO and 80% TiO 2 Mixed composition, the thickness of the first composite layer 1 and the second composite layer 3 is 50nm; the first functional layer 2 and the second functional layer 4 are Ag layers, and the thickness of the first functional layer 2 and the second functional layer 4 is 20nm; The protective layer 5 is a rhodium layer, and the thickness of the rhodium layer is 15nm; the color-changing layer 6 is silver halide, and the thickness of the color-changing layer 6 i...

Embodiment 2

[0033] Such as figure 1 As shown, a coated glass includes a glass substrate and a film layer arranged on one side of the glass substrate. The film layers are distributed from the glass substrate to the outside in sequence: a first composite layer 1, a first functional layer 2, a second composite layer 3, The second functional layer 4 , the protective layer 5 , the discoloration layer 6 , and the antifouling layer 7 . Among them, the first composite layer 1 and the second composite layer 3 are made of 80% ZnO and 20% TiO 2 Mixed composition, the thickness of the first composite layer 1 and the second composite layer 3 is 150nm; the first functional layer 2 and the second functional layer 4 are Ag layers, and the thickness of the first functional layer 2 and the second functional layer 4 is 30nm; The protective layer 5 is a rhodium layer, and the thickness of the rhodium layer is 25nm; the color-changing layer 6 is silver halide, and the thickness of the color-changing layer 6 ...

Embodiment 3

[0035] Such as figure 1 As shown, a coated glass includes a glass substrate and a film layer arranged on one side of the glass substrate. The film layers are distributed from the glass substrate to the outside in sequence: a first composite layer 1, a first functional layer 2, a second composite layer 3, The second functional layer 4 , the protective layer 5 , the discoloration layer 6 , and the antifouling layer 7 . Among them, the first composite layer 1 and the second composite layer 3 are made of 50% ZnO and 50% TiO 2 Mixed composition, the thickness of the first composite layer 1 and the second composite layer 3 is 100nm; the first functional layer 2 and the second functional layer 4 are Ag layers, and the thickness of the first functional layer 2 and the second functional layer 4 is 25nm; The protective layer 5 is a rhodium layer, and the thickness of the rhodium layer is 20nm; the color-changing layer 6 is silver halide, and the thickness of the color-changing layer 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com