Pile-sinking construction method for deep riprap unfavorable geologic region

A construction method and stone technology, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as unsmooth implementation, and achieve the effect of green civilization, high efficiency and low construction cost in the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

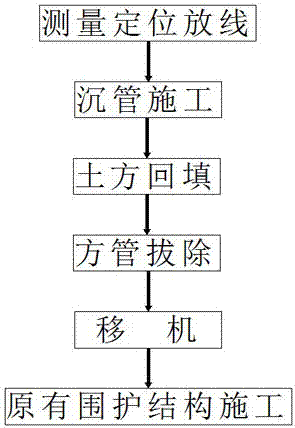

[0029] Example 1: A construction method for pile sinking in a deep and thick rock dumping area with poor geological conditions, see attached figure 1 As shown, including the following steps:

[0030] (1) Measuring and setting-out positioning;

[0031] (2) Immersed pipe construction:

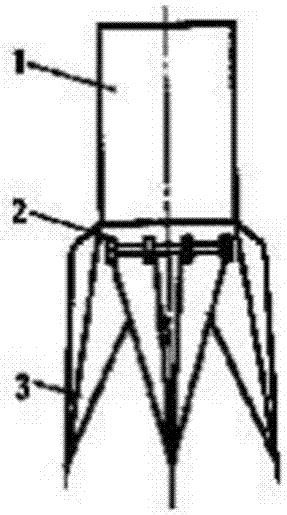

[0032] The pile pipe adopts a square pipe not larger than 500mm, if attached figure 2 As shown, the lower part of the pile pipe 1 is provided with a valve pile tip, wherein the valve 3 is rotatably connected to the lower end of the pile pipe 1 via a lock shaft 2.

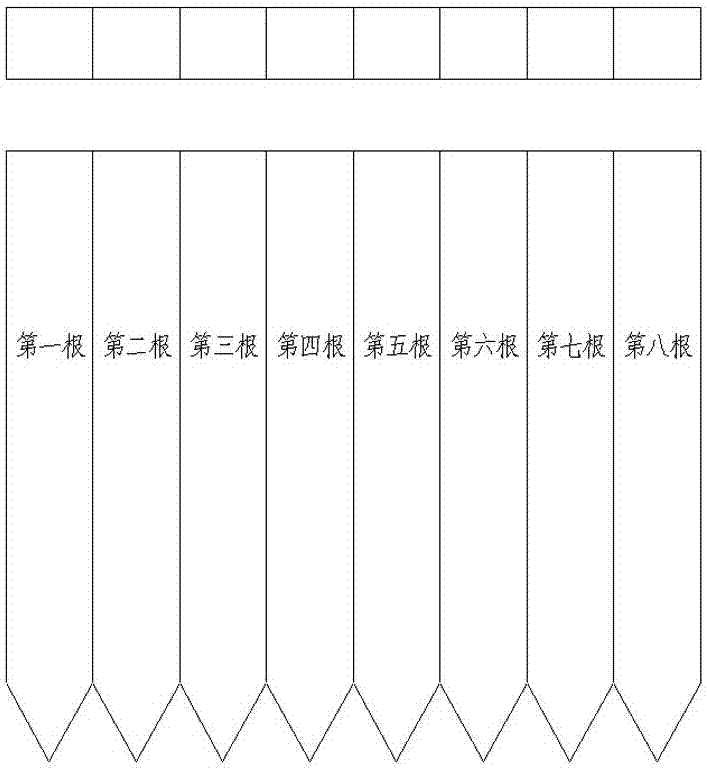

[0033] Such as image 3 As shown, when the pipe is sinking, multiple pile pipes are used as a group (8 pile pipes are shown in the figure);

[0034] When constructing, install the pile driver first, close the lower end of the pile pipe and the tip of the valve, align the pile position, slowly lower the pile pipe, correct the verticality of the pile pipe, activate the vibration exciter after meeting the requirements, and press the pile pipe at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com