Panel structure of concrete panel rock-fill dam

A technology for concrete face slabs and rockfill dams, applied in dams, barrages, marine engineering and other directions, can solve the problems of lack of face extrusion failure mechanism, face cracking failure and other problems, and achieve mechanized operation, quality assurance, and permeability reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

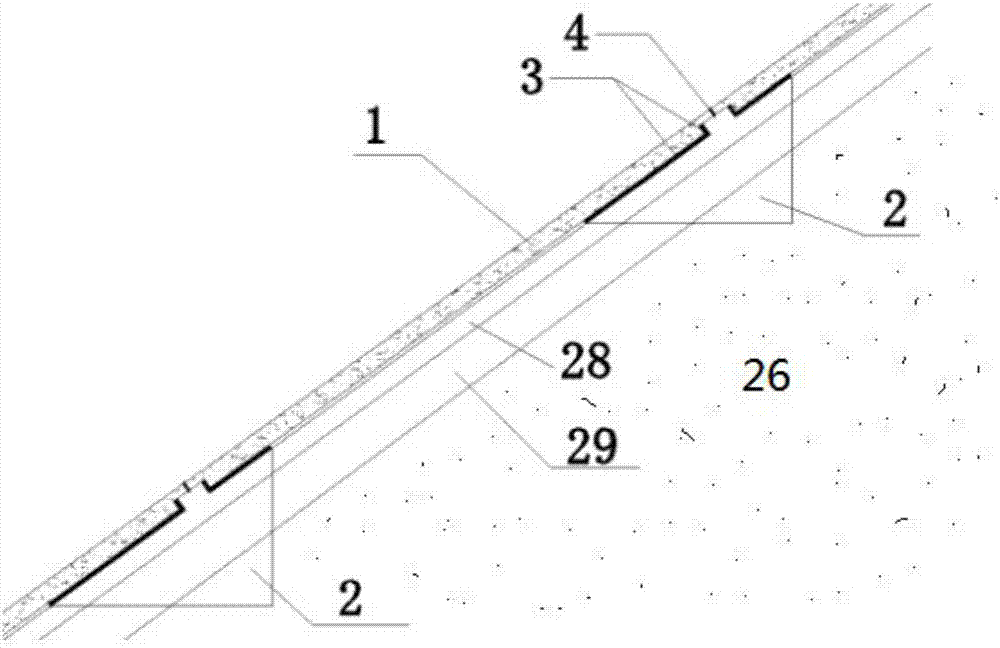

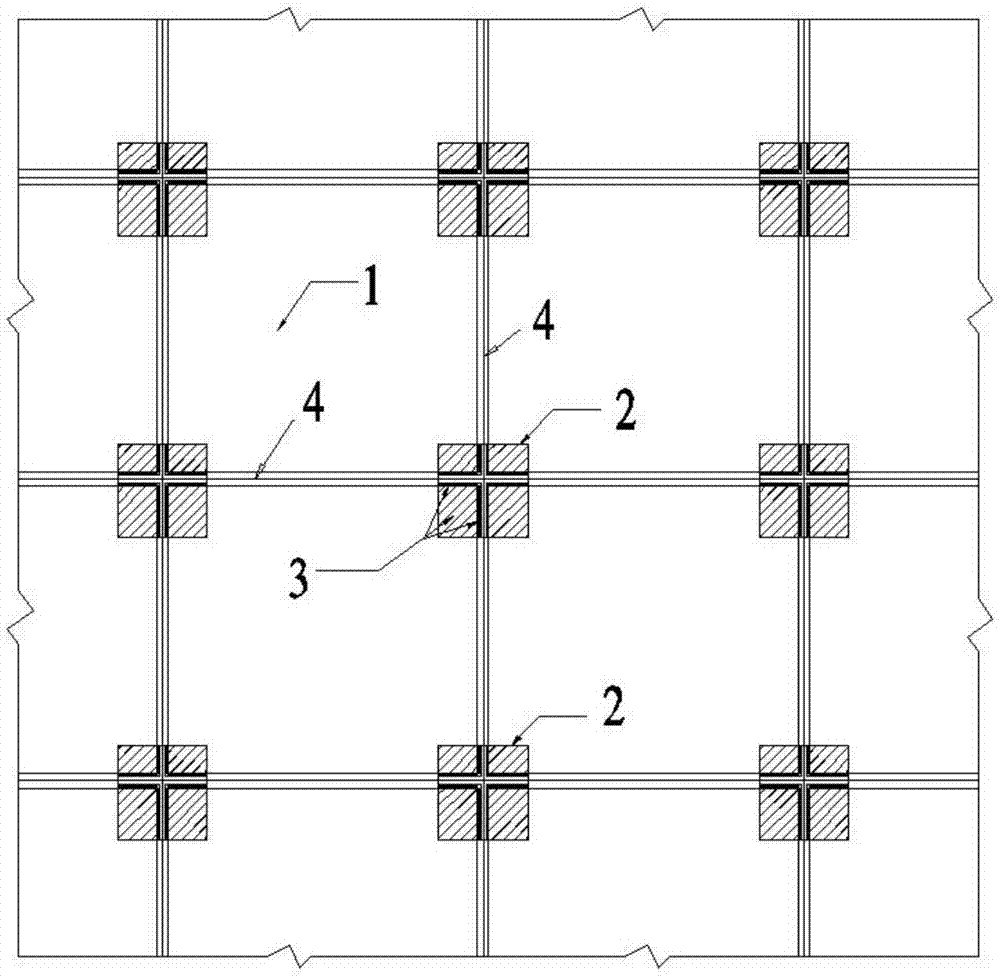

[0034] As shown in the figure, the face structure of a concrete face rockfill dam includes a face unit 1 arranged on the slope of the rock dam body, and a cushion area 28 and The supporting pier 2 of the transition layer area 29; the supporting pier 2 is arranged between the panel unit 1 and the rockfill of the dam body; the rubber bearing 3 is arranged between the contact surface of the panel unit 1 and the supporting pier 2; the A water stop device 4 is provided between two adjacent panel units 1 .

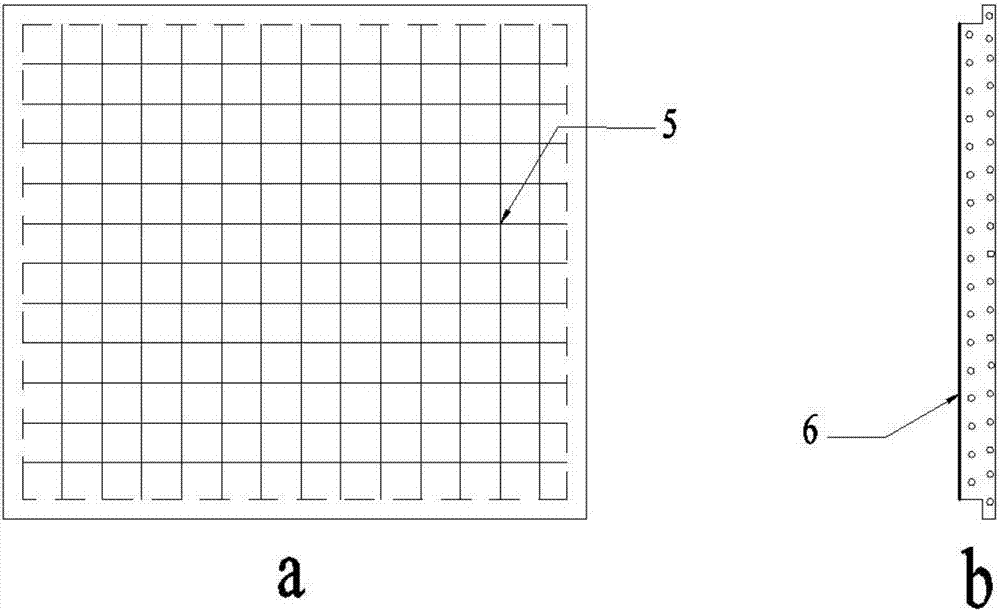

[0035] The panel unit 1 is a prefabricated prestressed reinforced concrete panel with a "T"-shaped cross section, and its inner bars are bound by double-layer prestressed steel bars 5; the lower surface of the panel unit 1 is pasted with carbon fiber cloth 6 .

[0036] The supporting pier 2 is in the shape of a right-angled triangular prism, and a triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com