Patents

Literature

237results about How to "Improve the water-stop effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

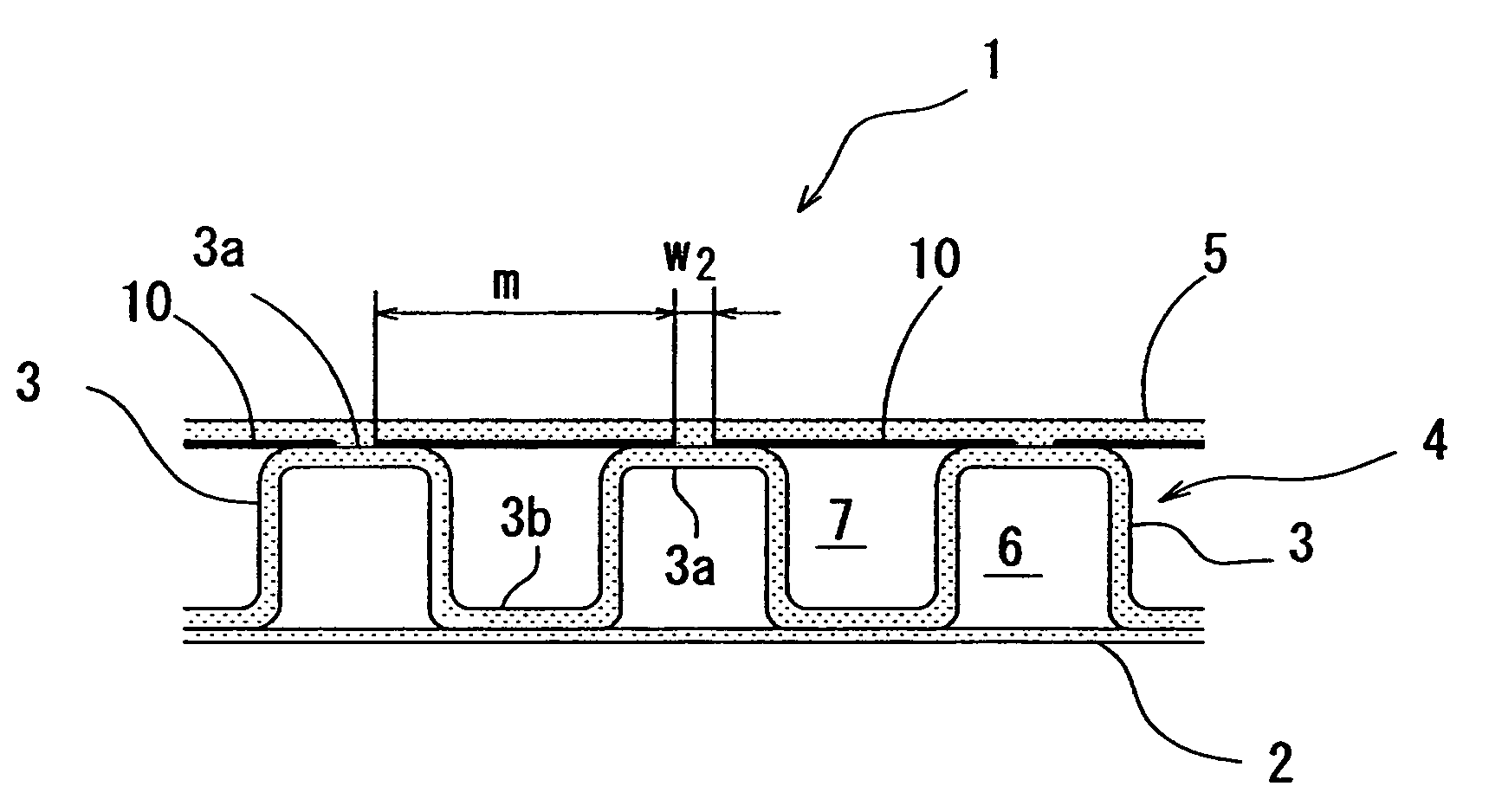

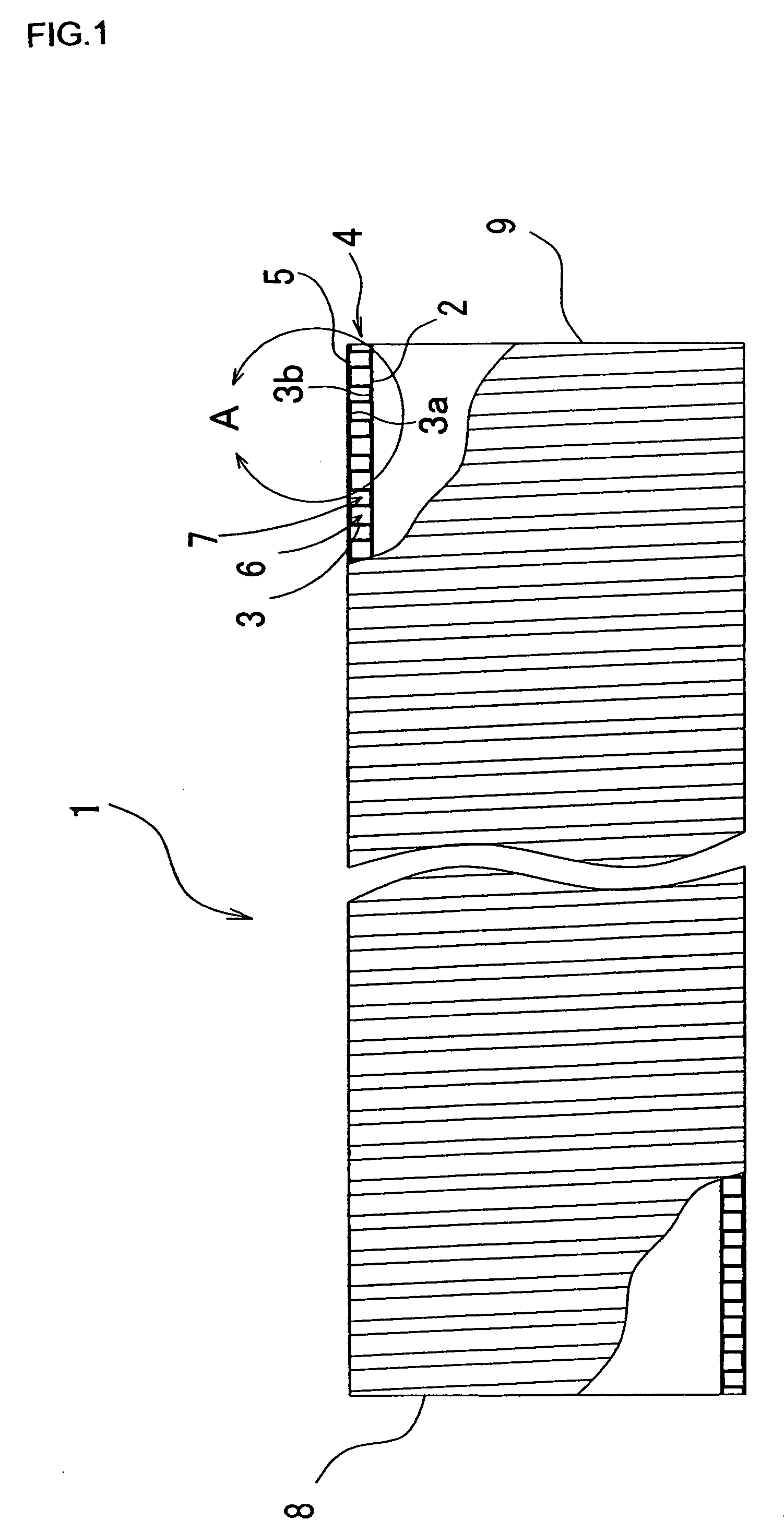

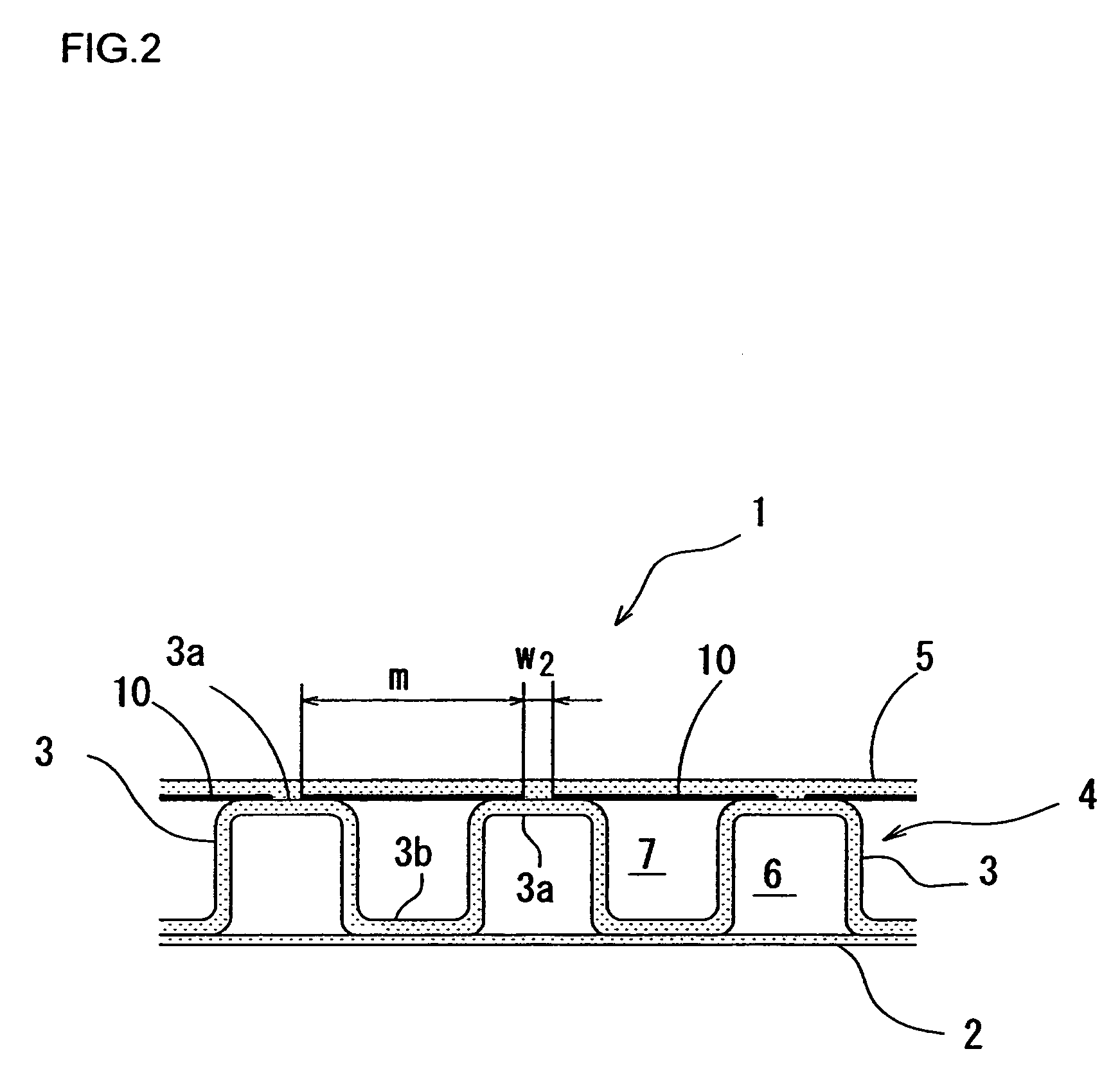

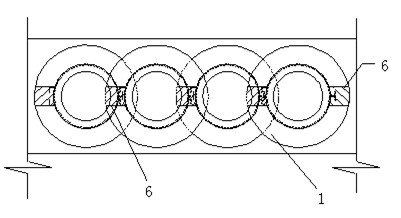

Synthetic resin pipe

InactiveUS7156128B1Avoid deformationIncrease synthesisFlexible pipesRigid pipesBand shapeEngineering

An object of the present invention is to provide a synthetic resin pipe configured to perform water stop accurately by forming a part connecting convex portions of an outer pipe to be flat without reducing flexibility in order to compose a synthetic resin pipe having flat inner and outer surfaces. A synthetic resin pipe according to the present invention includes an inner pipe formed by spirally winding a belt-like synthetic resin; a spiral reinforcing part formed by spirally winding a synthetic resin having a projected rim with convex portions projecting outside; an outer pipe of belt-like synthetic resin provided so as to connect a part or all of the convex portions arranged in a pipe axis direction; and a shape retaining material for the outer pipe made of a belt-like metal sheet for retaining a shape of the outer pipe flat and buried in or provide to an inner surface of the outer pipe; wherein the shape retaining material for the outer pipe is a synthetic resin pipe wound around the convex portions of the projected rim at predetermined intervals and connecting the convex portions of the projected rim.

Owner:KANA FURETSUKUSU KOOHOREESHON

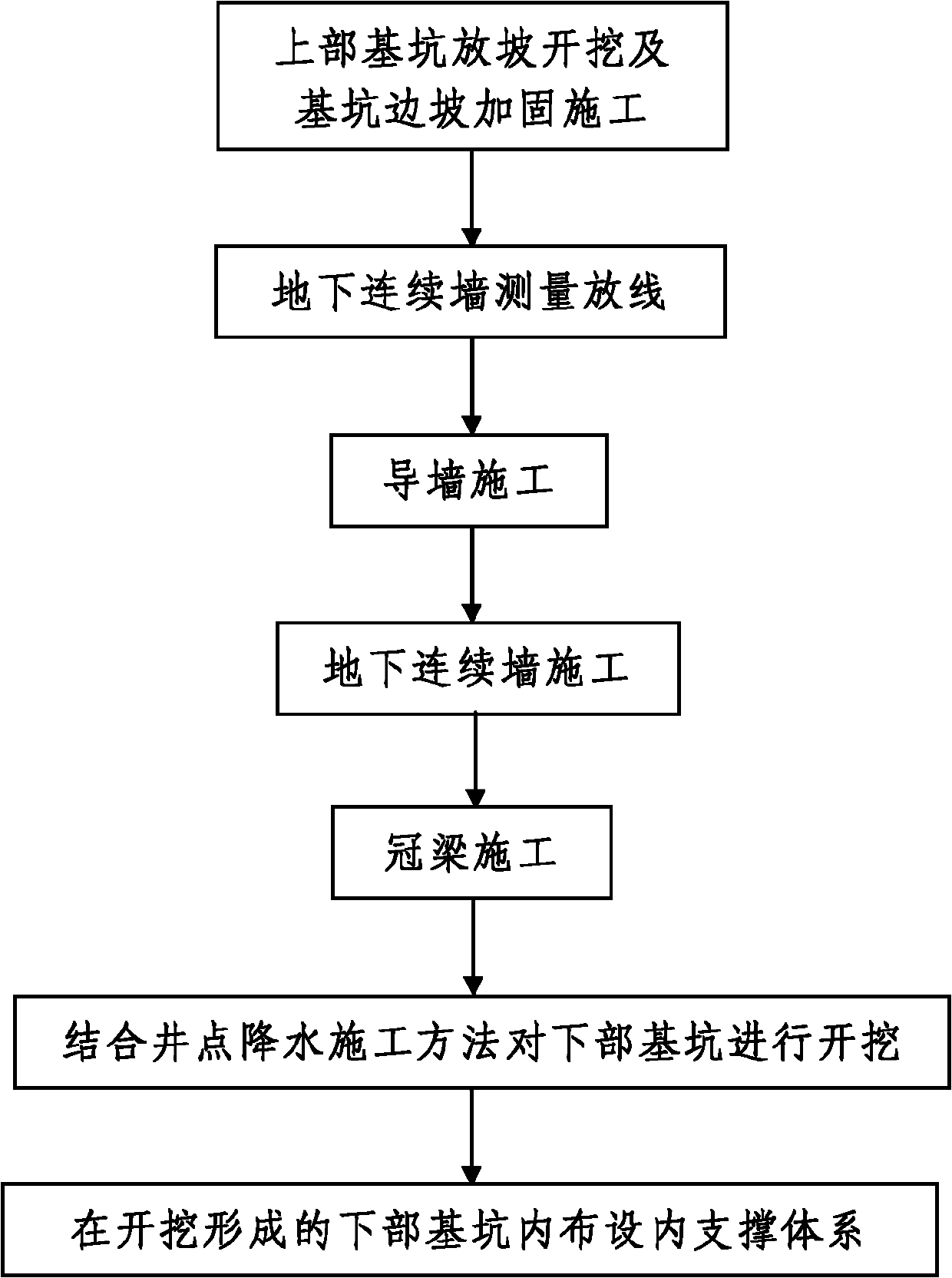

Construction method for underground diaphragm wall of deep foundation pit for subway station in collapsible loess areas

InactiveCN102322064AReasonable designSimplify construction stepsArtificial islandsExcavationsSlurry wallSubway station

The invention discloses a construction method for an underground diaphragm wall of a deep foundation pit for a subway station in collapsible loess areas. The constructed station deep foundation pit for the subway station is divided into an upper-part foundation pit and a lower-part foundation pit from top to bottom; the building enclosure of the lower-part foundation pit is the underground diaphragm wall; and the upper-part foundation pit is a foundation pit formed by slope excavation. The construction method disclosed by the invention has the following steps of: (1) construction for upper-part foundation pit slope excavation and foundation pit slope reinforcement; (2) construction for lower-part foundation pit building enclosure: surveying and paying off, guide wall construction and underground diaphragm wall construction; and (3) construction for cap beam, and then carrying out excavation on the lower-part foundation pit through combining a well-point dewatering construction method and arranging a bracing system in the excavated lower-part foundation pit. The construction method disclosed by the invention has the advantages of reasonable design, simplicity and convenience for construction, safety and reliability for construction and good construction effect, high construction quality and capability of effectively solving the practical problems, such as high difficulty for construction, complicated construction procedure, difficulty for ensuring the construction quality of deep foundation pits and the like, in a process of constructing the deep foundation pits for subway stations in the collapsible loess areas.

Owner:CHINA RAILWAY 20 BUREAU GRP

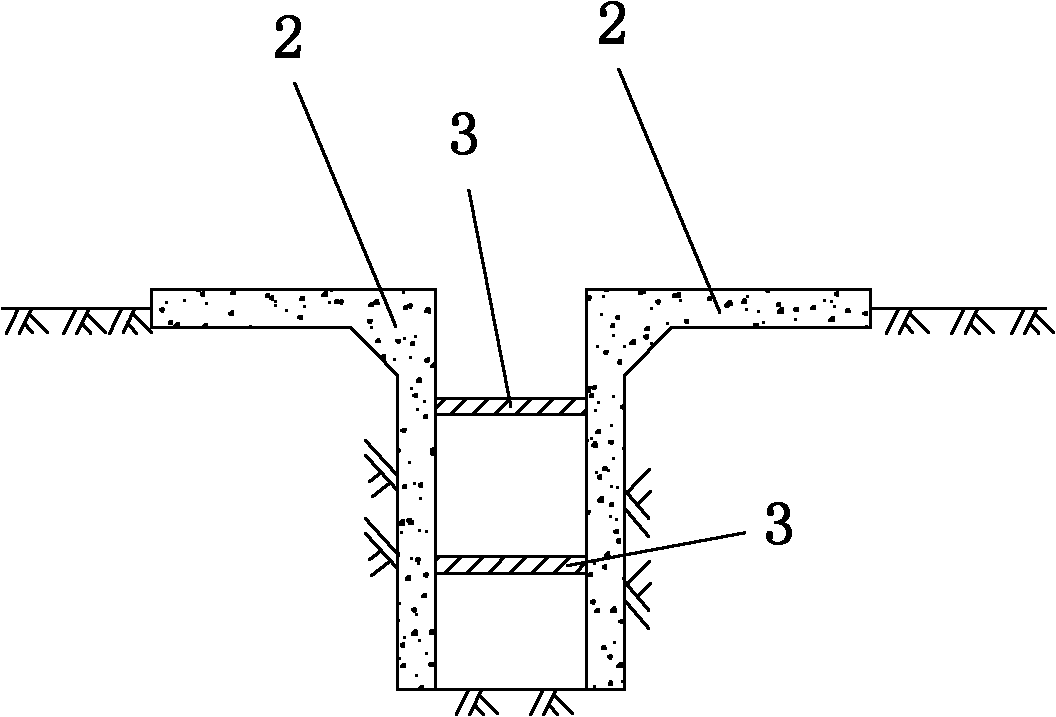

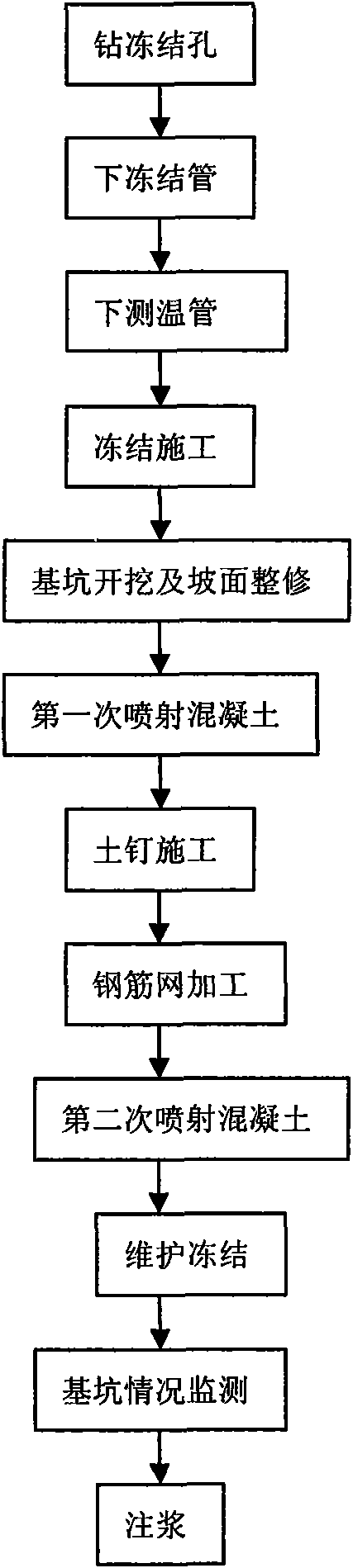

Soil nailing wall foundation pit support and construction method

The invention discloses a soil nailing wall foundation pit support and a construction method. The construction method is characterized by comprising the steps of drilling freezing holes, arranging freezing pipes, arranging temperature tubes, performing the freezing construction, performing the pit excavation and ramp finishing, spraying concrete for the first time, performing the soil nailing construction comprising the processes of positioning, pore forming, reinforcement bar inserting and mortar pouring, processing a reinforcement net, spraying the concrete for the second time, maintaining the freezing; monitoring the foundation pit condition and pouring mortar. The invention is secure and reliable, and the stability and water sealing property of the foundation pit can be improved.

Owner:ANHUI TONGJI CONSTR GRP

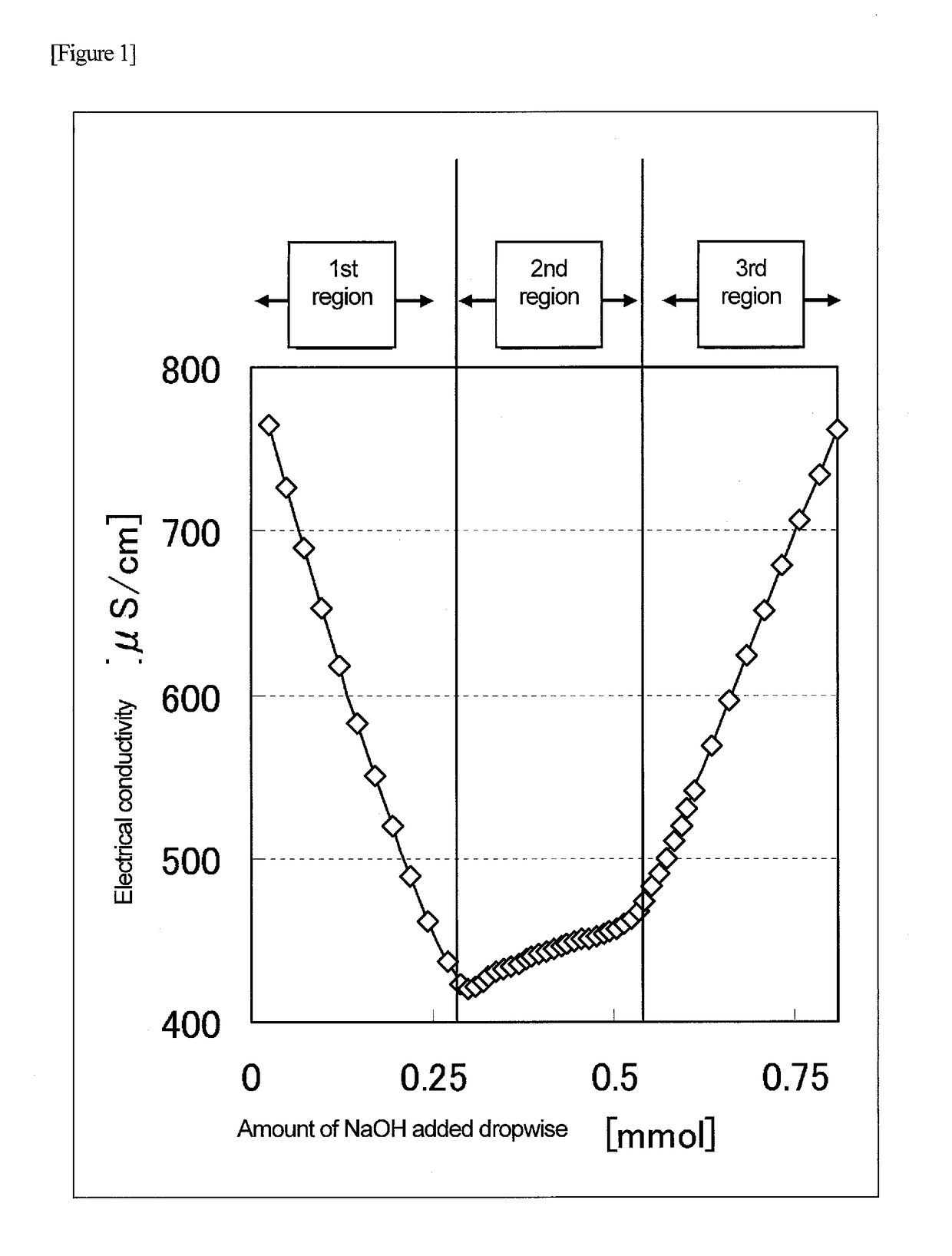

Composition containing minute cellulose fibers

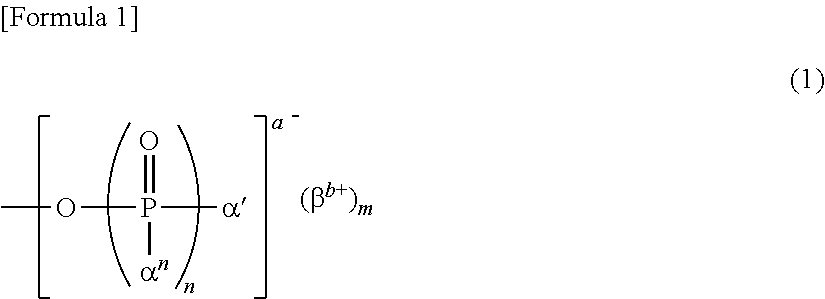

ActiveUS20170226398A1Improve the water-stop effectEfficient ConcentrationDrilling compositionInjection wellPhosphoric acid

The object is to provide a subterranean formation processing composition which has a highly stable viscosity against change in temperature and a high water stopping property. A subterranean formation processing composition comprising cellulose fibers wherein the composition contains ultrafine cellulose fibers having 0.14 to 2.5 mmol / g of a substituent is used. The substituent is preferably an anion group, particularly a phosphoric acid group. The present invention relates to various fluids which are used in well processing. The present invention relates to a method for processing a subterranean formation, for example, drilling of an exploratory well or a wildcat, an appraisal well, an exploratory well or an exploration well, a delineation well, a development well, a production well, an injection well, an observation well, and a service well; cementing; fracturing; and a method for producing petroleum resources. The present invention provides also a cellulose fiber-containing composition which is not limited to the subterranean formation processing use.

Owner:OJI HLDG CORP

Dynamic, fire-resistance-rated thermally insulating and sealing system having a F-rating of a min. of 120 min for use with curtain wall structures

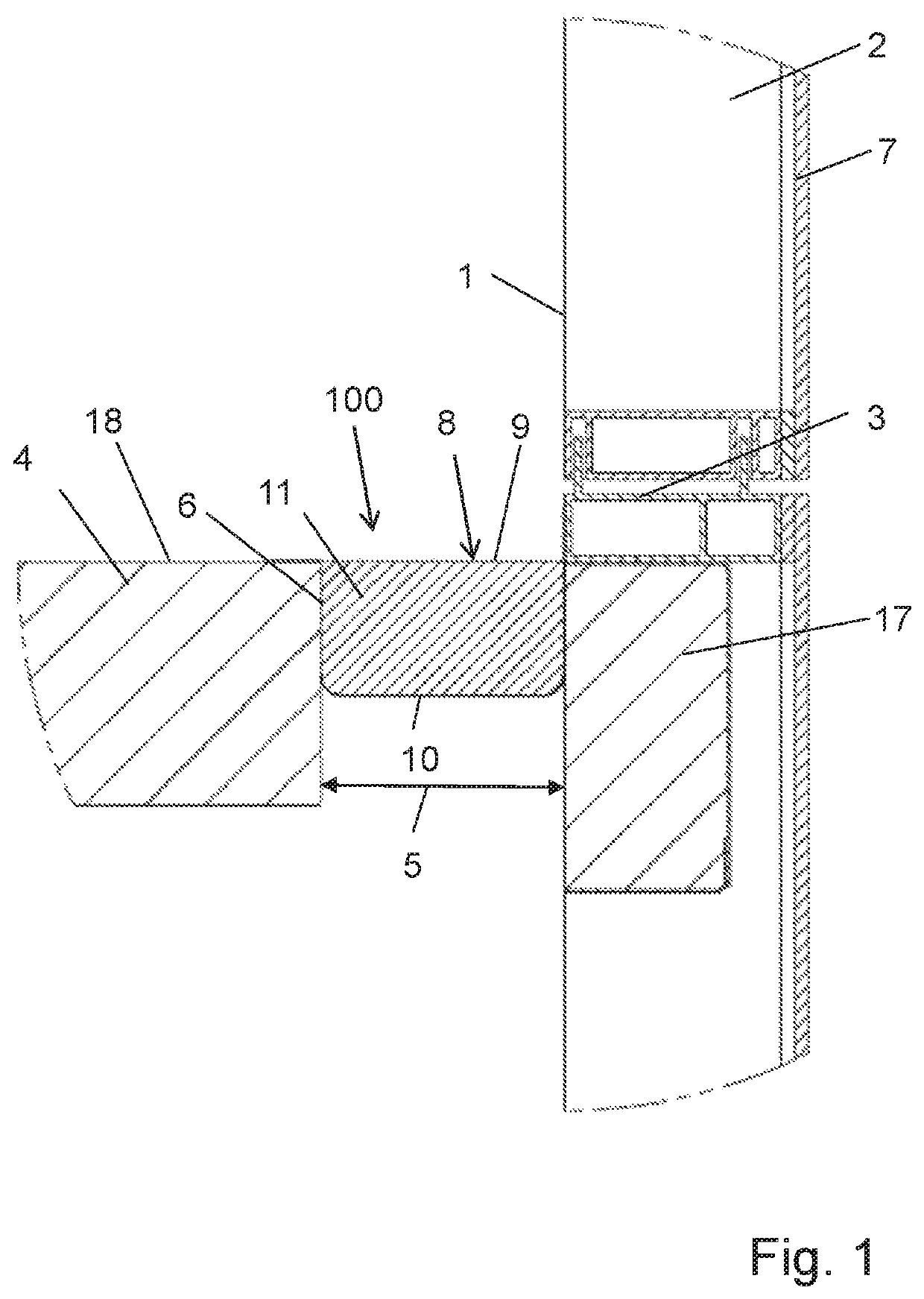

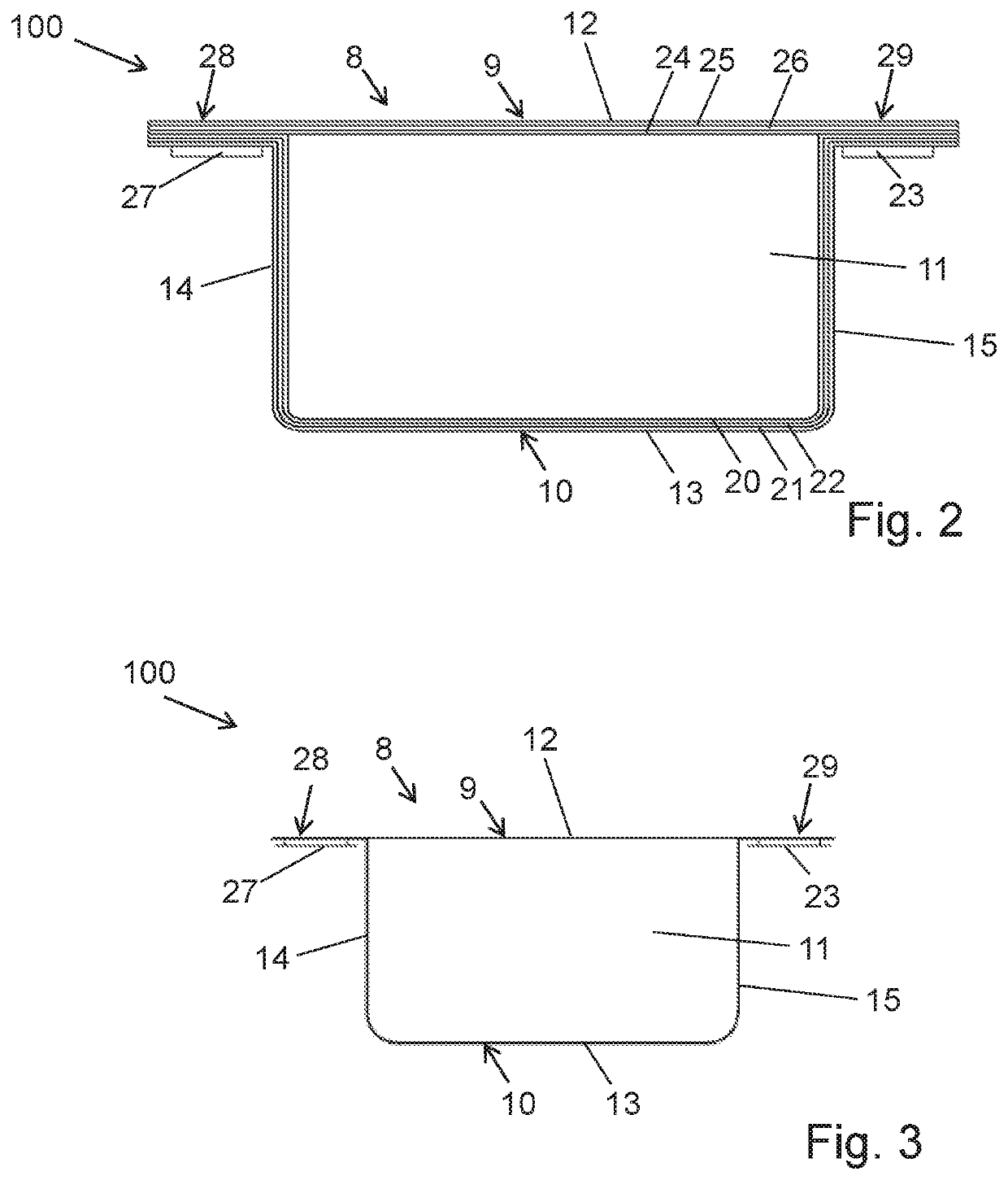

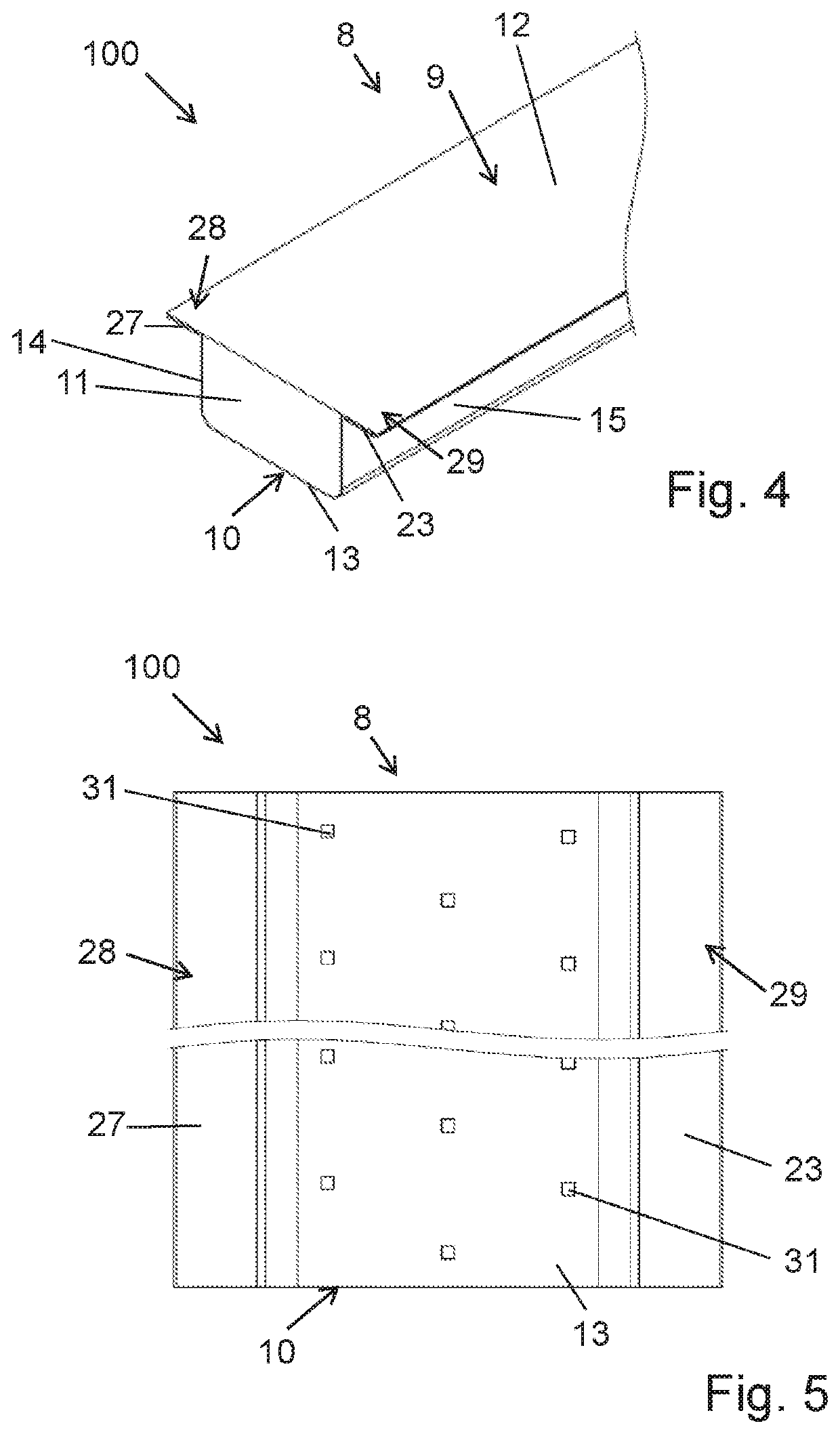

ActiveUS10731338B1Effectively thermally insulatingImprove sealingCeilingsWallsArchitectural engineeringExternal cladding

An approved dynamic construction is useful for effectively thermally insulating and sealing of a safing slot between a floor of a building and an exterior wall construction wherein the exterior wall construction comprises a curtain wall configuration defined by an interior wall surface. The dynamic, thermally insulating and sealing system contains a tubular sealing element having wing-like connection areas for attaching the tubular sealing element to the curtain wall construction and the floor of a building, to maintain thermally insulating and sealing of the safing slot during exposure to fire and heat as well as movement in order to maintain a complete seal extending across the safing slot and to enhance the water-stopping properties of the insulation and seal within the safing slot.

Owner:HILTI AG

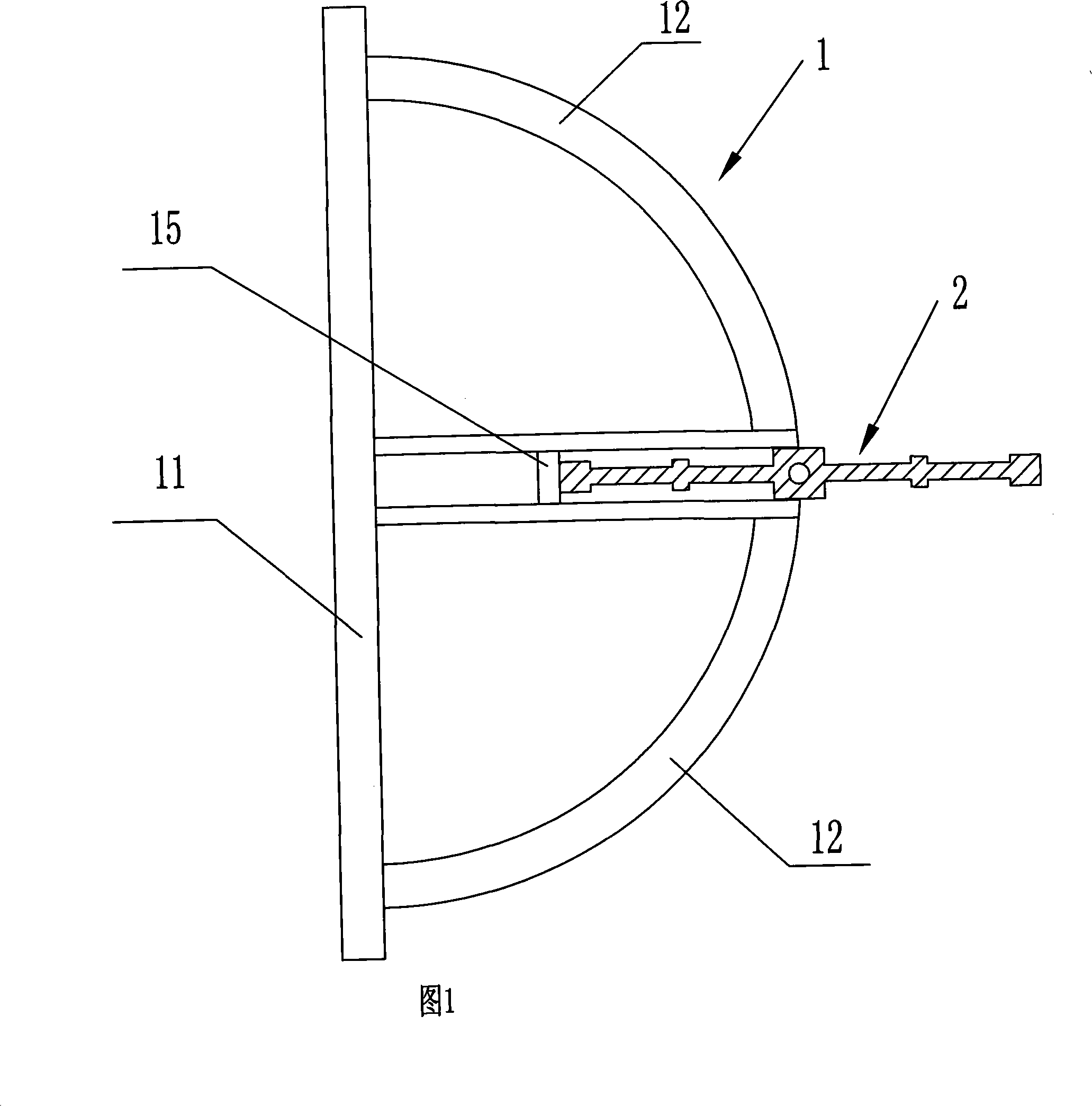

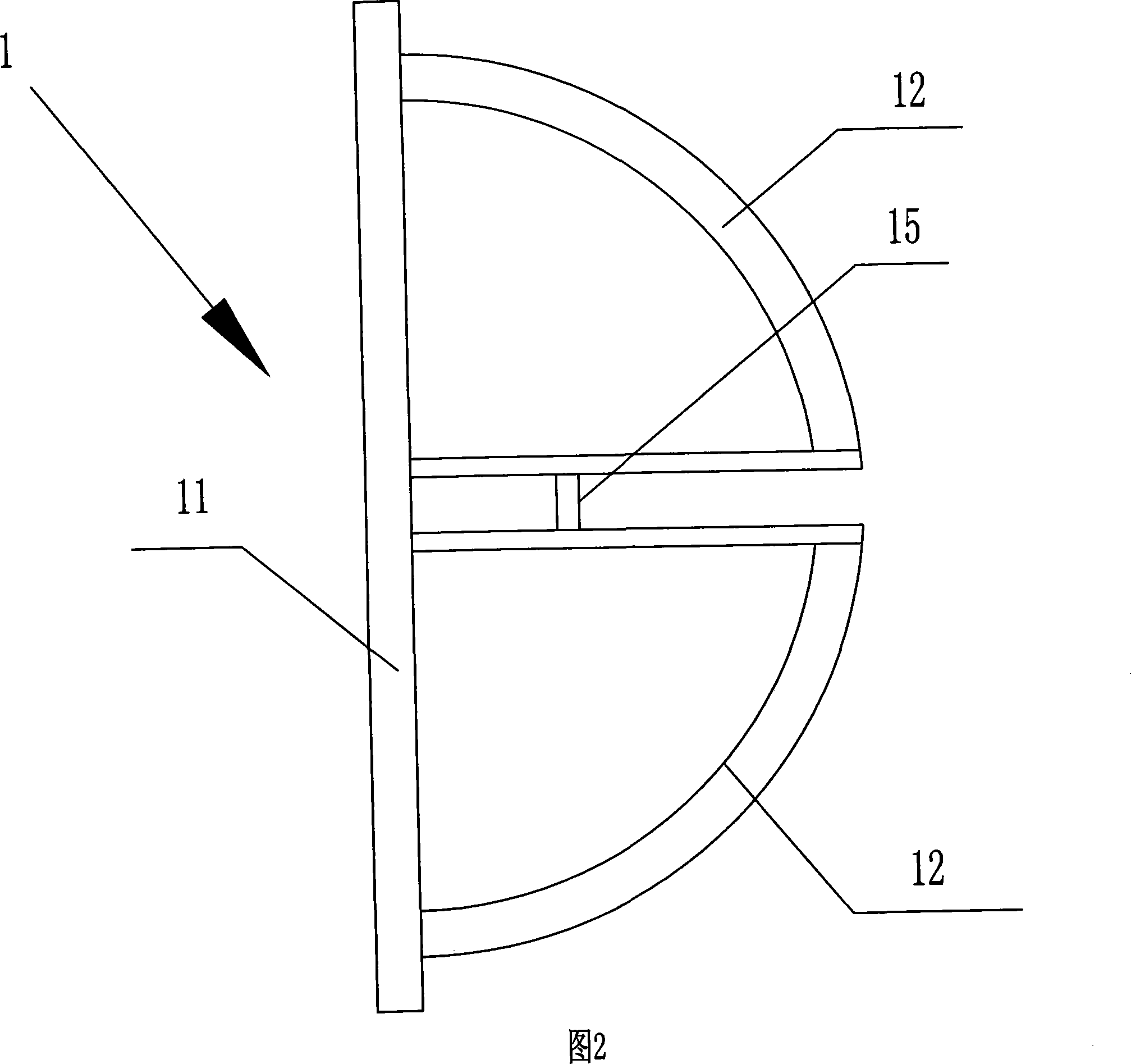

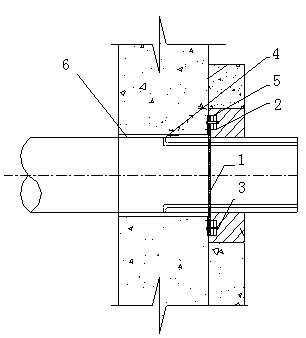

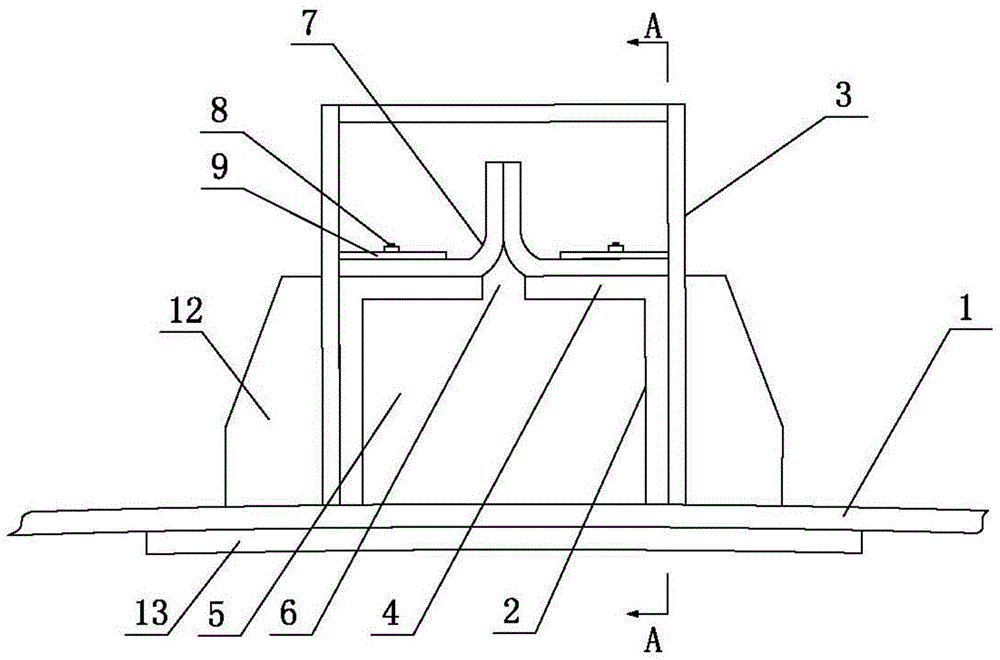

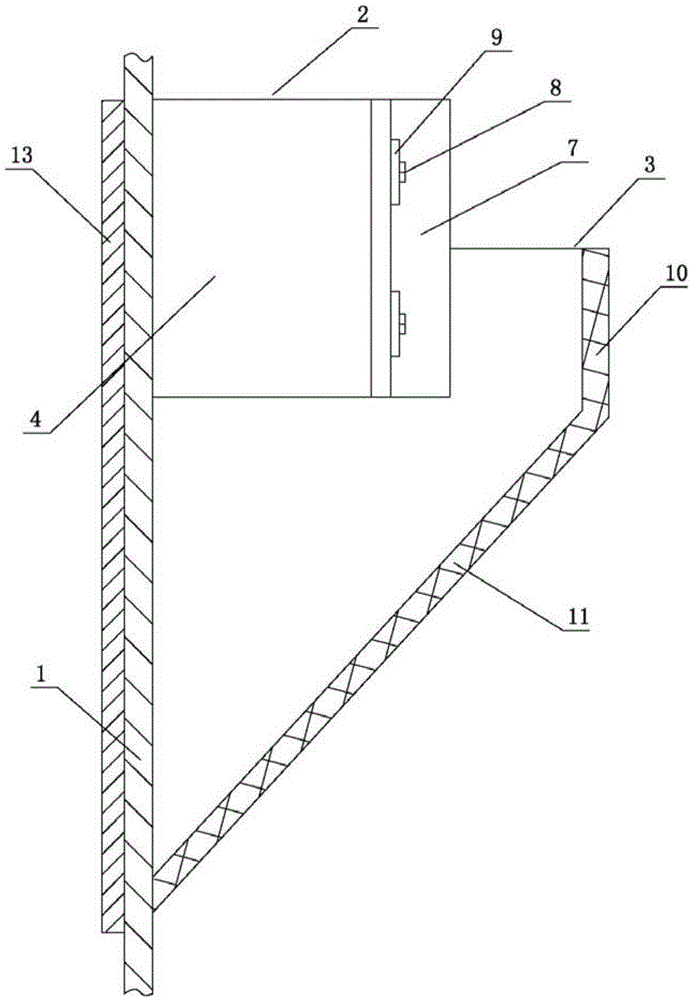

Large depth underground continuous wall water-stop joint device

ActiveCN101168963AAvoid generatingSave the process of brushing the wallArtificial islandsUnderwater structuresSlurry wallArchitectural engineering

The invention relates to a water sealing joint device of a large-depth underground continuous wall. The water sealing joint device consists of a water sealing connector plate and a rubber water stop; the water sealing connector plate comprises connector side plates connected in sequence, two arc shape plates, an H-shaped groove plate, an upper end plate and a lower end plate; the two arc shape plates are oppositely arranged in the middle at intervals along the width of a connector side plate, and the H-shaped groove plate is arranged in the middle between the two arc shape plates; the H-shaped groove plate has two opening ends, one end is fixed and connected with the two arc shape plates, and the other end is fixed and connected with the connector side plate; and the upper end plate and the lower end plate are arranged at the end parts of the two arc shape plates and the H-shaped groove plate. An opening slot is arranged at the middle part of the upper end plate and the lower end plate, and the rubber water stop is embedded in a gap between the opening slot and the opening end of the H-shaped groove plate. The connector side plate adopts a long strip shape thick steel plate, the upper end plate and the lower end plate adopt semi-circular steel plates, and the composite cross section of the two arc shape plates is matched with the shape of the upper end plate and the lower end plate. The depth of the opening slot of the upper end plate and the lower end plate is approximately identical to half of the width of the rubber water stop. The invention can improve the prior construction process, reduce the construction cost, and effectively improve the water sealing performance of the structure of the underground continuous wall.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

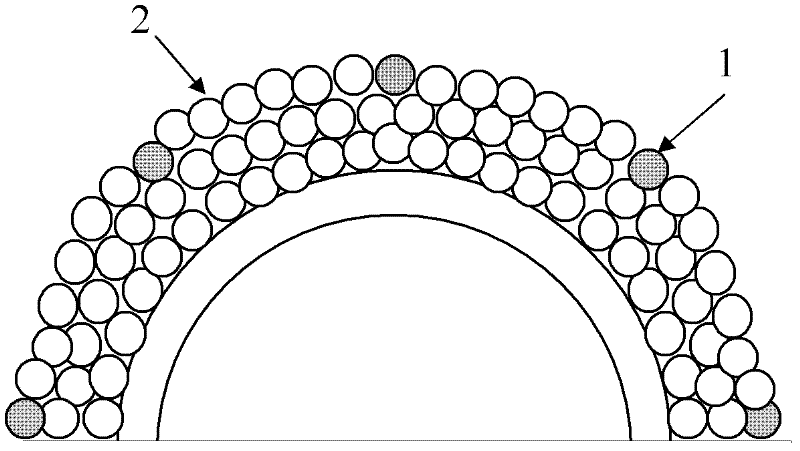

Reinforcement method for combined part of shield tunnel and mining-method tunnel

InactiveCN102400694AHigh strengthImprove the water-stop effectUnderground chambersTunnel liningShotcreteGrating

The invention discloses a reinforcement method for a combined part of a shield tunnel and a mining-method tunnel. The reinforcement method is used for using a shield machine to propel and enter the mining-method tunnel and comprises the following steps of: 1) primarily spraying concrete on a working face of the mining-method tunnel so as to prevent local collapse of the tunnel; 2) horizontally placing gratings at the positions of end walls of the mining-method tunnel and spraying the concrete after being fixed; 3) adopting a plurality of grouting pipes for injecting slurry at the end walls of the mining-method tunnel so as to carry out reinforcement; and 4) adopting plain concrete to block the full cross sections at the two end walls of the mining-method tunnel and the shield tunnel.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD

Opening treatment method for pipe-roofing continuous perforation

InactiveCN102561405AImprove the water-stop effectArtificial islandsProtective foundationEngineeringPre embedding

The invention relates to an opening treatment method for pipe-roofing continuous perforation. Pipe-roofing opening water-stopping is characterized in that a circular water-stop rubber seal board is disposed at each opening, and a sector rubber pressure board is connected and fastened to an underground structure of each hole through expansion bolts. The rubber seal boards are mutually tangent at the continuous openings and are mutually overlapped to form a whole. A grouting pipe is pre-embedded into an opening structure for water stopping at the juncture inside each opening, and the opening and the structural juncture are filled with grout for water stopping after entry of the grouting pipe into the hole. By the opening treatment method, impact on adjacent pipe roofs can be reduced greatly, the water-stop effect of the openings and the water-stop effect of the juncture of each opening with the pipe roof are enhanced, and the opening treatment method is superior to the traditional methods in terms of technical feasibility, operating efficiency and implementation effect. Presently, the opening treatment method is applied to underground channel pipe roofing at a source N0.33 in the Shanghai bund.

Owner:SHANGHAI FOUND ENG GRP

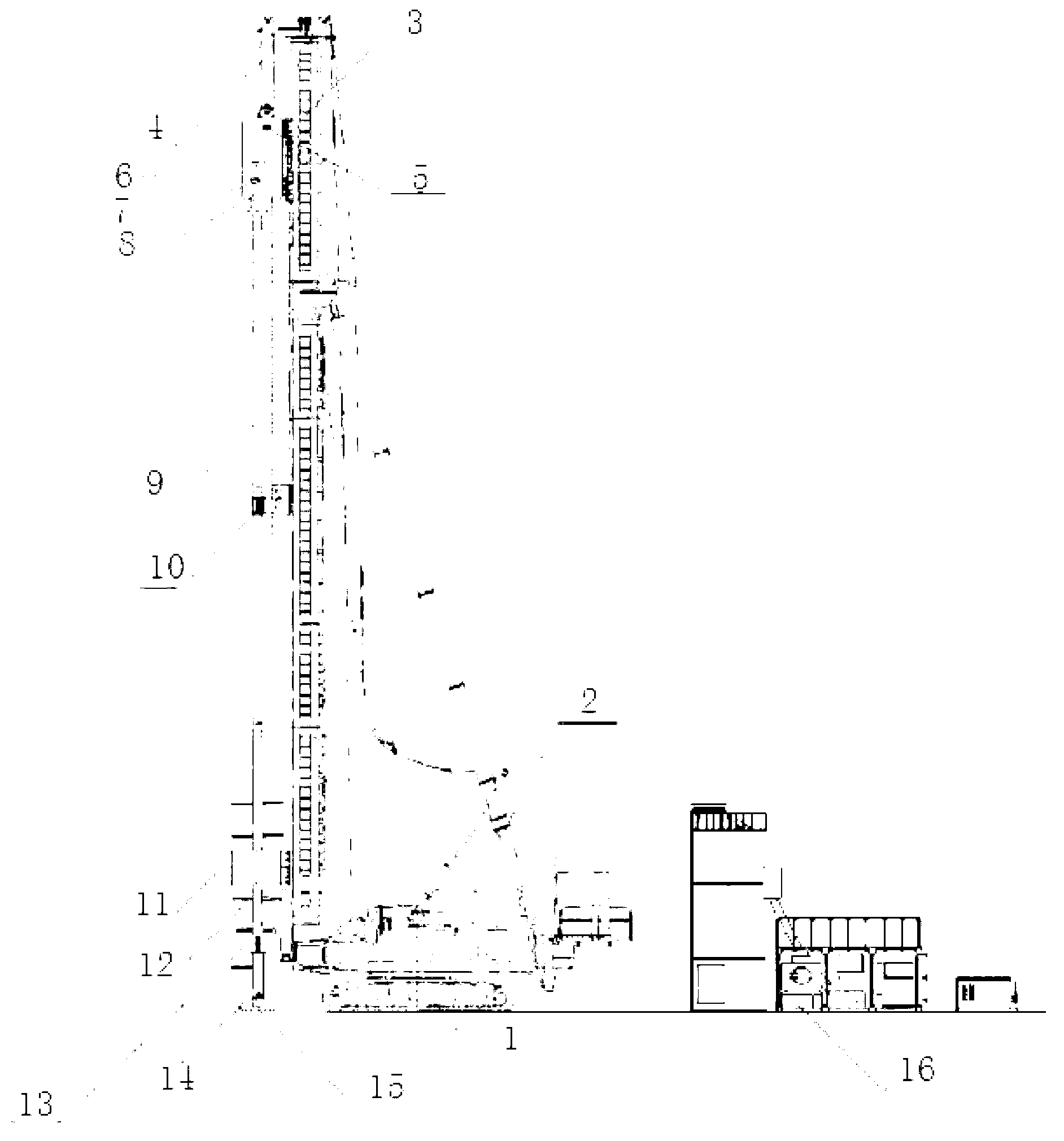

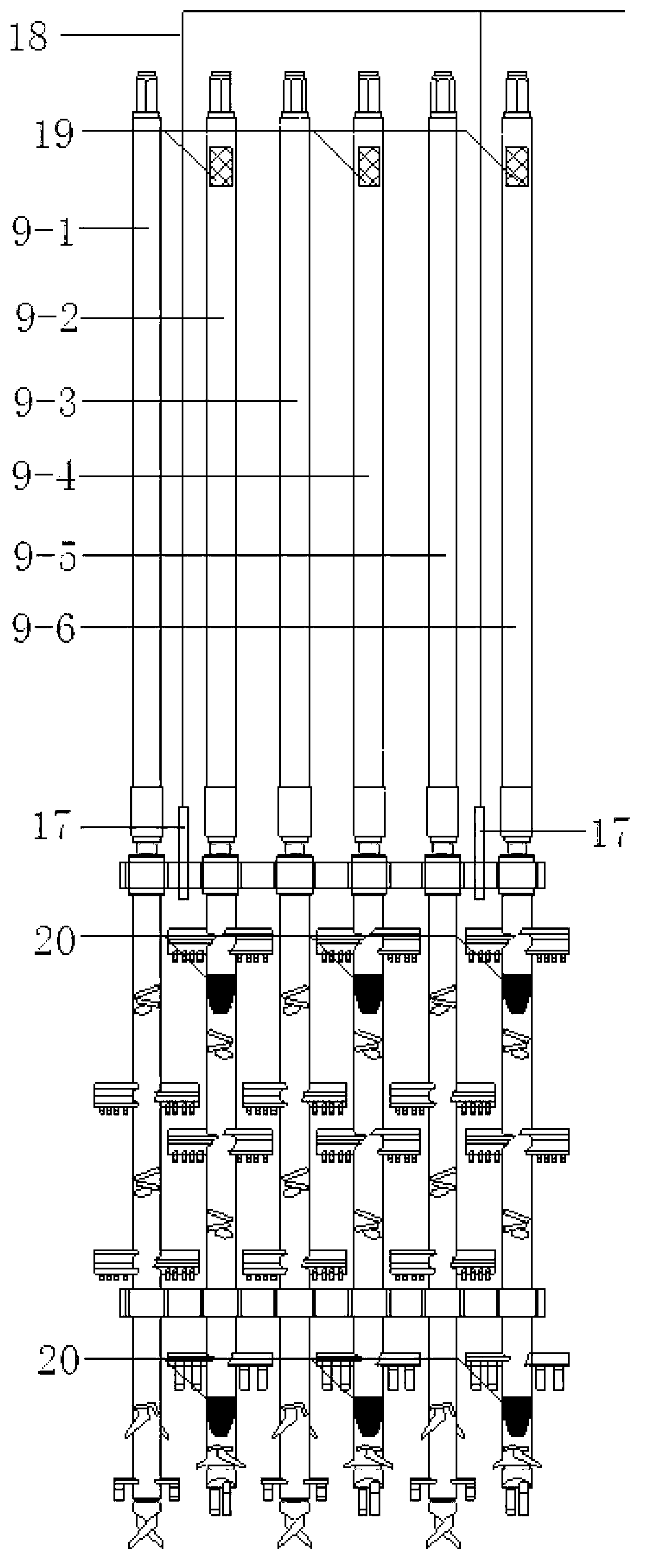

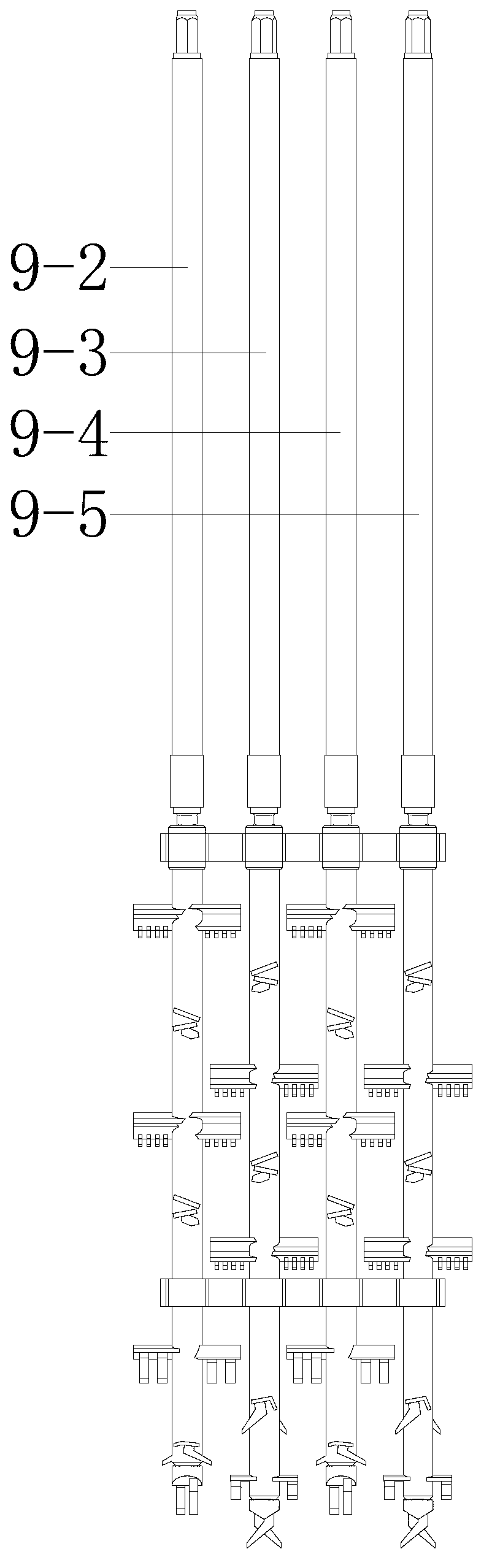

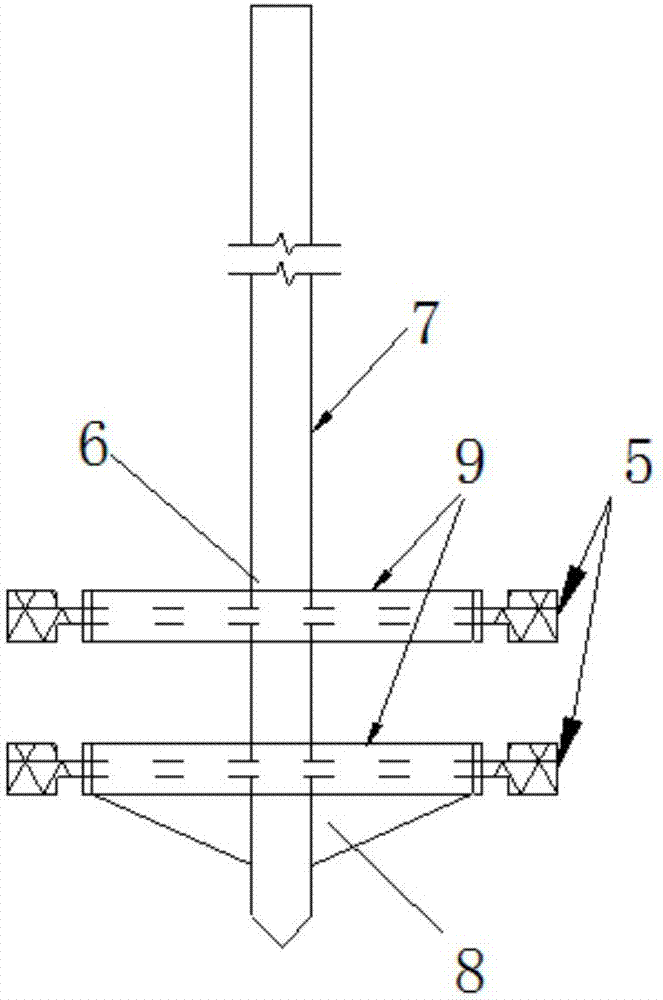

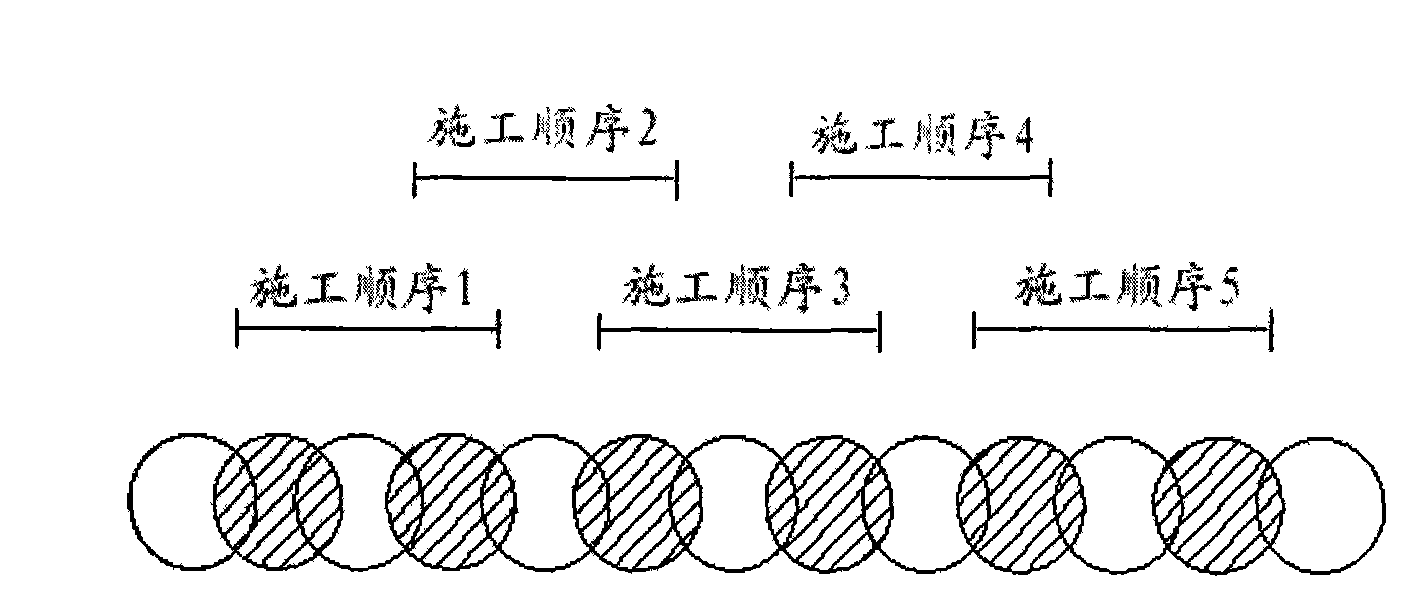

Two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and construction method thereof

ActiveCN103074892AReduce the number of lapsImprove the water-stop effectSurveyDirectional drillingCement slurrySoil cement

The invention relates to a two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and a construction method thereof. The device comprises a host, a guide rod, a power assembly, a plurality of drill pipes, drill pipes with wings, multifunction drill bits, a background cement slurry stirring system, flow meters, a soil penetrating depth sensor and verticality real-time monitors, wherein the power assembly is connected with the drill pipes, the lower end of each drill pipe with the wing is connected with each multifunction drill bit, the top part of each drill pipe is provided with a slurry inlet, the middle part of each drill pipe is provided with a middle bearing bracket, each flow meter is arranged on a slurry spraying port, the penetrating depth sensor is arranged on a slide rail of the guide rod, each verticality real-time monitor is arranged on each middle bearing bracket, the flow meters, the soil penetrating depth sensor and the verticality real-time monitors are respectively connected with the host, and detachable drill pipes are adopted as the drill pipes. Compared with the prior art, the device has the advantages that the pile forming function is versatile, the cost is saved, the verticality is controllable, the pile forming effect is good, and the like.

Owner:SHANGHAI CHENGDI CONSTR

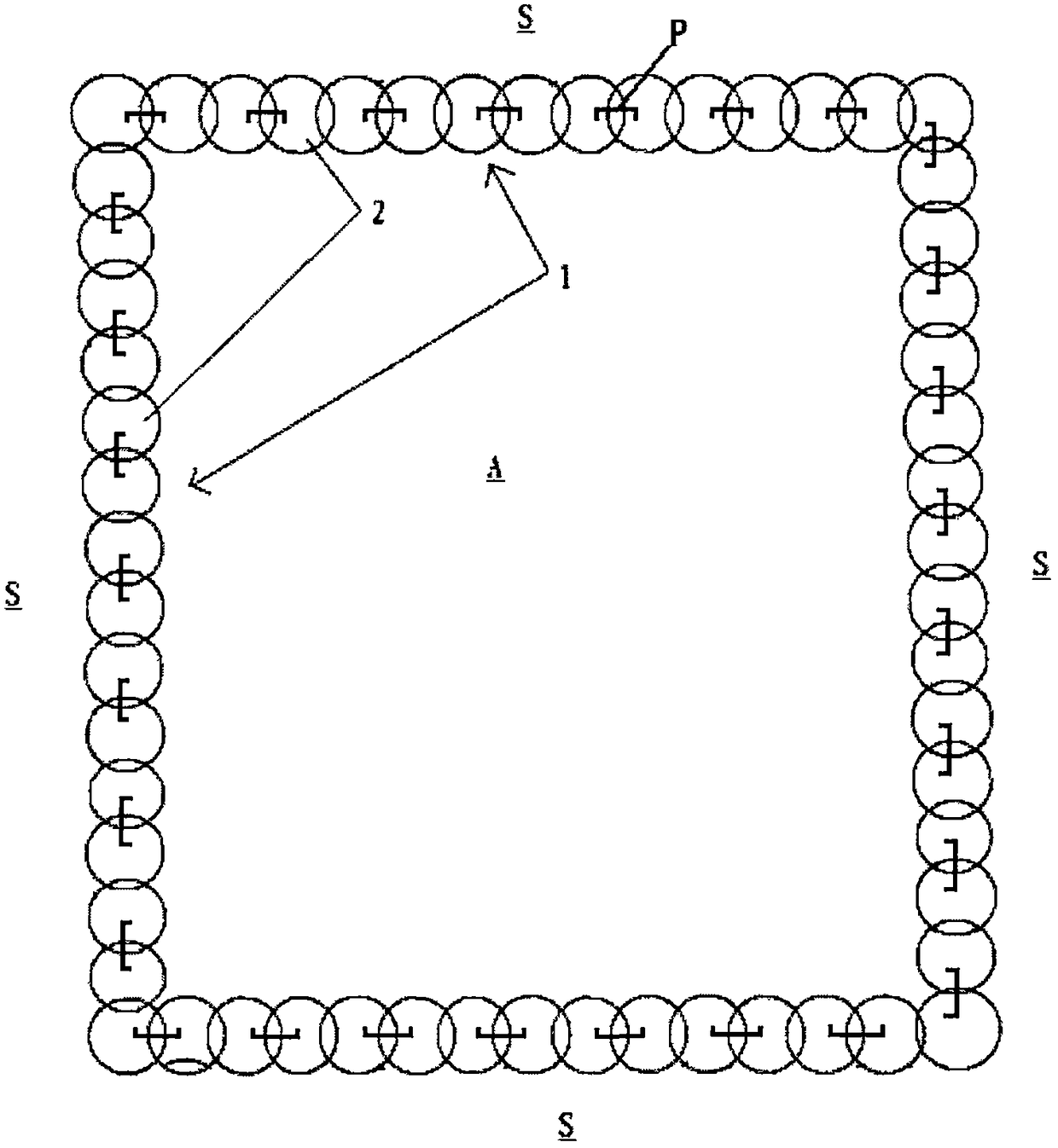

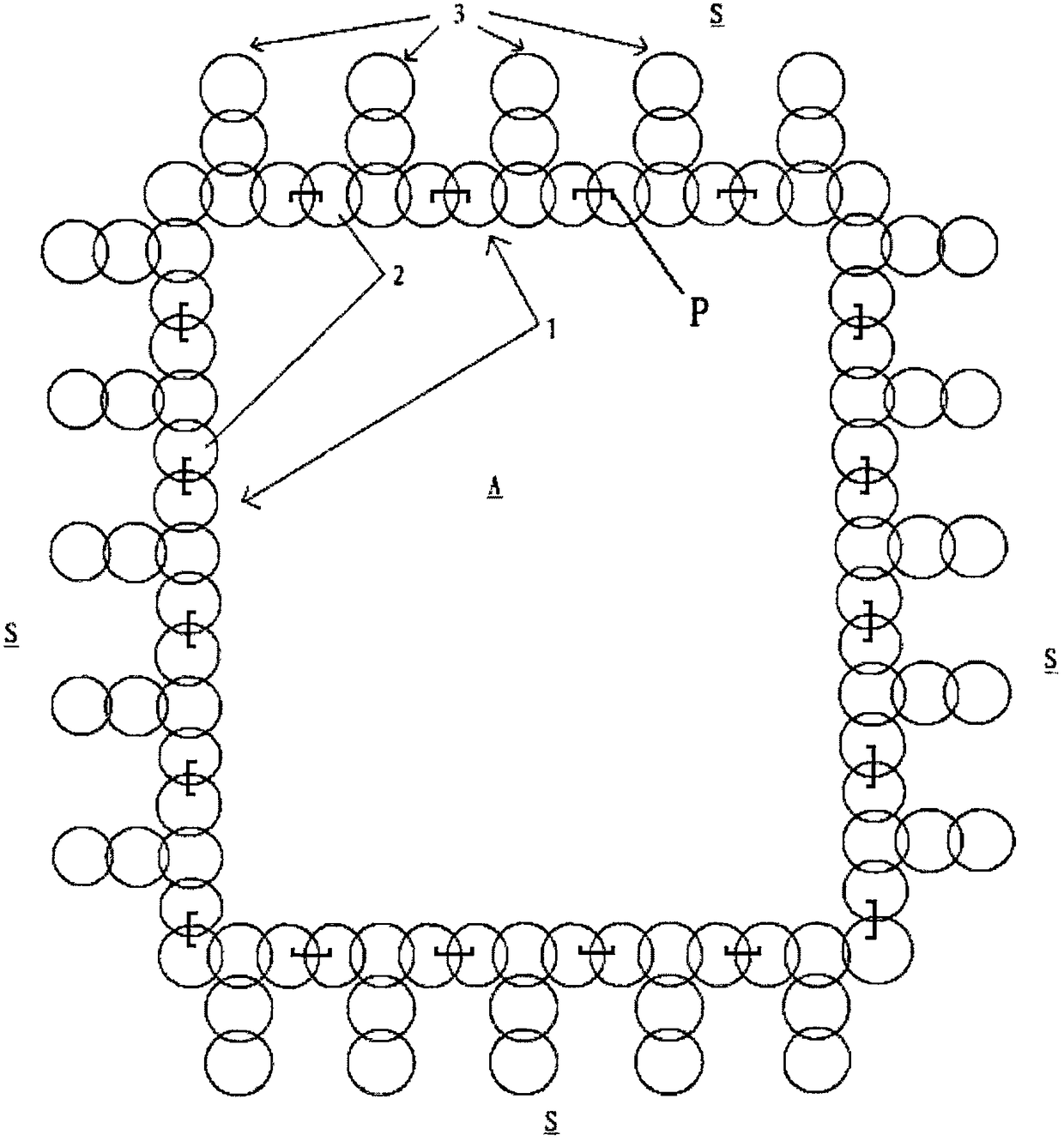

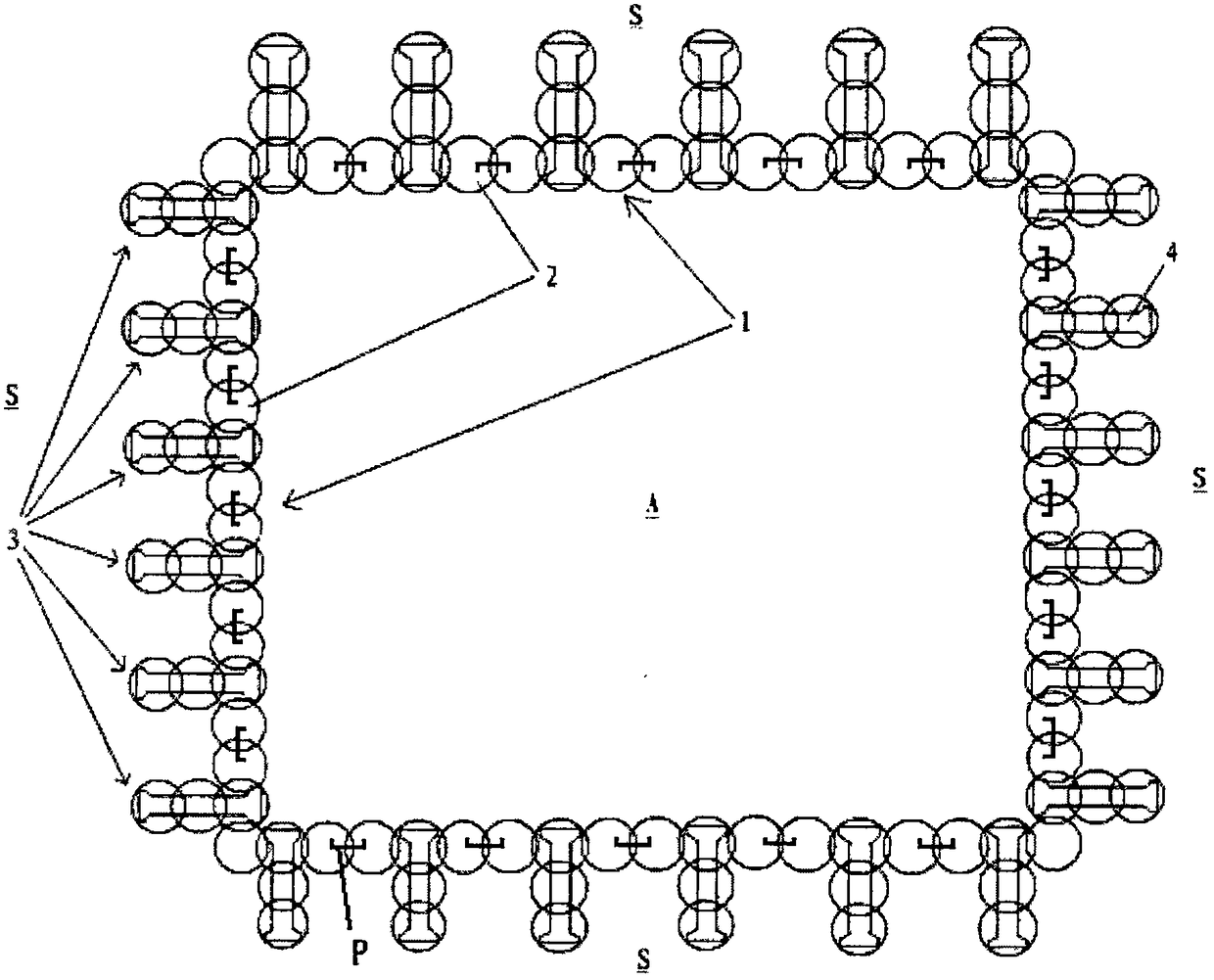

Continuous retaining wall of deep foundation pit and construction method thereof

InactiveCN108708382AEnsure water-stopping abilityPrevent penetrationArtificial islandsExcavationsWater blockGroundwater

The invention provides a continuous retaining wall of a deep foundation pit. The continuous retaining wall comprises a continuous engaged part and a water blocking component, wherein the continuous engaged part is formed in a way that at least one layer of pile bodies are continuously engaged with each other and are circularly arranged around the foundation pit; the water blocking component is longitudinally inserted into the engaged position of at least two adjacent pile bodies and is used for preventing underground water from permeating from the outer side of the foundation pit to the innerside of the foundation pit of the continuous engaged part; and the water blocking component is made of channel steel or a steel plate. According to the structure, the underground water can be effectively prevented from permeating from the engaged position of the two adjacent pile bodies into the foundation pit by the water blocking component, so that the water blocking capability of the continuousretaining wall of the deep foundation pit is increased. The invention further provides a construction method of the continuous retaining wall of the deep foundation pit.

Owner:江西基良工程机械设备有限公司

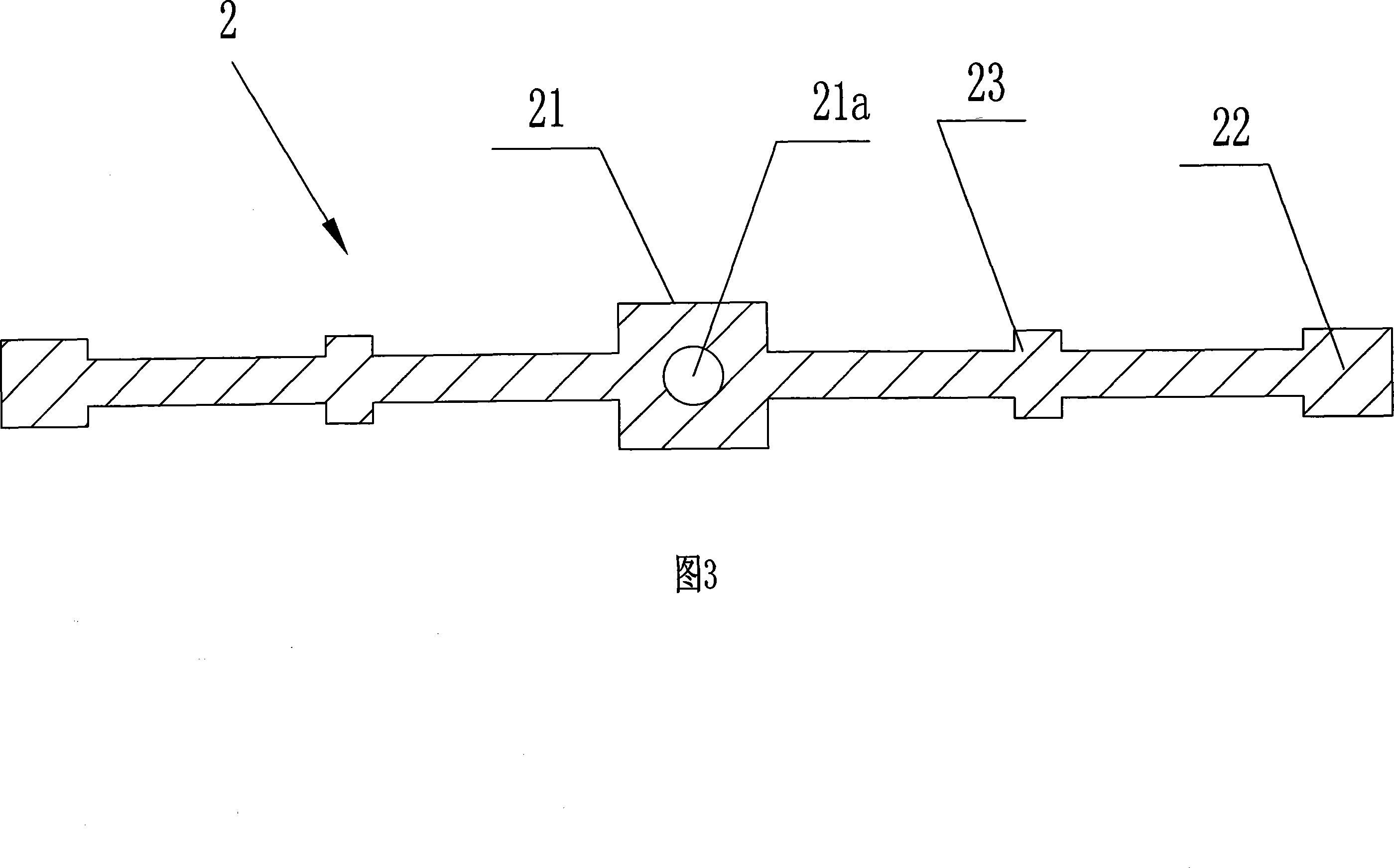

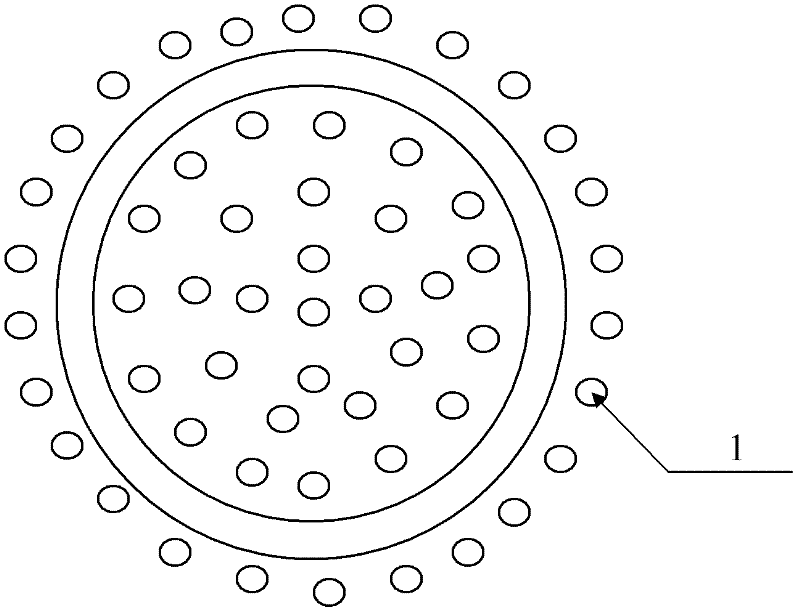

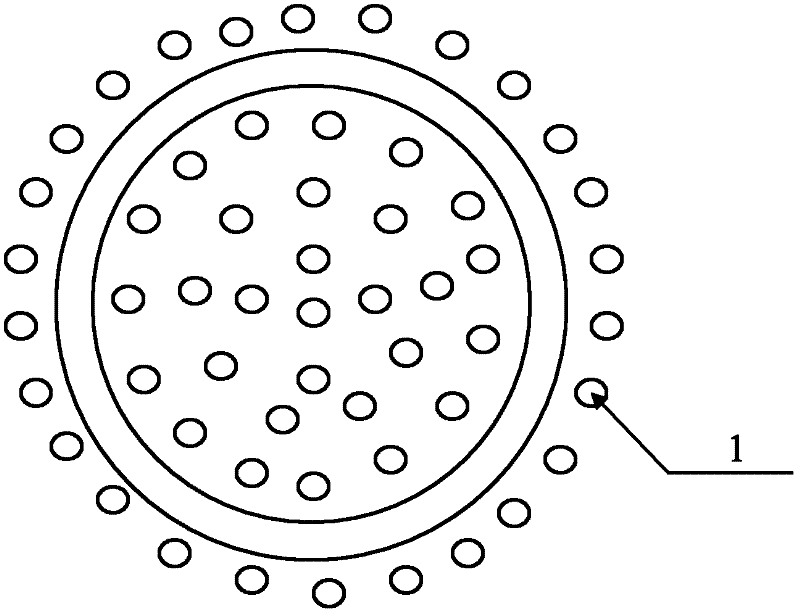

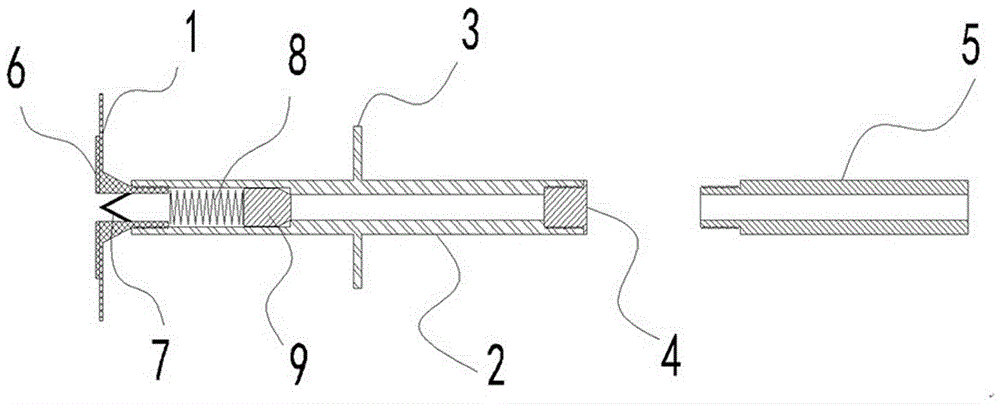

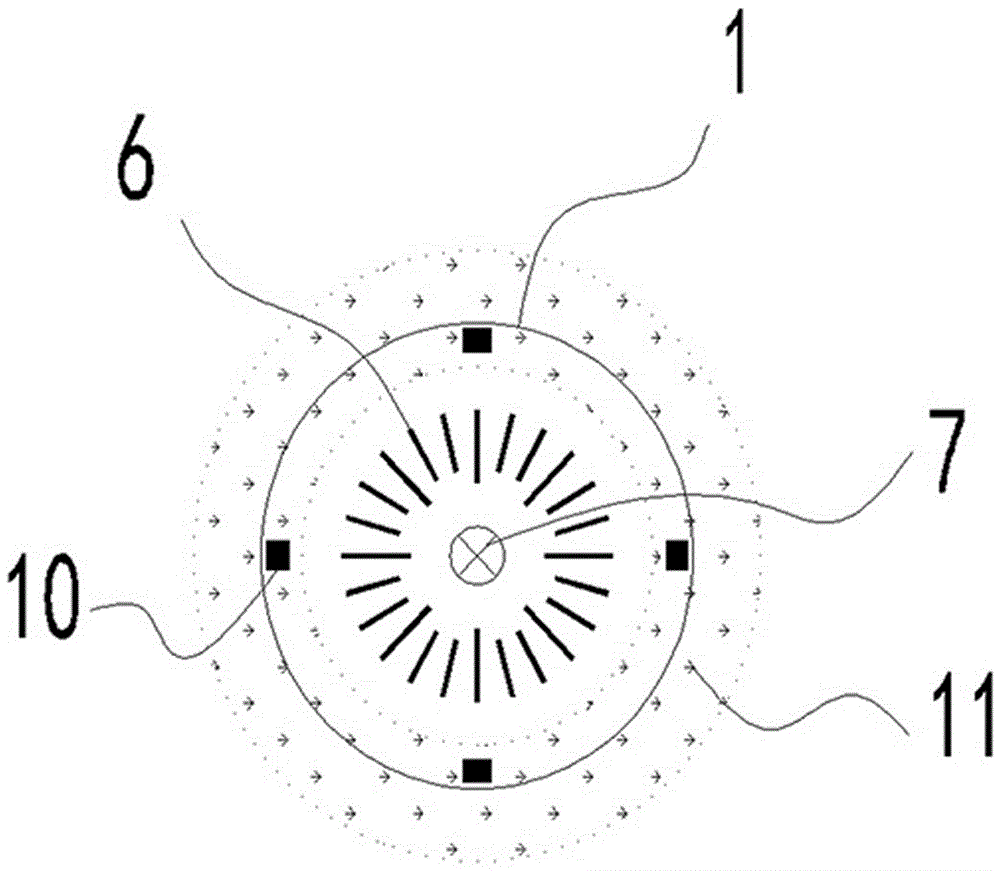

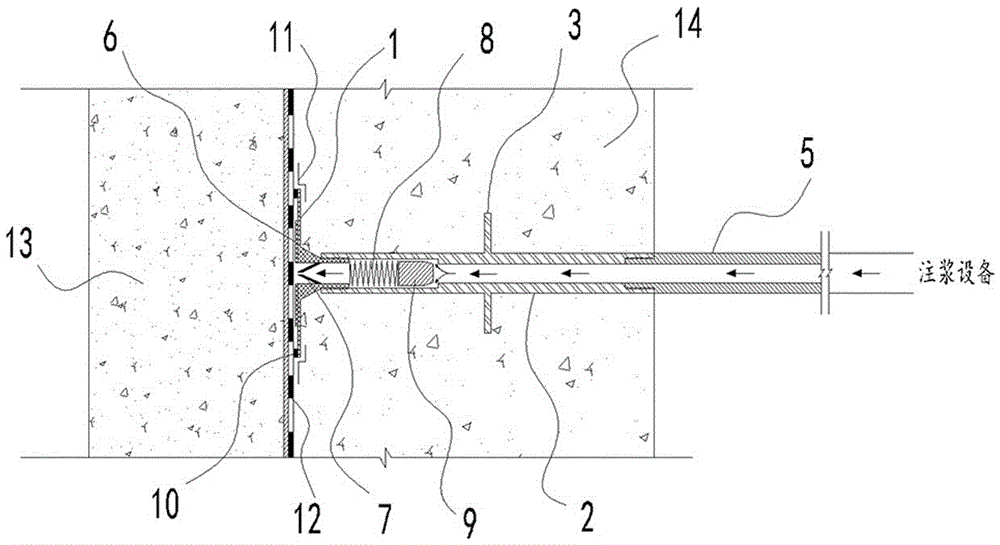

Grouting system and grouting method used for composite lining structure backfill and grouting

ActiveCN105697034ASolve the problem that grouting cannot be repeatedRealize repeated groutingUnderground chambersTunnel liningScrew threadGrout

The invention discloses a grouting system and a grouting method used for composite lining structure backfill and grouting.The grouting system comprises a one-way non-return suction cup, a one-way non-return grouting pipe, a water-stopping ring, a sealing plug and a connection pipe, wherein the one-way non-return suction cup is composed of a grouting disc and a non-return hole; the one-way non-return grouting pipe comprises a grouting pipe first end and a grouting pipe second end, a one-way valve is arranged at the grouting pipe first end, and the grouting pipe first end is communicated with a grout inlet of the grouting disc through a screw thread; the water-stopping ring is located on the outer wall of the middle of the one-way non-return grouting pipe; the sealing plug is connected with the grouting pipe second end through a screw thread; the connection pipe comprises a first end and a second end; the first end of the connection pipe is connected with the grouting pipe second end are connected through a screw thread, and the second end of the connection pipe is used for being connected with grouting equipment.The water-stopping ring is additionally arranged on the middle of the grouting pipe, and the water-stopping effect of a contact face between the outer wall of the pipe and a secondary lining structure can be effectively improved.The one-way non-return suction cup is arranged at the tail end of the one-way non-return grouting pipe, repeated grouting can be achieved, and the defect that a traditional grouting system cannot achieve repeated grouting is overcome.

Owner:BCEG CIVIL ENG

Water-seal structure with expansion joint and spraying and filling construction method for forming same

ActiveCN103696396AImprove the water-stop effectIncreased durabilityMarine site engineeringElastomerEngineering

The invention discloses a water-seal structure with an expansion joint. The side wall and upper edge of the expansion joint are provided with primer layers; an elastic waterproof filling body is filled in the expansion joint, the upper edge of the expansion joint is provided with a polyurea elastomer waterproof coating. The water-seal structure is good in water-seal property and durability and strong in impact and abrasion resistance, has capability of adapting to three-dimensional deformation of the expansion joint, and is simple in construction. The invention further provides a spraying and filling construction method for forming the water-seal structure.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

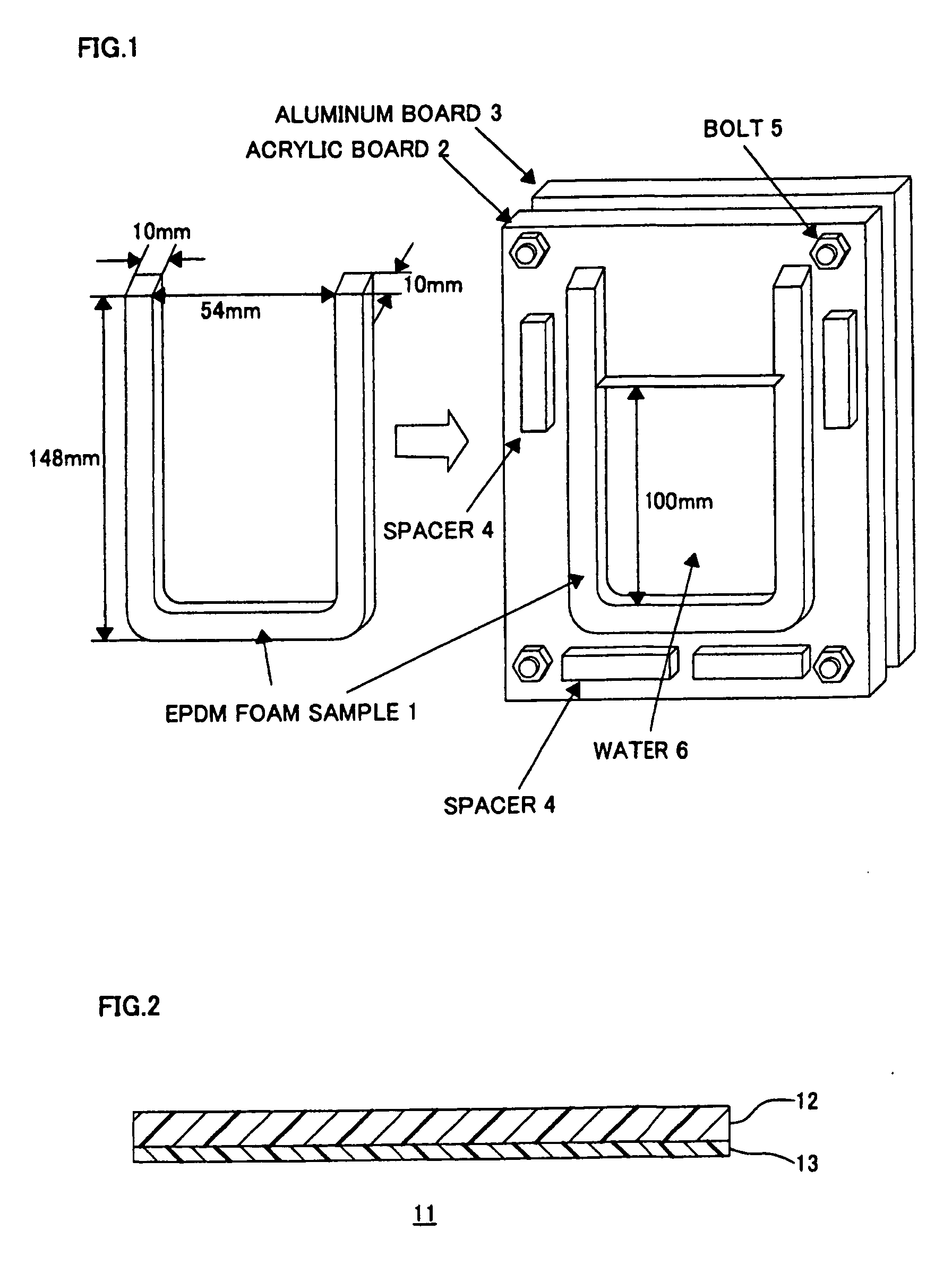

EPDM foam and adhesive sealing material

InactiveUS20120277337A1Improve the water-stop effectSame level of sealingOther chemical processesRubber derivative adhesivesMetalEPDM elastomer

Owner:NITTO DENKO CORP

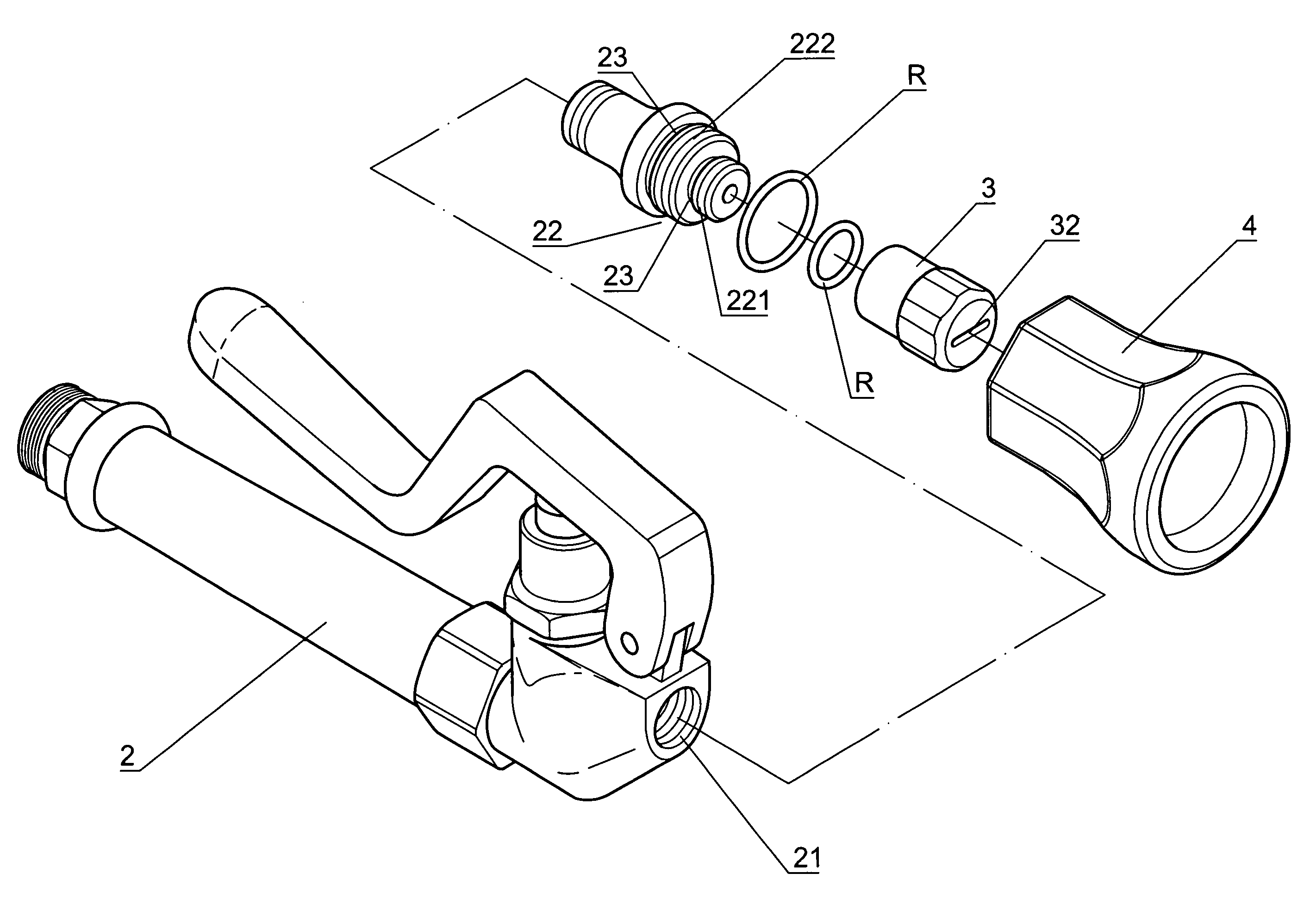

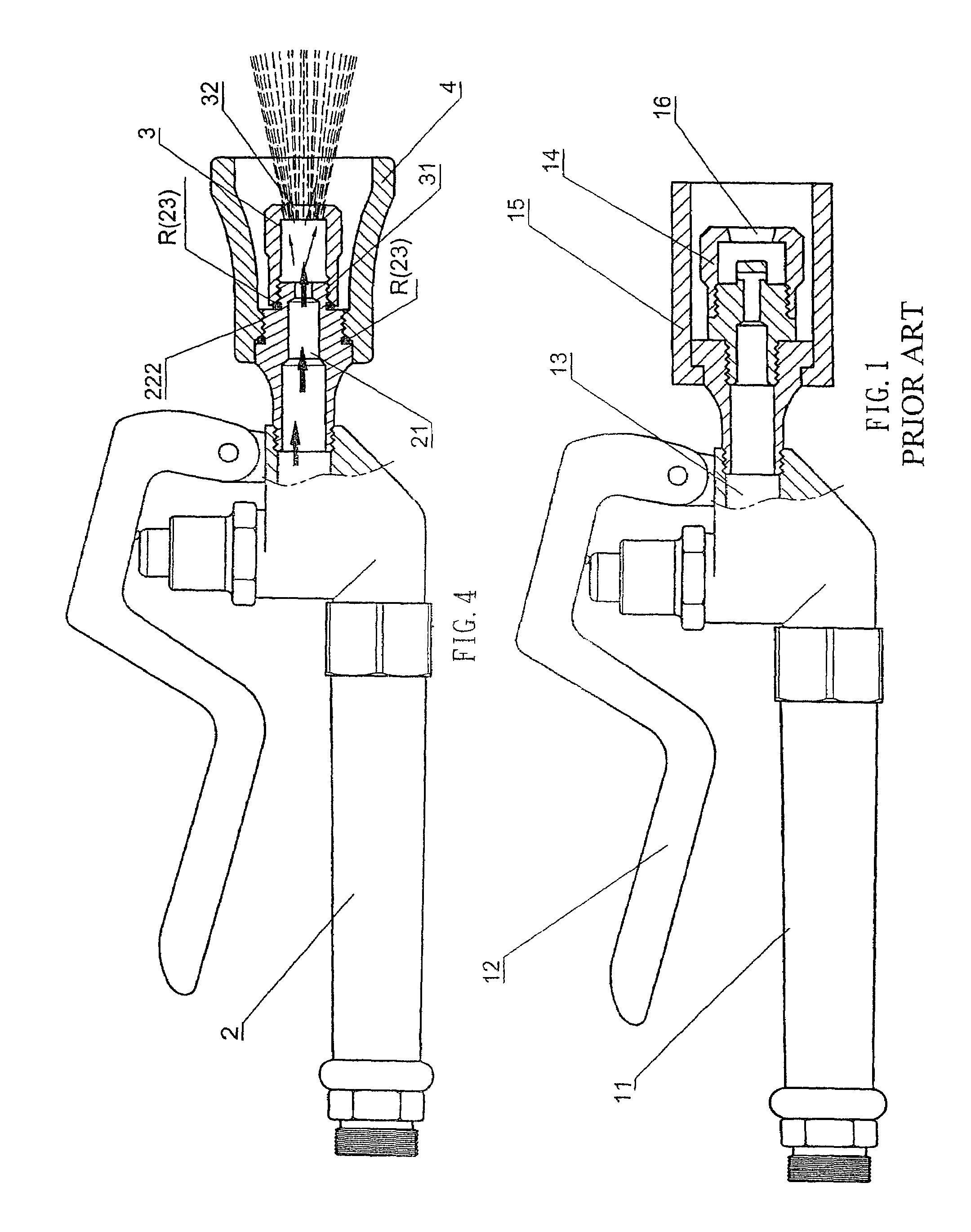

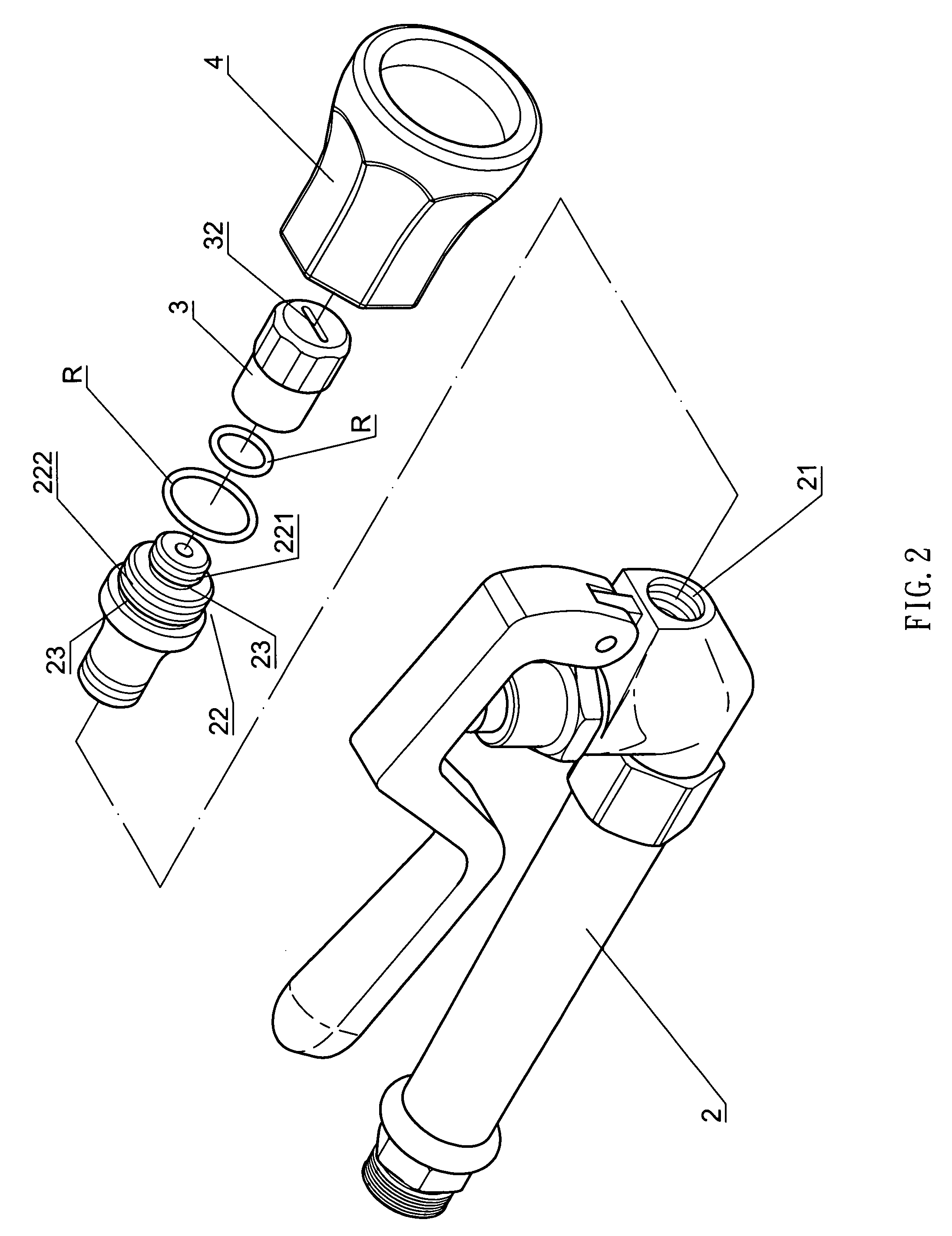

Adjustable knife-curtain outlet structure of cleanout handle

ActiveUS7516911B2Easy to disassemble and cleanConvenient to get washedSpray nozzlesLiquid spraying apparatusEngineeringScrew thread

Owner:CHUNG CHIU CHIH

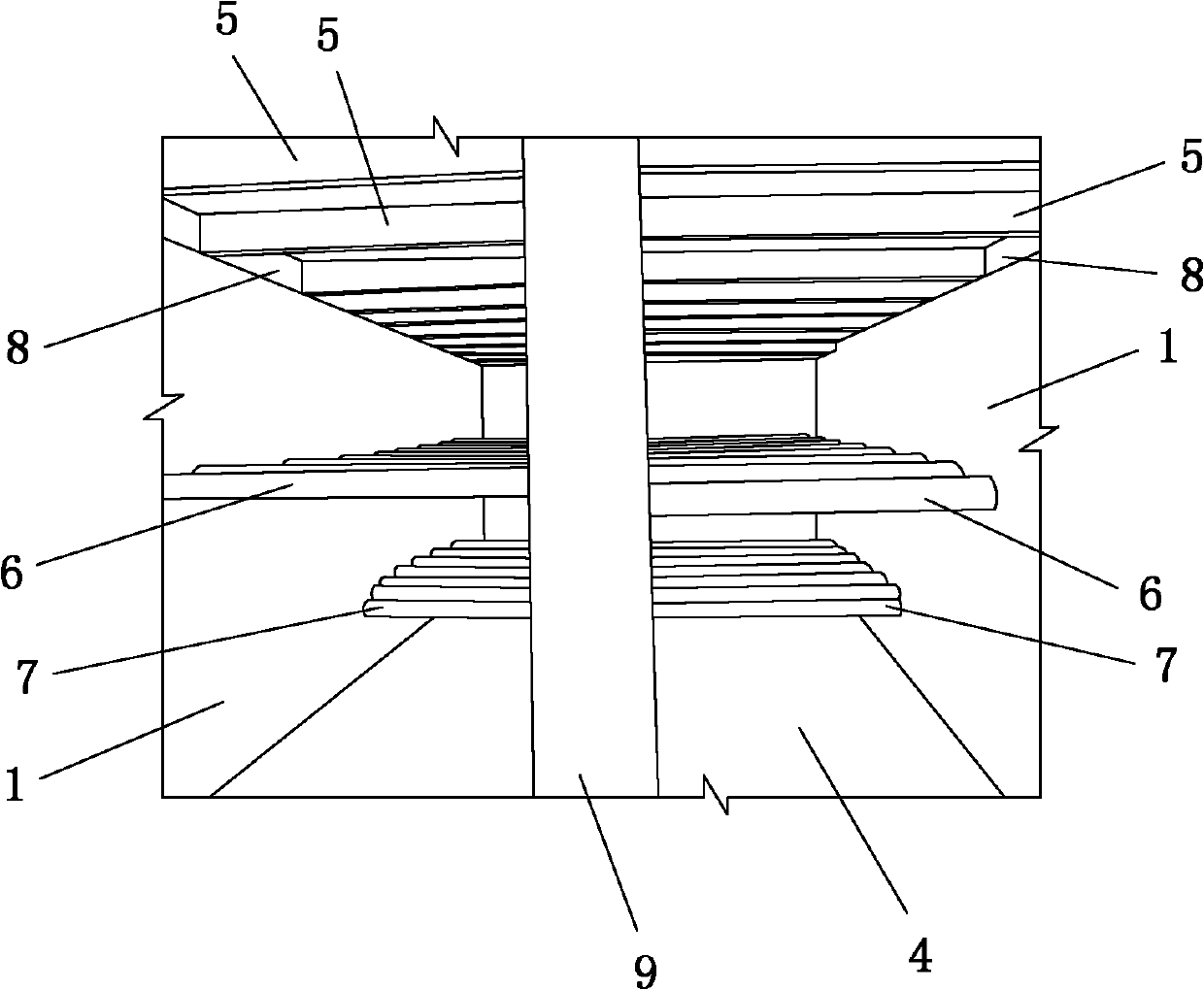

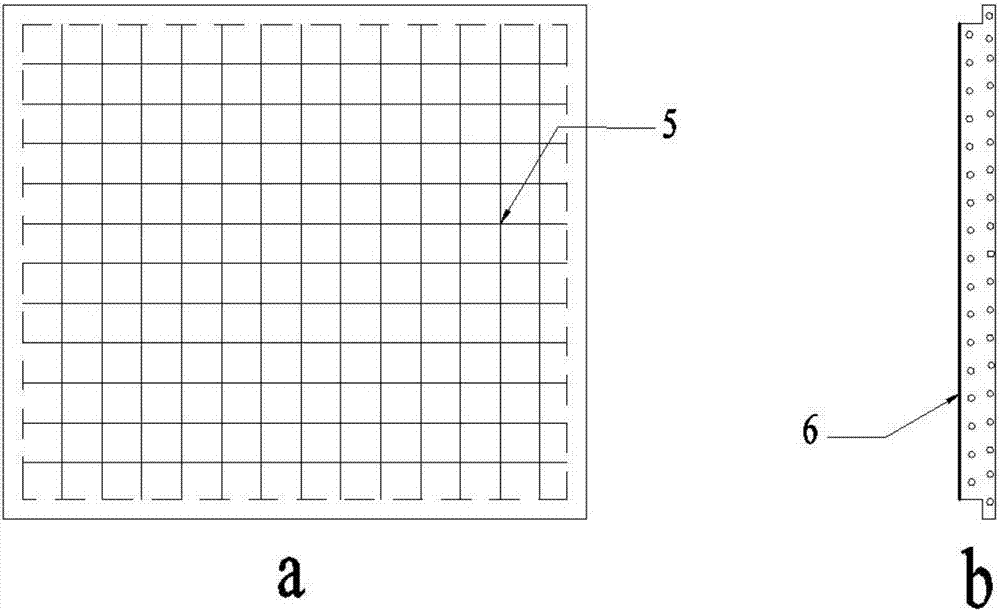

Ultra-long concrete wall body structure and method for controlling structural cracks by constructing wall body

InactiveCN104074285AReduce quantity and densityPrevent leakageArtificial islandsWallsRebarSteel plates

The invention discloses an ultra-long concrete wall body structure and a method for controlling structural cracks by constructing a wall body. The ultra-long concrete wall body structure comprises a wall body, wherein cutting steel plates (3) are arranged on a concrete inner core layer (2) arranged between two layers of steel bar nets (1) of the wall body in the length direction of the wall body at certain intervals; the continuous concrete inner core layer (2) arranged between two layers of steel bar nets (1) is cut into concrete inner core units (4) by the cutting steel plates (3); a plurality of horizontal connecting steel bars (5) in different heights are welded on each cutting steel plate (3); two ends of each connecting steel bar (5) are provided with bending sections (5.1); and the two bending sections (5.1) of each connecting steel bar (5) are respectively welded with horizontal steel bars (1.1) of the two layers of steel bar nets (1). The method comprises the key step that the cutting steel plates (3) are arranged in the length direction of the wall body at certain intervals. The structure and the method disclosed by the invention have the advantages that the effective control can be realized on the structural cracks, and harmful cracks can be eliminated.

Owner:浙江省二建建设集团有限公司

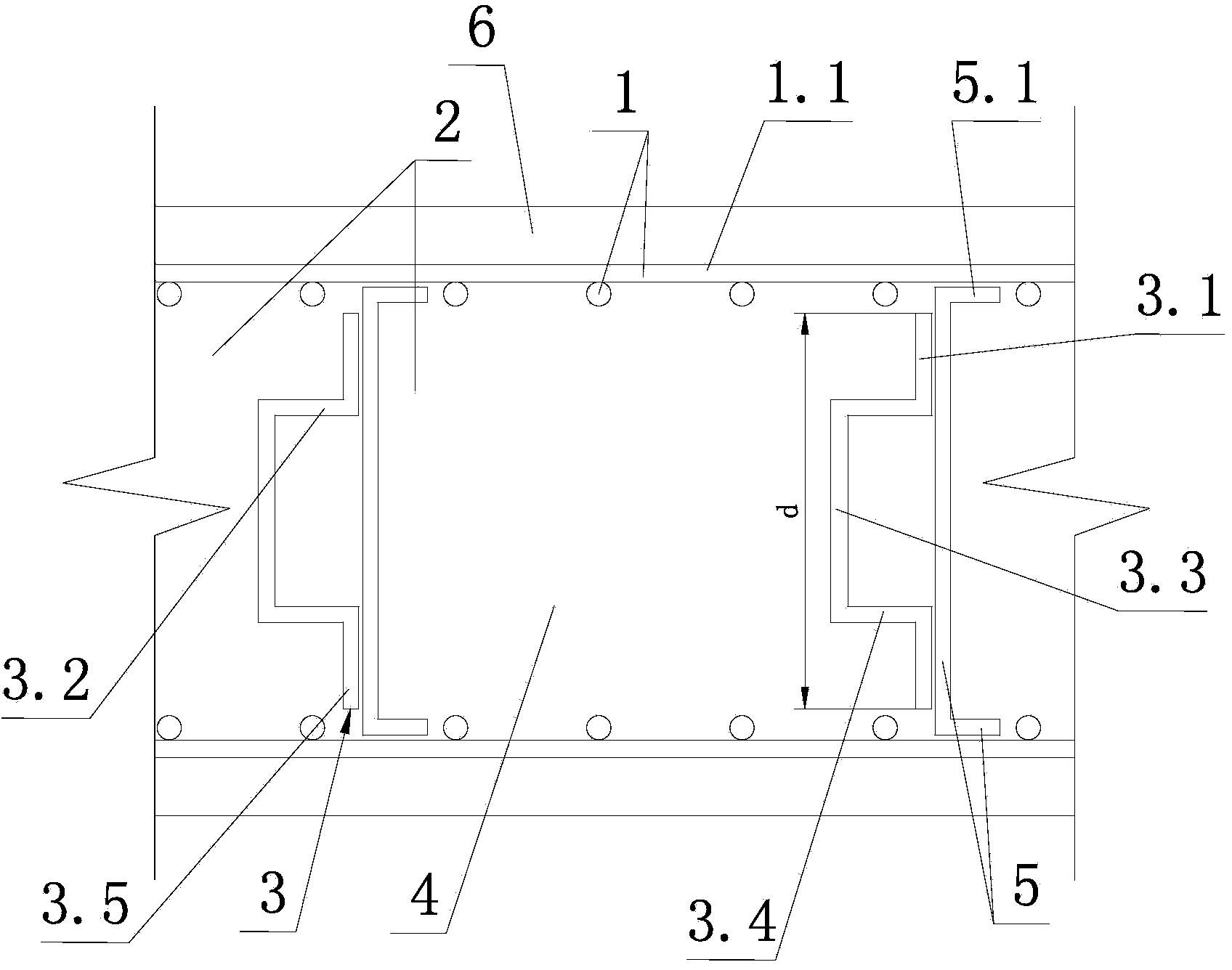

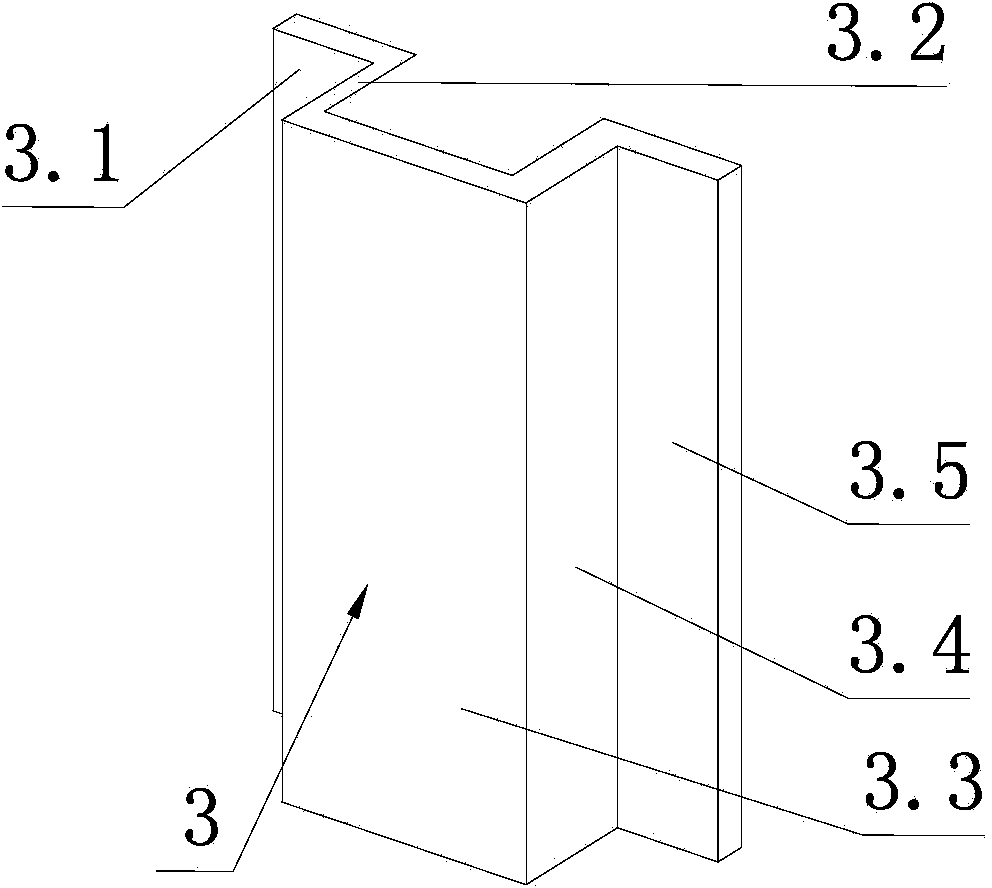

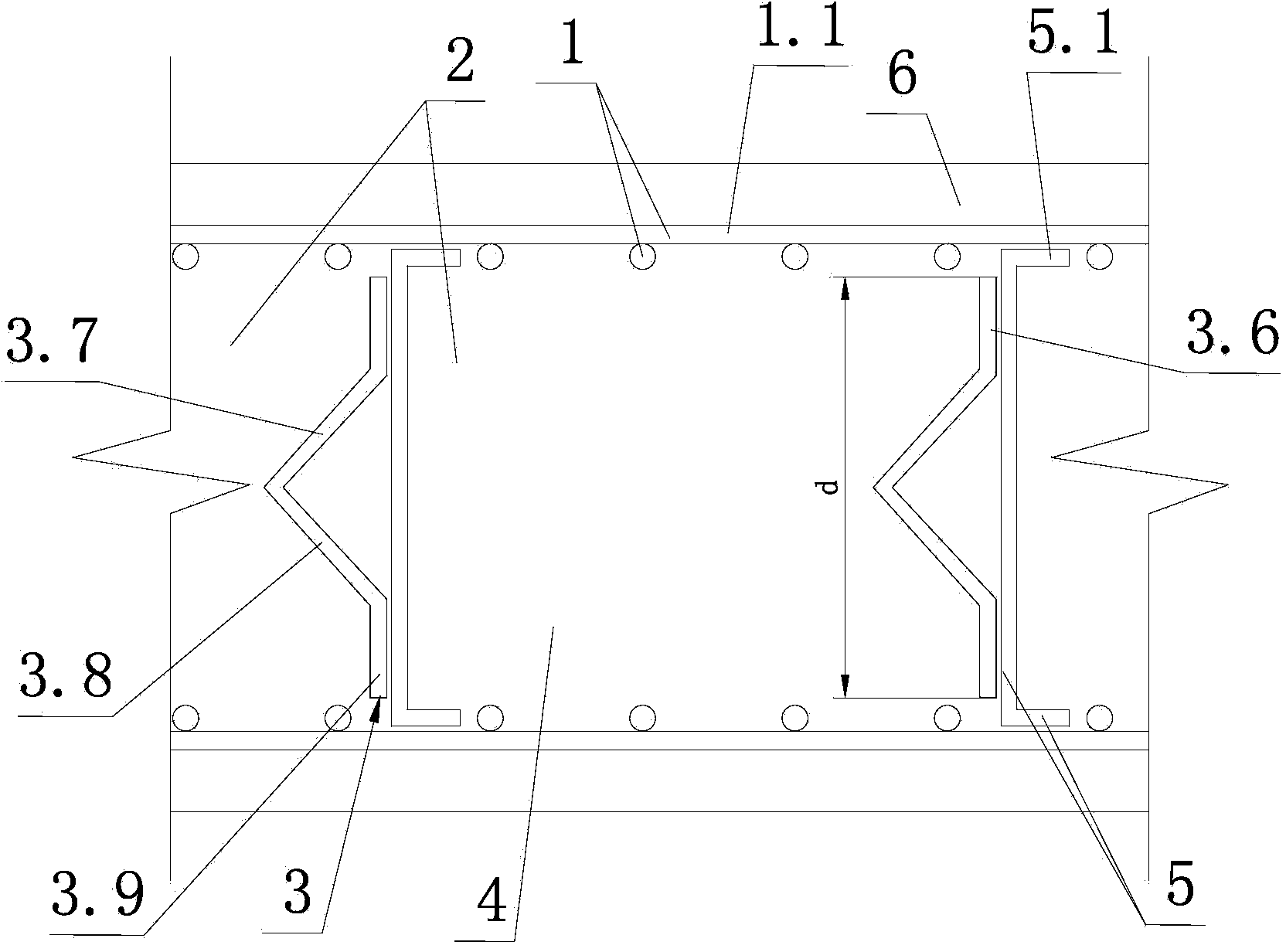

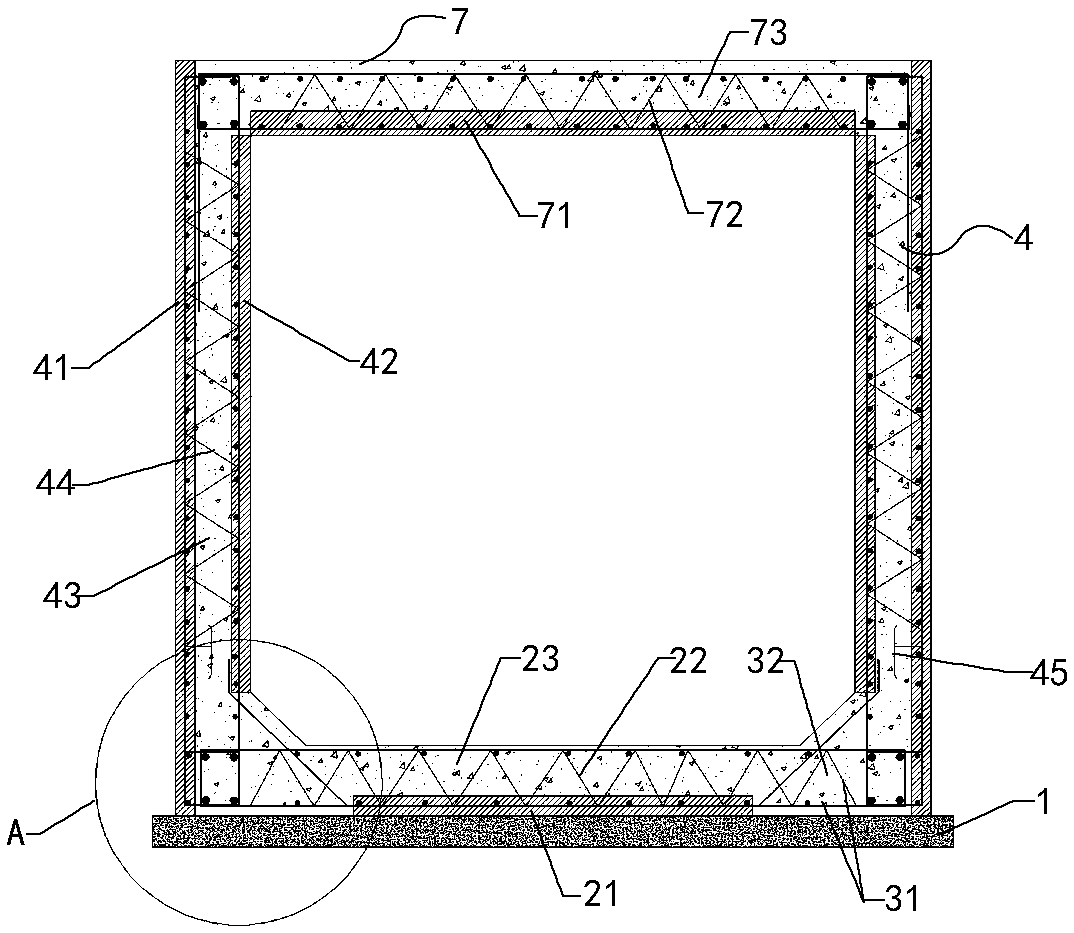

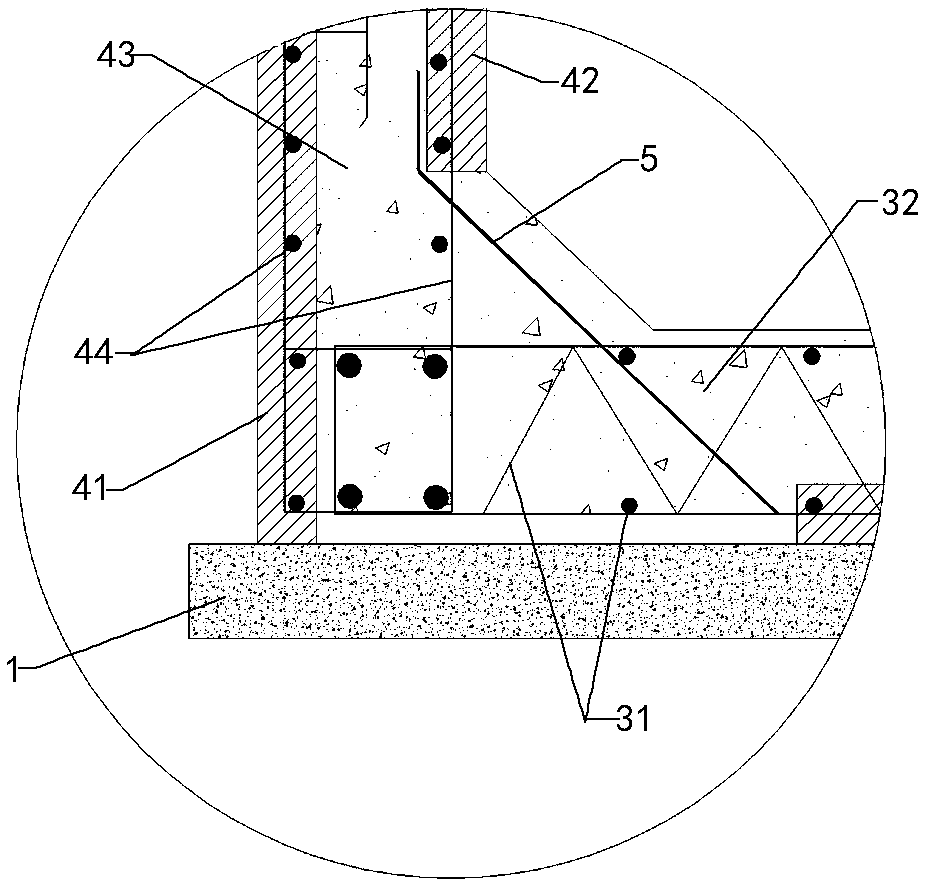

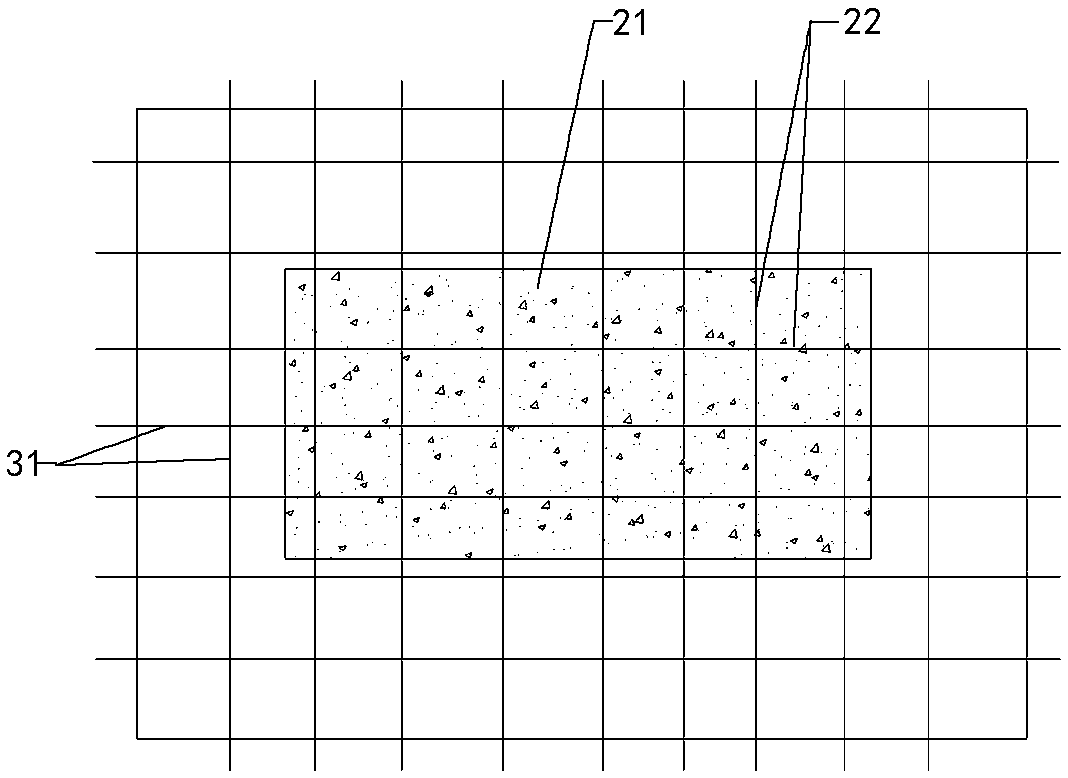

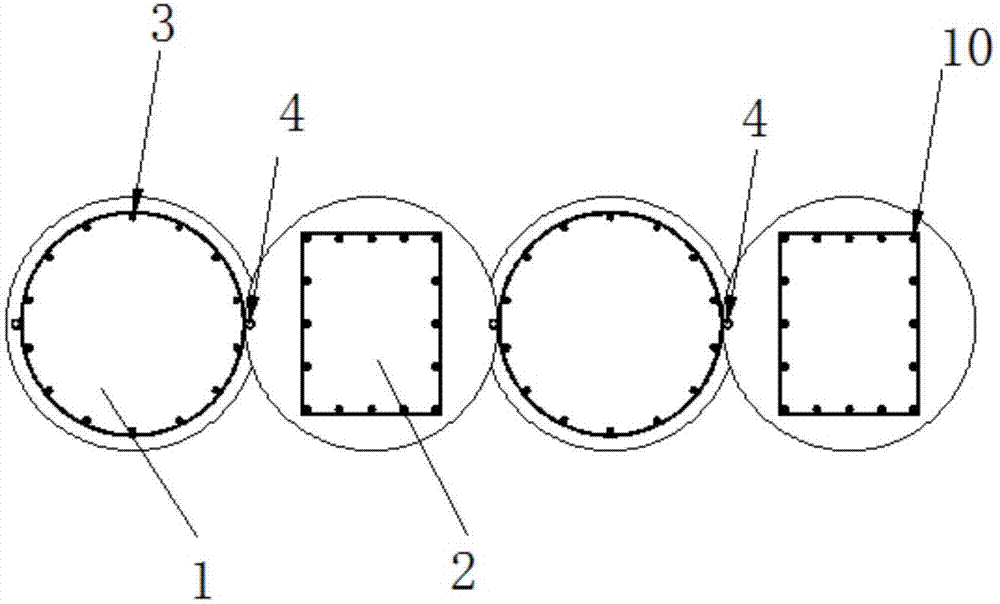

Integrated assembly type pipe gallery based on composite bottom plate and construction method thereof

PendingCN108797638AReduce flatness requirementsAvoid displacementArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention discloses an integrated assembly type pipe gallery based on a composite bottom plate and a construction method thereof. Each unit plate block in the composite bottom plate of the integrated assembly type pipe gallery comprises a laminated portion and a cast-in-place portion which is located on the periphery of the laminated portion, wherein each laminated portion comprises a prefabricated bottom plate which is fixedly connected with a foundation cushion layer, a bottom plate truss and a bottom plate cast-in-place layer, and the peripheral edges of each bottom plate truss horizontally outwards extends to form a steel bar framework of the corresponding cast-in-place portion; a double-layer laminated wallboard comprises an outer prefabricated plate which is located on a water attaining face, an inner prefabricated plate which is located on a water opposite face and a cast-in-place sandwich layer which is located between the outer prefabricated plate and the inner prefabricated plate, the outer prefabricated plates and the inner prefabricated plates are connected through wall truss steel bars, and the bottoms of the wall truss steel bars are connected with the margins ofside edges of the steel bar frameworks of the cast-in-place portions of the composite bottom plate; and the lower end surface of the outer prefabricated plate is tightly attached to the upper surfaceof the foundation cushion layer, and a top plate cast-in-place layer of a laminated top plate and the cast-in-place sandwich layer of the double-layer laminated wallboard are integrally casted. According to the integrated assembly type pipe gallery and the construction method, the construction is convenient, fast and efficient, the construction cost is low, the waterproof effect is good, and the overall performance of the pipe gallery is high.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

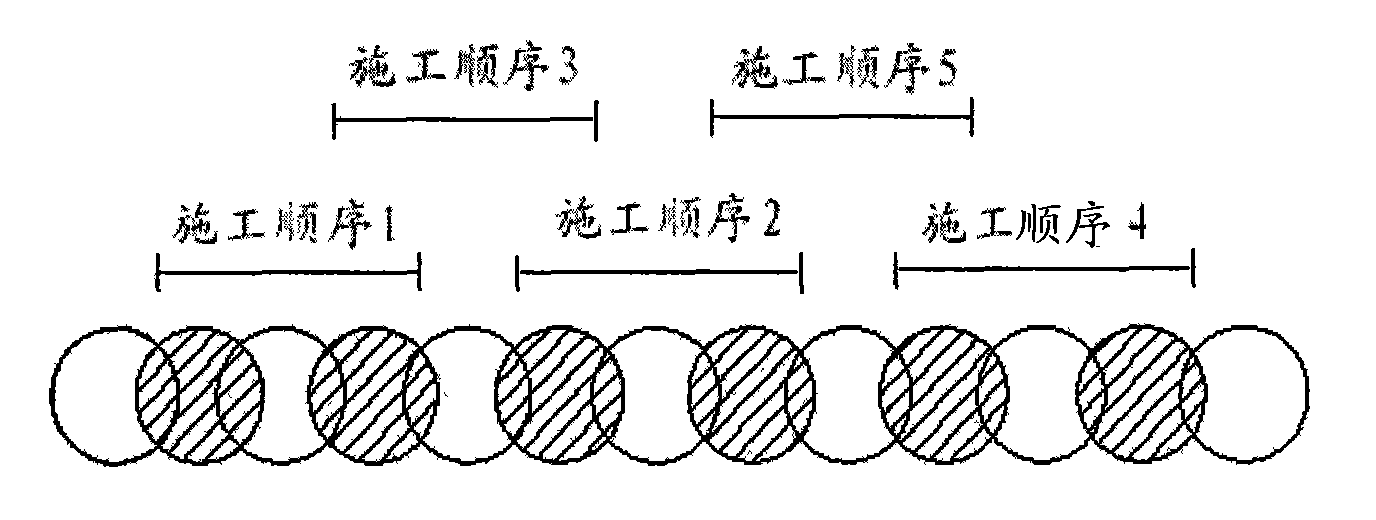

Support row pile construction method for closing and water stop of deep foundation pits

ActiveCN107460882AGuaranteed water stop effectImprove the water-stop effectDrill bitsExcavationsEngineeringWater level

The invention innovatively provides a support row pile construction method for closing and water stop of deep foundation pits. The support row pile construction method is characterized in that positioning and paying off are performed at a support pile site according to designed positions so as to make pile position marks; then a row pile guide wall is constructed; I-sequence pile hole construction and pouring are performed; then drilling construction is performed at II-sequence pile hole positions between every two adjacent I-sequence pile holes; when II-sequence pile hole construction is performed, a drilling component of which the outer side is provided with a wire brush is adopted, and concrete is used for pouring; and then grouting pipes on two sides of I-sequence pile steel reinforcement cages are grouted, so that clearances among the adjacent piles are sealed. The support row pile construction method is applicable to working conditions of foundation pit support row piles that the level of underground water is higher than an excavation surface; the adjacent piles are lap-jointed, and water stop and soil retaining support are performed by utilizing the own concrete of pile bodies; grouting closing is performed among the piles by adopting a grouting technique, so that the clearances among the piles are sealed closely, and the water stop effect is ensured; a water stop curtain does not need to be arranged separately, so that construction cost is lowered; the construction period is obviously shortened; and the water stop effect of the foundation pit support row piles is improved.

Owner:MCC TIANGONG GROUP

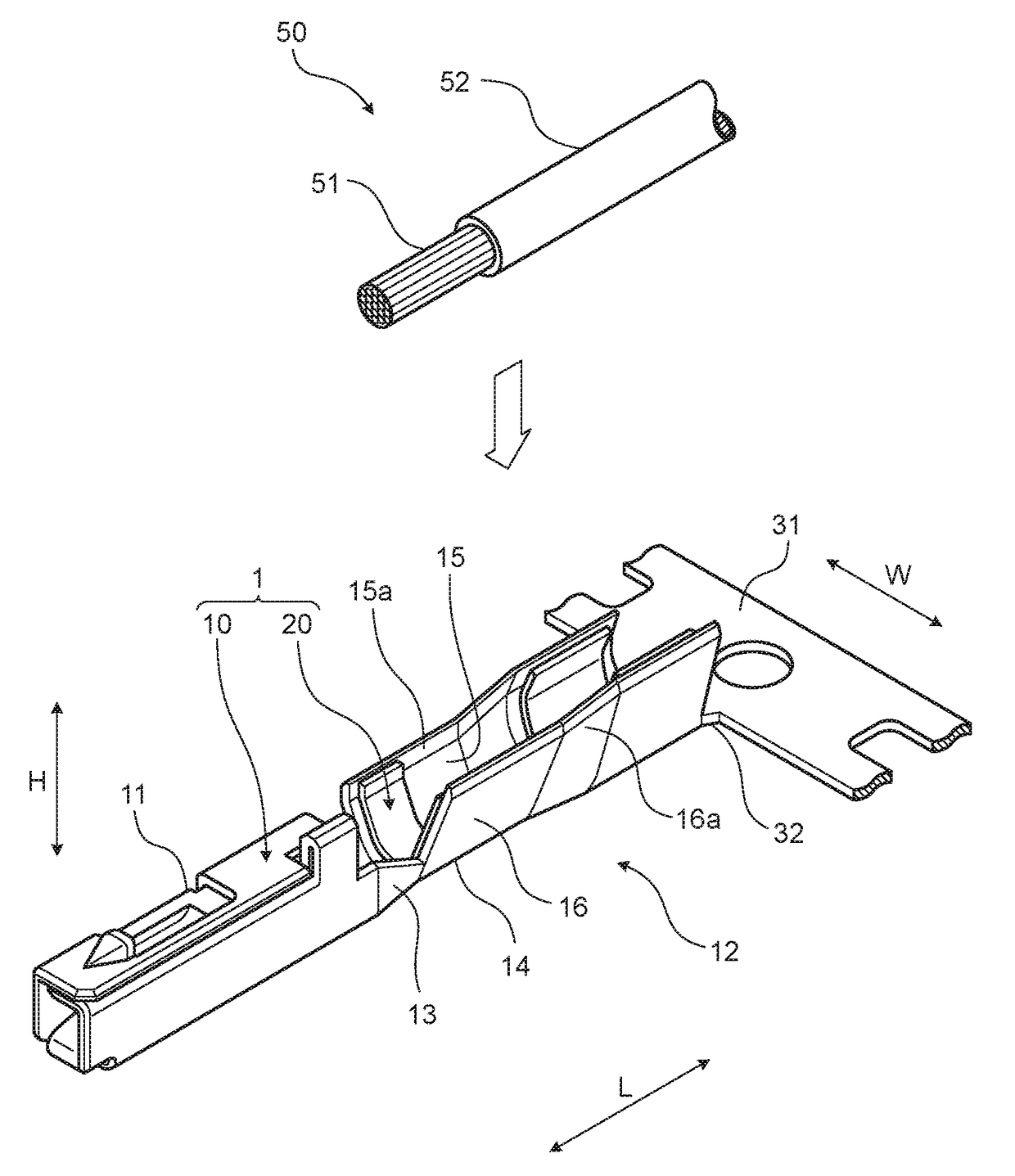

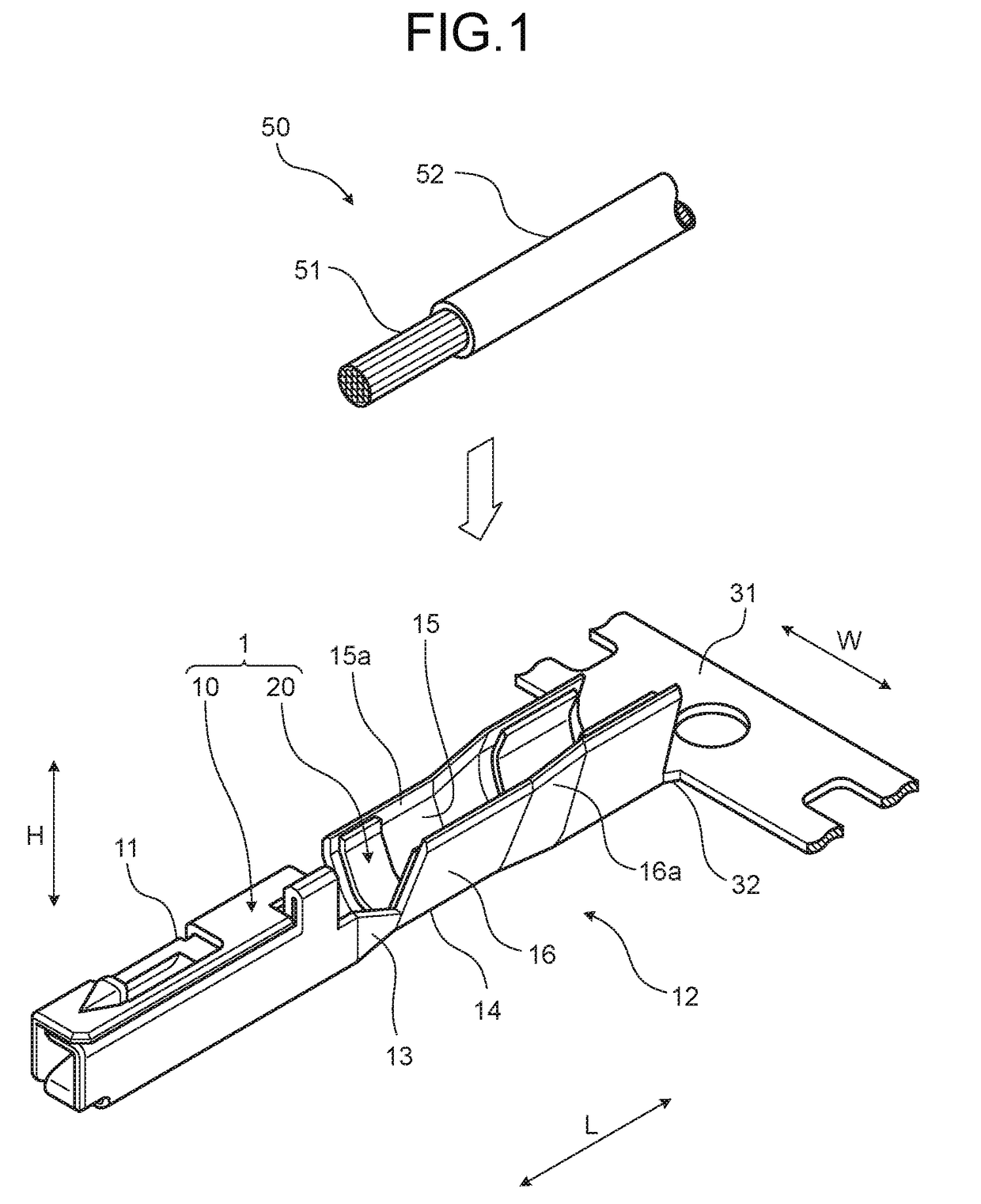

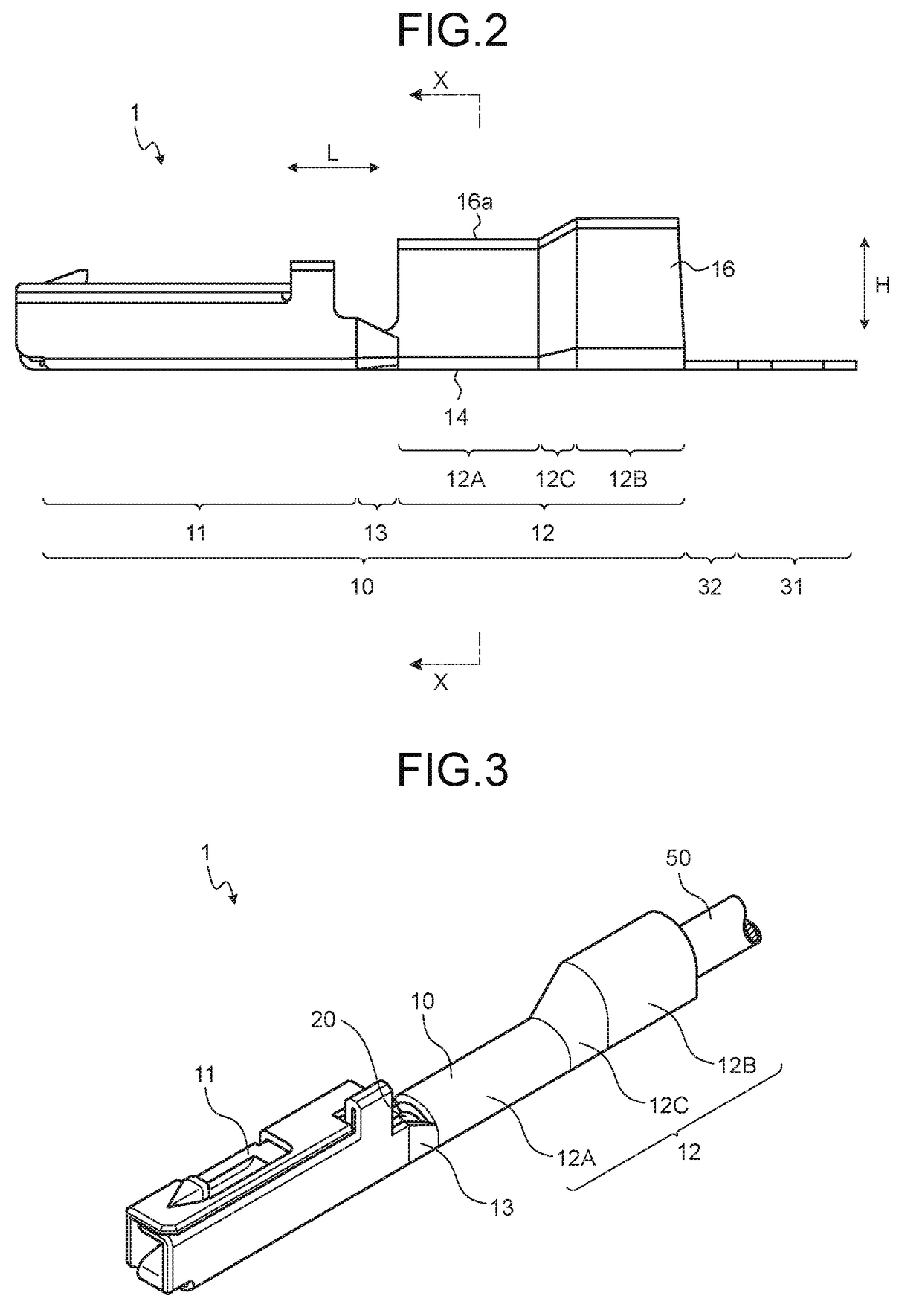

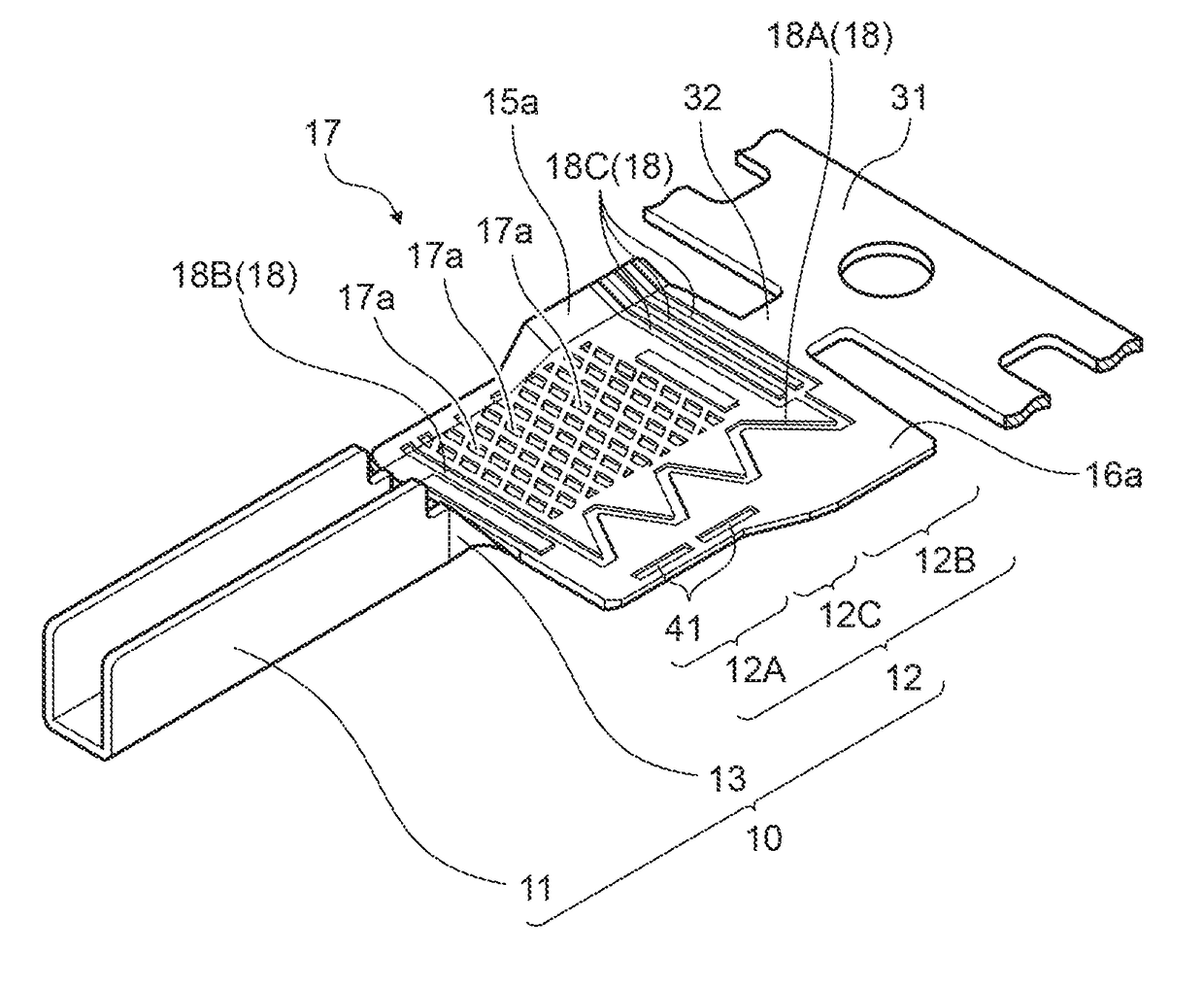

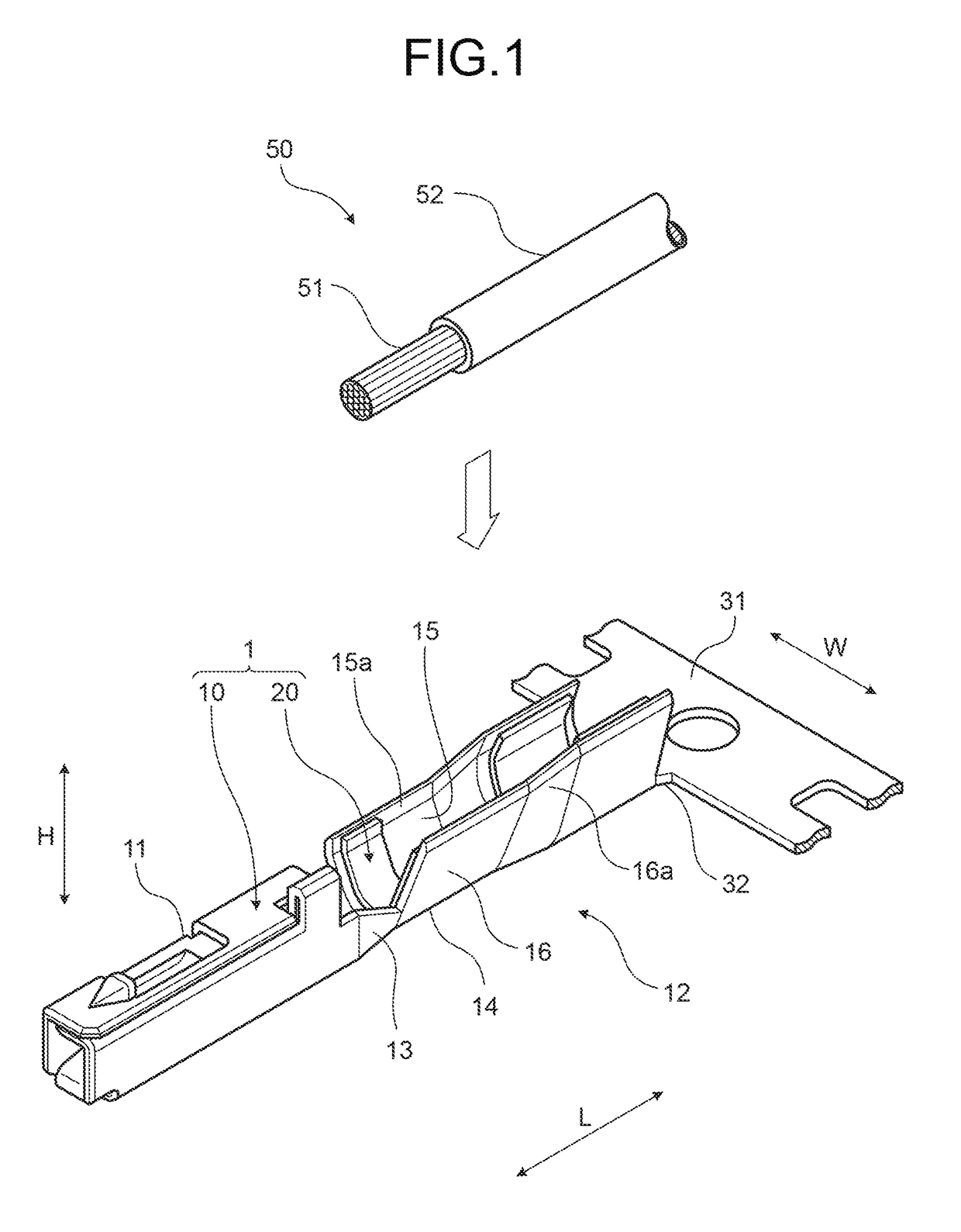

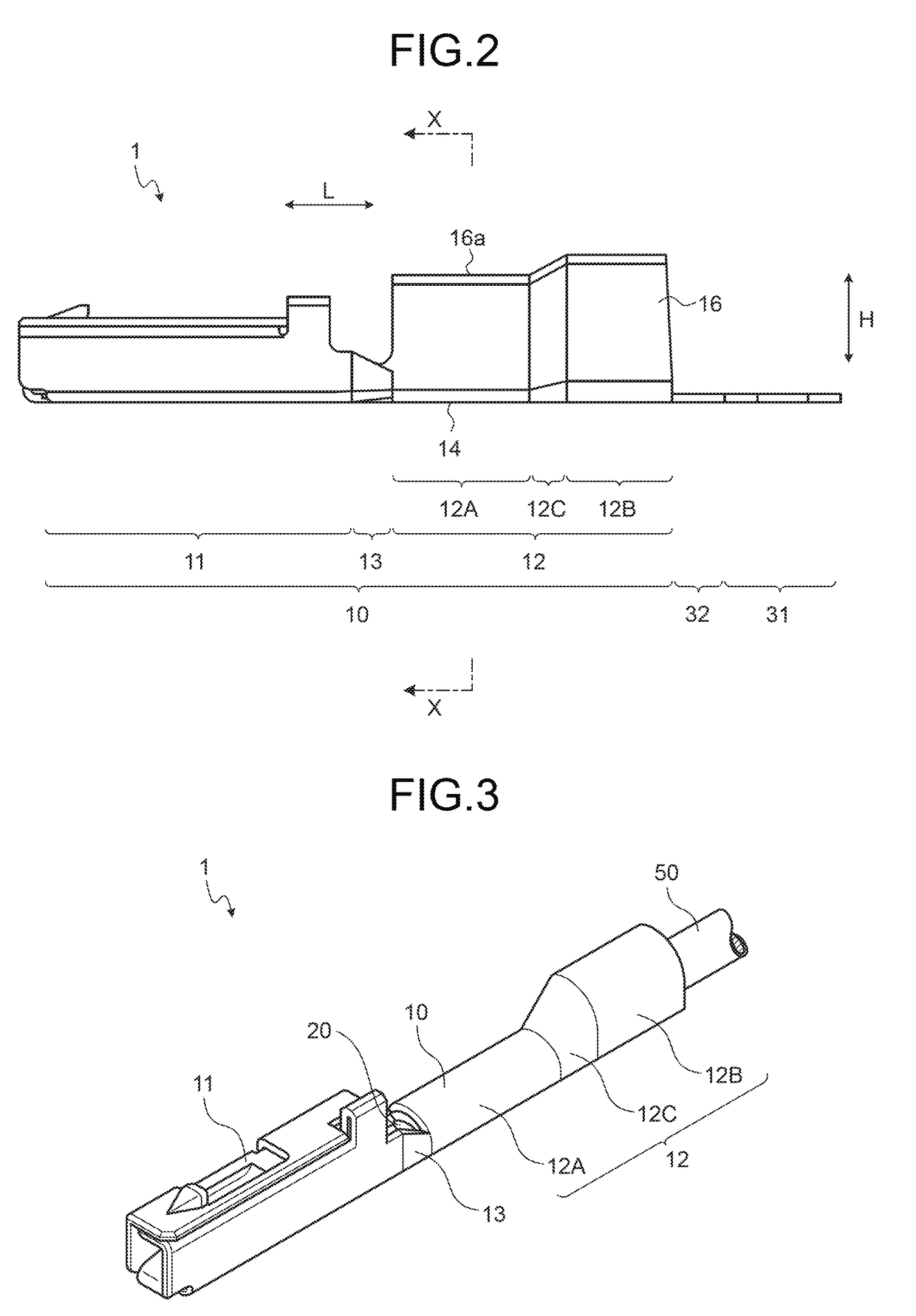

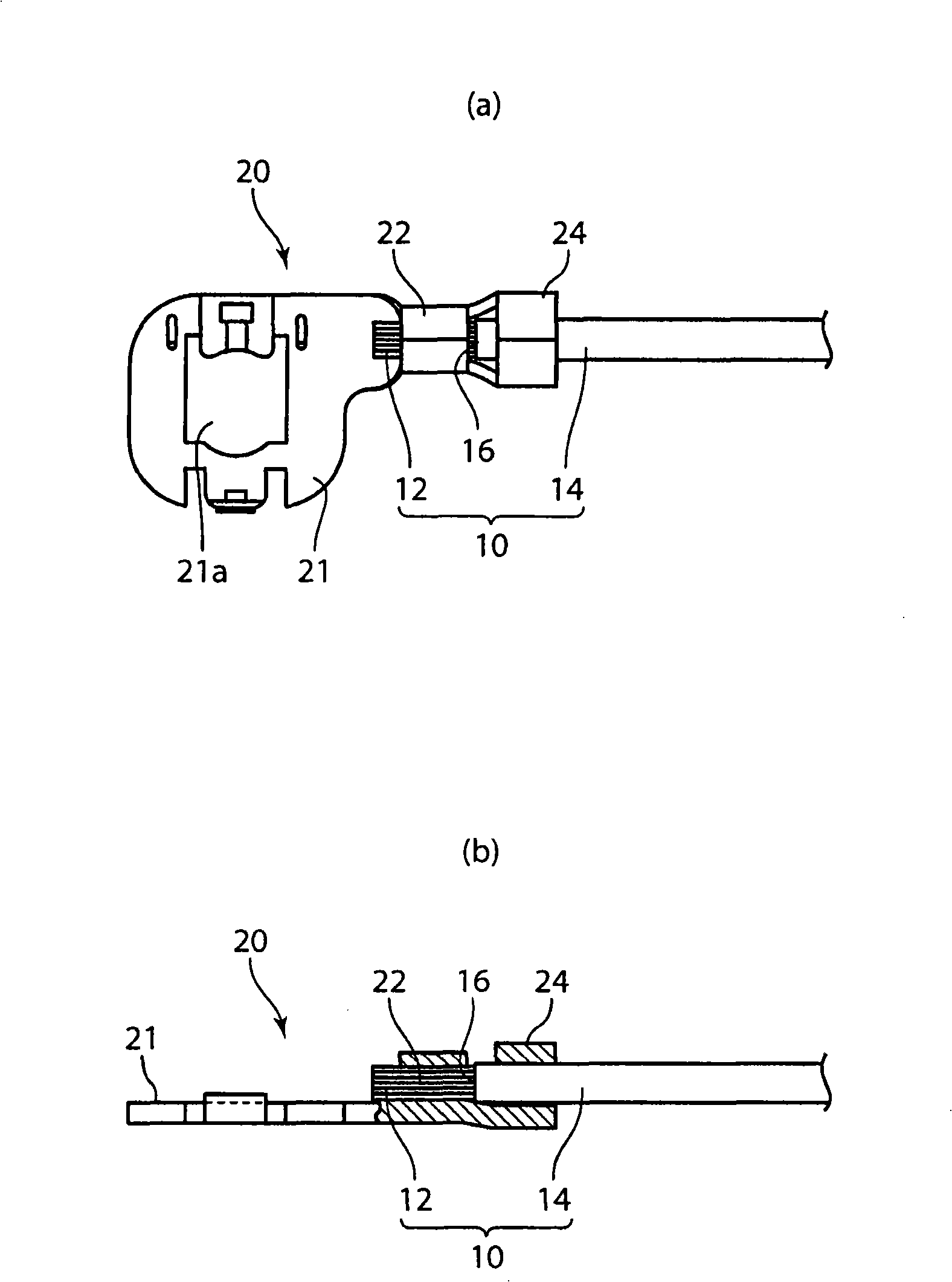

Crimp terminal

ActiveUS20170179618A1Improve the water-stop effectLine/current collector detailsCoupling contact membersEngineeringElectric wire

A water stop member of a crimp terminal is affixed to the inner wall surface of an electric wire connecting portion of a terminal fitting before crimping and forms into a first water stop area, a second water stop area, and a third water stop area after the crimping. The first water stop area suppresses entering of water from a space between the outer wall surface of a first barrel piece and the inner wall surface of a second barrel piece in the electric wire connecting portion. The second water stop area suppresses entering of water from the side closer to a terminal connecting portion of the terminal fitting than the distal end position of a core wire. The third water stop area suppresses entering of water from a space between the inner wall surface of a cover crimping portion of the electric wire connecting portion and a cover.

Owner:YAZAKI CORP +1

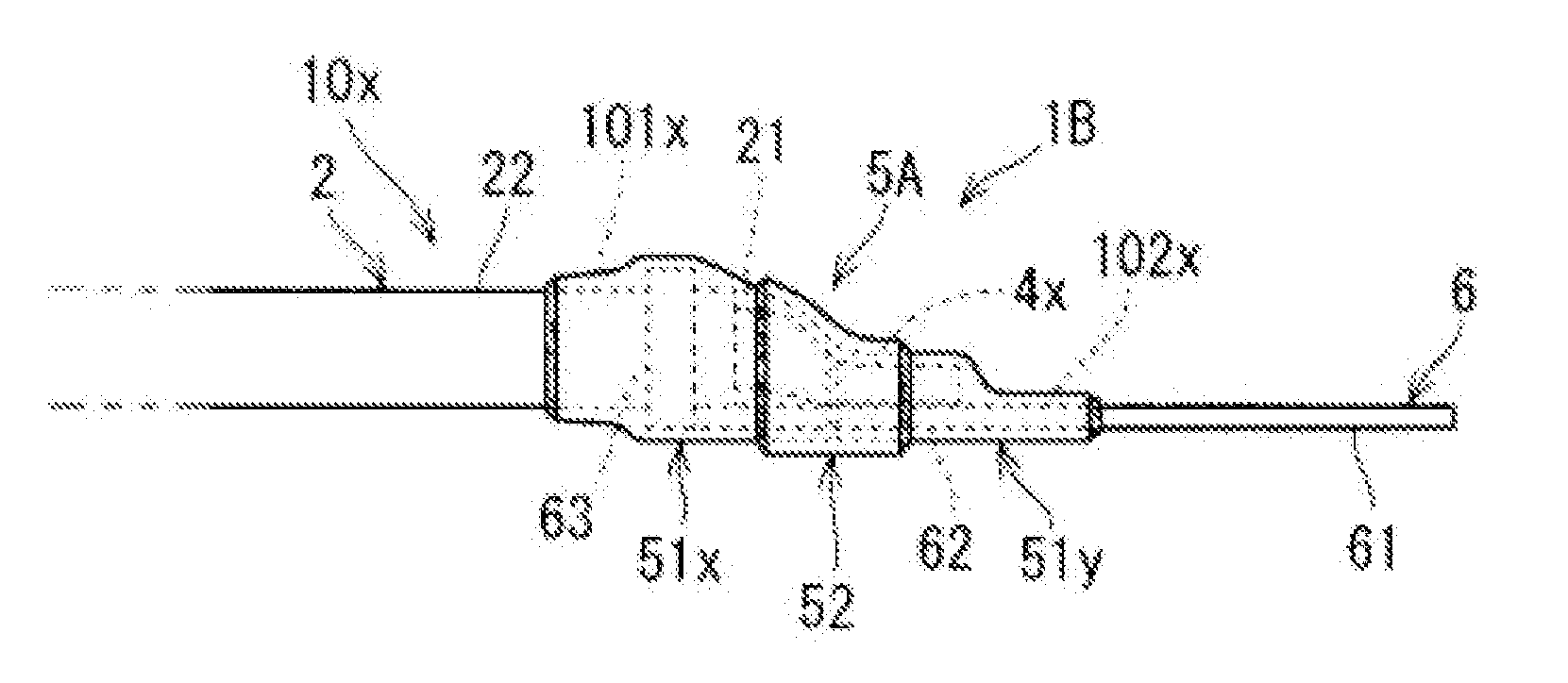

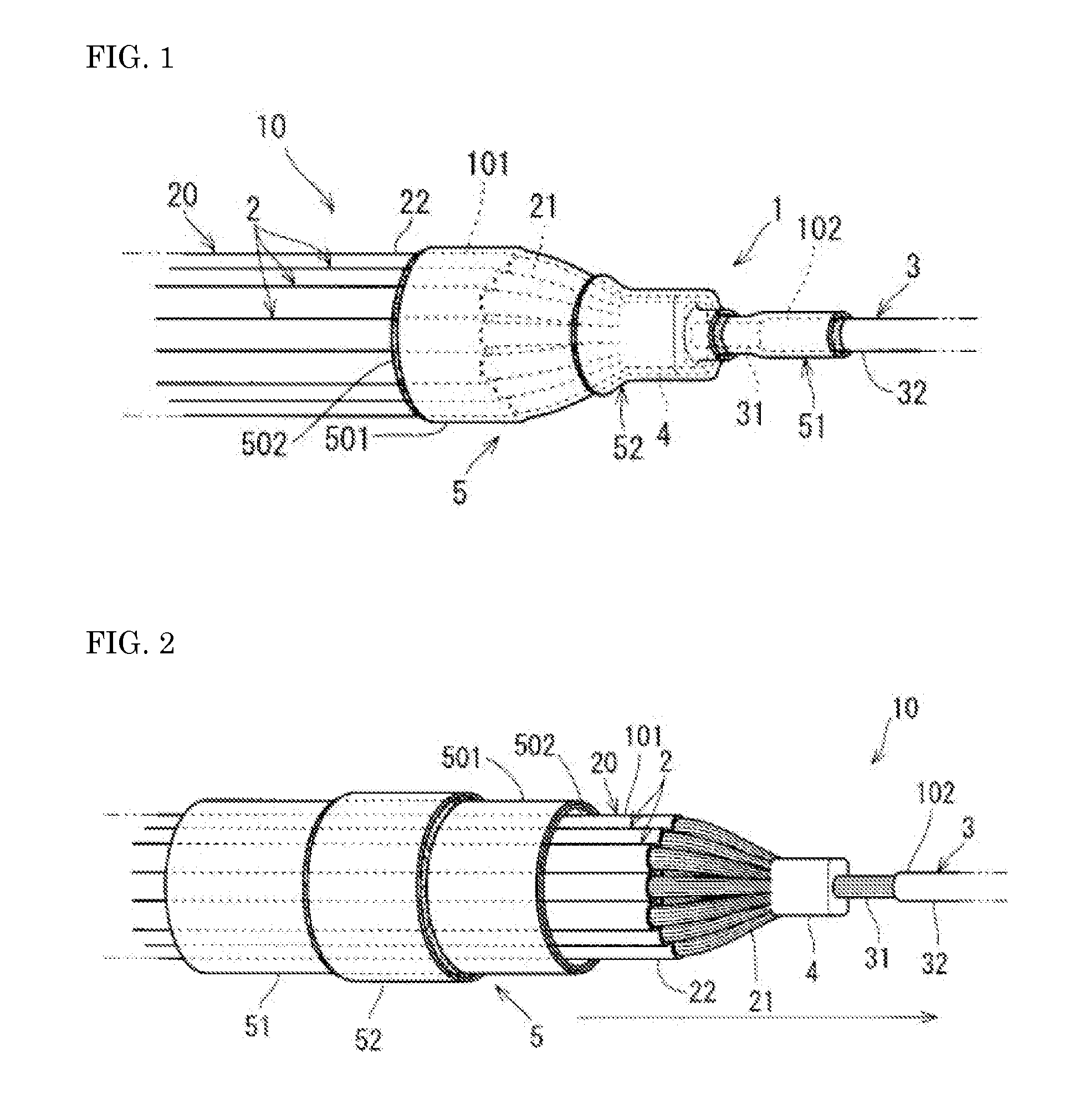

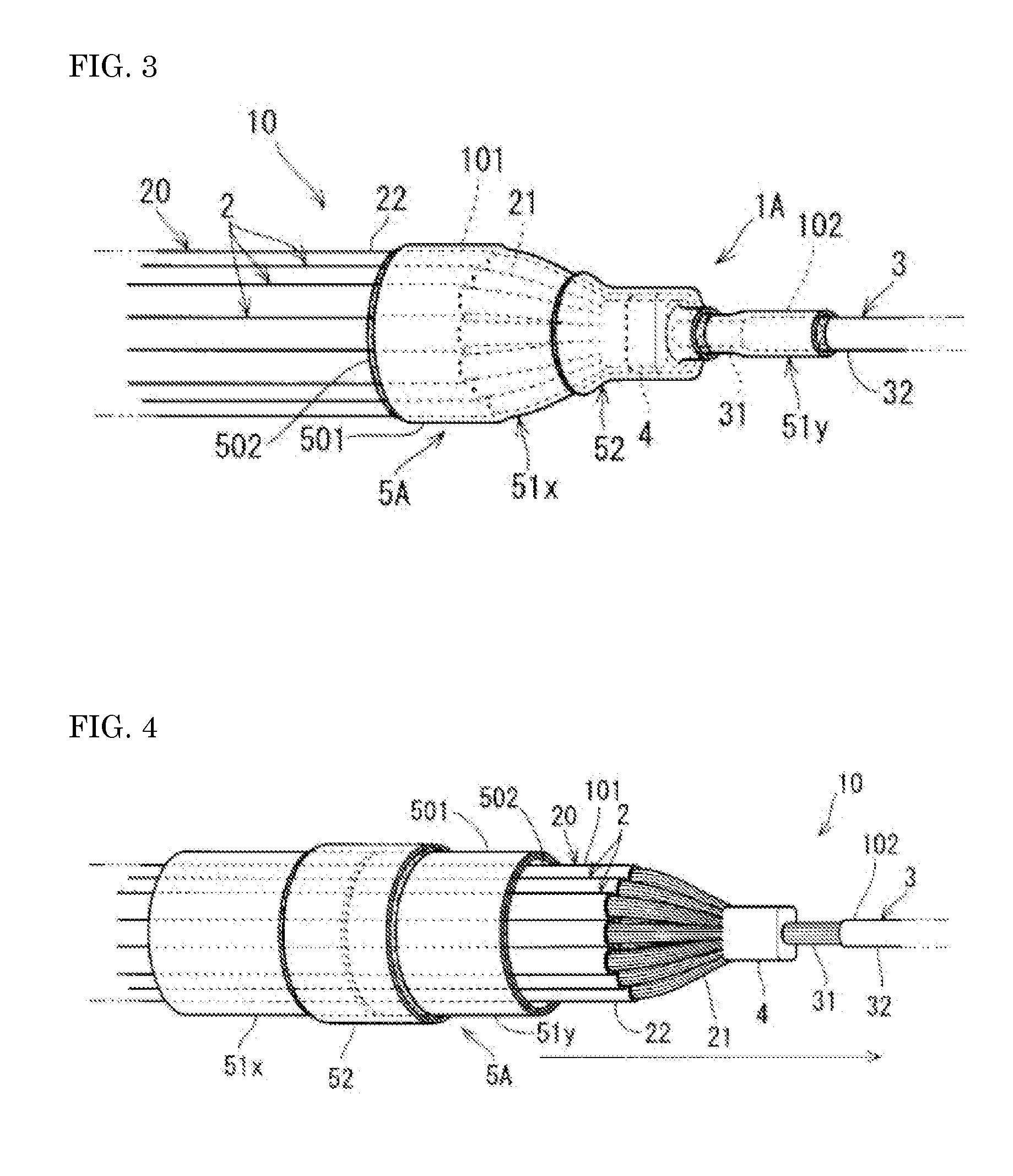

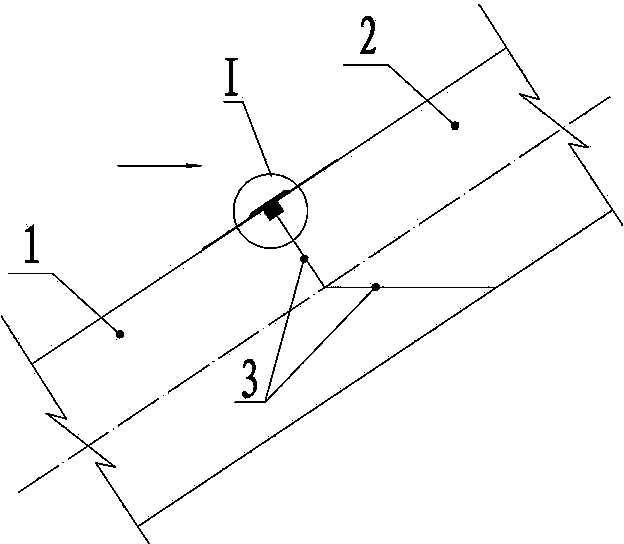

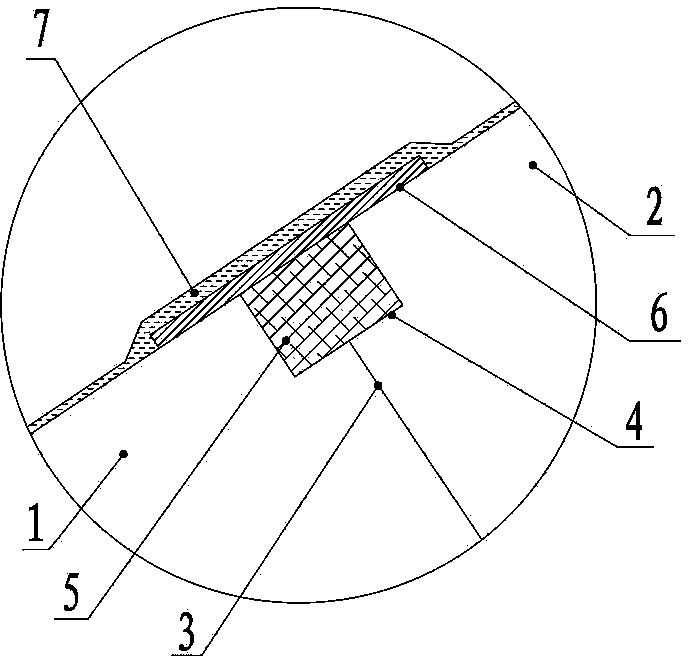

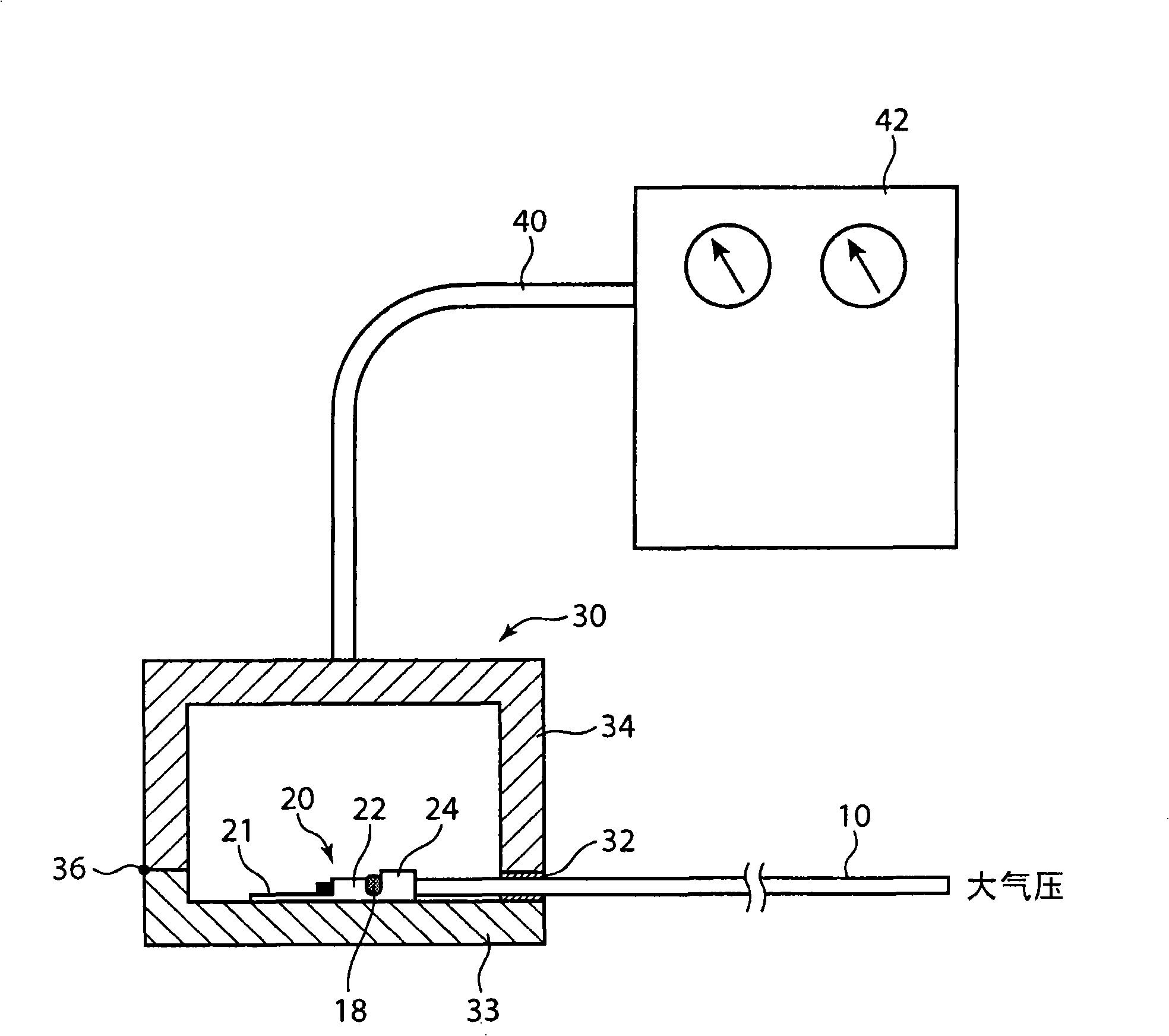

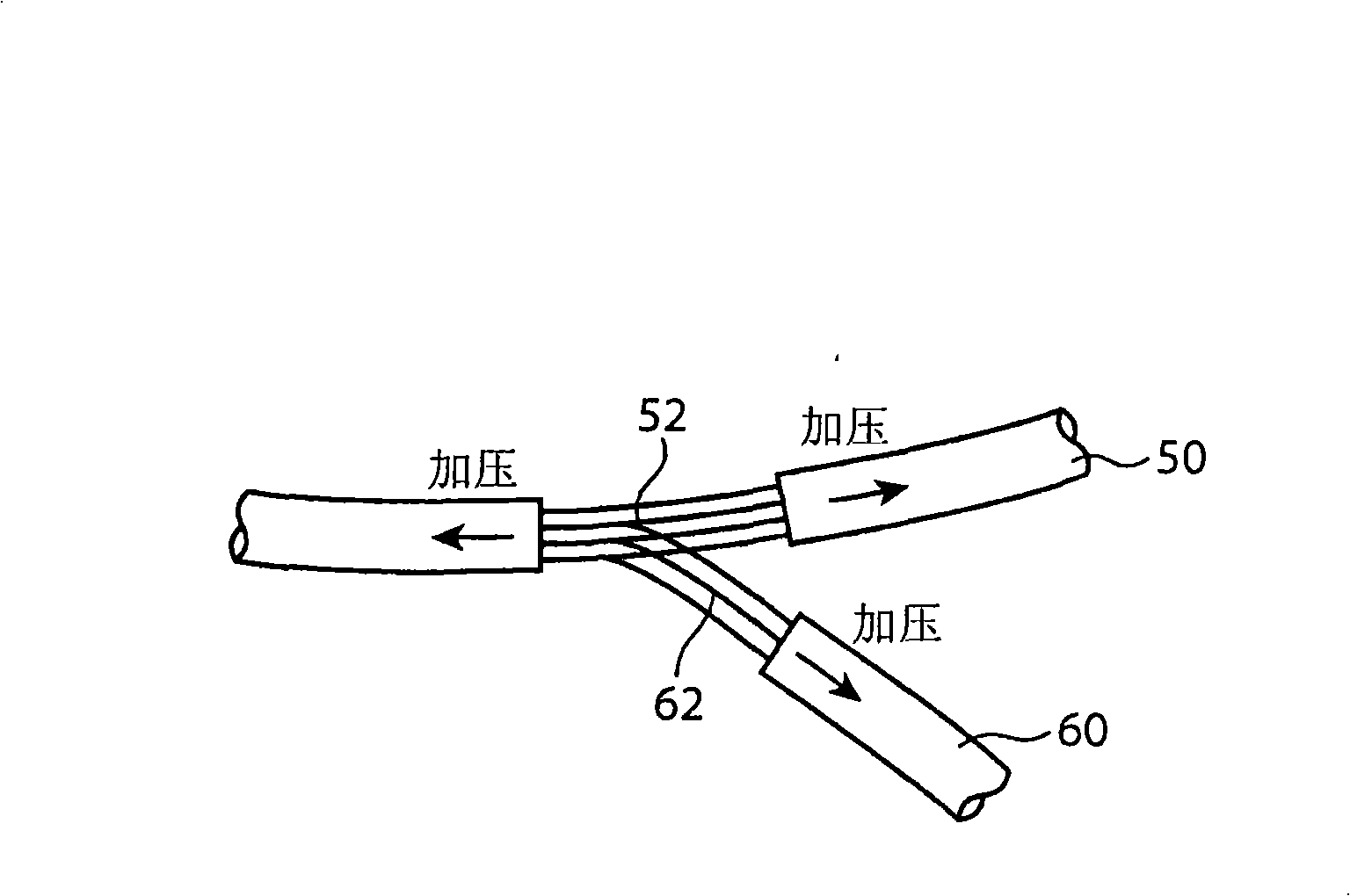

Water-stop structure for wire harness

InactiveUS20150122544A1Improve the water-stop effectEasy to fallClimate change adaptationInsulated cablesEngineeringMechanical engineering

A water-stop structure including a water-stop tube is provided in which the water-stop tube can be brought into intimate contact with a water-stop region in a wire harness having a steep thickness gradient and thus water-stop performance is improved. The wire harness includes a first portion and a second portion that is thinner than the first portion. An inner water-stop tube covers the water-stop region ranging from the first portion to the second portion in a state where the inner water-stop tube is heated and shrunk. An outer water-stop tube covers the inner water-stop tube at a position between a portion on the first portion side and a portion on the second portion side in the water-stop region in a state where the outer water-stop tube is heated and shrunk.

Owner:SUMITOMO WIRING SYST LTD

Crimp terminal and terminal crimping device

ActiveUS20170179615A1Reduce gapIncrease the gapCouplings bases/casesConnections effected by permanent deformationElectrical and Electronics engineeringSliding contact

A terminal fitting includes a terminal connecting portion and an electric wire connecting portion. A water stop member is affixed to an inner wall surface of the electric wire connecting portion before crimping process and suppresses entering of water between the electric wire connecting portion and a core wire of the electric wire after the crimping. The electric wire connecting portion is formed into a U-shape by raising the first barrel piece and the second barrel piece from both ends of the bottom. The distal end of the first barrel piece is bent toward the second barrel piece, to form a gap between a slide contact surface on a descending second die and the distal end of the first barrel piece.

Owner:YAZAKI CORP +1

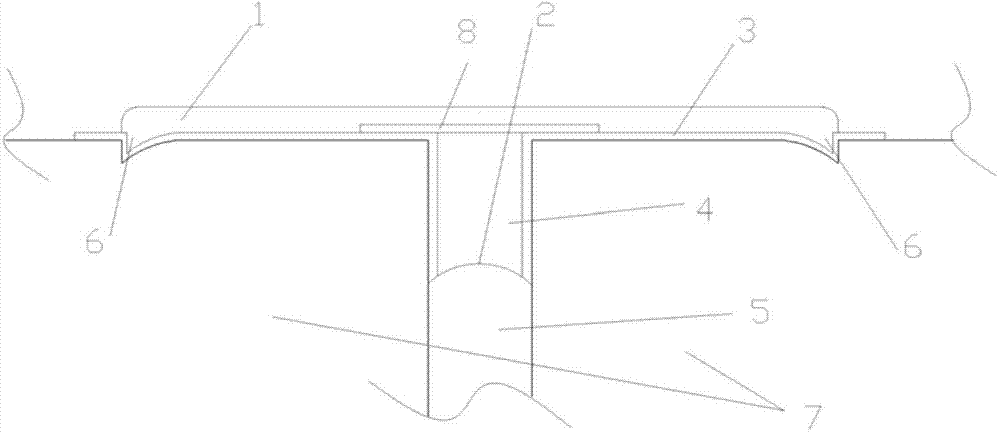

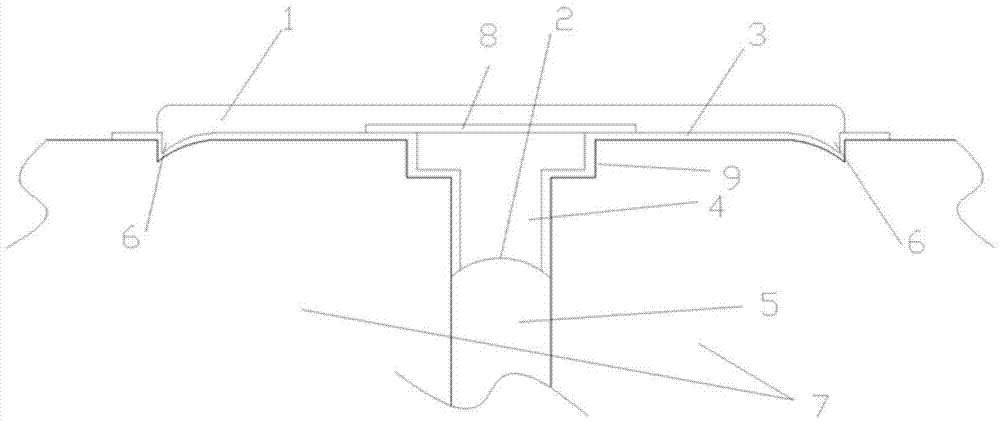

Water stopping construction method for horizontal seam of face rock-fill dam panel

The invention discloses a water stopping construction method for a horizontal seam of a face rock-fill dam panel. The water stopping construction method comprises the following steps: firstly, setting connection seams of first-stage and second-stage concrete panels into the crease line styles; secondly, forming grooves in seam closures of the connection seams on the water attaining surfaces of the first-stage and second-stage concrete panels, perpendicular to the face rock-fill dam inclination and carrying out construction and scabbling treatment; thirdly, filling a polysulfide sealant water stopping filler into the grooves; fourthly, water stop plates of which the width is larger than the groove mouth width of the grooves are attached to the groove mouths of the grooves; fifthly, coating a brushing-type plastic filler protective layer of which the width is larger than that of the water stop plate on the outer surface of each water stop plate. The water stopping construction method has the advantages that as the crease line connection seams are adopted, the first-stage and second-stage panels can be connected more securely, the construction is convenient and the operation is simple; as the polysulfide sealant water stopping filler is filled into the rectangular grooves, embedded into the rectangular seams and kept at the embedding part to perform a water stopping function, and flows into the connection seams from the embedding part under the action of water pressure, the water stopping effect of the connection seams is greatly improved.

Owner:YELLOW RIVER ENG CONSULTING

Structure and connecting and construction method for buoyancy dam type emergency water retaining small dike

InactiveCN103306238ARealize water-stop and air-tightImprove the water-stop effectDamsDykesHigh integrityEngineering

The invention discloses a flexible emergency water retaining small dike capable of being quickly constructed by splicing combination. A dam body can autonomously lift and descend along with the rise and fall of a water level by means of own buoyancy. The basic structure of the emergency water retaining small dike comprises a water retaining dam body, basic dam cloth, an anchor pile, anchor lines, a dam body buoyancy body, a wave resistant ridge, a basic water stop and air closed curtains. The flexible emergency water retaining small dike has the advantages of high integrity, simple and convenient construction, high construction speed, low labor intensity, good effect of retaining water and resisting waves, safety and stability in operation, low construction cost and the like.

Owner:LINYI YEBO WATER CONSERVANCY PROJECT TECH

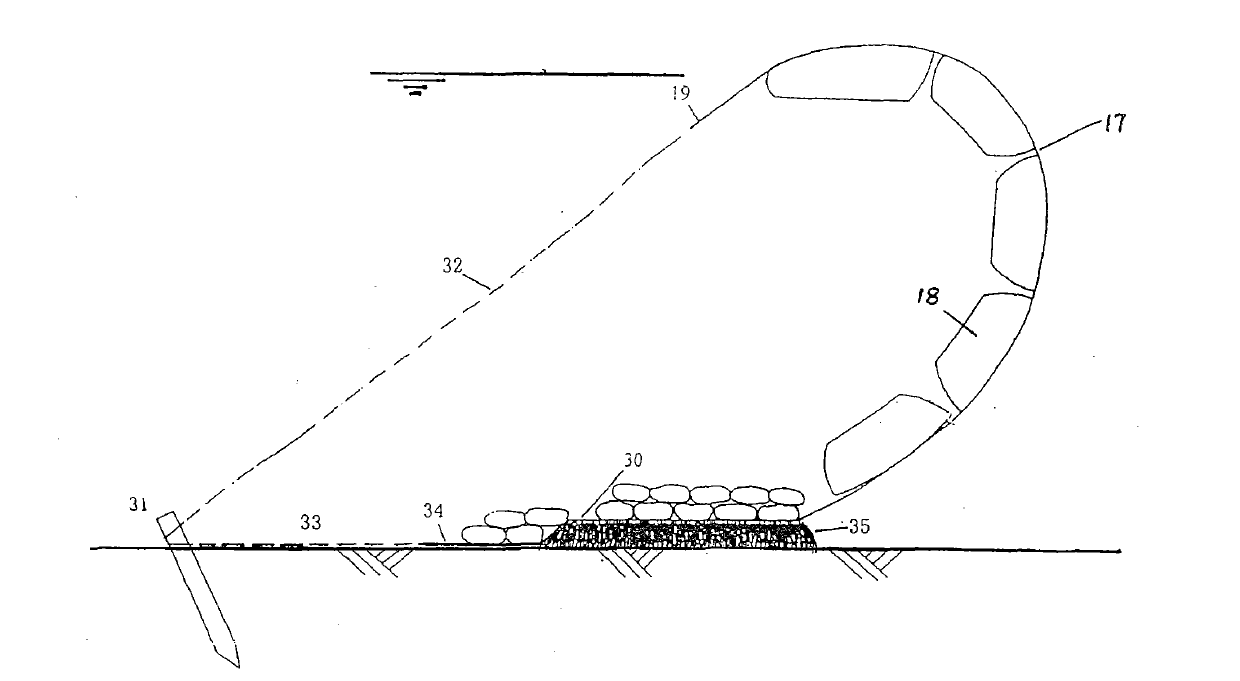

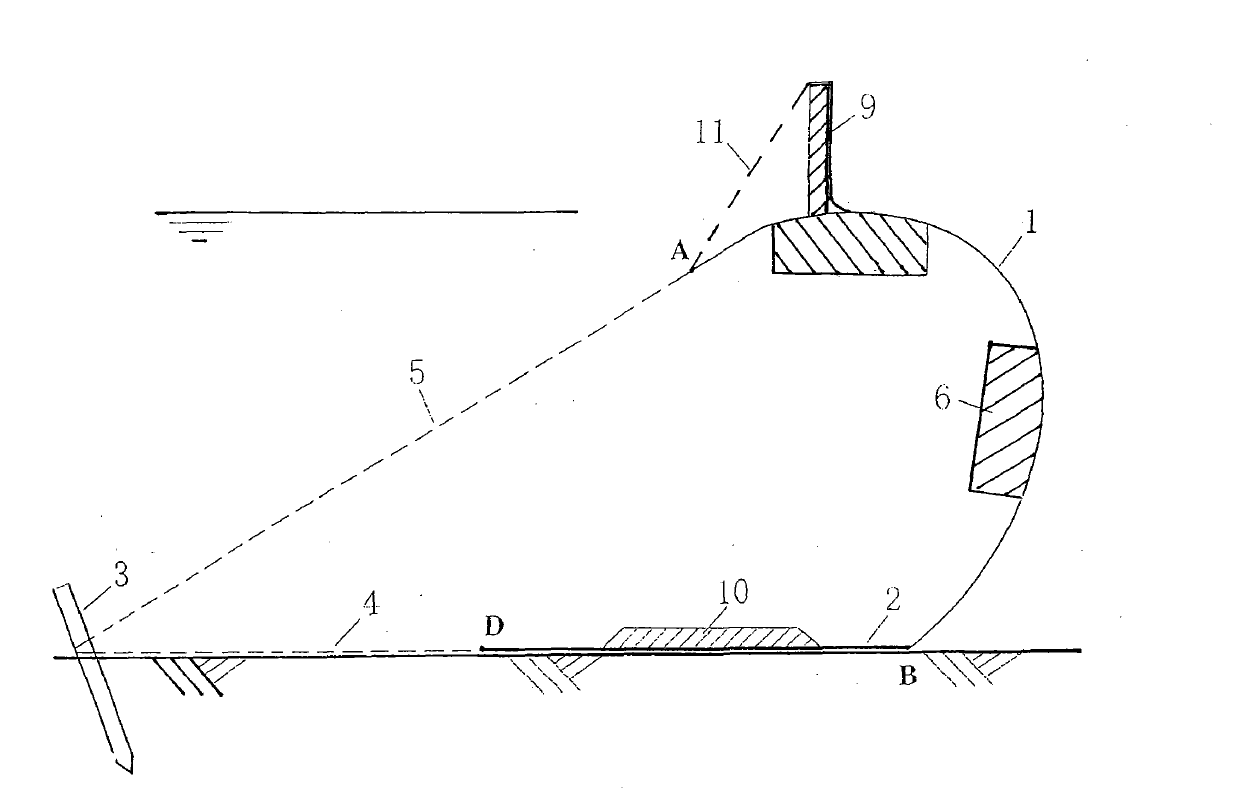

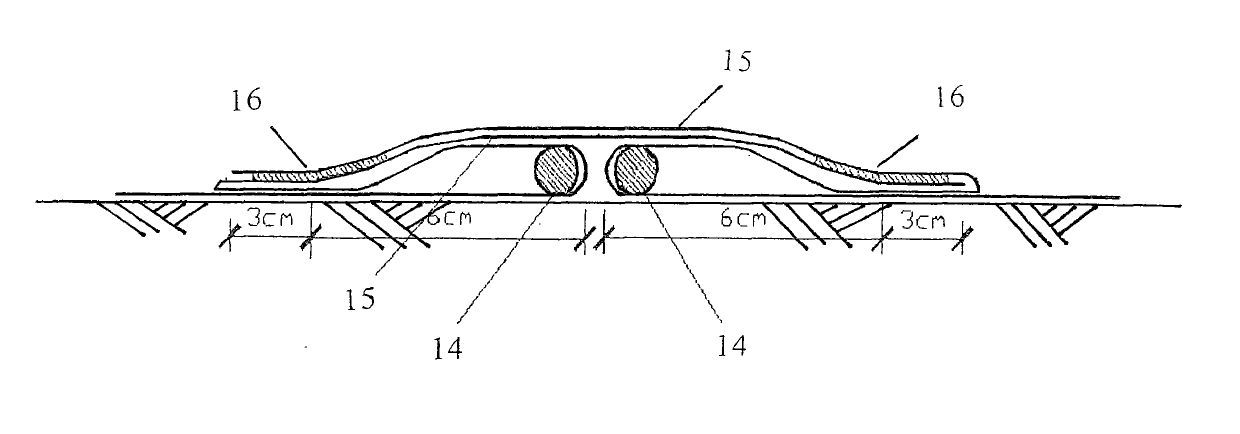

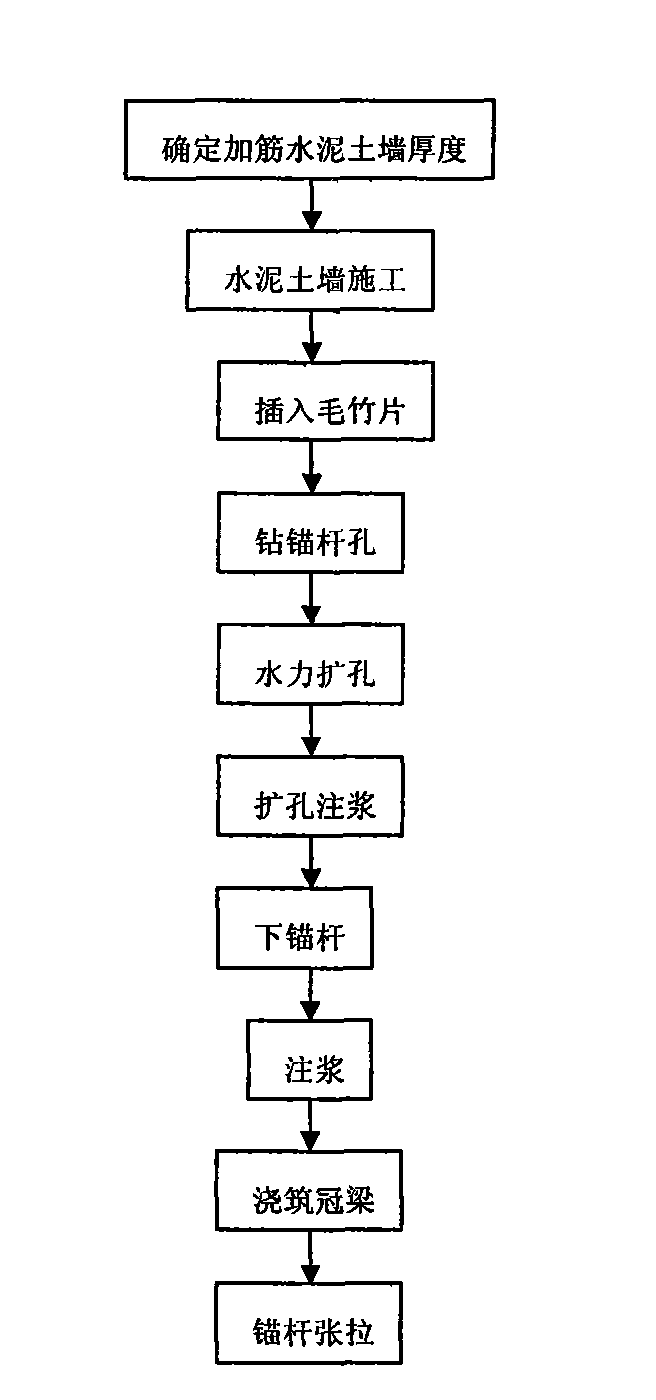

Construction method for supporting foundation ditch of reinforced cement earth wall

InactiveCN101629422AEasy to operate and very economicalImprove the water-stop effectExcavationsRotary drillingSupporting systemReinforced concrete

The invention discloses a construction method for supporting a foundation ditch of a reinforced cement earth wall, which is characterized in that reinforced concrete and an improved prestress anchor rod act together and are used as a foundation ditch supporting system, moso bamboo slices are inserted into cement earth, the tensile force is transferred to a good soil layer through the prestress anchor rod, and the stress performance of the prestress anchor rod is improved by enlarging the anchor head in an anchored region, and the enlarged head anchor rod construction adopts a hydraulic power expanding method. The construction method comprises the following steps: firstly, determining the thickness of a reinforced cement earth wall; secondly constructing the cement earth wall; thirdly, inserting the moso bamboo slices; fourthly, drilling an anchor rod hole with a sleeve; fifthly, expanding the hole by water power; sixthly, expanding and slip-casting; seventhly, inserting the anchor rod; eighthly, slip-casting; ninthly, casting a top beam; and tenthly, tensioning the anchor rod. The invention has the characteristics of high watertight performance and good permeability resistance.

Owner:朱奎

Steel cylinder with wide tongue and groove fitting

ActiveCN104099940BEffective protectionAvoid enteringFoundation engineeringLand reclamationEngineeringTongue and groove

The invention relates to a steel cylinder with a wide tenon and groove device, in particular to a steel cylinder with a wide tenon and groove protected by a protective cover of the wide tenon and groove device; There is a wide tongue and groove device, and the wide tongue and groove device includes a wide tongue and groove and a protective cover arranged outside the wide tongue and groove. The invention adopts the design of the protective cover, which can effectively protect the wide tenon and groove, and prevent the seabed sediment from entering the wide tenon and groove when the steel cylinder enters the mud, and prevent the steel cylinder from being damaged when it enters the soil layer. The sealing mudguard rubber on the wide tenon groove is torn or damaged; the depth of water injection material pouring is fully guaranteed, so that the water stop material in the wide tenon groove is poured more fully and thoroughly, so that seawater will not enter due to the gap along the bottom of the wide tenon groove The sub-grid steel arc plate affects the water-stop performance of the overall structure of the artificial island; the construction quality of the sub-grid steel arc plate vibration sinking is improved, thereby greatly improving the water-stop performance of the artificial island enclosure structure.

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

Steel cylinder with wide mortise device

ActiveCN104099940AEffective protectionAvoid enteringFoundation engineeringLand reclamationEngineeringRubber sheet

The invention relates to a steel cylinder with a wide mortise device, in particular to a steel cylinder capable of protecting a wide mortise by a protection cover of the wide mortise device. The steel cylinder comprises a cylinder body, wherein the wide mortise device is arranged on the cylinder body and comprises the wide mortise and the protection cover which is arranged outside the wide mortise. Due to the adoption of the design of the protection cover, the wide mortise is effectively protected; when the steel cylinder is sunken into mud, silt of the sea bed is prevented from entering the wide mortise, and when the steel cylinder enters a dirt bed, a sealing mud stop rubber sheet on the wide mortise is prevented from being torn or destroyed; the pouring depth of a water injection material is fully ensured, the filling of a water stop material in the wide mortise is more full and thorough, and the condition that the water stop performance of an artificial island whole structure is influenced as seawater cannot enter an auxiliary grid steel arc plate along a gap in the bottom of the wide mortise is avoided; the construction quality of vibrating, sinking and inserting the auxiliary grid steel arc plate is improved, and the water stop performance of an artificial island space enclosing structure is greatly improved.

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

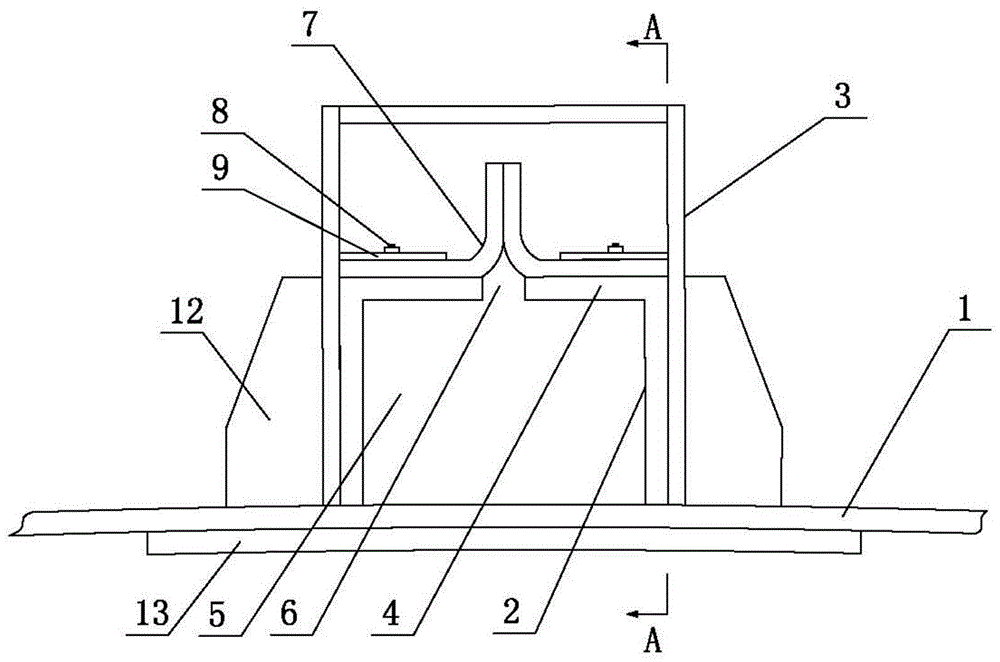

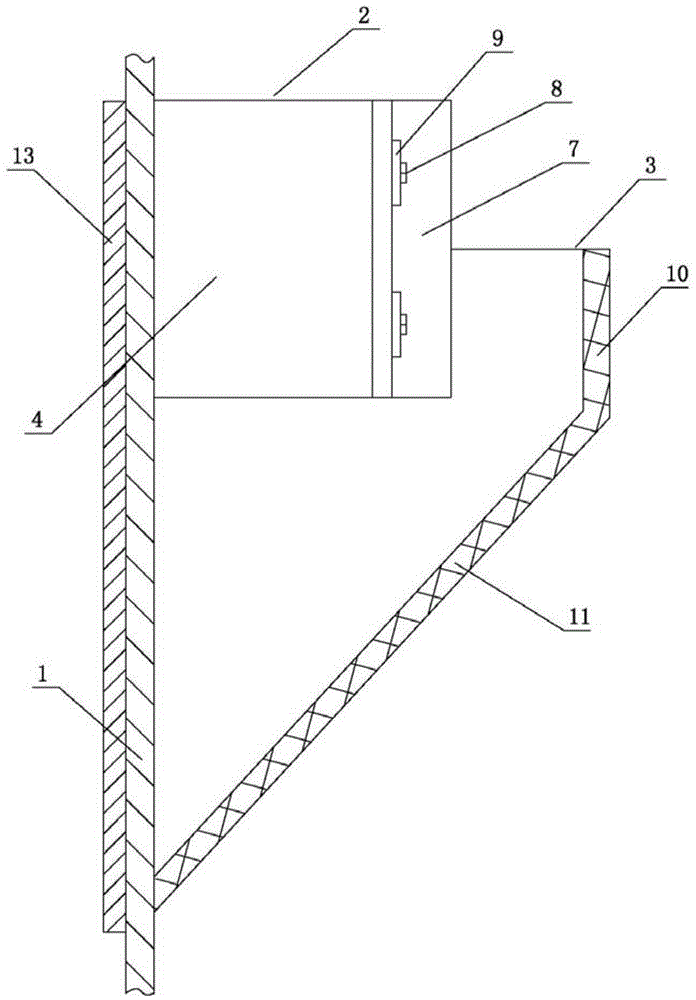

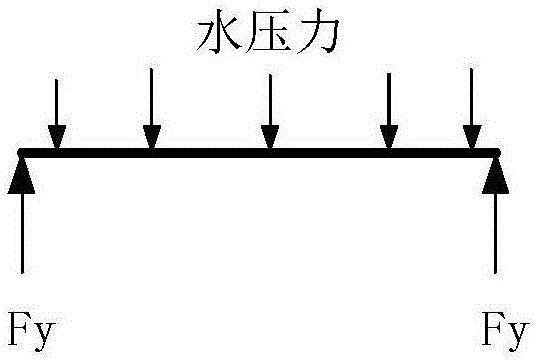

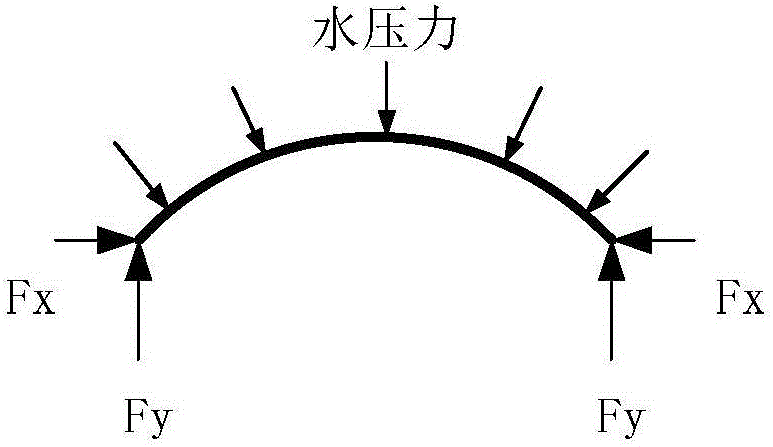

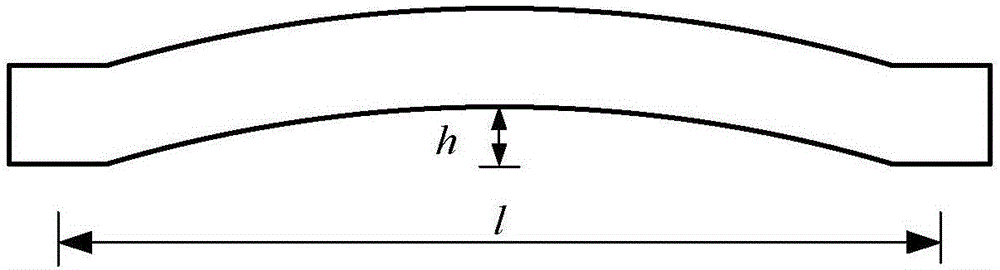

Arch type aluminum alloy flood prevention plate

The invention provides an arch type aluminum alloy flood prevention plate. The arch type aluminum alloy flood prevention plate comprises a foundation, an upright, water blocking plates and a water stopping device. The upright is fixed to the foundation. The two sides of the upright are provided with vertical insertion slots used for clamping and fixing the arch type aluminum alloy water blocking plates. The water stopping device comprises seal rubber mats which are arranged in the insertion slots, between the arch type aluminum alloy water blocking plates and in the positions where the arch type aluminum alloy water blocking plates making contact with the foundation. The water blocking plates are arch water blocking plates protruding towards the water blocking direction. The bending moment and deformation of the arch type water blocking plates provided by the invention are both much smaller than those of a traditional structure, and stress, sealing water stopping and material saving are facilitated. Multiple arch arrangement is adopted, thus horizontal thrust of adjacent arches to the uprights can be balanced mutually, a multiple arch effect is achieved, additional loads of the uprights are not increased, the stress advantage of the arches is used, and the adverse influence of arch thrust is also overcome.

Owner:HOHAI UNIV

Method for improving residue soil for shield excavation of water-rich weathering uneven slate interaction formation

InactiveCN105041324AImprove the water-stop effectMaintain stabilityTunnelsHigh concentrationEngineering

The invention discloses a method for improving residue soil for shield excavation of a water-rich weathering uneven slate interaction formation. Through a cutterhead panel injection channel and holes in various spiders in front of a shield cutterhead, high-concentration foams are injected into the residue soil by a foam mixing and generating system; and through an injecting channel and holes in a soil bin, low-mixing-amount high-molecular polymer is injected to the residue soil by a polymer injecting system so as to implement combined injection.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

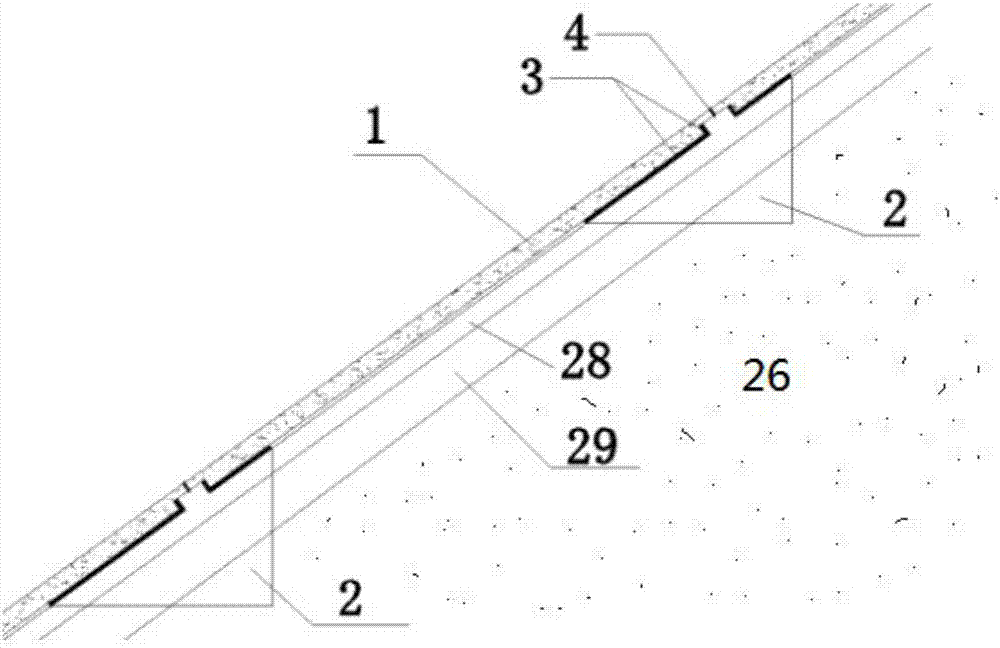

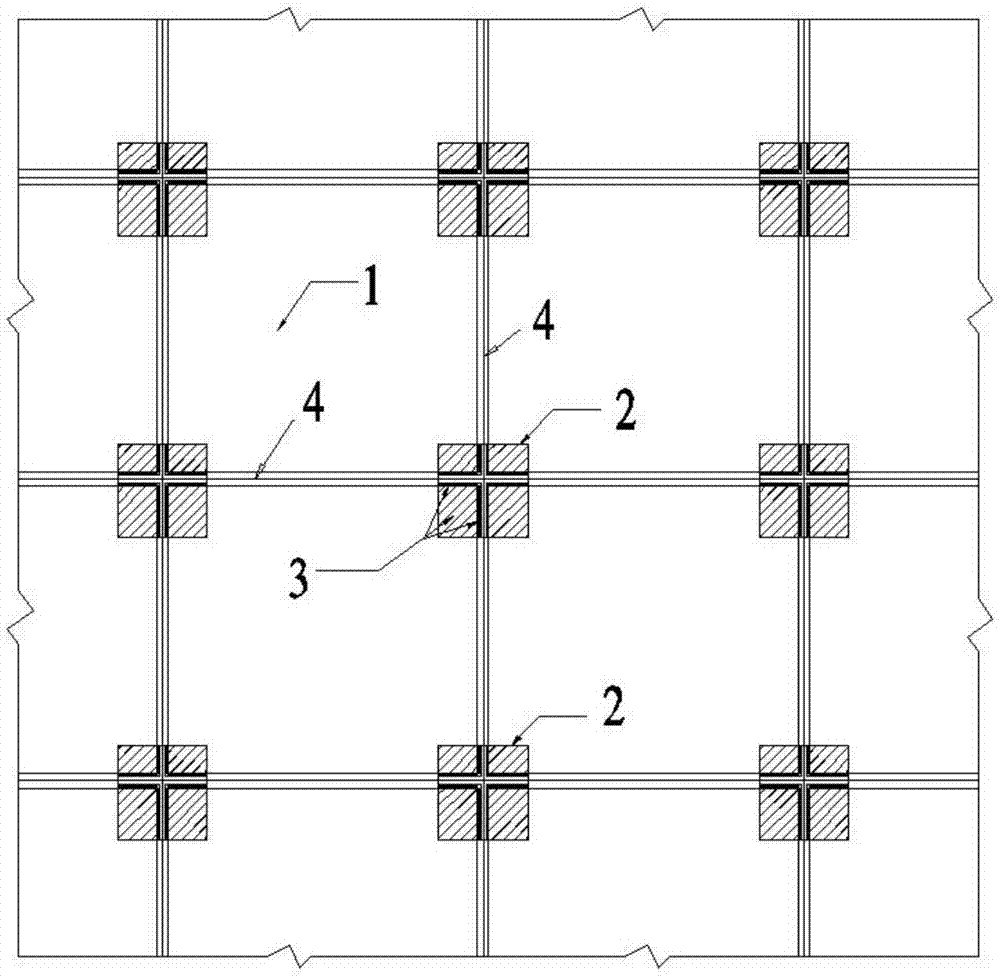

Panel structure of concrete panel rock-fill dam

ActiveCN106939586ASolve the leakImprove the water-stop effectEarth-fill damsRock-fill damsFiberReinforced concrete

The invention provides a panel structure of a concrete panel rock-fill dam. The panel structure comprises panel units which are arranged on a stone dam body slope surface, wherein a gasket layer region and a transition layer region are sequentially laid between the panel units and the stone dam body slope surface from outside to inside; supporting piers are arranged between the panel units and dam body enrockment; rubber supporting bases are arranged among contact surfaces of the panel units and the supporting piers; and a water stop device is arranged between every two adjacent panel units. According to the panel structure provided by the invention, influences, on panel cracking failure, of uneven stress deformation of a dam body are effectively alleviated in a mode of transmitting force through the rubber supporting bases and bearing force through the supporting piers; the bottom surface of the concrete panel is pasted with carbon fiber cloth, so that strength of the panel is greatly improved, and permeability of the panel is reduced; water stop facilities of the panel structure are good in water stop effect; and a reinforced concrete face slab of the panel structure is prefabricated, so that project progress can be effectively quickened, and quality of the panel also can be guaranteed.

Owner:WUHAN UNIV

Method for water stopping in on-vehicle electric wires

InactiveCN101300645AEffective water stop treatmentImprove the water-stop effectCoupling device detailsInsulated cablesEngineeringElectric wire

Owner:AUTONETWORKS TECH LTD +2

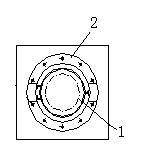

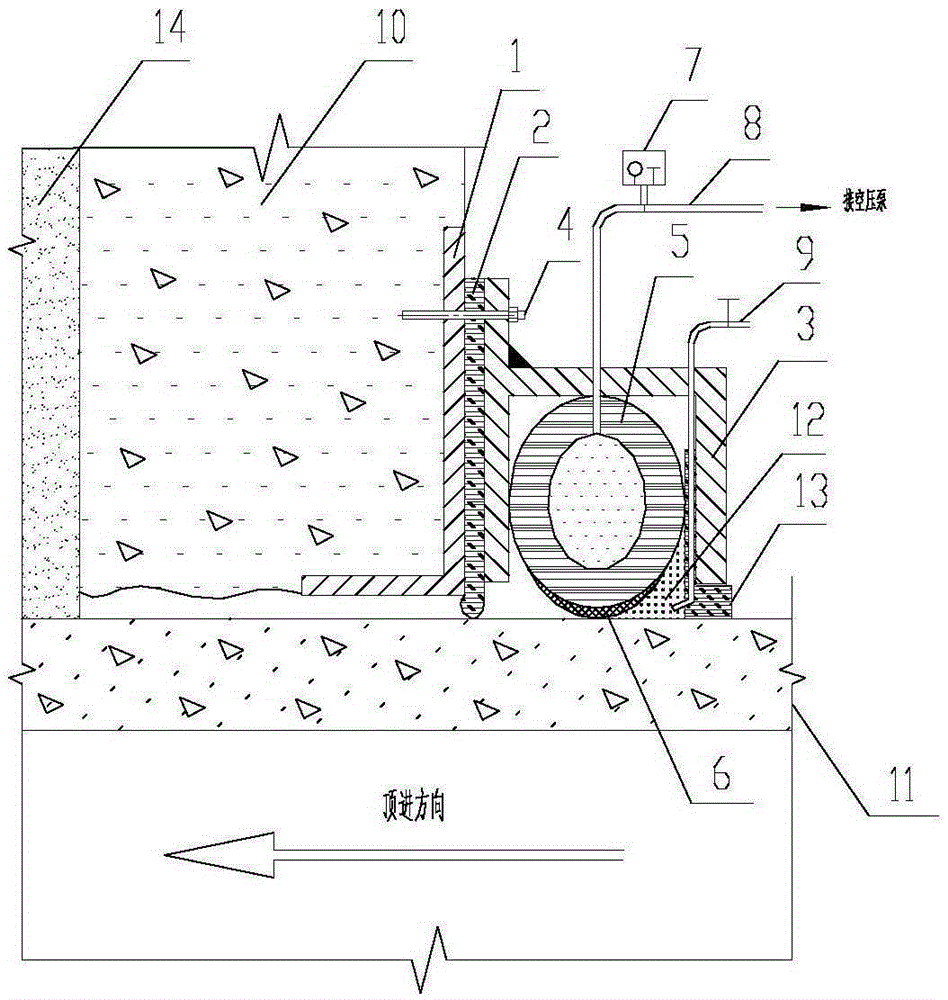

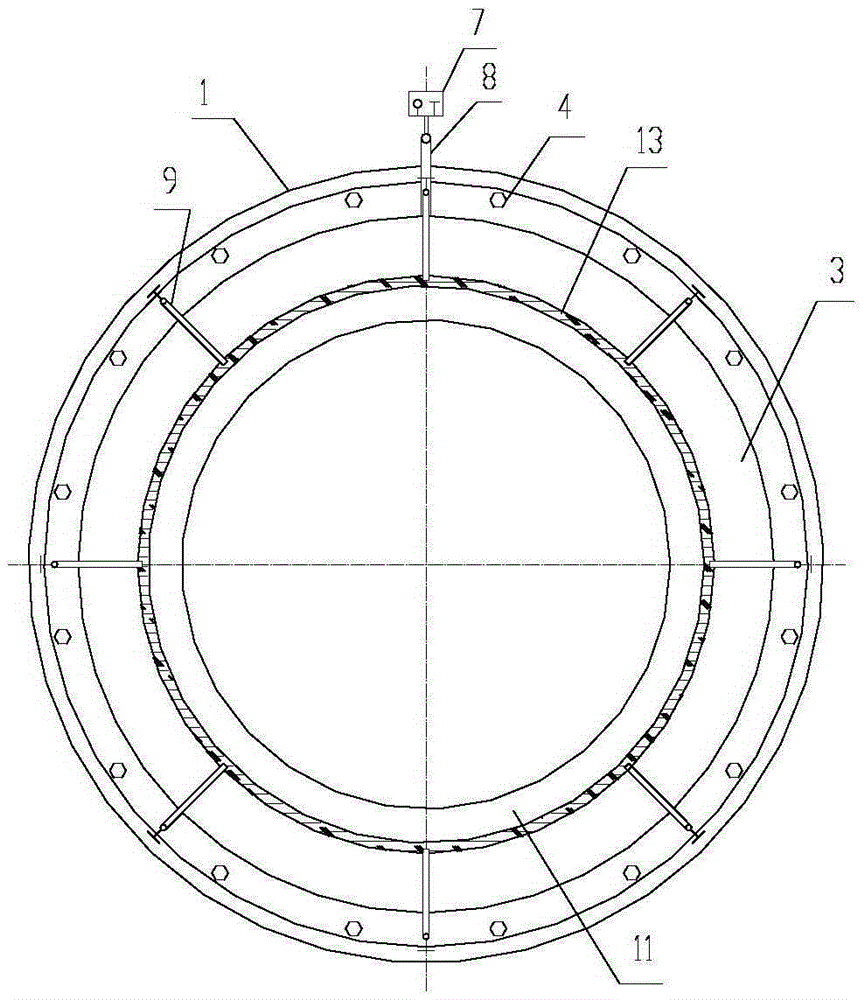

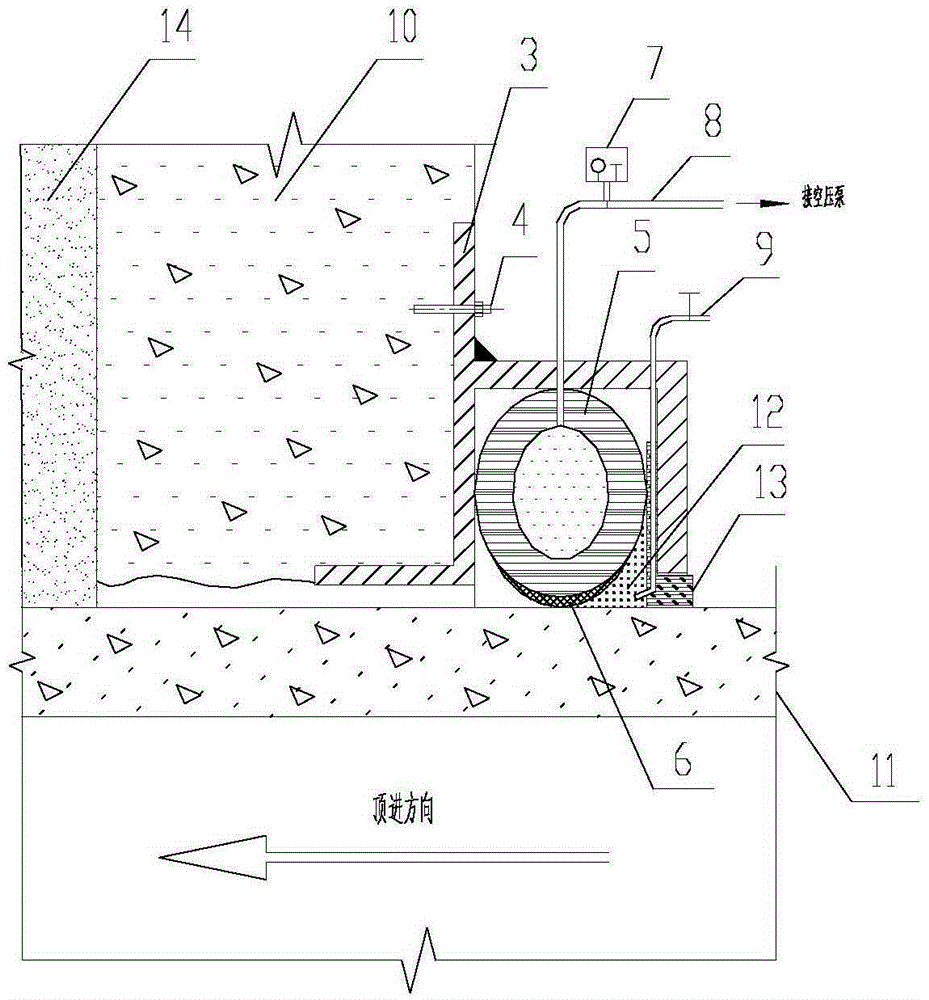

Pipe jacking tunnel inlet stop water device

InactiveCN106703841AWidely adapted to the needs of sealing and water sealingAdapt to the needs of sealing and water sealingUnderground chambersTunnel liningRubber ringWorking pressure

The invention relates to a pipe jacking tunnel inlet stop water device, which comprises an inflatable rubber sealing ring installation slot fixed on a borehole of a pipe jacking tunnel, and an inflatable flexible rubber sealing ring installed in the inflatable rubber seal a flexible rubber seal ring mounting groove. The inflatable rubber sealing ring installation slot is further provided with an air pipe connecting the inflatable rubber sealing ring and a ground air pump. In an inflated state, an outer side of the inflatable rubber sealing ring is in close contact with the bottom of a hole fitting groove, and an inner side faces an outer surface of a pipe joint. At the same time, the inflatable rubber sealing ring of the air pipe connects with an automatic pressure keeping and warning device. The water makes the rubber ring maintain the pressure in a normal working pressure range. While there is inflatable ring grinding off the gas and other abnormal phenomena, the device will automatically alarm. The pipe jacking tunnel inlet stop water device has the advantages of good sealing reliability and wear resistance and is applicable to the hole sealing of round and rectangular and other special-shaped cross-section of the tunnel construction.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com