Patents

Literature

94results about How to "Guaranteed water stop effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

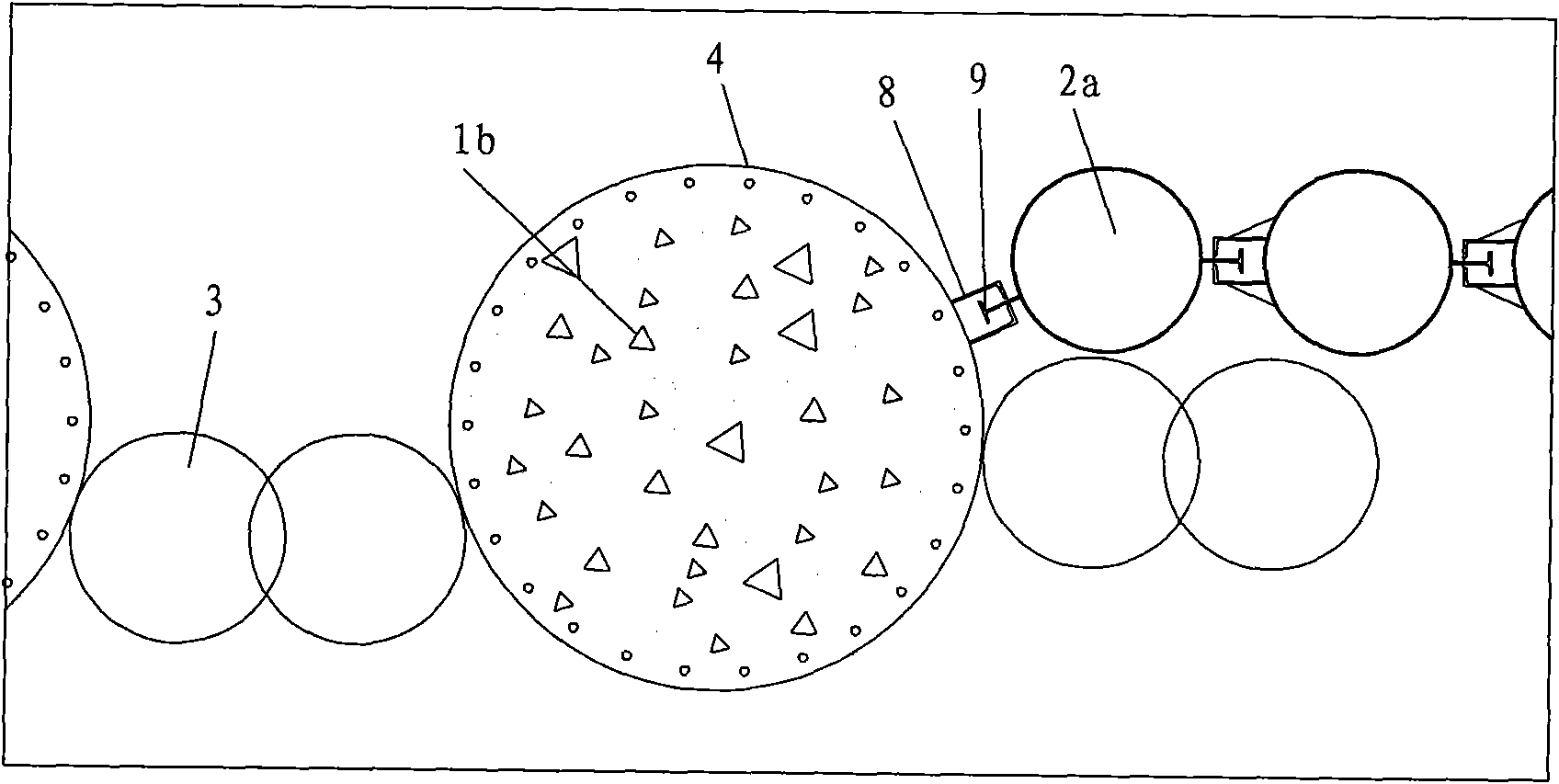

Pi-shaped concrete pile

InactiveCN103726488AWith load-bearing functionImprove bending resistanceArtificial islandsUnderwater structuresEngineeringUltimate tensile strength

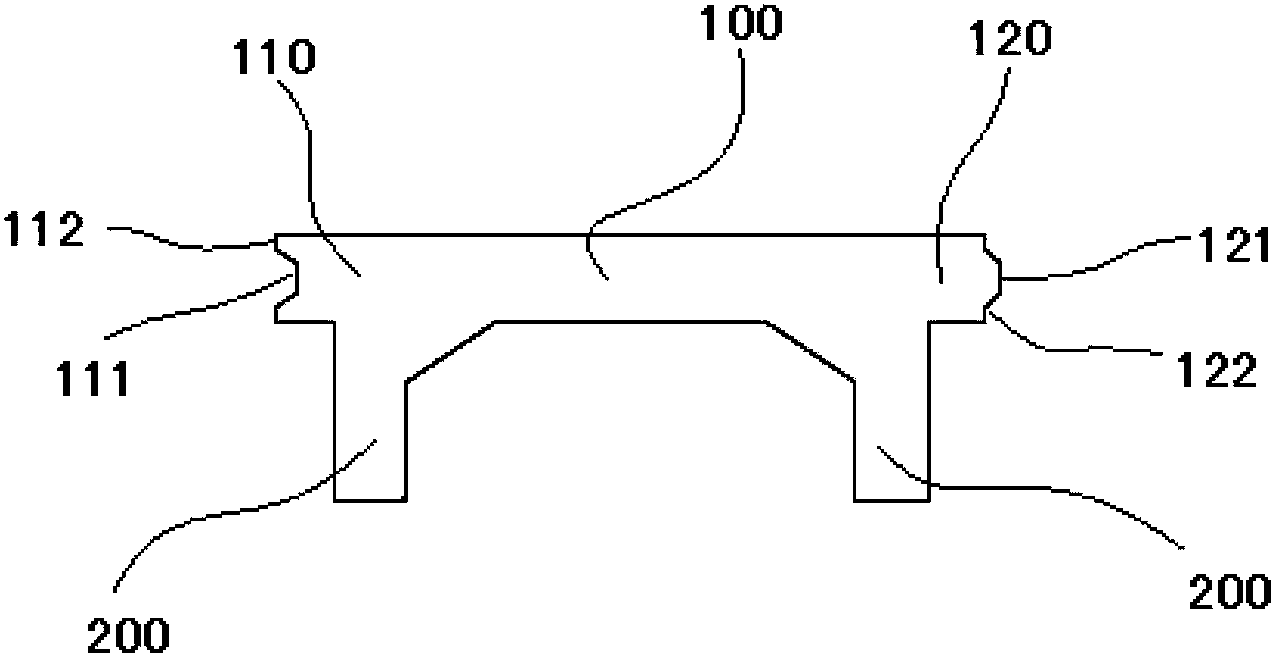

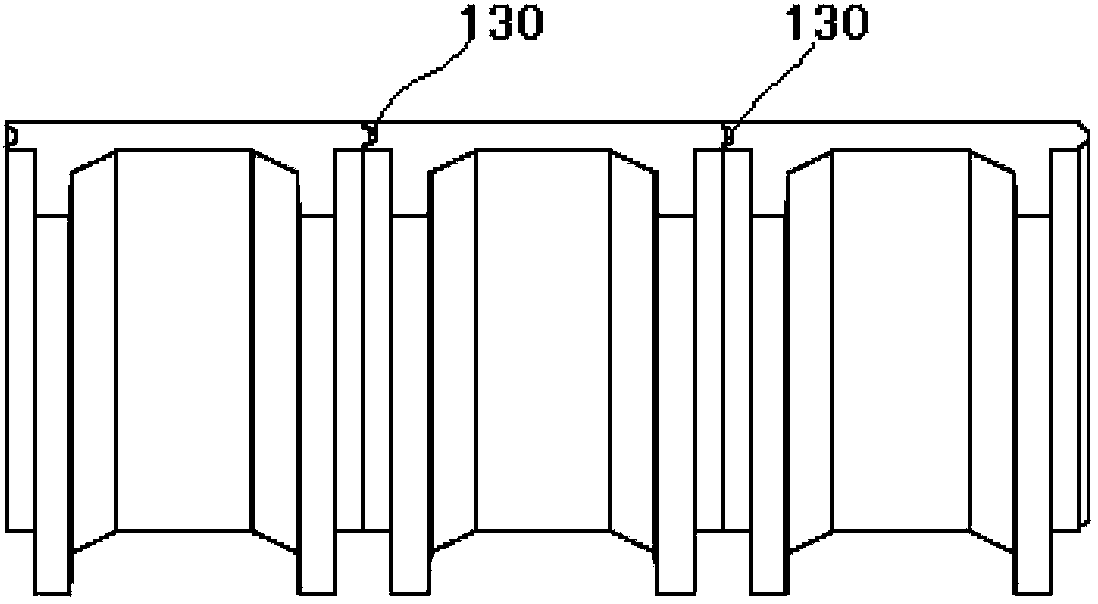

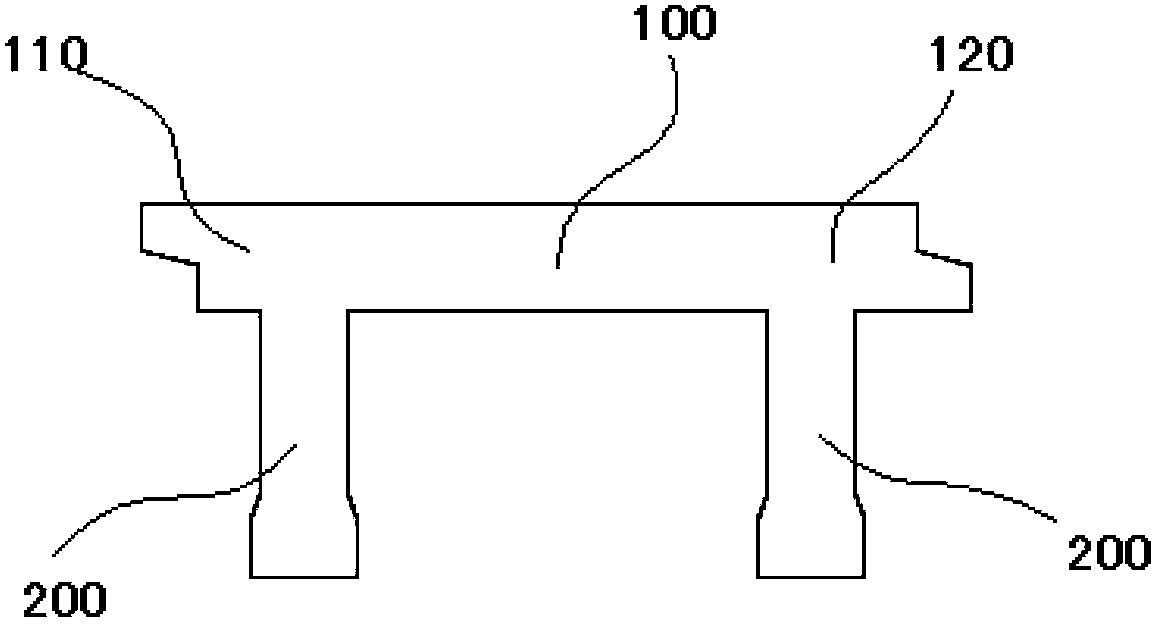

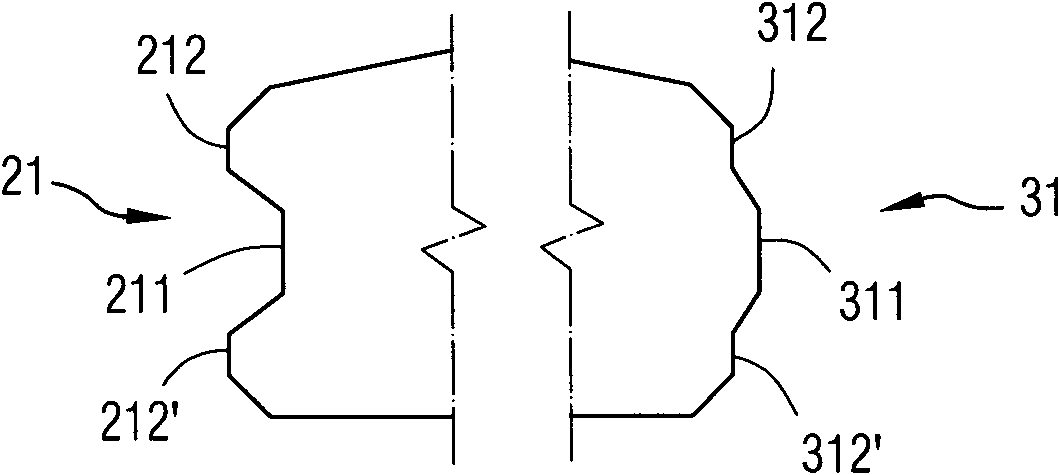

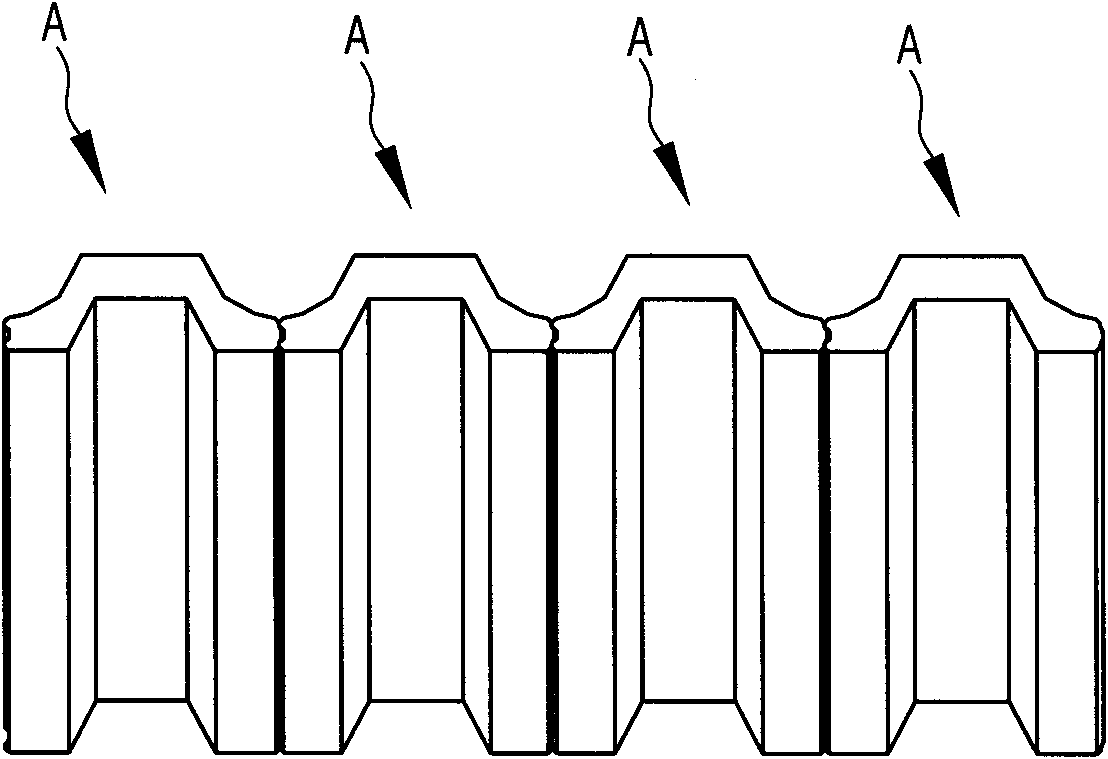

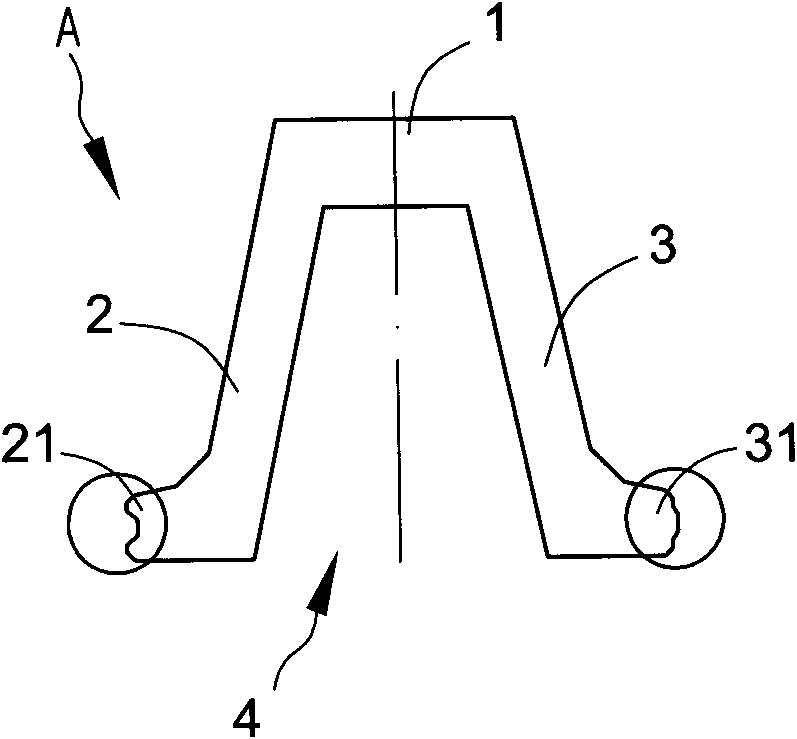

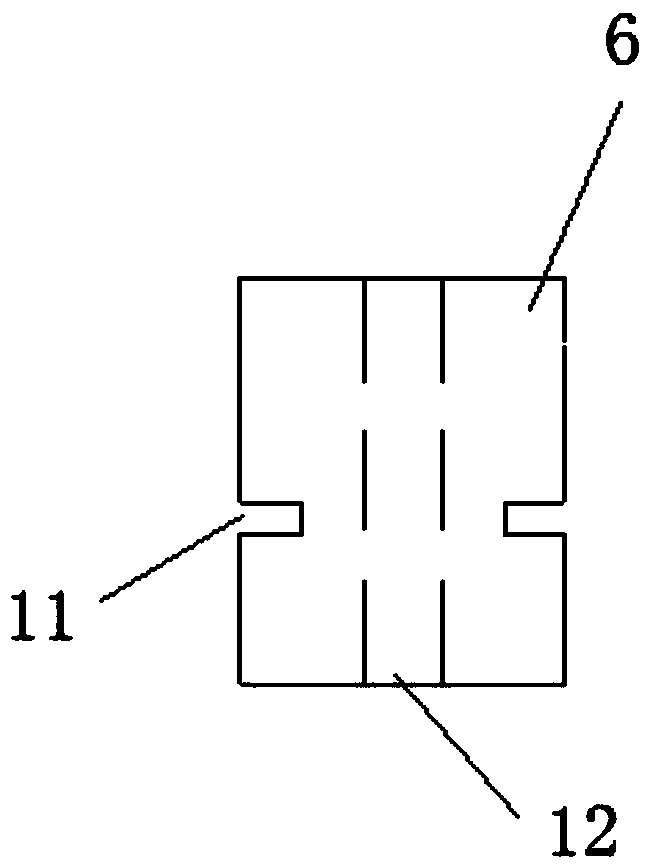

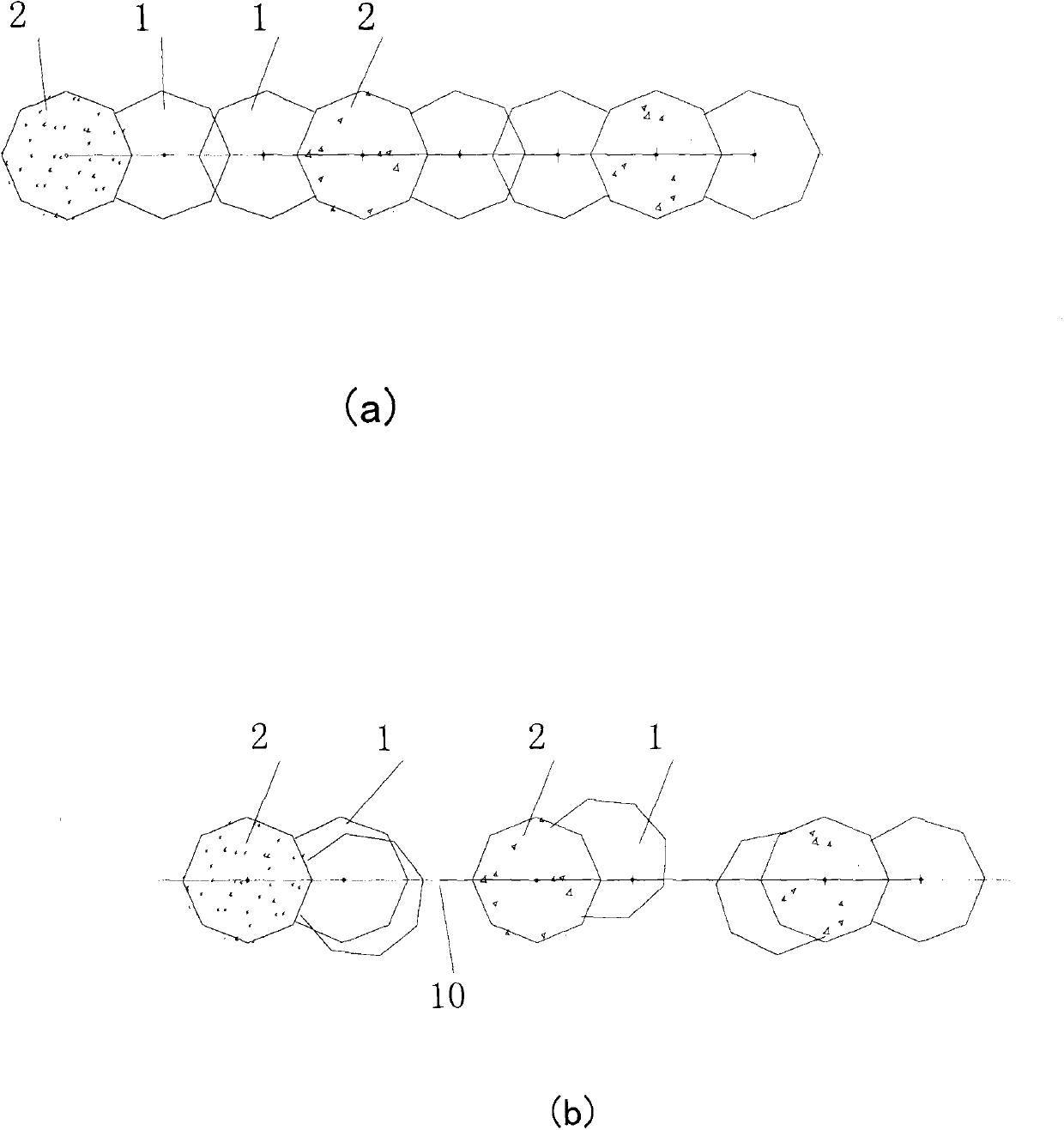

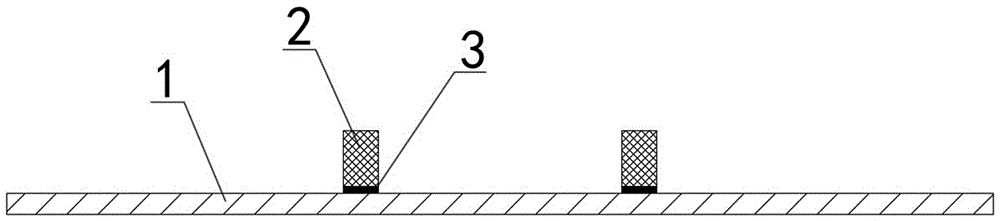

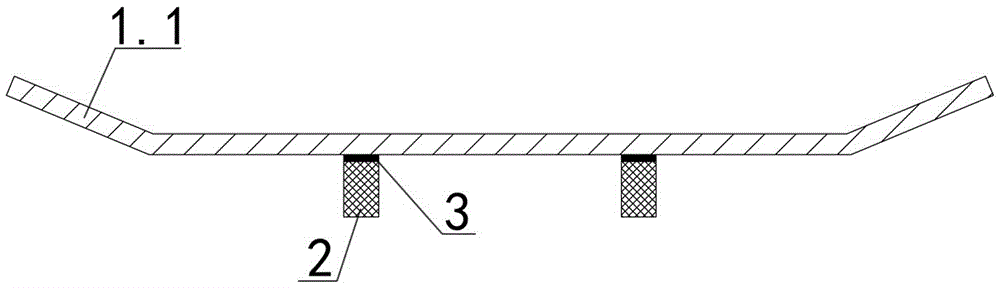

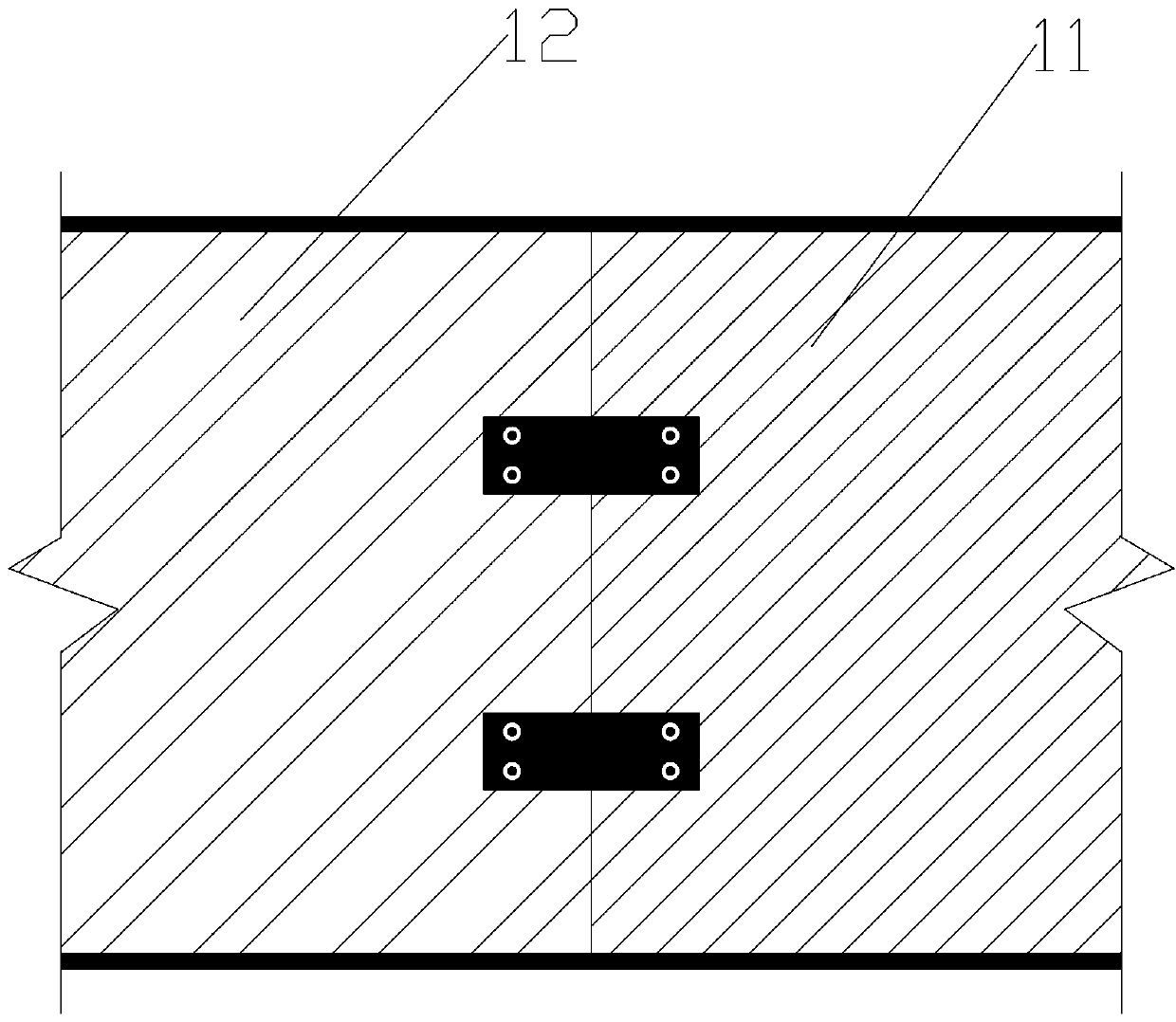

The invention discloses a pi-shaped concrete pile which is made of concrete and comprises a pile body with a pi-shaped cross section. The pile body is composed of a cross beam located on the upper portion of the pile body and a supporting leg component located on the lower portion of the pile body and connected with the cross beam, the two sides of the cross beam are provided with a first connecting portion and a second connecting portion playing a connection role respectively, a gap is formed between matching faces of the first connecting portion and the second connecting portion, the matching faces are matched in shape in an abutting against mode, and the gap is filled with concrete grout and water-stopping rubber bars or sealing materials. The cross section of the pile body is in the pi shape, and the pile body has high bending resistance and high shear resistance in structural stress, and has a certain load bearing function. In addition, the connecting portions on the two sides are equivalent to buckling plates, the gap can be formed between the connecting portions after connectors are spliced and can be filled with the grout materials or other connecting materials, the water stopping effect and connecting strength can be guaranteed, and the pile can be used as a permanent supporting structure.

Owner:SHANGHAI ZHONGJI PILE IND

U-shaped concrete slab pile

InactiveCN101812840AWith load-bearing functionImprove bending resistanceBulkheads/pilesEngineeringUltimate tensile strength

The invention relates to an enclosing structure concrete slab pile in the building field, the slab pile is made of concrete and is provided with a cross section which is approximately in a U shape; the U-shaped cross section is provided with a bending section at the bottom of the U shape, and a first connection section and a second connection section which are arranged on both sides of the U shape; and the first connection section and the second section are respectively provided with a first connection part and a second connection part which are provided with matched shapes. The cross section of the U-shaped concrete slab pile provided by the invention is similar to an English letter U, and the pile has high anti-bending and high anti-shear performance in structural stress, and a certain bearing function. In addition, the connection parts on both sides are equivalent to a fastening plate, a gap can be left in the middle after connector splicing; and some paste material or other connection material can be filled into the gap in the middle, thereby ensuring the water sealing effect and the connection strength.

Owner:SHANGHAI ZHONGJI PILE IND +1

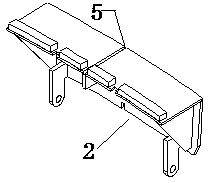

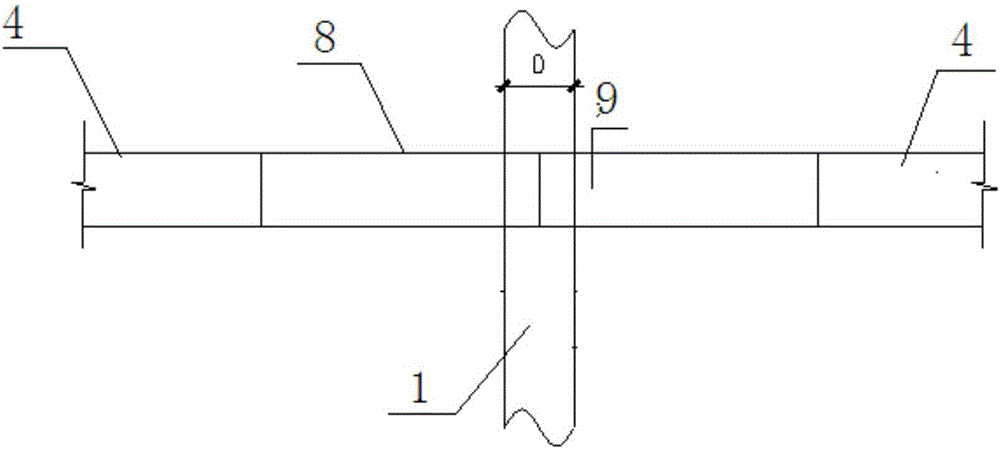

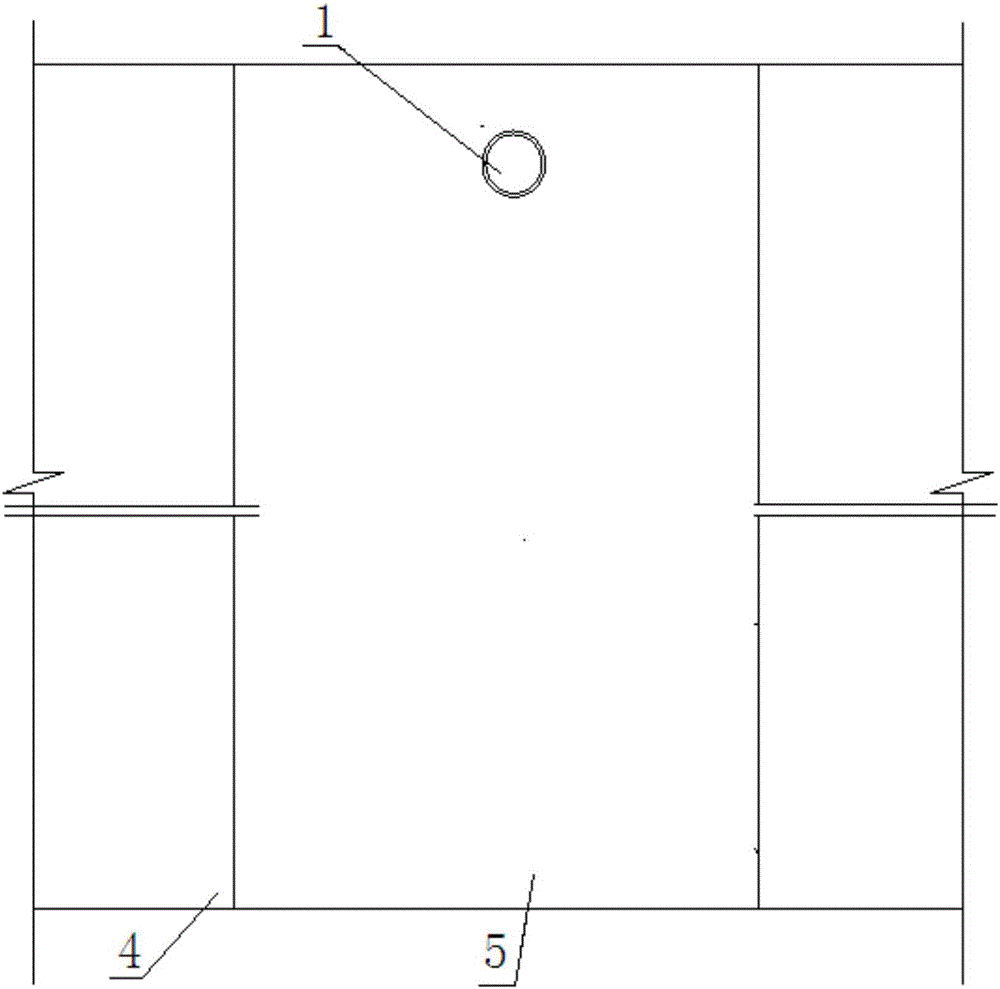

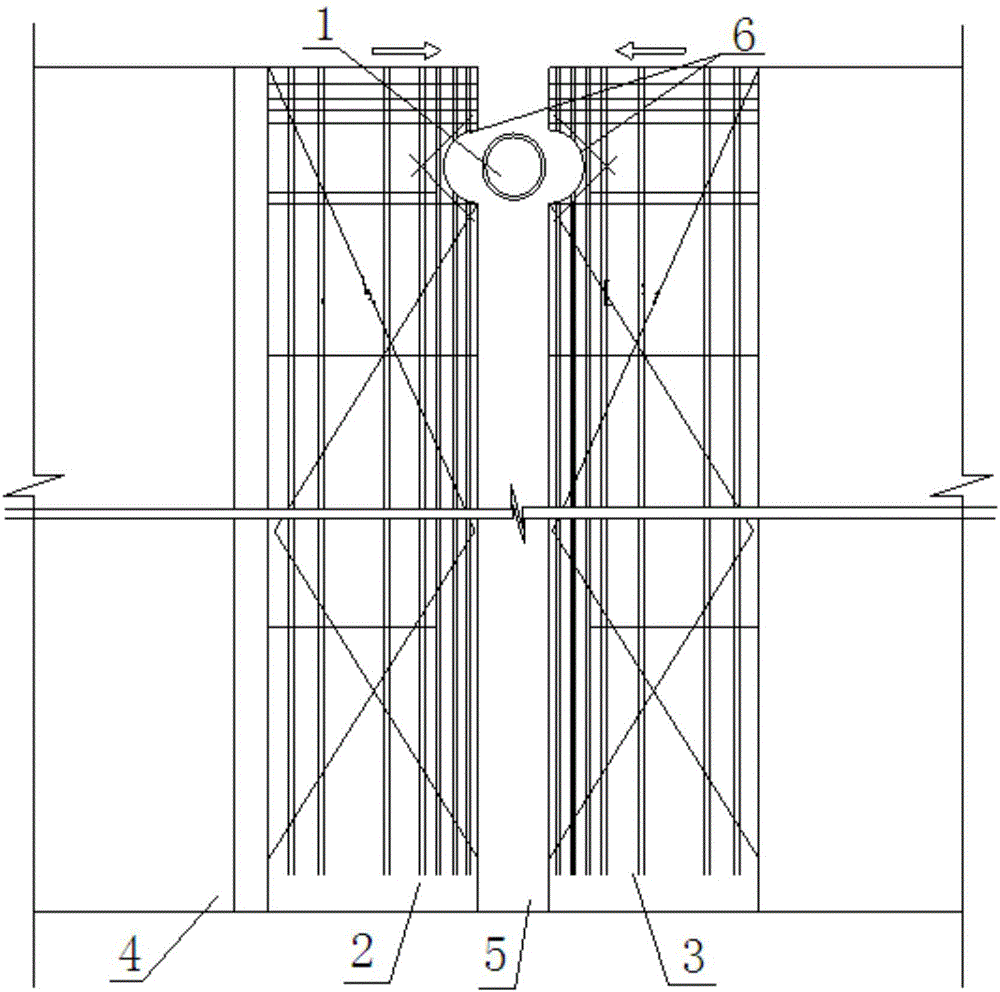

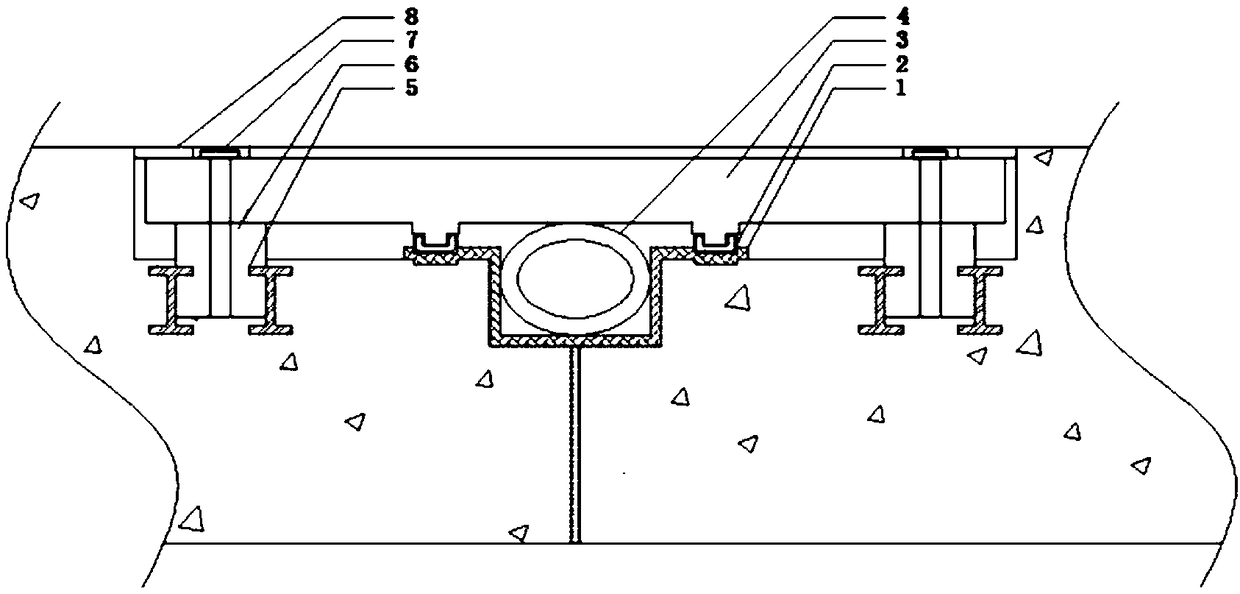

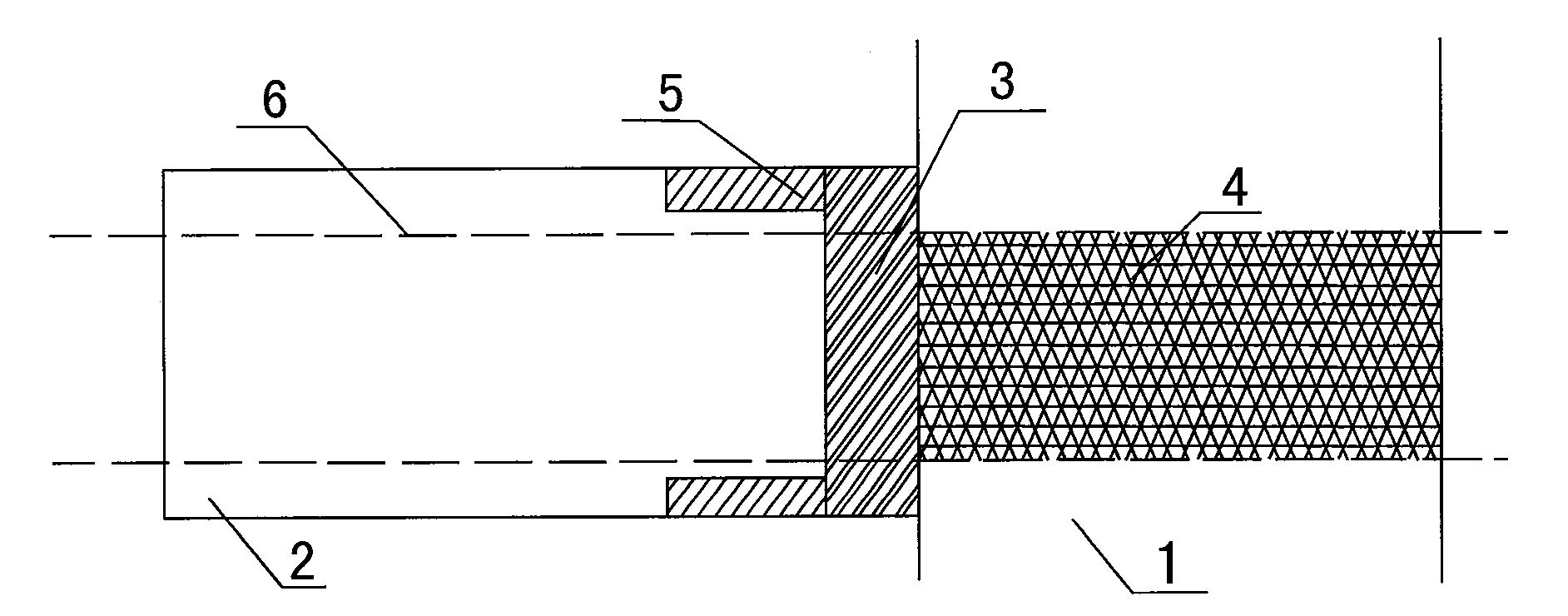

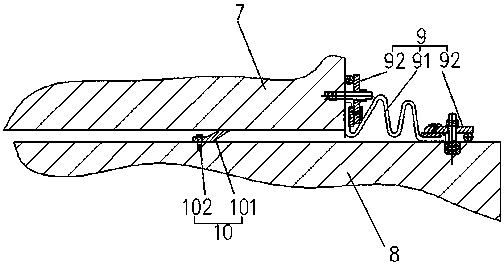

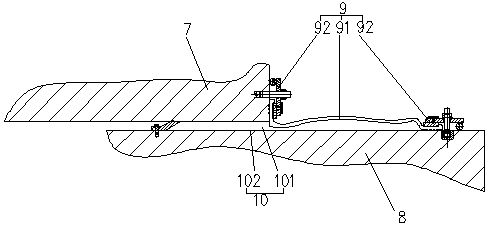

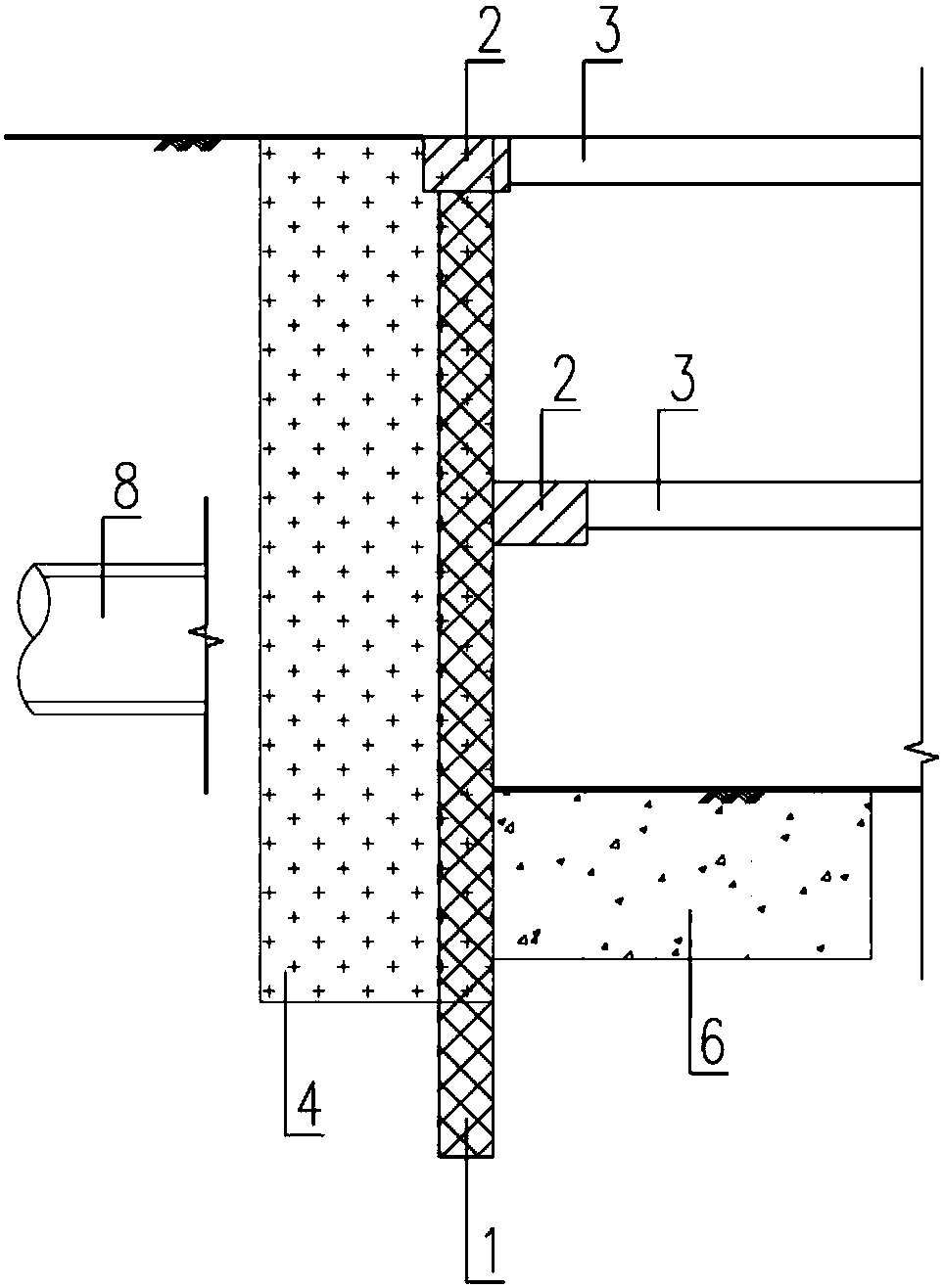

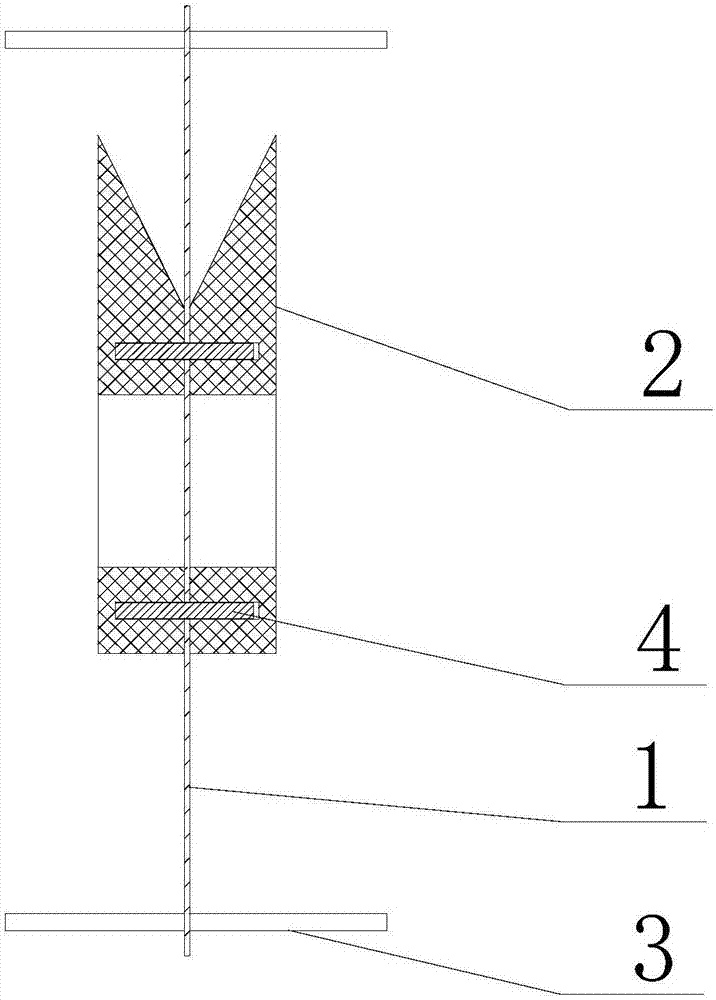

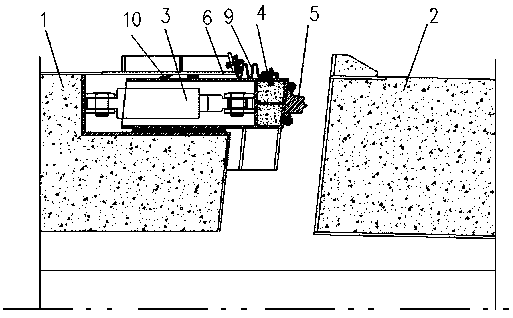

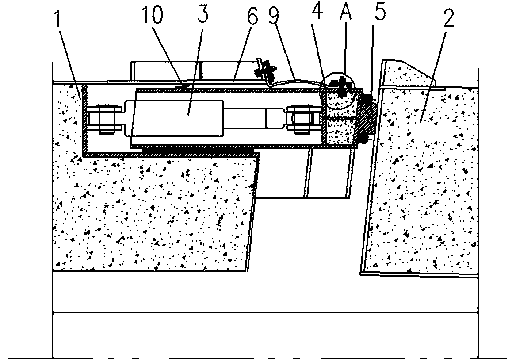

Installation structure and method for accurately positioning tunnel arch wall lining buried type water-stop belt

ActiveCN103670452AReally play the role of water stopGuaranteed water stop effectUnderground chambersTunnel liningRebarMechanical engineering

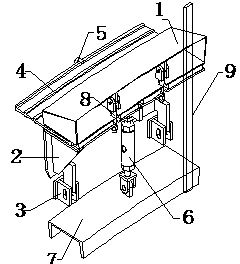

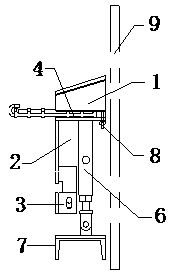

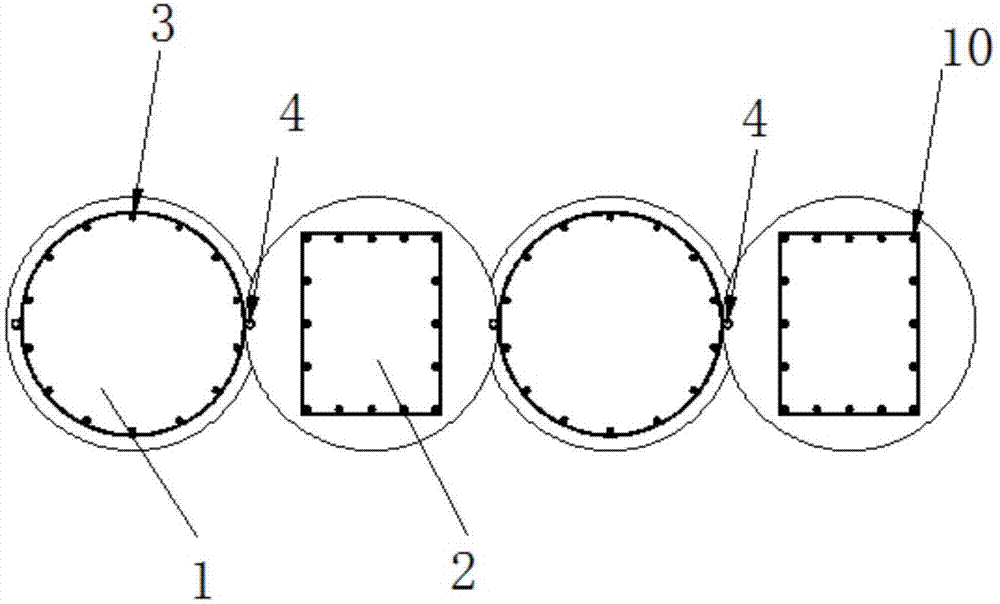

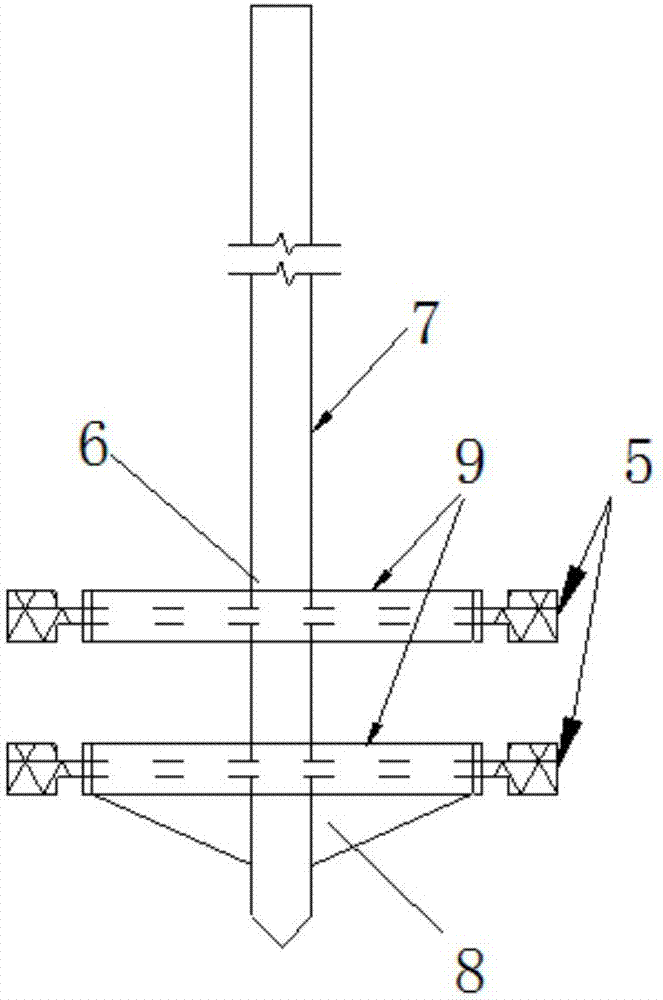

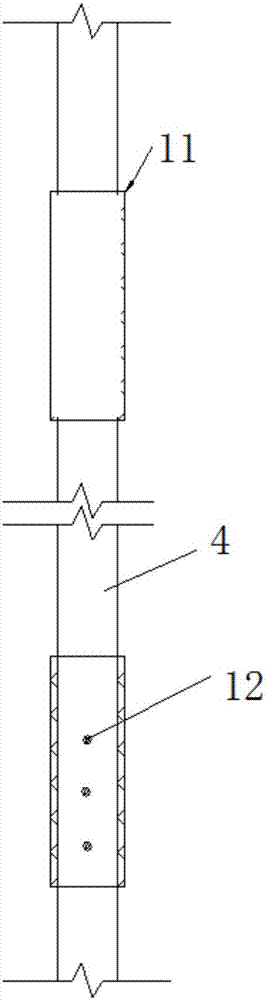

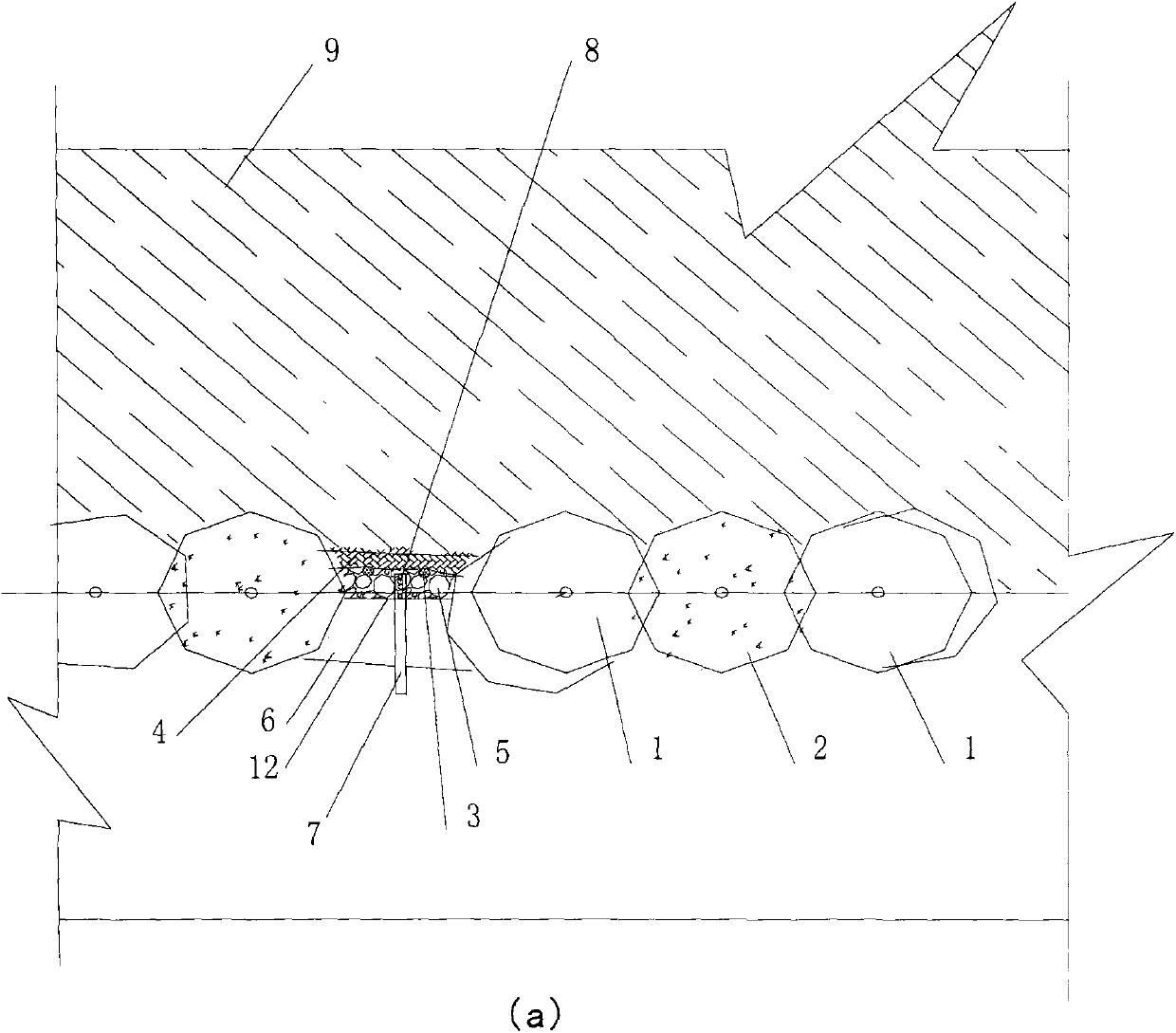

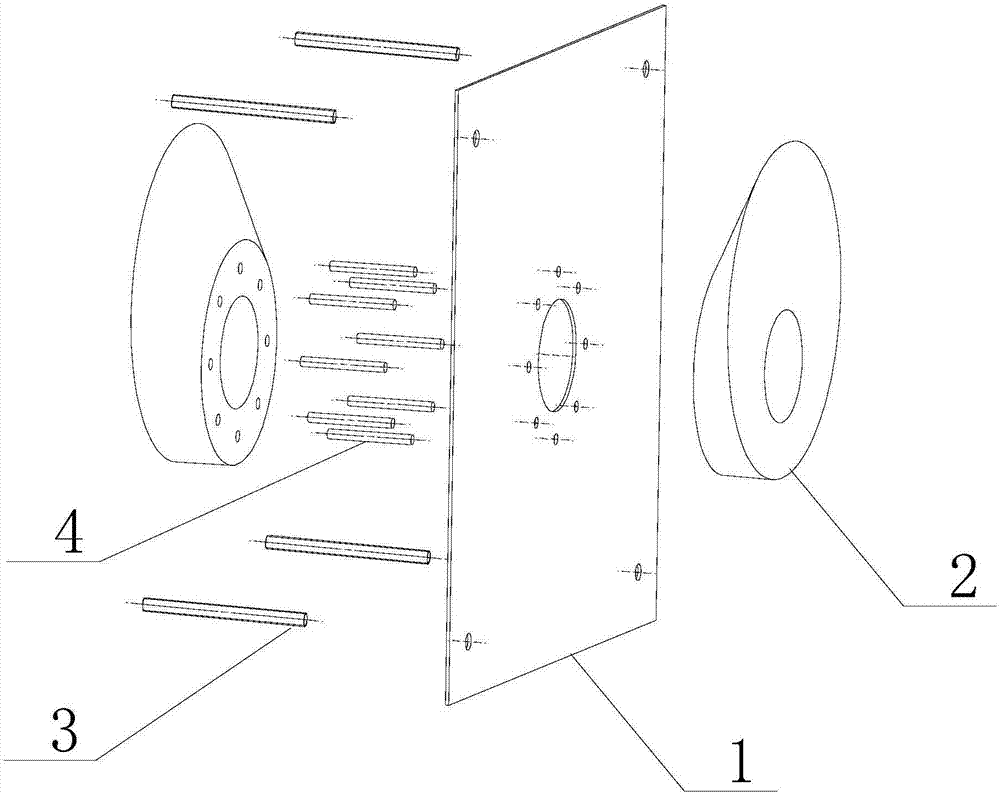

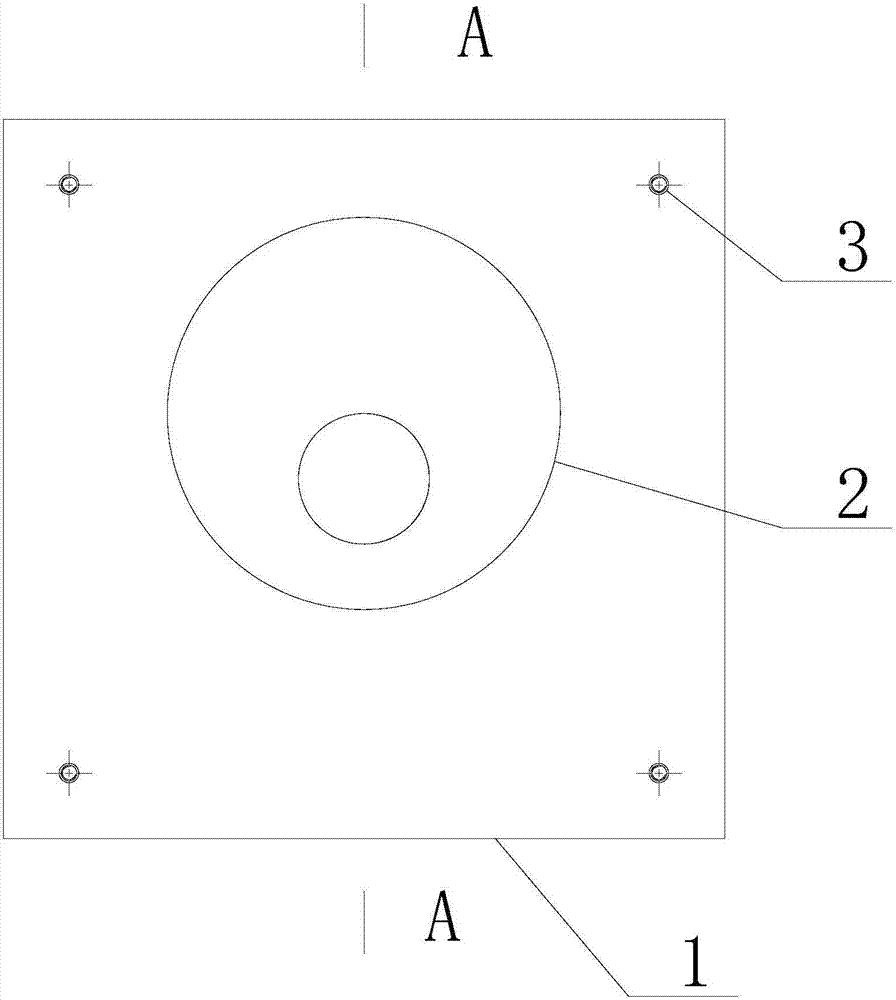

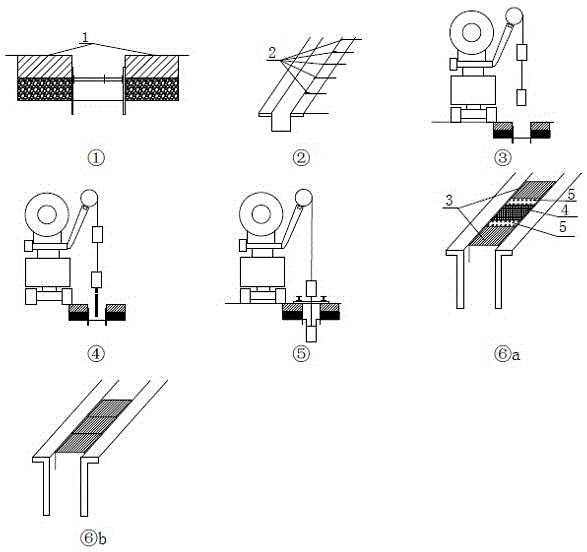

The invention discloses an installation structure for accurately positioning a tunnel arch wall lining buried type water-stop belt. The buried type water-stop belt (4) is arranged between an upper formwork (1) and a lower formwork (2), and a steel bar clamp (5) is arranged at the bottom of the buried type water-stop belt (4). Belt twisting threaded rods (8) are arranged on the lower edge of the upper formwork (1), and the buried type water-stop belt (4) between the upper formwork (1) and the lower formwork (2) is fixedly clamped through the belt twisting threaded rods (8). A lead screw (6) is arranged in the middle of the lower formwork (2), and twisting bases (3) are arranged on the lower edges of the two sides of the lower formwork. The lead screw (6) is used for supporting between a supporting pad steel channel (7) and the lower formwork (2). According to the installation structure, the other components excepting a wood pattern insertion plate are of a steel structure, and in addition, the supporting pad steel channel and the lead screw act together to have a reinforcing function, so that the formworks do not deform in the casting process of concrete, and meanwhile the buried type water-stop belt is not damaged in the dismantling process of the formworks. After the formworks are dismantled, the buried type water-stop belt is buried in a standard and even mode, and the water-stop effect of tunnel lining concrete circumferential construction seams is guaranteed.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Casing-less, long-spiral concrete secant pile construction method

InactiveCN102628267AImprove protectionGuarantee the construction qualityBulkheads/pilesConstruction managementEngineering

A casing-less, long-spiral concrete secant pile construction method relates to the construction of concrete secant pile structures in the field of construction projects. The construction method includes the following steps: (A) pile positions are determined, and neighboring pile bodies are secantly lapped; (B) a long-spiral drilling machine is mounted in place and aligned; when the long-spiral drilling machine is moved to nearby a pipe position, the chassis of the long-spiral drilling machine is adjusted to be flat, the tower of the long-spiral drilling machine is adjusted to be vertical, and the drill bit of the long-spiral drilling machine is adjusted to be aimed at the center of a pile; (C) a hole is drilled by a designed depth; (D) after the hole is drilled by the designed depth, the drill bit is lifted up by 0.2m to 1m, and a concrete pump is then used for feeding concrete to the bottom of the hole via a concrete hose and a hollow drill stem; (E) after the concrete is filled to the orifice of the operating face, the long-spiral drilling machine is moved; (F) the long-spiral drilling machine is moved to the next pile position, and steps B, C, D and E are repeated. According to the method, not only the construction quality and the water-stopping effect are better guaranteed, but also the construction efficiency is greatly increased, the cost is lower, and the method is more favorable for on-site civilized construction management and environment protection.

Owner:吴传清 +1

Migration-free foundation-pit-crossing underground pipeline construction method

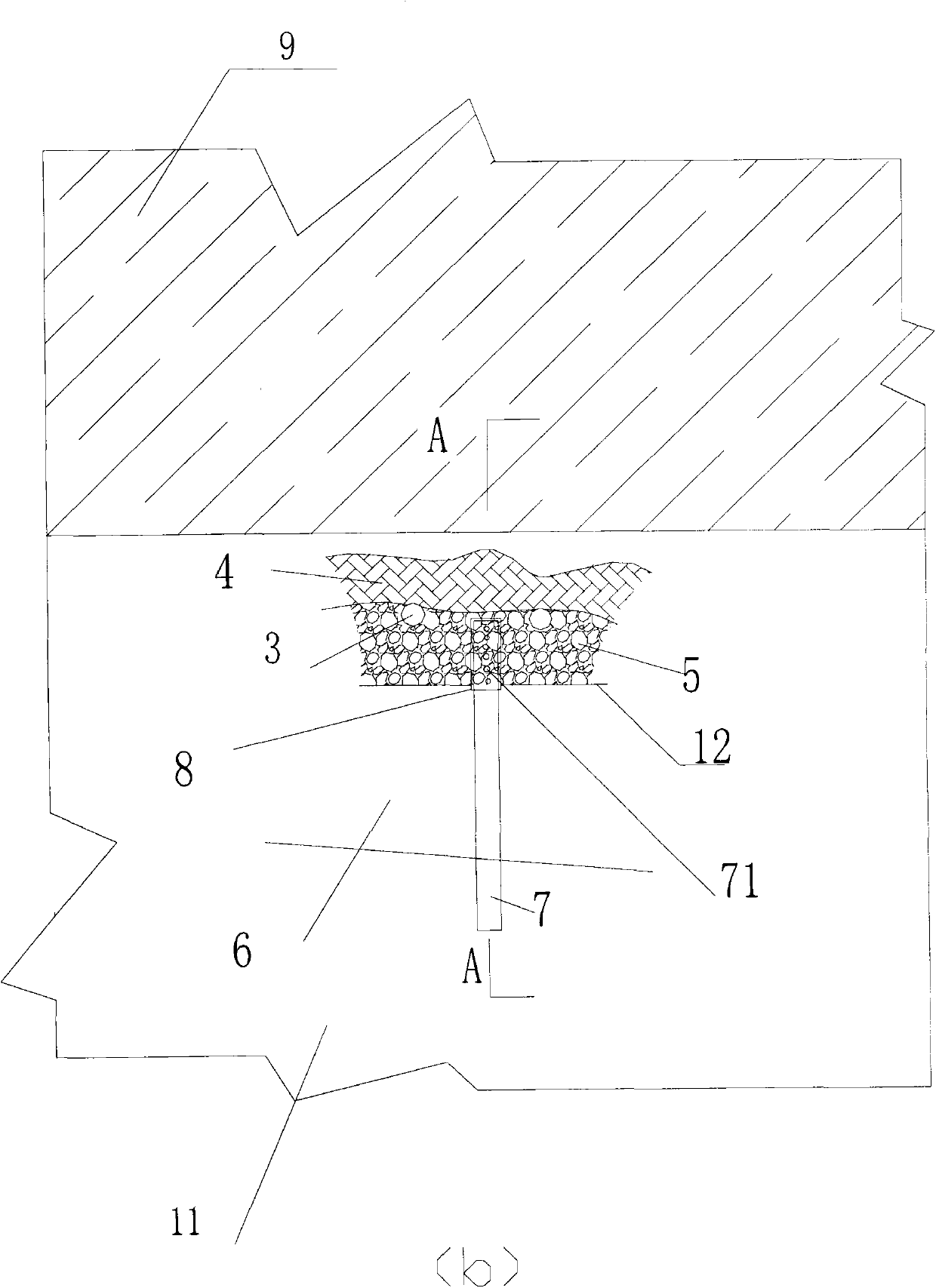

InactiveCN106120799ALess investmentReduce external coordinationPipe supportsExcavationsUnderground pipelineRebar

The invention provides a construction method for underground pipelines spanning foundation pits without modification and relocation, comprising the following steps: a. Excavating the soil on both sides of the pipeline to form underground grooves; The first steel cage and the second steel cage that protect and support the outside of the pipeline; c. lift the first steel cage and the second steel cage at the same time and place them in the underground grooves on both sides of the pipeline; d. Translate the first reinforcement cage and the second reinforcement cage in the same direction to make the first reinforcement cage and the second reinforcement cage contact; space; f. Pour concrete into the first reinforcement cage and the second reinforcement cage respectively to form the first wall width and the second wall width; g. After recycling the sand bags, construct the first wall width and the second wall width External ground connection wall. The invention reasonably solves the problem of design and construction of the ground connecting wall enclosure structure under the working condition that the underground pipeline across the foundation pit is free from modification and relocation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Fabricated multi-arch wall foundation pit supporting structure and construction technology

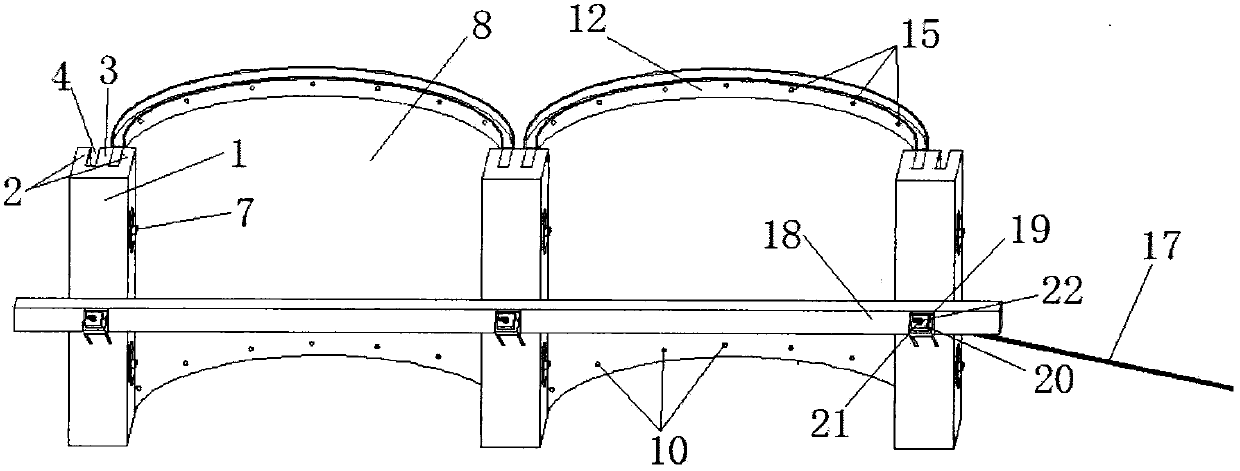

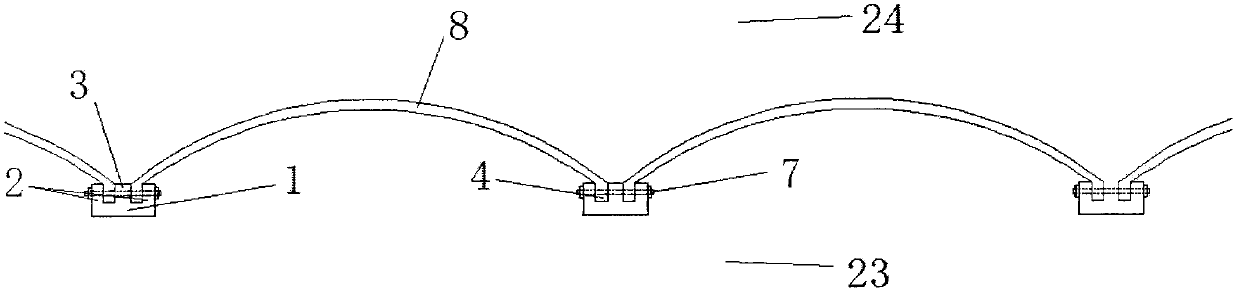

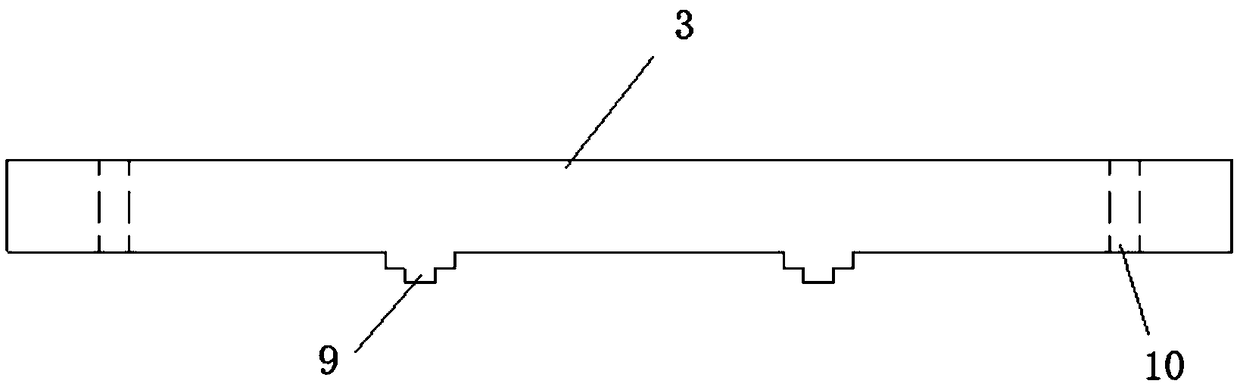

InactiveCN107740426AReasonable forceImproved force transmissionArtificial islandsProtective foundationSupporting systemReinforced concrete

The invention discloses a fabricated multi-arch wall foundation pit supporting structure and a construction technology, and belongs to the field of geotechnical engineering. The fabricated multi-archwall foundation pit supporting structure comprises precast concrete arch pieces and steel piles in the special shape like the Chinese character 'shan'. Arc-shaped steel with the H-shaped cross section, and each precast concrete arch piece are vertically combined together through casting, and the two arc pieces can be in butt joint at grooves of the arc-shaped steel in the vertical direction and connected at reserved holes through bolts. The cross section of each special-shaped pile shaped like the Chinese character 'shan', oblong reserved holes are formed in the flange of each steel pile at intervals and communicate with reserved holes in a corresponding arc piece connection rib, the oblong reserved holes in the steel piles can be connected with the reserved holes in the arc piece connection ribs through bolts, and reserved anchor rod holes can be formed in special-shaped pile webs. If a foundation pit is shallow, the special-shaped piles and the reinforced concrete precast arc piecesare subjected to combination construction, thus, a complete and closed cantilever pile foundation pit supporting system can be formed, no support or cat anchor need to be arranged, and if the foundation pit is deep, a cat anchor or an inner support can be additionally arranged.

Owner:NANJING UNIV OF TECH

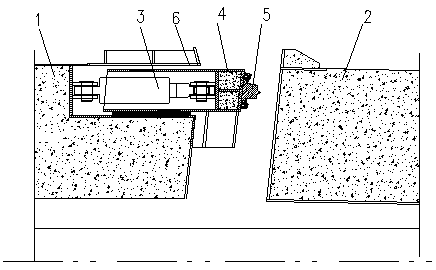

Extrusion type closing method for joint of pecast concrete utility tunnels

InactiveCN109083194ARealize sealing and waterproofingImprove sealingArtificial islandsProtective foundationEngineeringUtility tunnel

The invention relates to the technical field of municipal engineering, in particular to an extrusion type closing method for a joint of pecast concrete utility tunnels. The technical scheme provided by the invention is that nut fasteners are clamped on profile steel members and are screwed with bolts; by tightening the bolts, a gland compresses a water stop airbag, the water stop airbag expands and compresses water stop belts and further sealing water resistance of the joint of two pecast concrete utility tunnels is realized. The extrusion type closing method for the joint of the pecast concrete utility tunnels, provided by the invention, can realize sealing water resistance and has the advantages of simple structure, high construction speed and low cost.

Owner:NORTHEASTERN UNIV

Support row pile construction method for closing and water stop of deep foundation pits

ActiveCN107460882AGuaranteed water stop effectImprove the water-stop effectDrill bitsExcavationsEngineeringWater level

The invention innovatively provides a support row pile construction method for closing and water stop of deep foundation pits. The support row pile construction method is characterized in that positioning and paying off are performed at a support pile site according to designed positions so as to make pile position marks; then a row pile guide wall is constructed; I-sequence pile hole construction and pouring are performed; then drilling construction is performed at II-sequence pile hole positions between every two adjacent I-sequence pile holes; when II-sequence pile hole construction is performed, a drilling component of which the outer side is provided with a wire brush is adopted, and concrete is used for pouring; and then grouting pipes on two sides of I-sequence pile steel reinforcement cages are grouted, so that clearances among the adjacent piles are sealed. The support row pile construction method is applicable to working conditions of foundation pit support row piles that the level of underground water is higher than an excavation surface; the adjacent piles are lap-jointed, and water stop and soil retaining support are performed by utilizing the own concrete of pile bodies; grouting closing is performed among the piles by adopting a grouting technique, so that the clearances among the piles are sealed closely, and the water stop effect is ensured; a water stop curtain does not need to be arranged separately, so that construction cost is lowered; the construction period is obviously shortened; and the water stop effect of the foundation pit support row piles is improved.

Owner:MCC TIANGONG GROUP

C-C type interlocking steel pipe pile cofferdam and construction method

The invention discloses a C-C type interlocking steel pipe pile cofferdam and a construction method. The cofferdam is encircled by a plurality of C-C type interlocking steel pipe piles which are closely connected in sequence, wherein each C-C type interlocking steel pipe pile comprises a vertical steel pipe as well as a male lock catch and a female lock catch which are distributed at the outer side of the vertical steel pipe, and each two adjacent vertical steel pipes are connected through an interlocking structure composed of the corresponding male lock catch and female lock catch; and each interlocking structure is internally densely filled with an interlocking filling structure, and each interlocking filling structure comprises a cloth bag, heating resistance wires distributed in the cloth bag, and a mortar filling structure formed by sulphur mortar filled in the cloth bag. The construction method comprises the following steps: 1. surveying and setting out; 2. steel pipe pile inserting piling and closure construction; 3. interlocking structure filling; 4. cofferdam construction completion; and 5. cofferdam removal. The cofferdam disclosed by the invention is reasonable in design, simple and convenient to disassemble and assemble, safe and reliable, good in water-stopping effect, and capable of effectively achieving the engineering purposes of interlocking connection, water-stopping and rapid removal of the steel pipe pile cofferdam.

Owner:CHINA RAILWAY FIRST GRP CO LTD

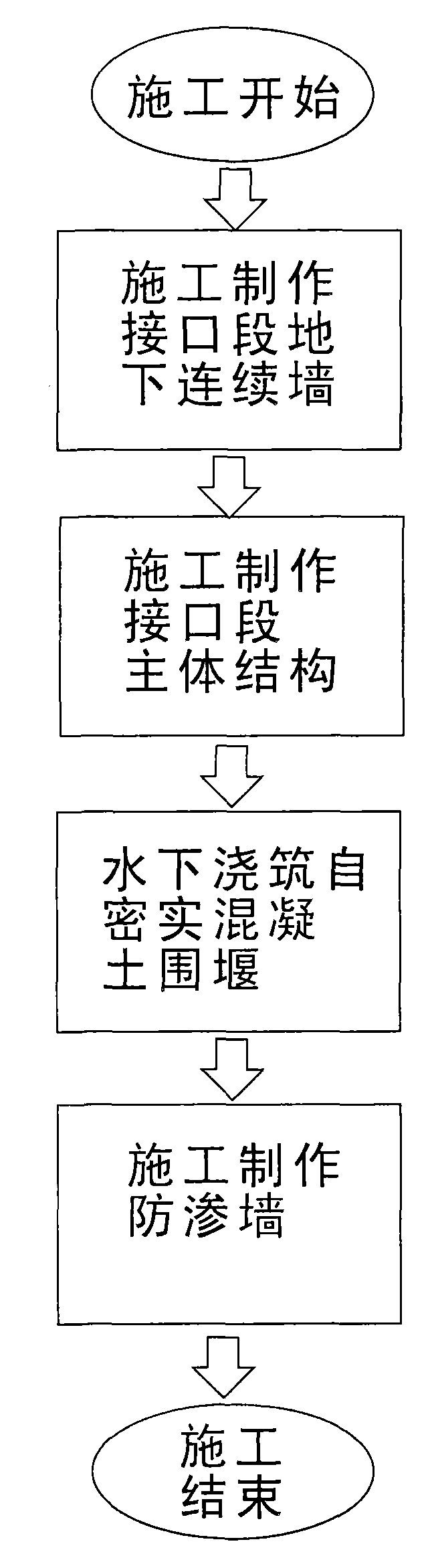

Method for constructing seepage prevention system of secondary cofferdam for immersed tube tunnel

ActiveCN101603315ASave processing spaceReduce security risksArtificial islandsUnderwater structuresSlurry wallCofferdam

The invention relates to a method for constructing a seepage prevention system of a secondary cofferdam for an immersed tube tunnel, belonging to the field of constructional engineering. The method includes the following steps: (1) construction and manufacturing of underground continuous walls of a joint section; (2) construction and manufacturing of the main body structure of the joint section; (3) underwater casting of the self-compacting concrete cofferdam; and (4) construction and manufacturing of seepage prevention walls. The invention has the advantages of small processing field, strong controllability of hoisting operation, high construction accuracy, favorable stability of the secondary cofferdam and watertight effect, less security risk, etc.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

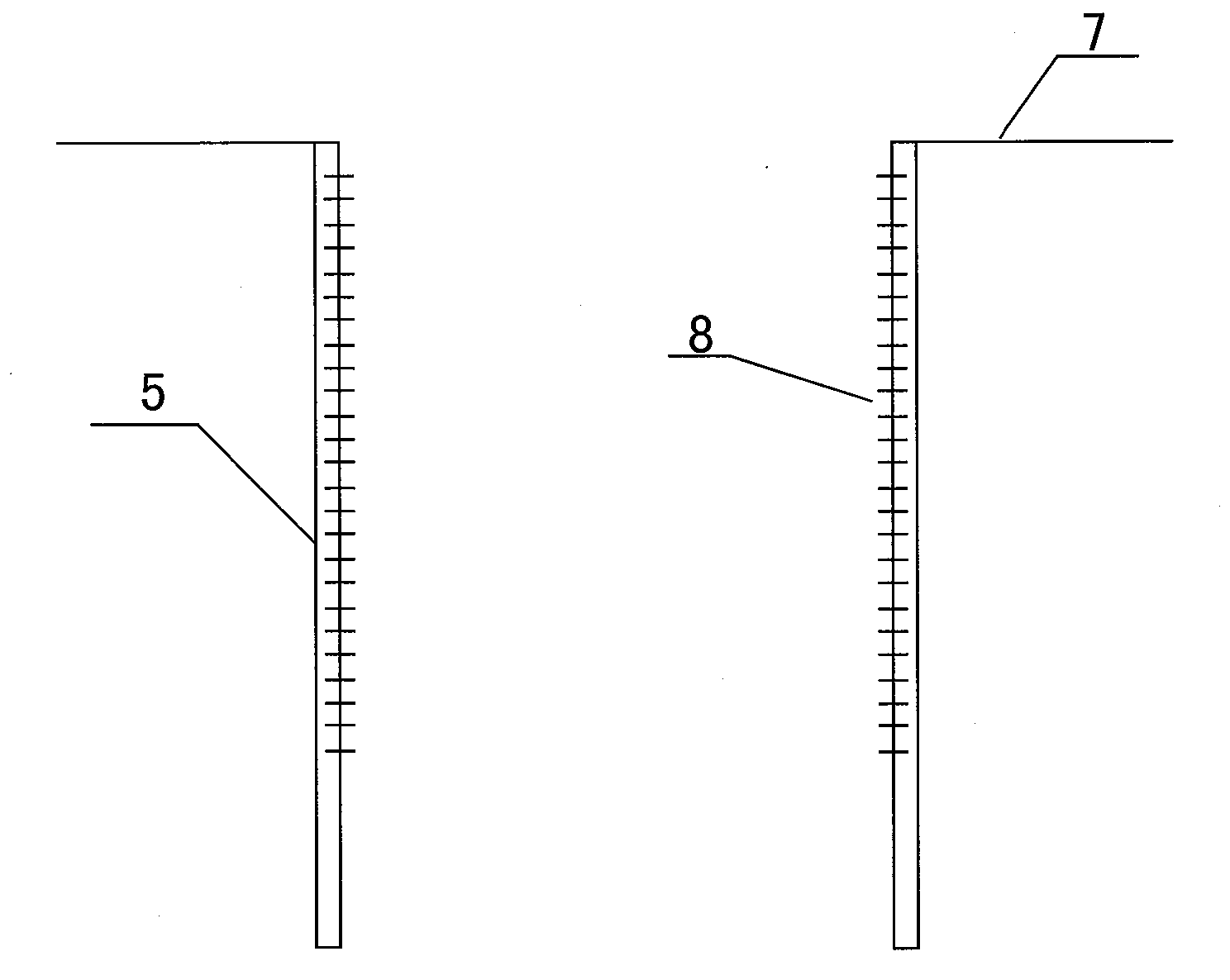

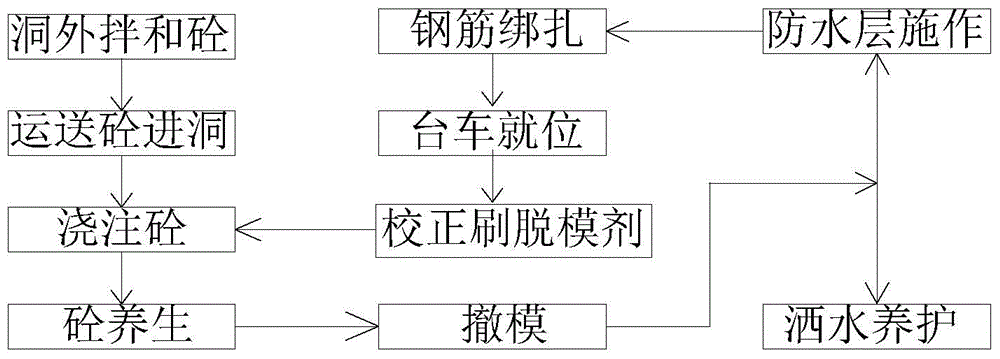

Construction method for pre-positioning water stop belt of setting arc-shaped die of quadratic lining concrete end head

InactiveCN104564107AReduce investmentEasy constructionUnderground chambersTunnel liningSheet steelEngineering

The invention discloses a construction method for pre-positioning a water stop belt of a setting arc-shaped die of a quadratic lining concrete end head. The method comprises the steps of welding a steel plate at the end head of a quadratic lining concrete trolley; arranging a U-shaped steel bar loop at the end head of the steel plate by spot welding; mounting one end of an embedded rubber water stop belt into the U-shaped steel bar loop and arranging the other end on the steel plate by reverse pressing to separate the embedded rubber water stop belt embedded into the quadratic lining concrete to be poured from the concrete surface of a poured quadratic lining concrete platform; sealing an end die through a wooden die plate; dismounting the quadratic lining concrete trolley after pouring the quadrate lining concrete so as to separate the U-shaped steel bar loop from the steel plate. According to the construction method for pre-positioning the water stop belt of the setting arc-shaped die of the quadratic lining concrete end head, the setting arc-shaped die of the quadratic lining concrete end head is processed, so that the embedded rubber water stop belt can be embedded into the quadrate lining concrete to be poured of the poured quadratic lining concrete; the setting arc-shaped die is welded on the end head die plate of the quadratic lining trolley; the investment is small, the processing is easy, the construction is simple and convenient, and wide popularization can be carried out.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Maintenance method for emergency gate of low-head gate dam and gate dam structure

ActiveCN104452702AReduce height requirementsEasy maintenanceWater-power plantsHydro energy generationArchitectural engineeringHydraulic ram

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

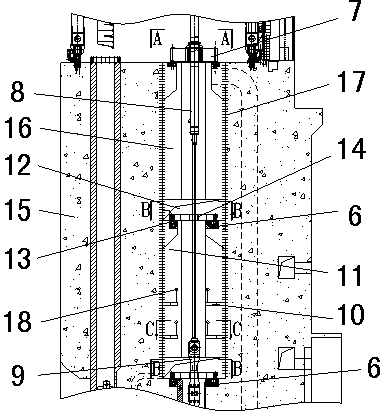

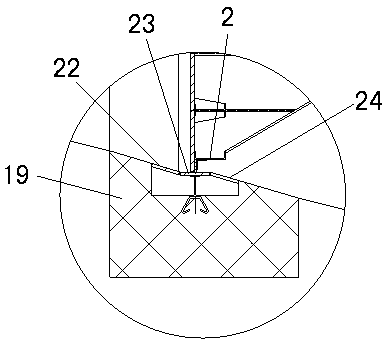

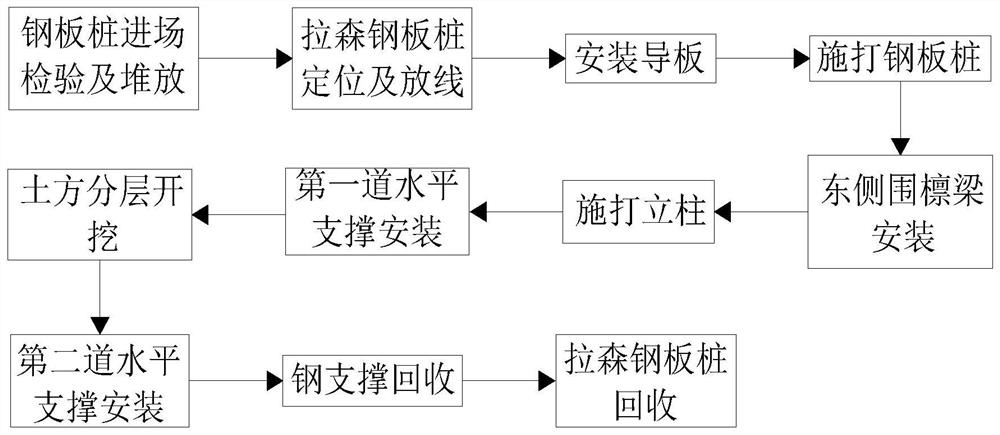

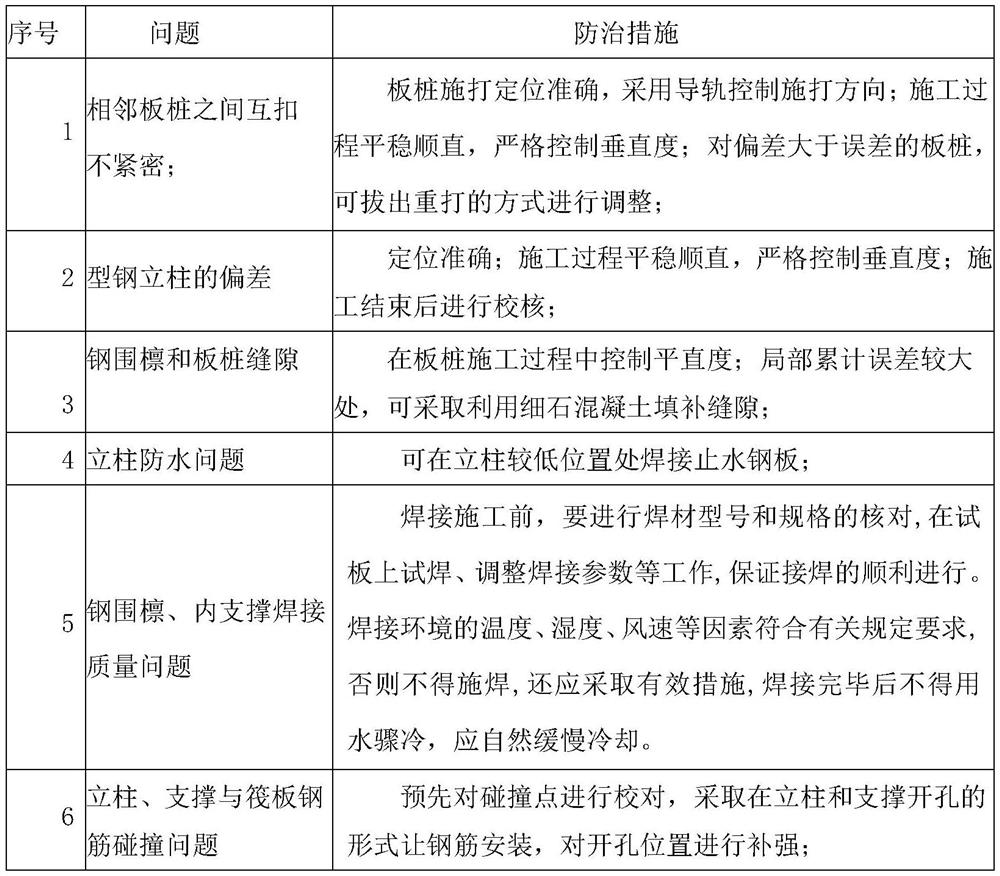

Construction method for pit-in-pit profile steel interior support of super high-rise building

InactiveCN111608186ASolve the inconvenience of installation and recyclingGuaranteed to closeExcavationsBulkheads/pilesRebarSteel plates

The invention relates to the technical field of constructional engineering and discloses a construction method for a pit-in-pit profile steel interior support of a super high-rise building. The construction method comprises steps as follows: S1, adopted steel sheet piles are subjected to receiving inspection and stacked; S2, positioning paying-off is carried out firstly, and then a guide bracket is mounted; S3, Larsen steel sheet piles are subjected to pile driving; S4, a stand column, a first support and a second support are mounted; and S5, the interior support and the steel sheet piles aredismantled to be recovered. According to the construction method for the pit-in-pit profile steel interior support of the super high-rise building, a pile driver strikes the Larsen steel sheet piles and the stand column and then steel enclosing purlin and profile steel support beams are mounted, a complete profile steel support system is formed, after early pouring maintenance of a tower raft is finished, the profile steel supports are dismantled and recovered, nodes of the pit-in-pit profile steel interior support of the super high-rise building are optimized, the nodes comprise collision nodes of the profile steel stand column and reinforcements, connecting nodes of the stand column and the support beams and connecting nodes of the enclosing purlin and the steel sheet piles, and therefore, the problem of inconvenience in subsequent mounting and recovery is effectively solved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Silicon lime sand water guiding, draining and filtering multifunctional rapid and rigid congealing body manual repaired foundation pit water-stopping curtain

ActiveCN103993609AGuaranteed water stop effectQuality assuranceFoundation engineeringCrushed stoneEngineering

The invention discloses a silicon lime sand water guiding, draining and filtering multifunctional rapid and rigid congealing body manual repaired foundation pit water-stopping curtain which comprises an overall single-row closed water-stopping curtain body arranged on the inner side wall of a foundation pit, wherein the overall single-row closed water-stopping curtain body is formed in the mode that adjacent reinforced concrete support piles are connected in a lap joint mode through primary-secondary curtain piles. The silicon lime sand water guiding, draining and filtering multifunctional rapid and rigid congealing body manual repaired foundation pit water-stopping curtain further comprises multifunctional rapid and rigid congealing bodies which are located below the underground water level and integrally formed by steel chisels, water permeable filter layers, macadam filter material layers, silicon lime sand isolating layers and silicon lime sand layers, the primary-secondary curtain piles and the reinforced concrete support piles or every two adjacent primary-secondary curtain piles are connected into a whole through the multifunctional rapid and rigid congealing bodies, and water guiding pipes are inserted in the macadam filter material layers. The silicon lime sand water guiding, draining and filtering multifunctional rapid and rigid congealing body manual repaired foundation pit water-stopping curtain has the water drainage pressure reducing function, further has the functions of water stopping, water drainage, water reduction, water filtering, soil conservation, sand fixing and the like, and is easy and convenient to use, practical and economical, and cost is saved; the quality of the curtain is guaranteed, the water stopping effect of the water-stopping curtain is guaranteed, and the project construction cost is reduced.

Owner:龚金京

Combined cofferdam under complex geological condition and construction method thereof

The invention discloses a combined cofferdam under the complex geological condition and a construction method thereof. The combined cofferdam is characterized in that a concrete antiskid pile section and a locking steel pipe pile section are arranged in the whole cofferdam by sections; and a front end concrete antiskid pile and a tail concrete antiskid pile in the concrete antiskid pile section are respectively connected with a tail locking steel pipe pile and a front end locking steel pipe pile in the locking steel pipe pile section to form the whole sealed cofferdam. The cofferdam under the complex geological condition has clear structural stress, firm structure, good water stopping effect and simpler construction method and can effectively protect basic construction quality.

Owner:THE FIRST CIVIL ENG CO LTD OF CREC SHANGHAI GRP

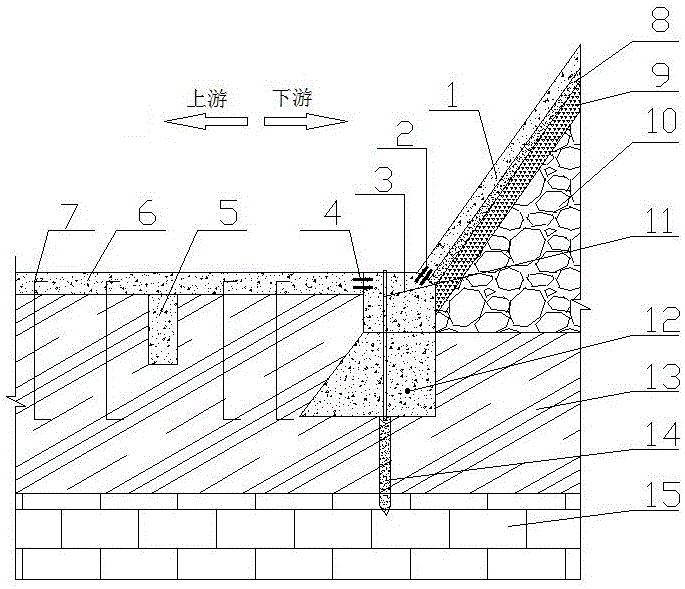

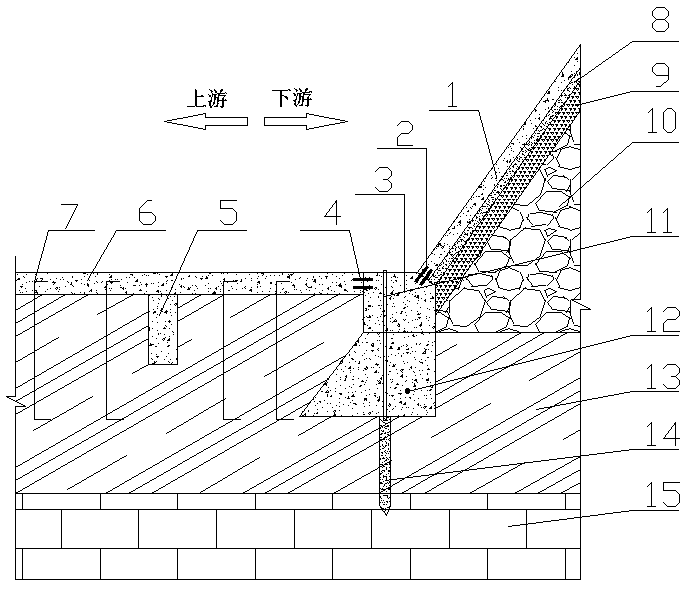

Seepage prevention structure of concrete face rockfill dam

ActiveCN105672205AGuaranteed water stop effectEasy constructionEarth-fill damsRock-fill damsBedrockOn board

The invention discloses a seepage prevention structure of a concrete face rockfill dam. The seepage prevention structure of the concrete face rockfill dam comprises bed rock and a covering layer located on the bed rock, a dam body is arranged on the covering layer and comprises rockfill, and dam transition material, dam bedding material and a face plate are sequentially laid on the slope surface of the rockfill from bottom to top; a foundation abutment wall is arranged at the part, located at the lower end of the face plate, of the upstream side of the dam body in an excavated mode and is provided with a toe board, one side of the top of the toe board makes contact with the face plate, and water stop copper sheets are arranged at the contact part; a seepage prevention board flush with the toe board is arranged on the upstream side of the toe board, and water stop copper sheets are arranged at the joints between the toe board and the seepage prevention board. According to the seepage prevention structure of the concrete face rockfill dam, the stress property of the structure is greatly improved, and the toe board cannot be moved upwards or overturned. Structural construction of the toe board does not interfere with dam filling. Construction is convenient, the construction period is shortened, the engineering cost is lowered, and the project benefit is good.

Owner:POWERCHINA ZHONGNAN ENG

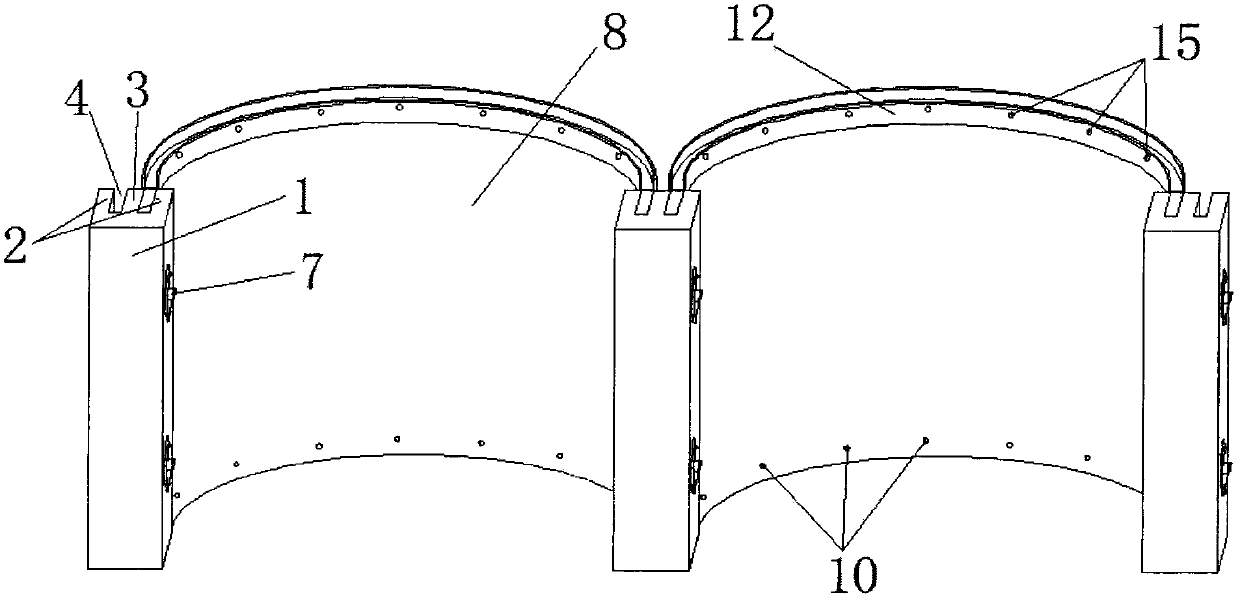

Mobile composite water stopping system and using method thereof

ActiveCN107700538AAchieve sealingImprove the water-stop effectArtificial islandsUnderwater structuresEngineering

The invention relates to the technical field of immersed tunnels, in particular to a mobile composite water stopping system and a using method thereof. The mobile composite water stopping system comprises a first component and a second component which move mutually, a combing cavity is formed between the first component and the second component, the two components are provided with an exterior water stopping device enabling the combining cavity to be relatively sealed, the exterior water stopping device comprises flexible water stopping belts which are connected with the first component and the second component, and the extending length of the flexible water stopping belts corresponds to the relatively-moving length of the two components; an interior water stopping device is further installed in a cavity of the combining cavity, the exterior water stopping device of the water stopping system has the main water stopping effect, and the interior water stopping device has the standby andcomposite water stopping effect; and when the exterior water stopping device has leakage or damage, the interior water stopping device plays a role, the water stopping function is further achieved, influences on construction or use are avoided, the composite water stopping effect is achieved, and the dual water stopping aim and effect are achieved.

Owner:CCCC HIGHWAY CONSULTANTS

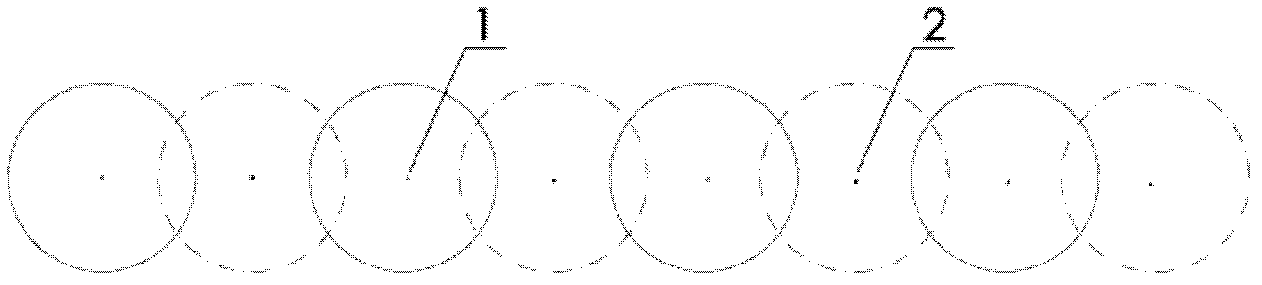

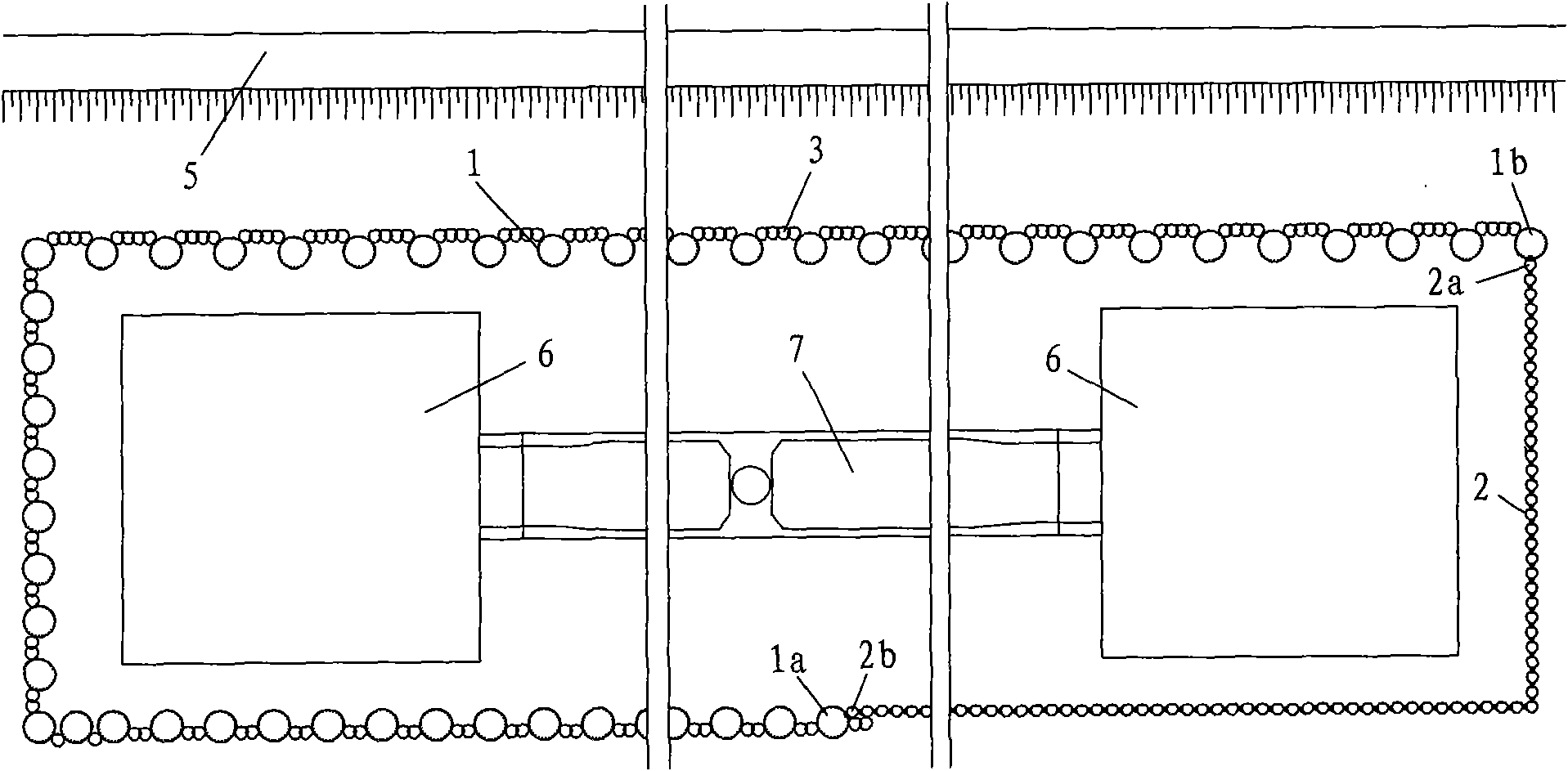

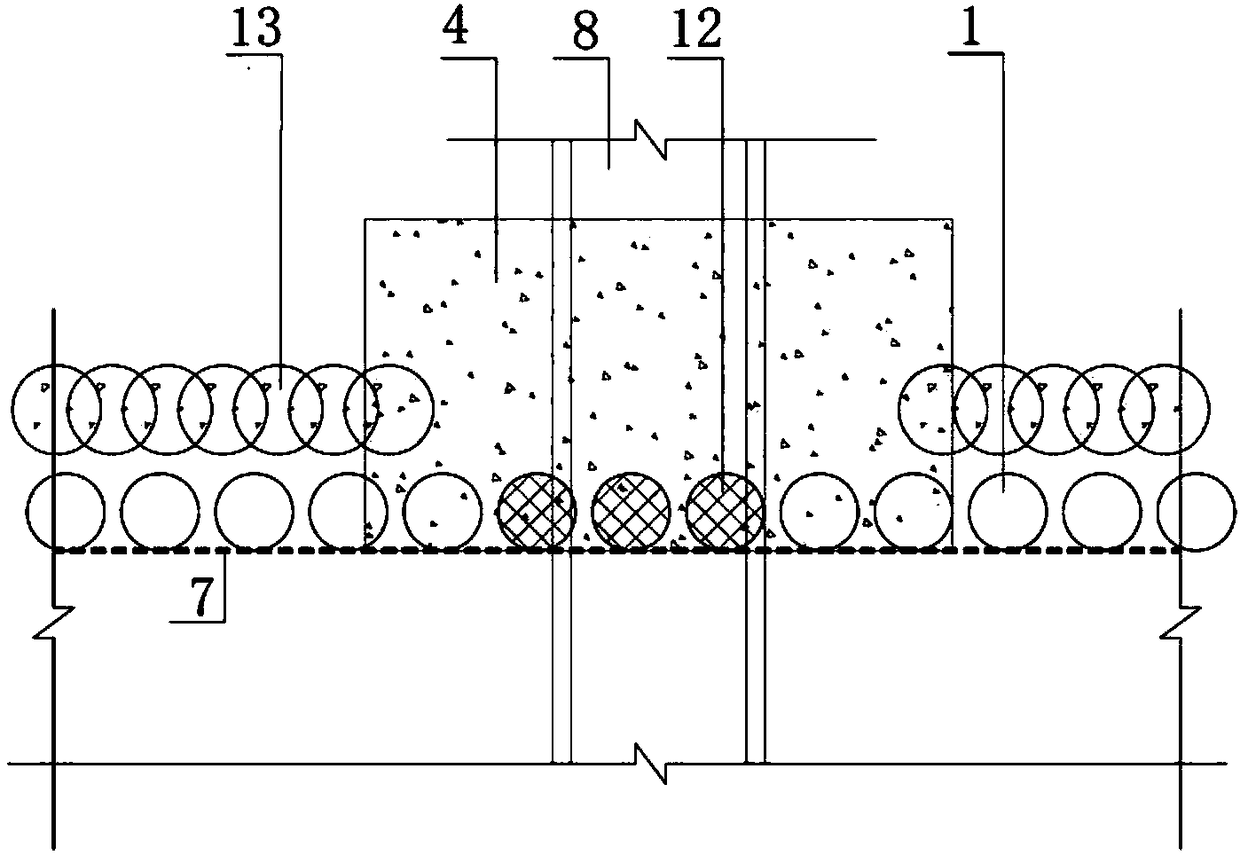

Supporting structure suitable for non-closed foundation pit

PendingCN108149692AWide range of applicationsThe reinforcement effect is reliableExcavationsEngineeringStructural engineering

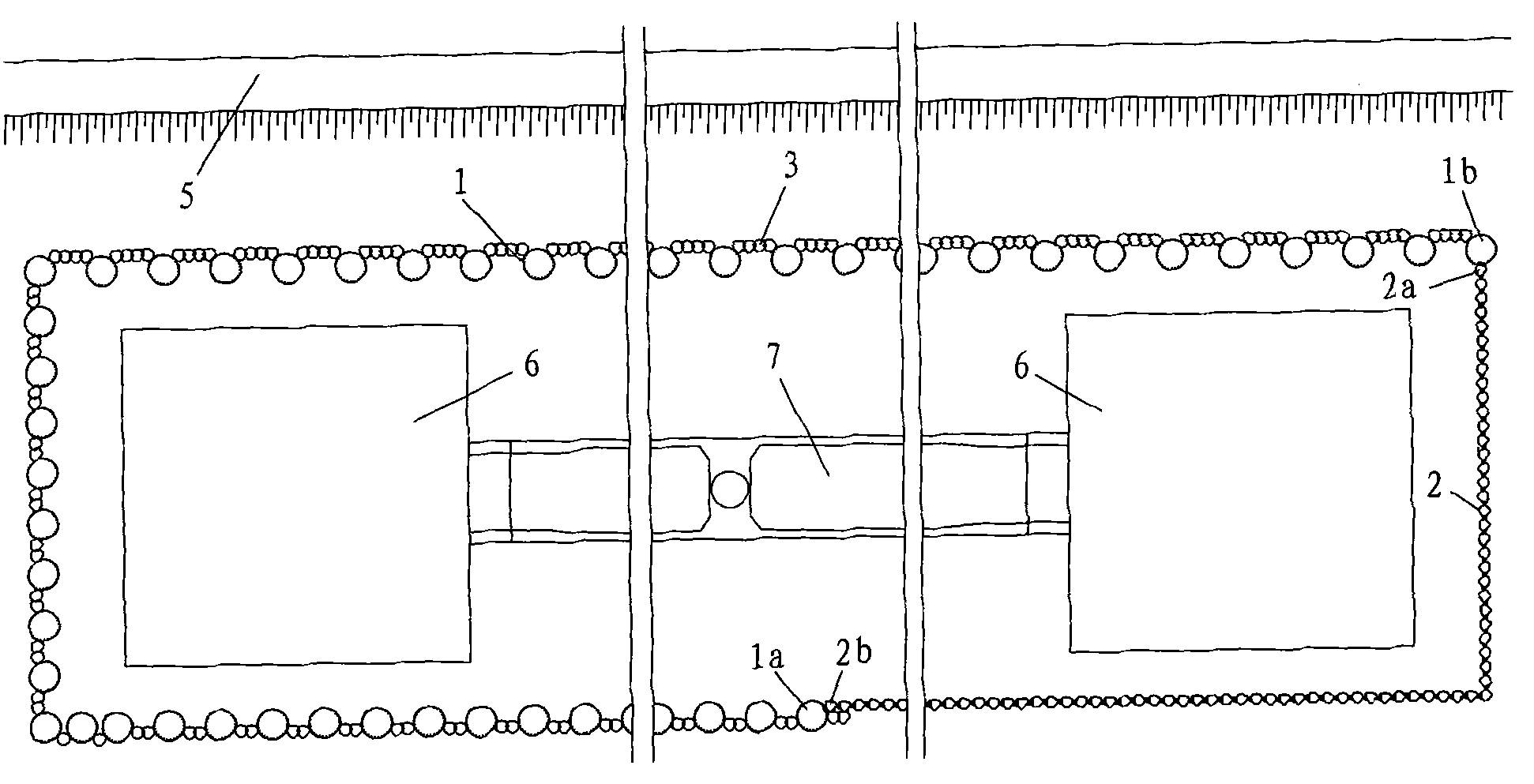

The invention relates to a supporting structure suitable for a non-closed foundation pit. The supporting structure is arranged around the pit wall of a foundation pit and comprises enclosing piles (1)and ring beams (2), and the ring beams (2) are attached to the inner sides of all the enclosing piles (1) for arrangement to form a horizontally-enclosed beam system. The supporting structure furthercomprises an MJS reinforcing body (4) and a soil retaining board (5). Waterproof curtains (13) are arranged at the outer sides of the enclosing piles (1) outside an existing pipeline area of the foundation pit wall. The pile bottoms of the enclosing piles (1) are constructed to the position above an existing pipeline (8) in the existing pipeline area of the foundation pit wall. The MJS reinforcing body (4) is arranged around the existing pipeline (8) in the pit wall at the outer side of the foundation pit. The soil retaining board (5) is arranged between an excavation face of the foundation pit and a soil mass free face below the existing pipeline (8), and the two ends of the soil retaining board (5) are connected with the enclosing piles (1) at the two sides of the existing pipeline (8)correspondingly. Compared with the prior art, the supporting structure suitable for the non-closed foundation pit has the advantages of being capable of protecting the ambient environment, wide in application face, safe and reliable in structure and the like.

Owner:SHANGHAI PUDONG ARCHITECTURAL DESIGN & RES INST

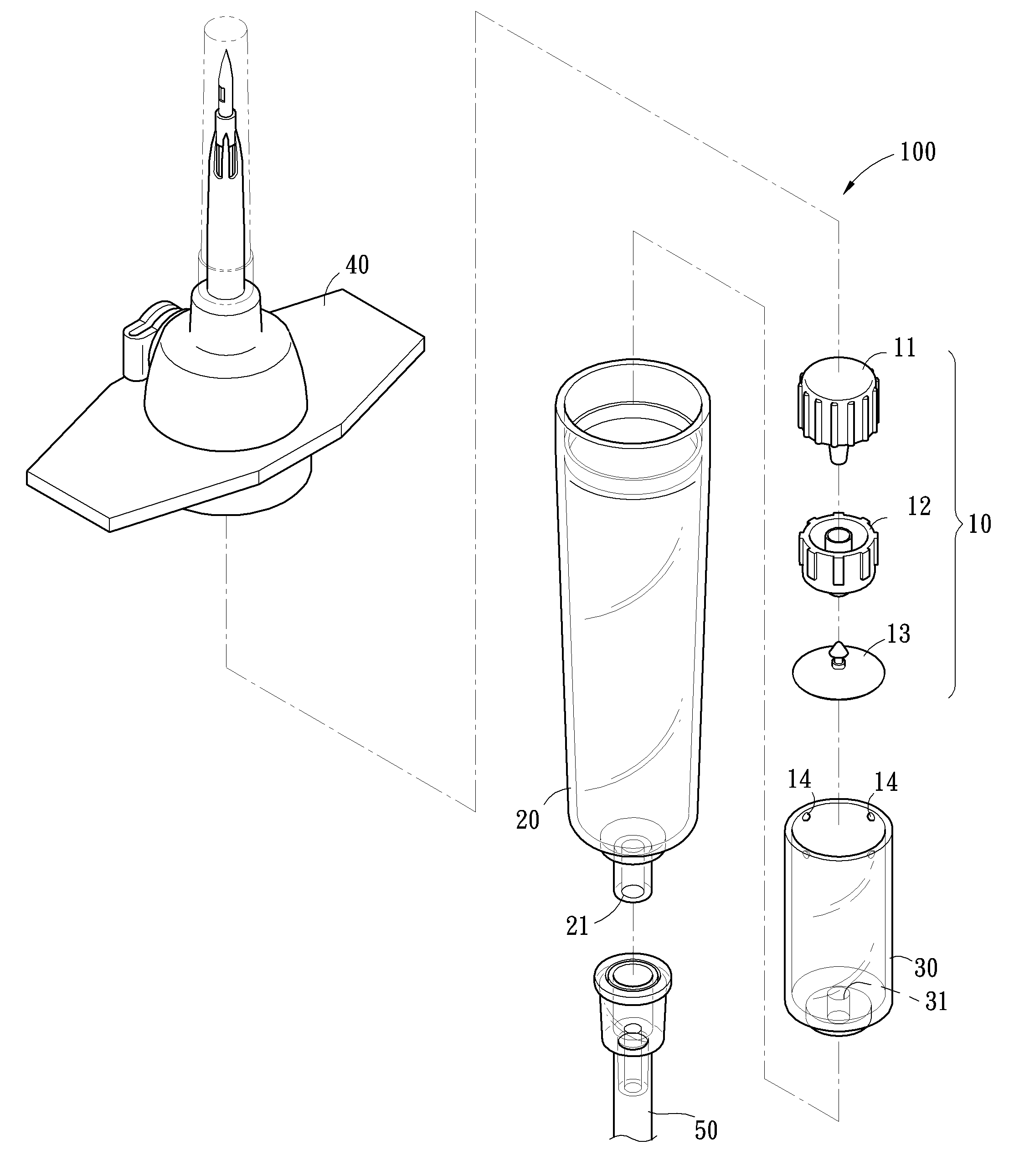

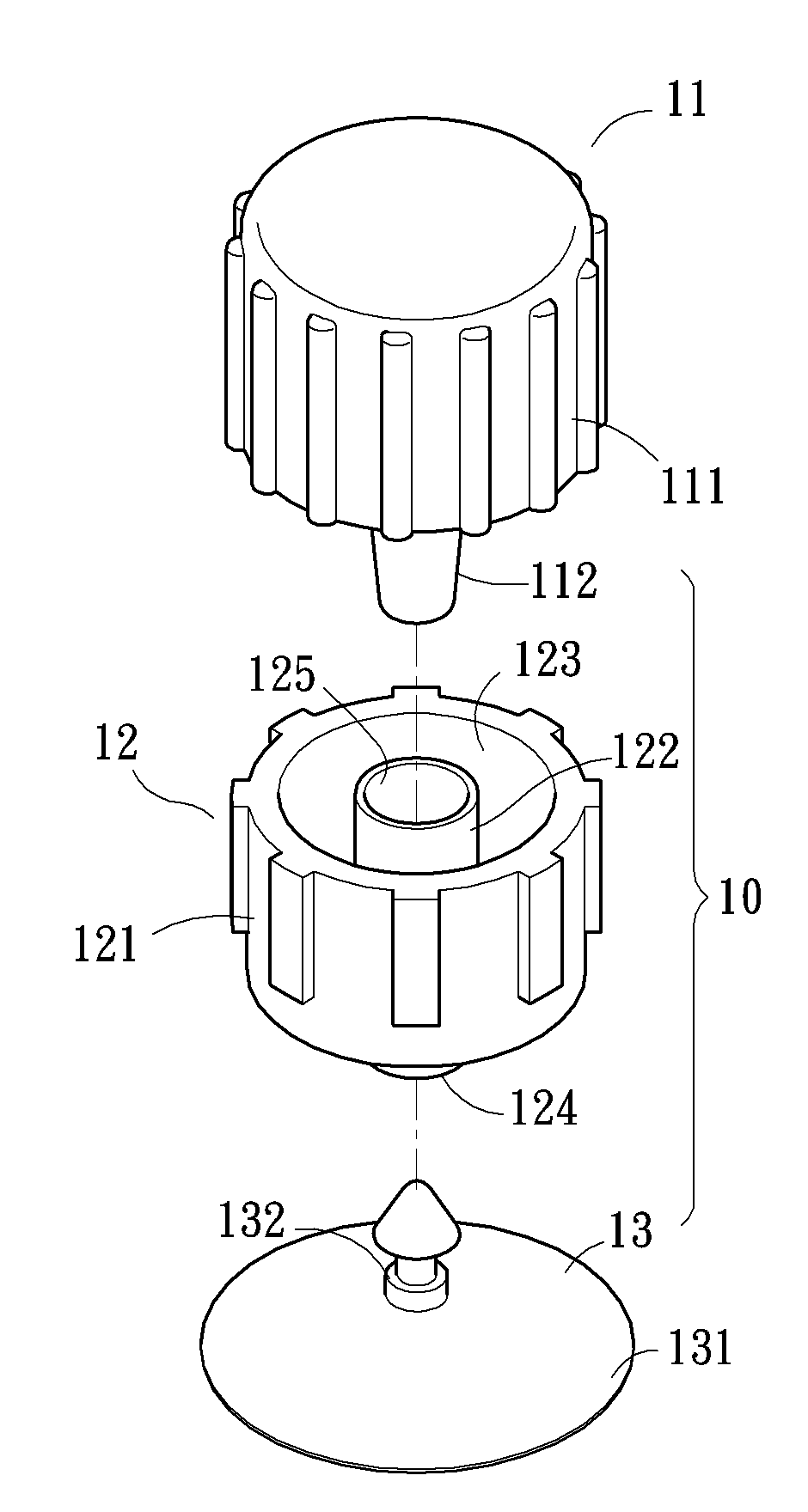

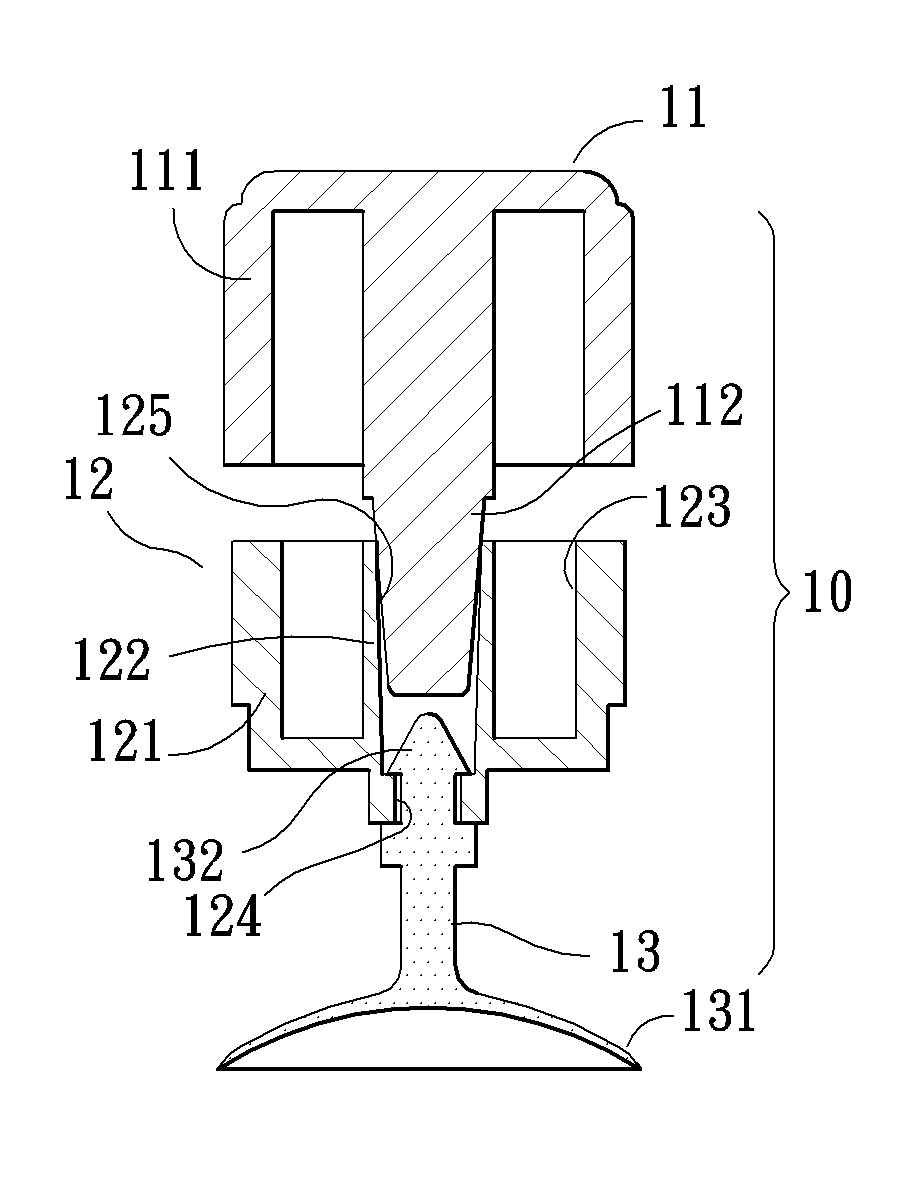

Anti-extrusion drip transfusion safety control device

ActiveCN102085401AAffect the water-stop effectDrip storage cup to preventInfusion devicesDetentSafety control

The invention relates to an anti-extrusion drip transfusion safety control device which mainly comprises a floating detent plug device and a drip storage cup, wherein the floating detent plug device is arranged in the drip storage cup and floats above a liquid outlet of the drip storage cup; the floating detent plug device floats up and down under the action of floating power and can block the liquid outlet of the drip storage cup when the liquid level falls so as to stop the liquid; and an internal support sleeve is arranged in the drip storage cup to prevent the pressed deformation of the drip storage cup, thereby avoiding the situation that the floating detent plug device is obstructed when floating up and down.

Owner:汪贤宗 +1

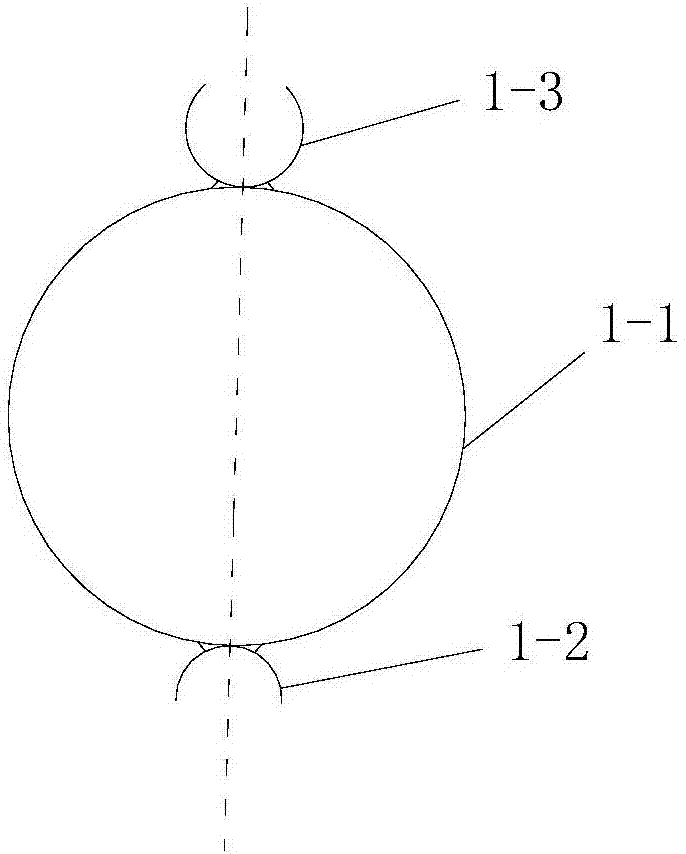

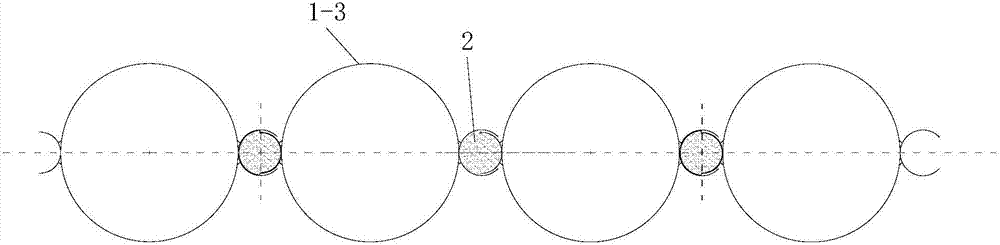

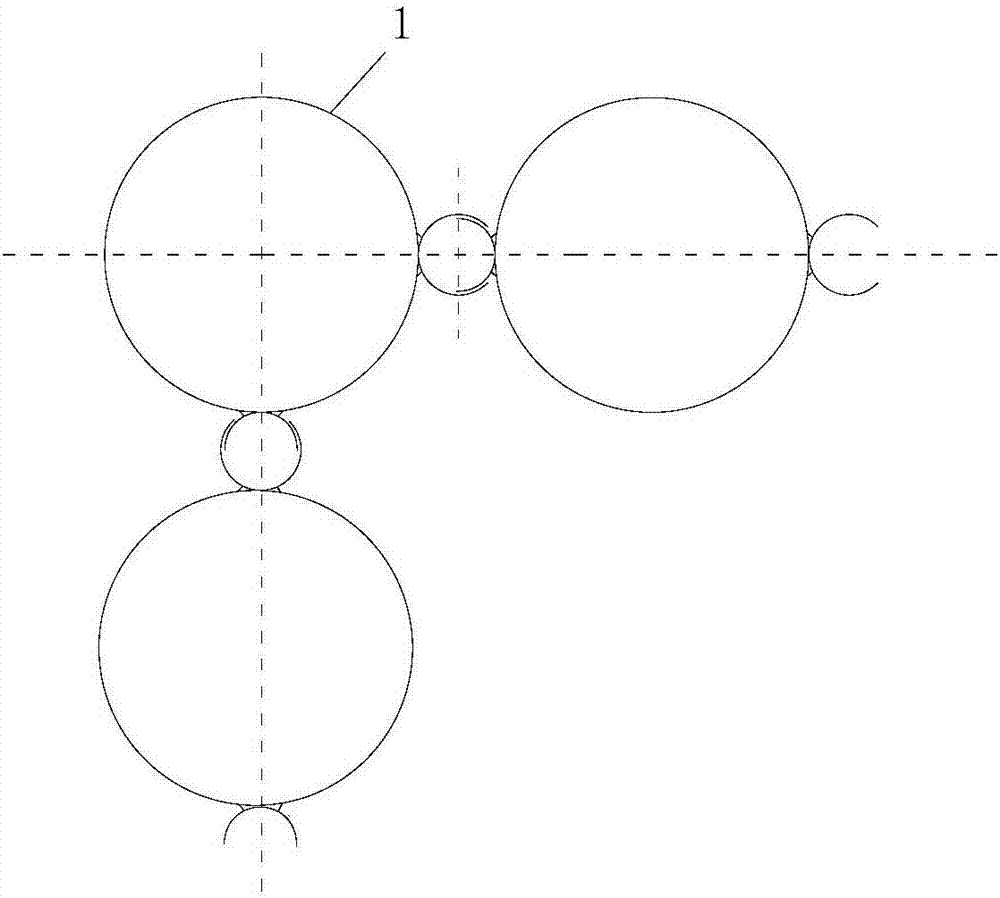

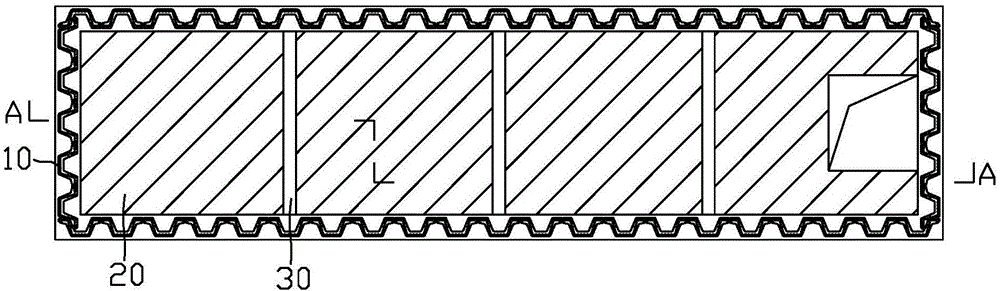

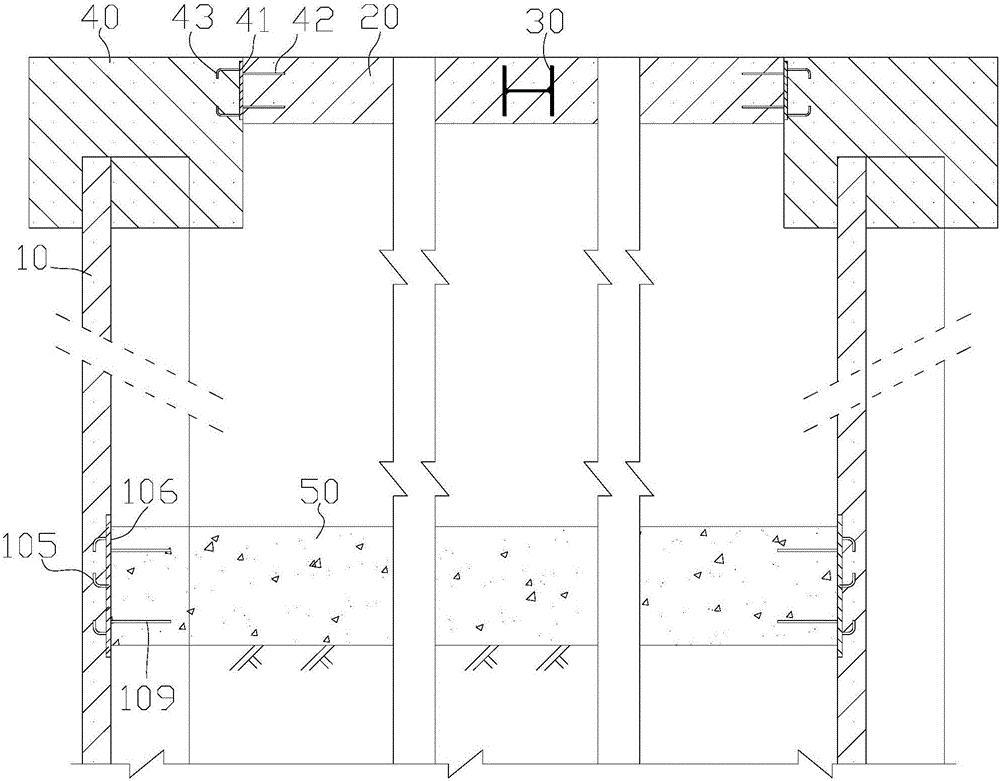

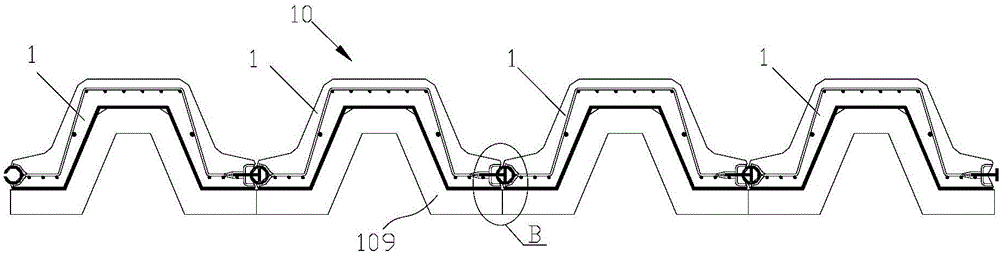

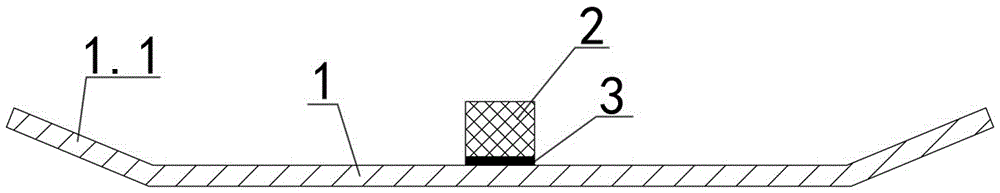

Permanent plate pile underground structure and construction method thereof

ActiveCN106812131AShorten the demolition periodLow construction costProtective foundationExcavationsSupporting systemReinforced concrete

The invention discloses a permanent plate pile underground structure. The permanent plate pile underground structure comprises a plate pile wall formed by reinforced concrete corrugated plate piles which are mutually connected, a crown beam arranged on the top of the plate pile wall, a horizontal supporting beam supporting the inner side of the crown beam, a top plate with the horizontal supporting beam as a structural beam, and a reinforced concrete bottom plate connected to the inner side face of the plate pile wall, wherein the plate pile wall serves as an outer wall of the underground structure and is a supporting structure of a foundation trench of the underground structure, and the crown beam and the horizontal supporting beam serve as a crown beam and a horizontal supporting beam of a supporting system of the foundation trench of the permanent plate pile underground structure. The invention further discloses a construction method of the underground structure. According to the permanent plate pile underground structure, the crown beam and the horizontal supporting beam in the supporting system of the foundation trench are remained, the crown beam and the horizontal supporting beam serve as a frame structure of the top plate of the underground structure, the dismounting construction period of the crown beam and the horizontal supporting beam is saved, the building expenditure of the top plate of the underground structure is saved, and meanwhile the anti-seismic performance of the top plate of the underground structure is improved.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD +1

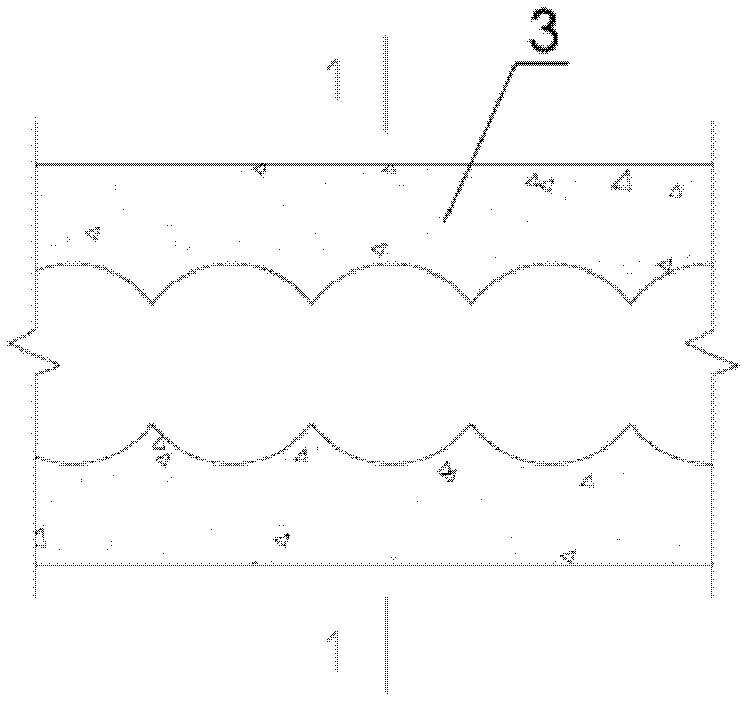

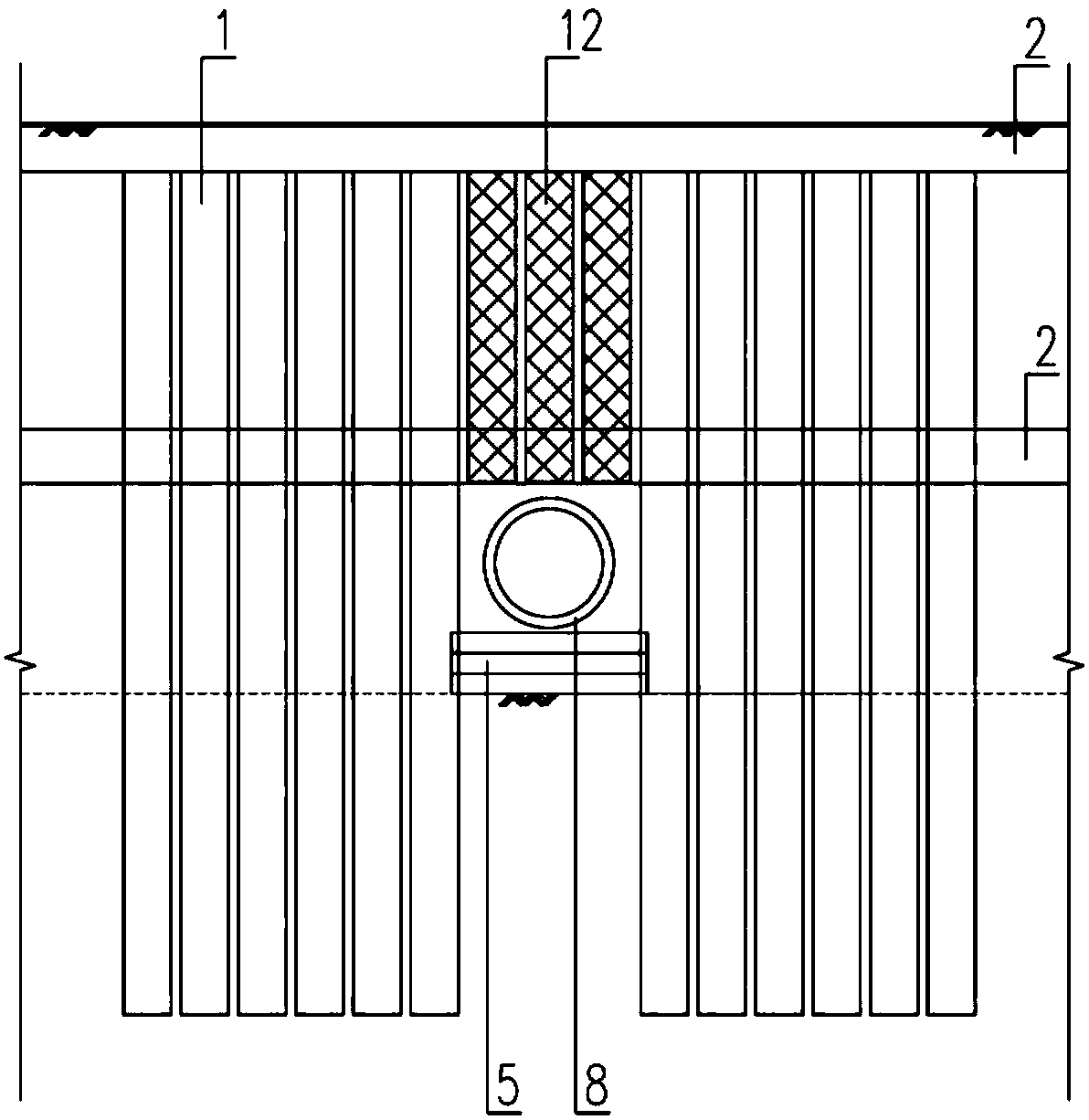

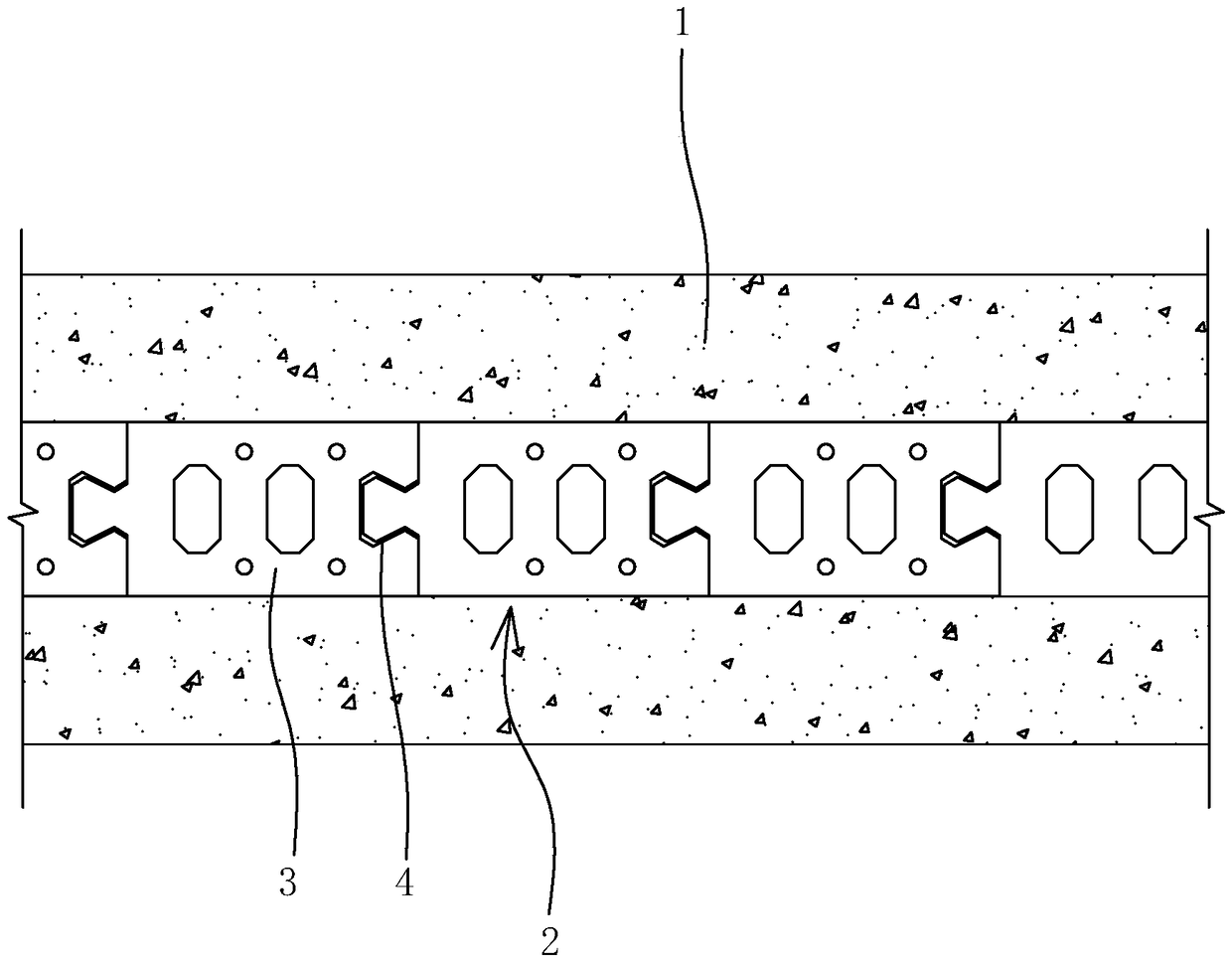

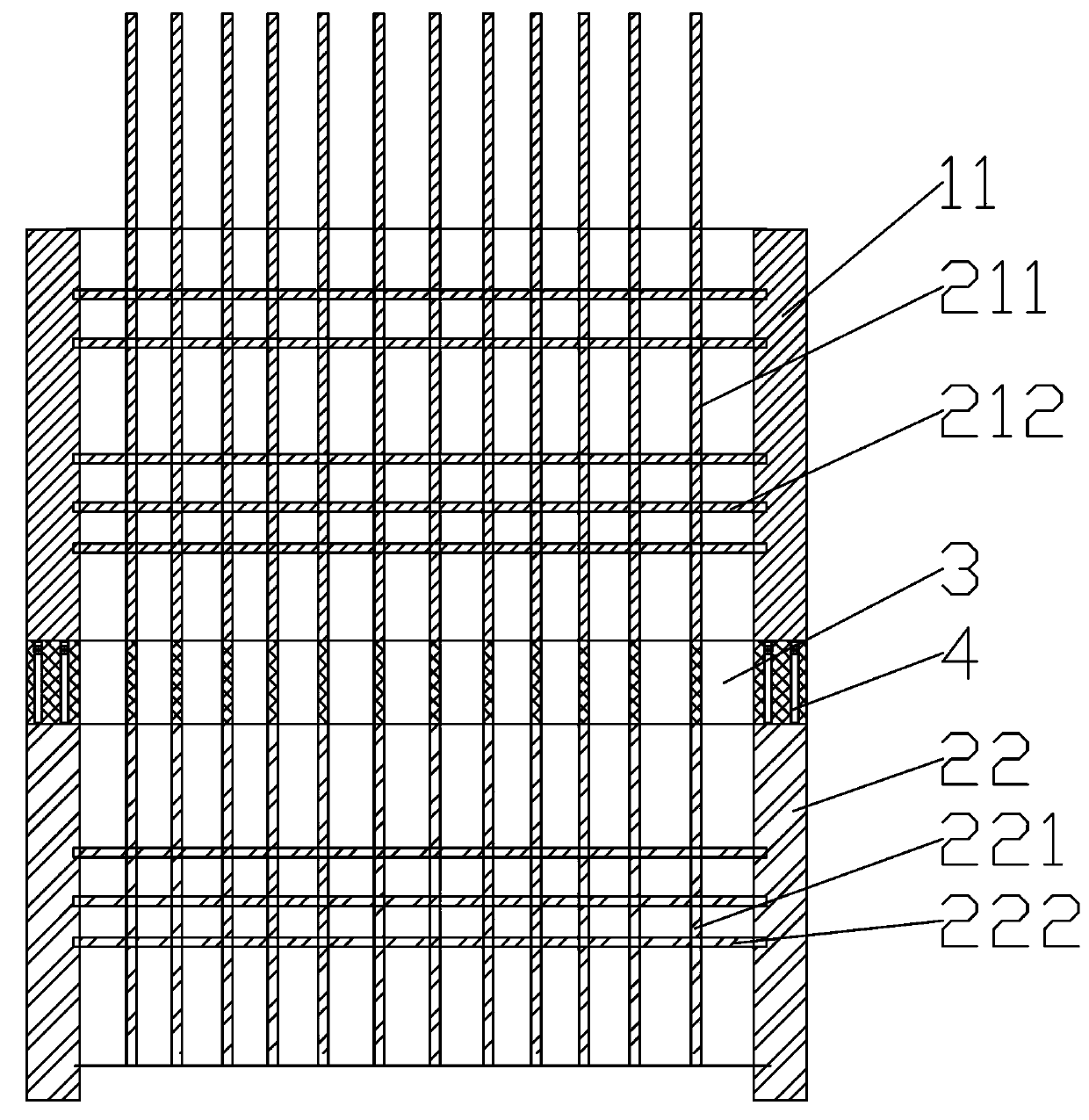

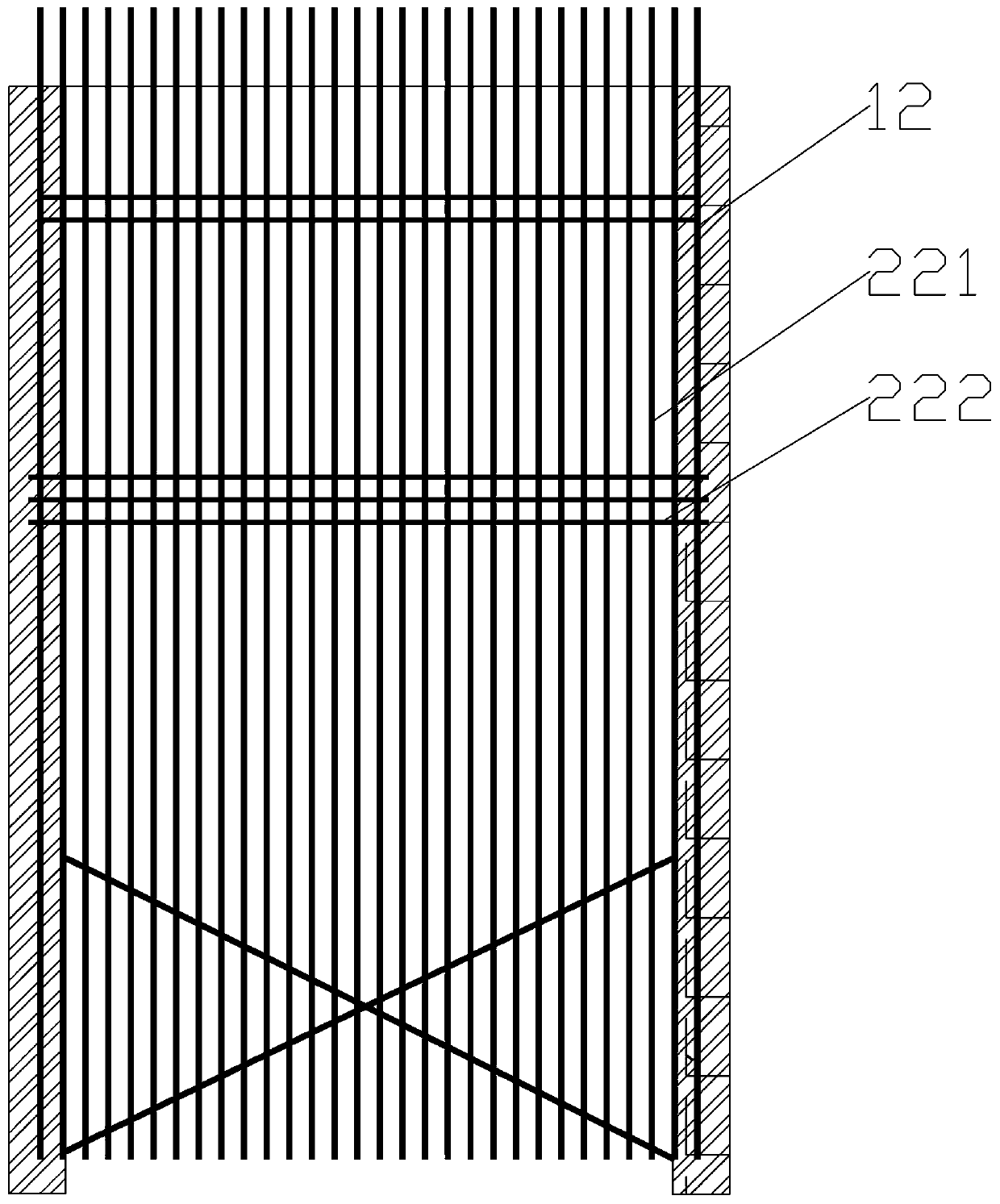

Multiple water stop belt, waterproof structure and construction method of waterproof structure

InactiveCN105821908AGuaranteed water stop effectPlay the role of water stopArtificial islandsProtective foundationEconomic benefitsEngineering

The invention discloses a multiple water stop belt, a waterproof structure and a construction method of the waterproof structure. The multiple water stop belt comprises a metal water stop plate and at least one water stop strip fixedly connected to the surface of the metal water stop plate. The water stop strips are arranged in the length direction of the metal water stop plate in a through-length manner. The water stop strips are located on the upper side and / or the lower side of the metal water stop plate. The waterproof structure comprises multiple water stop belts, structural reinforcing steel bars, fore-poured concrete and post-poured concrete. A fore-poured concrete water stop strip body of each multiple water stop belt is embedded in the fore-poured concrete, and a post-poured concrete water stop strip body of each multiple water stop belt is embedded in the post-poured concrete. The construction method of the waterproof structure includes the construction steps that the multiple water stop belts are machined, the structural reinforcing steel bars are bound, the multiple water stop belts are fixed, a formwork is erected, and the concrete is poured. A water stop function of the concrete can be achieved, a waterproof effect is ensured, the water stop belts release stress under the dead load of concrete pouring, water can be stopped effectively, and therefore economic benefits are improved.

Owner:姚攀峰

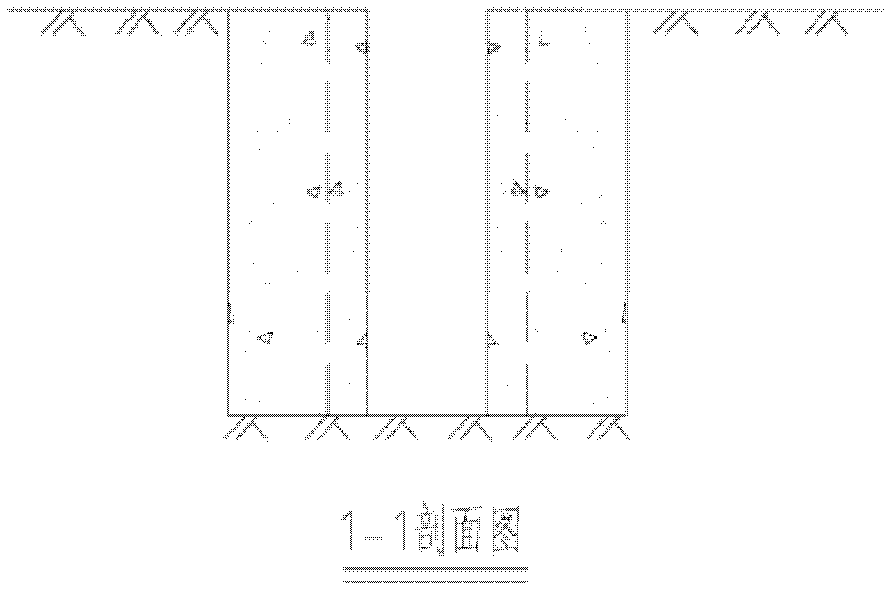

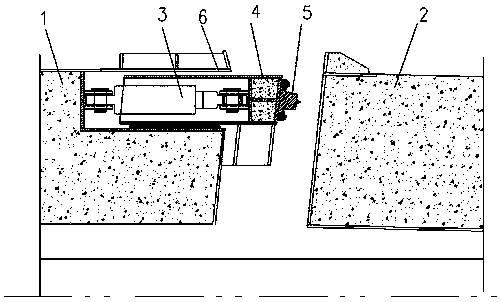

Horizontal wall reserved hole manufacturing and plugging device and method

ActiveCN107217844AGuaranteed water stop effectAvoid it happening againBuilding repairsForms/shuttering/falseworksWater leakageReinforced concrete

The invention provides a horizontal wall reserved hole manufacturing and plugging device and method. The horizontal wall reserved hole plugging device comprises a water stop component and two plugging components, the water stop component is fixed in the middle of a reinforced concrete wall, and the plugging components are positioned on two sides of the water stop component, fixed at openings of a reserved hole of the reinforced concrete wall and used for plugging materials filling the reserved hole. According to the manufacturing and plugging device and method, the water stop component seals the reserved hole through rubber gaskets, water stop effect of a water stop plate is ensured, the plugging components are fixed at the hole openings, fillers can be tamped, and cracks caused by shrink of solidified fillers are avoided, so that water penetration, water leakage and the like generated after plugging of the horizontal reserved hole are effectively improved.

Owner:MCC5 GROUP CORP SHANGHAI

Channel cutting assembly type underground continuous wall and construction method

ActiveCN108951611AGuaranteed water stop effectShorten the construction periodBulkheads/pilesSlurry wallReinforced concrete

The invention discloses a channel cutting assembly type underground continuous wall and a construction method. The channel cutting assembly type underground continuous wall and a construction method which is capable of guaranteeing soil blocking capability and water stopping capability of a foundation pit enclosure, and a construction period of the foundation pit enclosure is effectively shortened, the occupied space of a foundation pit support is reduced is provided. The channel cutting assembly type underground continuous wall comprises an underground water soil continuous wall and an assembly type wall body component, wherein the underground water soil continuous wall is used for blocking underground water to form a foundation pit enclosure body, the assembly type wall body component isarranged into the underground water soil continuous wall in an inserted mode, the assembly type wall body component comprises a plurality of vertical reinforced concrete prefabricated parts which aredistributed in sequence along the length direction of the underground water soil continuous wall, and every two adjacent vertical reinforced concrete prefabricated parts are connected through a mortise and tenon structure.

Owner:浙江吉通地空建筑科技有限公司

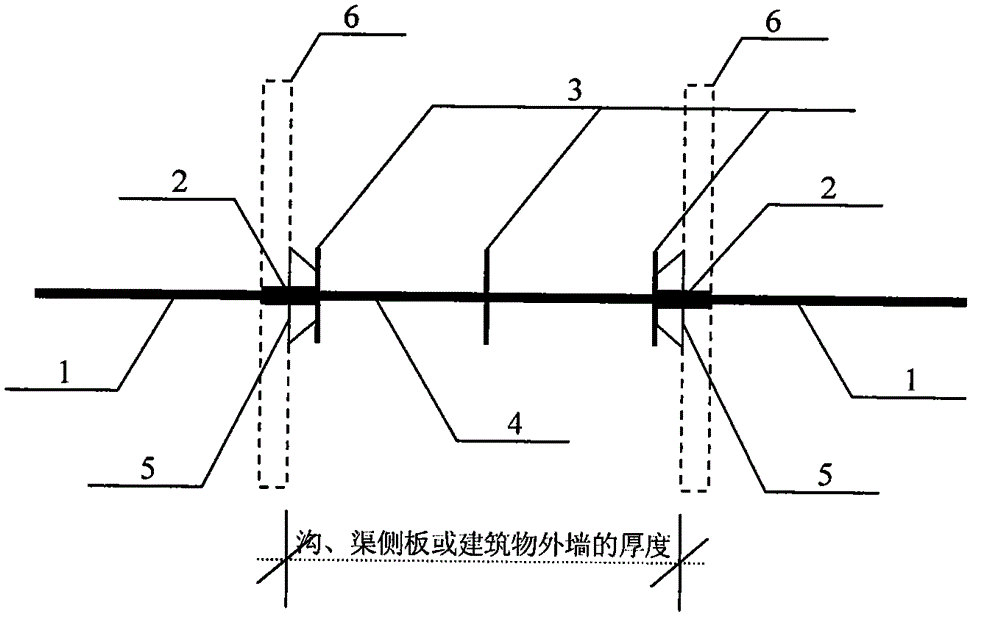

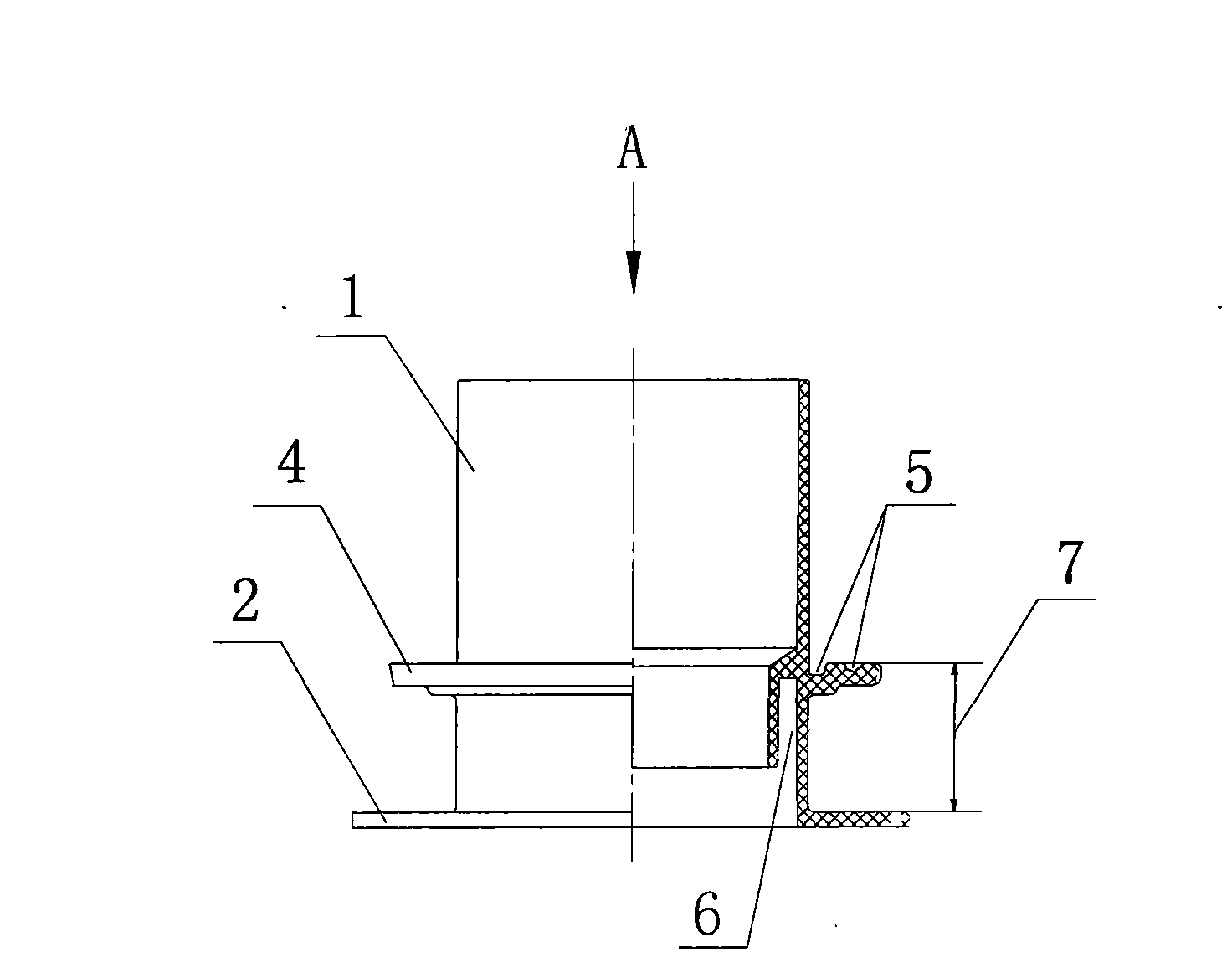

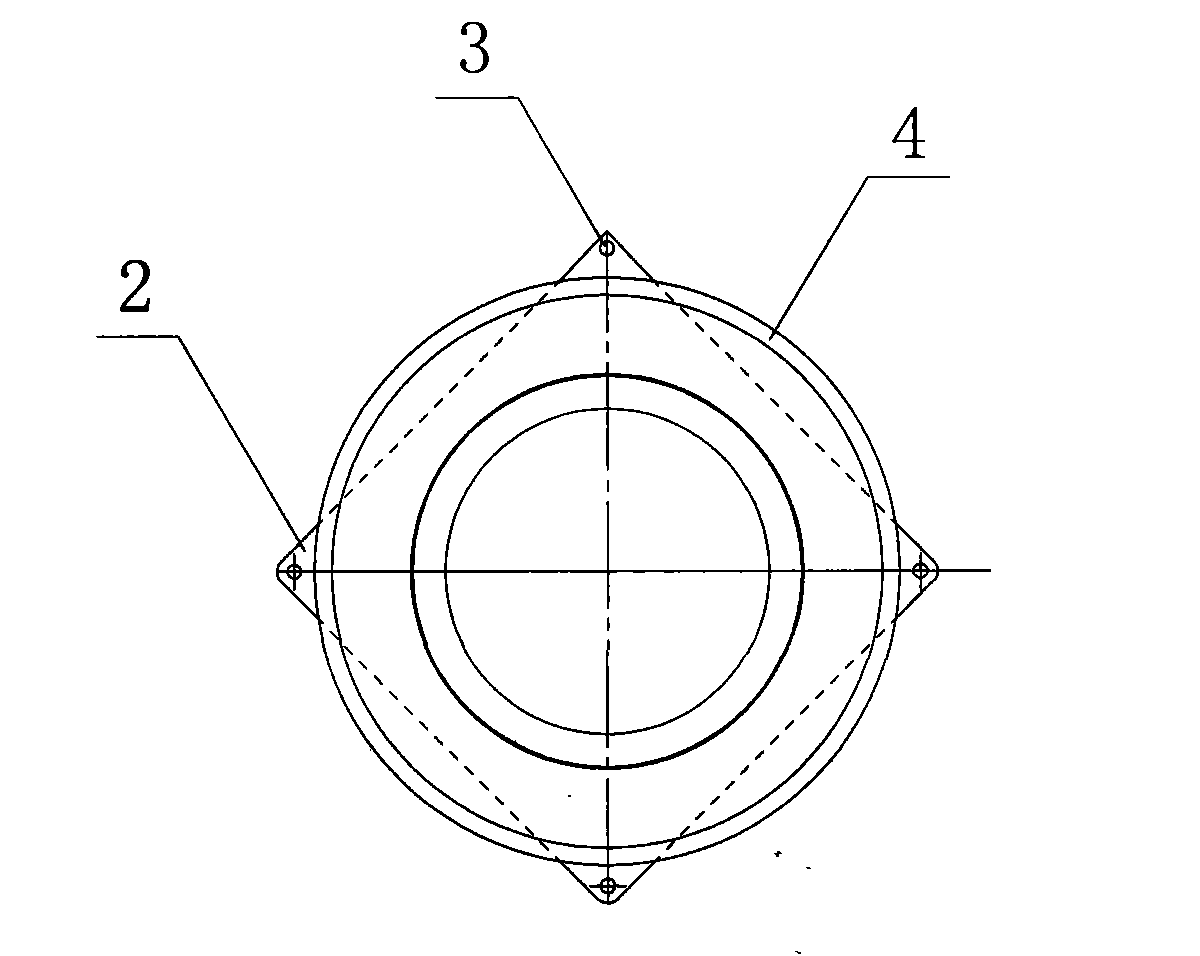

Energy-saving sectional type water stop split screw rod device

InactiveCN105888244AEasy to removeZero lossArtificial water canalsAuxillary members of forms/shuttering/falseworksRear quarterMechanical engineering

The invention relates to an energy-saving sectional type water stop split screw rod device. The device consists of a phi 12 long screw rod with threads at the two ends and three water stop pieces in the middle, two phi 12 full-threaded short screw rods, two M12 long nuts and two plastic conical caps. When the device is in use, firstly, the phi 12 long screw rod with, the threads at the two ends and the three water stop pieces in the middle is selected to be processed according to the thickness of a ditch and channel side plate or a building outer wall; then the M12 long nuts are connected with the phi 12 full-threaded short screw rods and are screwed down and fixed by ordinary nuts after being sleeved by the plastic conical caps, covered with plywood forms and sleeved by 1g type E-shaped cards. During disassembly, the phi 12 full-threaded short screw rods, the M12 long nuts, and the phi 12 long screw rod with the threads at the two ends and the three water stop pieces in the middle only need to be disassembled, the plastic conical caps are removed, and waterproof mortar is used for repair and leveling, so that after the completion of anti-seepage concrete pouring of the ditch and channel side plate or the building outer wall, the redundant screw rods on the two sides can be conveniently removed.

Owner:TONGZHOU CONSTR GENERAL CONTRACTING GROUP +1

Site cast sealed water-stop joint

ActiveCN101666404AImprove sealing rateGuaranteed waterproof performanceSleeve/socket jointsEngineeringWater pipe

The invention discloses a site cast sealed water-stop joint, relating to a water pipe connector and comprising a hollow water pipe connector (1), wherein a bottom edge (2) is arranged on the external peripheral wall at the bottom of the water pipe connector (1) and is provided with a mounting hole (3); a water-stop step (4) is arranged on the external peripheral wall of the water pipe connector (1) above the bottom edge (2); the step face of the water-stop step (4) is provided with at least one water-stop ring (5), and the water-stop step (4) is provided with a groove matched therewith; and adouble-layer plug-in bottom bell mouth is arranged below the water-stop step. The water-stop ring is fixed on the water-stop step on the external surface of the water pipe connector, and simultaneously a dermatoglyph processing section on the external surface of the water pipe connector between the water-stop step and the part from the water-stop step to the bottom edge can ensure the waterproof effect of the water-stop joint and a pre-contact surface, thereby effectively reducing the possibility of leakage due to long time use after installation, and moreover, a site cast fixed hole on the bottom edge can maximally reduce size error when in installation.

Owner:成都川路塑胶集团有限公司

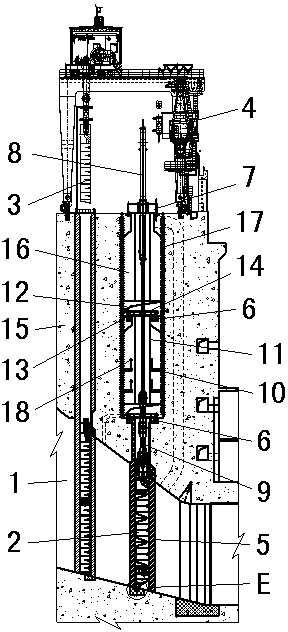

Movable water stop system of final connector and application method

ActiveCN107700537ARealize water stopImprove the water-stop effectArtificial islandsProtective foundationWater flowEngineering

The invention relates to the technical field of immersed tunnels, in particular to a movable water stop system of a final connector and an application method. The final connector and a pushing small beam are provided with an outer water stop device making an annular cavity and outer water flow relatively sealed. The outer water stop device comprises a flexible water stop belt, one end of the flexible water stop belt is connected with the final connector, the other end of the flexible water stop belt is connected with the pushing small beam, and the stretching length of the flexible water stopbelt corresponds to the outward movement length of the pushing small beam. An inner water stop device is further arranged in a cavity body of the annular cavity. The movable water stop system is formed by the outer water stop device and the inner water stop device of the water stop system at the same time. The dual water stop devices are adopted, the function of composite water stop is achieved, and when the outer water stop device leaks or is damaged, the inner water stop device plays a role, the purpose of water stop is further achieved, and smooth installation of the final connector is guaranteed.

Owner:CCCC HIGHWAY CONSULTANTS

I-shaped GFRP-I-shaped steel connector structure, splicing cage for underground diaphragm wall and construction method thereof

PendingCN110424376AShorten the processing cycleReduce construction risk and difficultyExcavationsBulkheads/pilesRebarShield machine

The invention discloses an I-shaped GFRP-I-shaped steel connector structure. The I-shaped GFRP-I-shaped steel connector structure comprises I-shaped steel and I-shaped GFRPs. The I-shaped GFRPs and the I-shaped steel are in seamless connection and are matched in size. The invention further discloses a splicing cage for an underground diaphragm wall. The splicing cage comprises two pieces of spliced I-shaped steel of the I-shaped GFRP-I-shaped steel connector structure. Wing plates of the two pieces of spliced I-shaped steel are connected with main rebars, truss rebars and scissor rebars to form any one of the GFRP cage, the rebar cage and the GFRP-rebar cage, and the main rebars, the truss rebars and the scissor rebars are made of GFRP ribs / rebar materials which are longitudinally and horizontally crossed. The invention further discloses a construction method of the splicing cage for the underground diaphragm wall. The construction method is used for solving the technical problems thatthe water stop effect of the connection portion of the underground diaphragm wall of a starting hole door of a shield tunnelling machine is poor, the starting risk is high, the construction difficulty and the risk degree in the process that an underground shield tunnel line downwards passes through the underground diaphragm wall of a foundation pit enclosure structure are high, and the later-period maintenance is difficult.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Rotary milling type deep stirring water sealing curtain construction method

InactiveCN105113526AWell mixedIncrease usageArtificial islandsUnderwater structuresSodium BentoniteArchitectural engineering

The invention relates to a rotary milling type deep stirring water sealing curtain construction method, which comprises the following steps: 1 concreting cushion construction; 2 marking the construction work position; 3 positioning the center of a milling type mixer; 4 injecting cement slurries: the milling top injects a mixture of bentonite and water when drilling downwards and injects a mixture of cement, bentonite and water when lifting upwards to form a gelling material; 5 cutting slurry: the milling type mixer can cut the soil fully in horizontal direction; 6 moulding a wall: two construction processes of sleeving-milling combination and single extruding can be adopted based on demand in the construction process; 7 repeating steps 3 to 6 to complete the construction process of the whole water sealing curtain. Through the process, the construction quality in the milling type deep stirring water sealing curtain construction can be substantially improved, and a stable underground water sealing curtain can be formed.

Owner:SHANGHAI FOUND ENG GRP

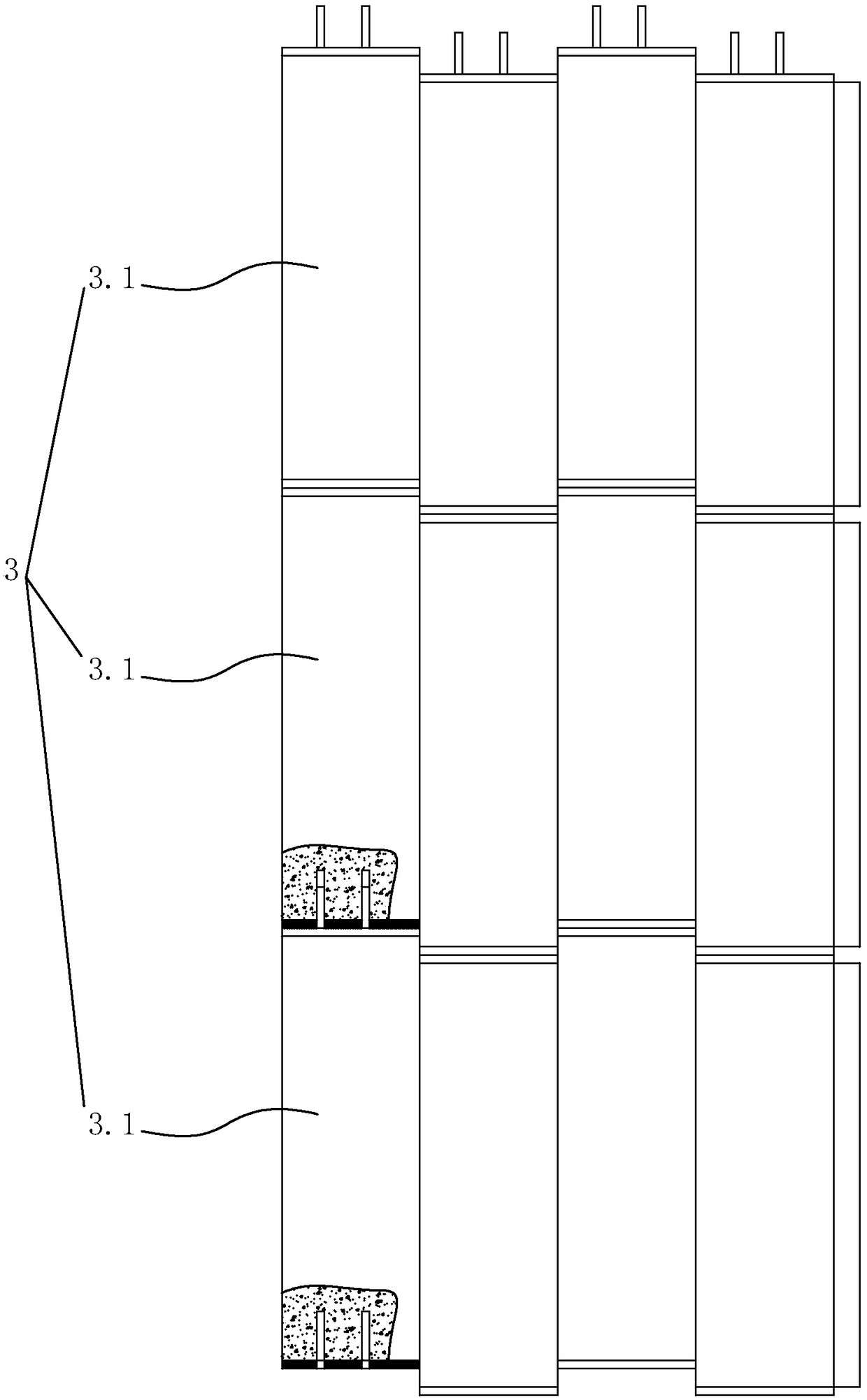

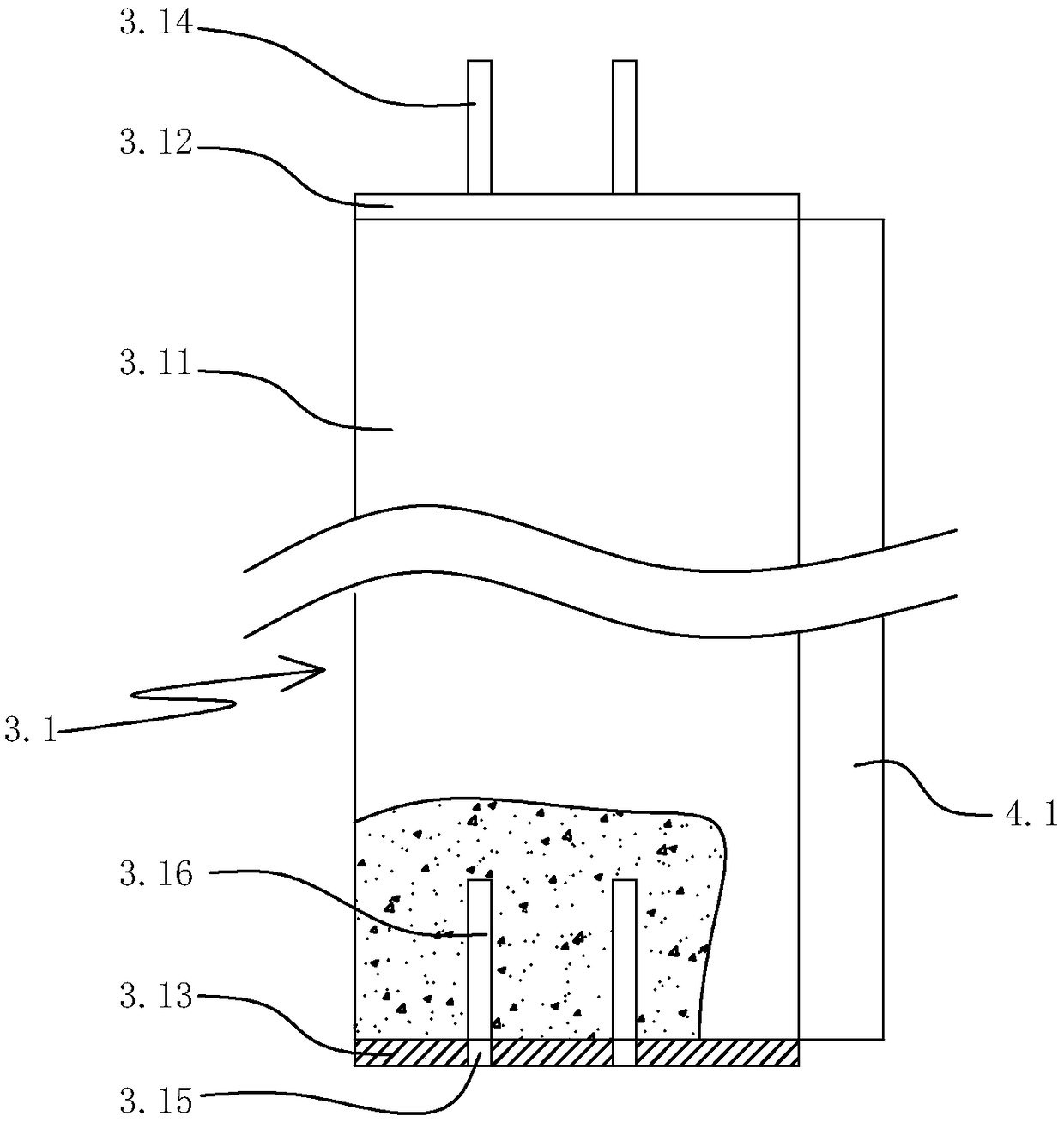

Underground water nest bundle type layered monitoring well system

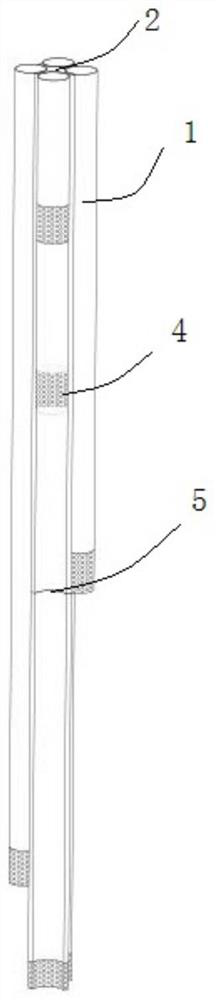

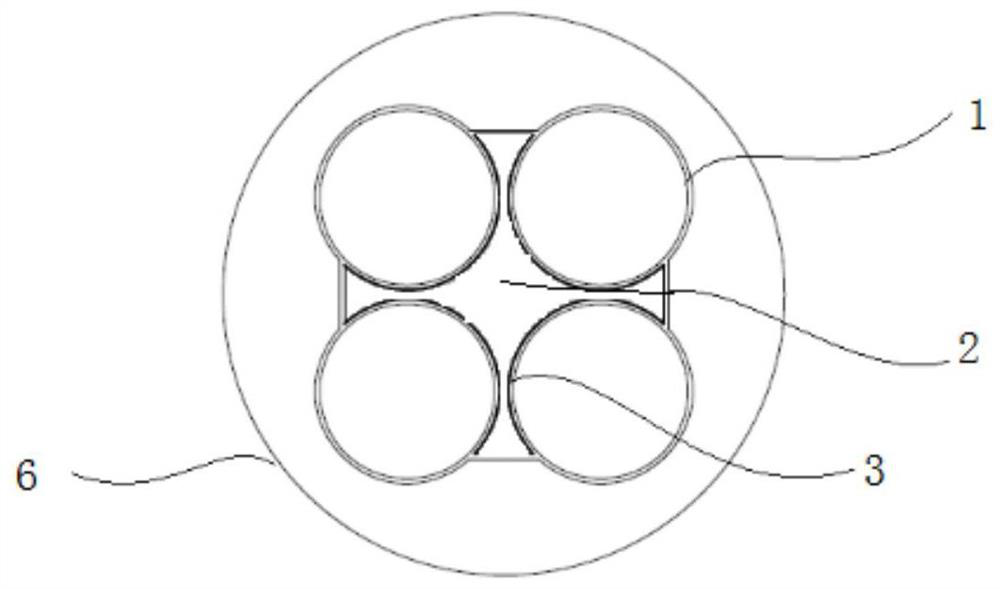

PendingCN113404488ASuitable for embeddingGuaranteed StrengthSurveyWithdrawing sample devicesEngineeringMechanical engineering

The invention relates to the technical field of underground water monitoring, and particularly relates to an underground water nest bundle type layered monitoring well system. The ends of a plurality of monitoring pipes are located on the same surface, the lengths of the plurality of monitoring pipes are different, and the bottom of each monitoring pipe corresponds to a corresponding water-bearing layer; and a plurality of sunken parts are arranged in the circumferential direction of a positioning pipe, the number of the sunken parts corresponds to the number of the monitoring pipes, and the sunken parts are suitable for embedding of the monitoring pipes. The monitoring pipes and the positioning pipe are tightly connected into a bundle type well pipe, the overall strength of the monitoring pipes and the positioning pipe is guaranteed, then the water stopping effect between the monitoring pipes and the positioning pipe is guaranteed, the overall strength of a monitoring well is improved, and the service life of the monitoring well is prolonged. Due to the fact that the monitoring well only needs to be drilled once, each monitoring pipe and the positioning pipe can be monitored corresponding to the multiple water-bearing layers, the process is simple, the construction efficiency and the well forming quality are improved, the number of drilling construction is reduced, the construction and management cost is saved, and large-scale application and popularization are facilitated.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

A face rockfill dam anti-seepage structure

ActiveCN105672205BGuaranteed water stop effectImprove mechanical performanceEarth-fill damsRock-fill damsAbutmentCopper

Owner:POWERCHINA ZHONGNAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com