Channel cutting assembly type underground continuous wall and construction method

An underground diaphragm wall, prefabricated technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of prolonged construction period and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

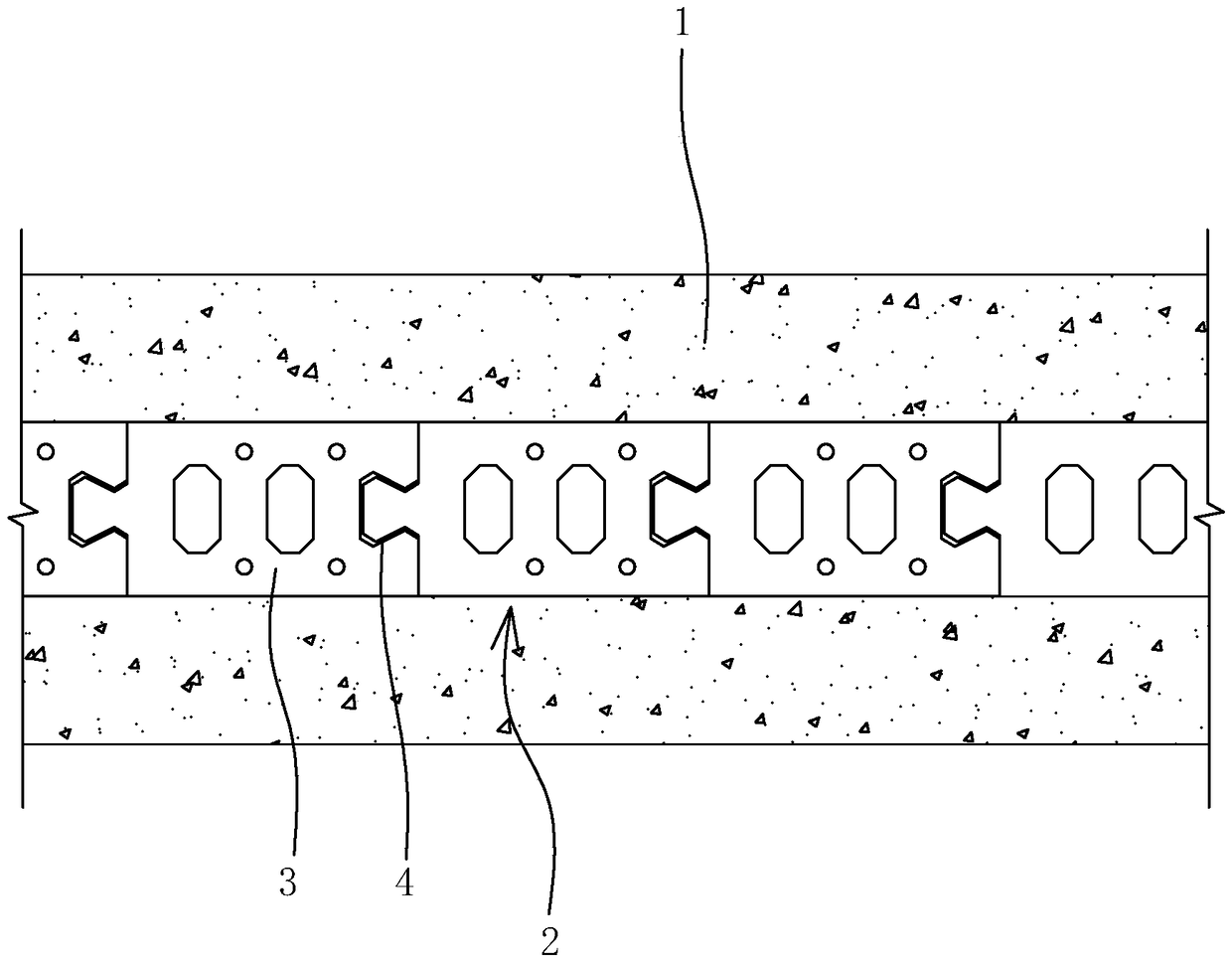

[0082] Embodiment 1: as figure 1 , figure 2 As shown, a canal-cut assembled underground diaphragm wall includes: an underground cement-soil diaphragm wall 1, which is used to block groundwater to form a foundation pit enclosure; and an assembled wall inserted in the underground cement-soil diaphragm wall body member2.

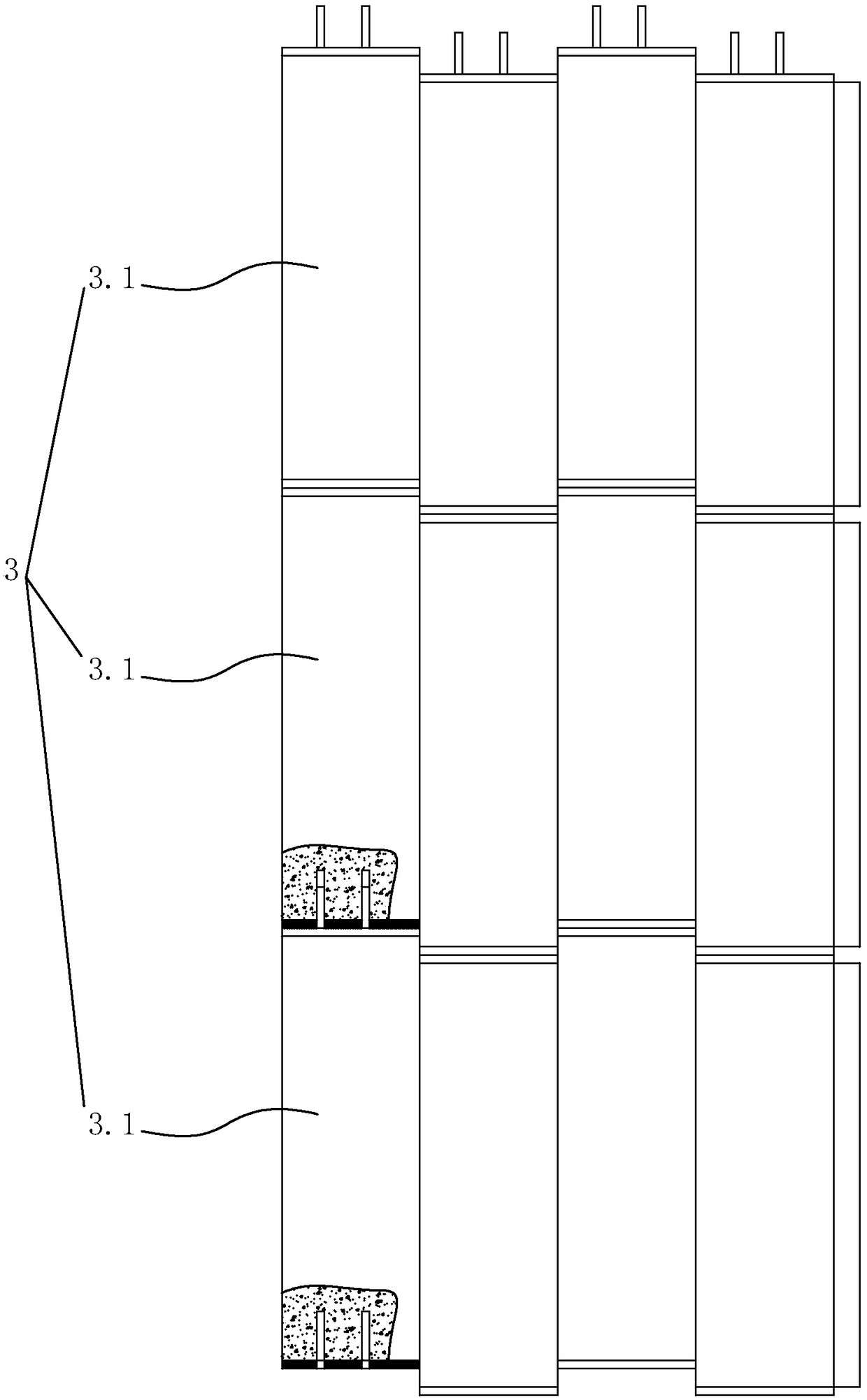

[0083] The prefabricated wall components include a number of vertical reinforced concrete prefabricated parts 3 arranged in sequence along the length direction of the underground cement-soil continuous wall, and two adjacent vertical reinforced concrete prefabricated parts are connected by a mortise and tenon structure 4 .

[0084] Such as figure 1 , Figure 4 As shown, the mortise and tenon structure includes a vertical mortise 4.0 arranged on the side of one of the vertical reinforced concrete prefabricated parts and a vertical mortise 4.0 arranged on the side of the other vertical reinforced concrete prefabricated part and matched with the vertical To t...

Embodiment 2

[0096] Embodiment 2: A construction method of a canal-cut and assembled underground diaphragm wall. For the specific structure of the canal-cut and assembled underground diaphragm wall in this embodiment, refer to Example 1.

[0097] The construction method of the canal-cut prefabricated underground diaphragm wall includes the following steps in sequence:

[0098] Such as figure 1 As shown, an underground cement-soil continuous wall 1 is constructed on the foundation soil, such as a canal-cut cement-soil wall.

[0099] During the construction of the underground cement-soil diaphragm wall, after each construction of an underground cement-soil diaphragm wall with a set length (for example, after each construction of an underground cement-soil diaphragm wall with a set length of 5-10 meters), within this section of the underground cement-soil diaphragm wall Construction of the corresponding prefabricated wall components 2.

[0100] The construction of prefabricated wall compone...

Embodiment 3

[0108] Embodiment 3, the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

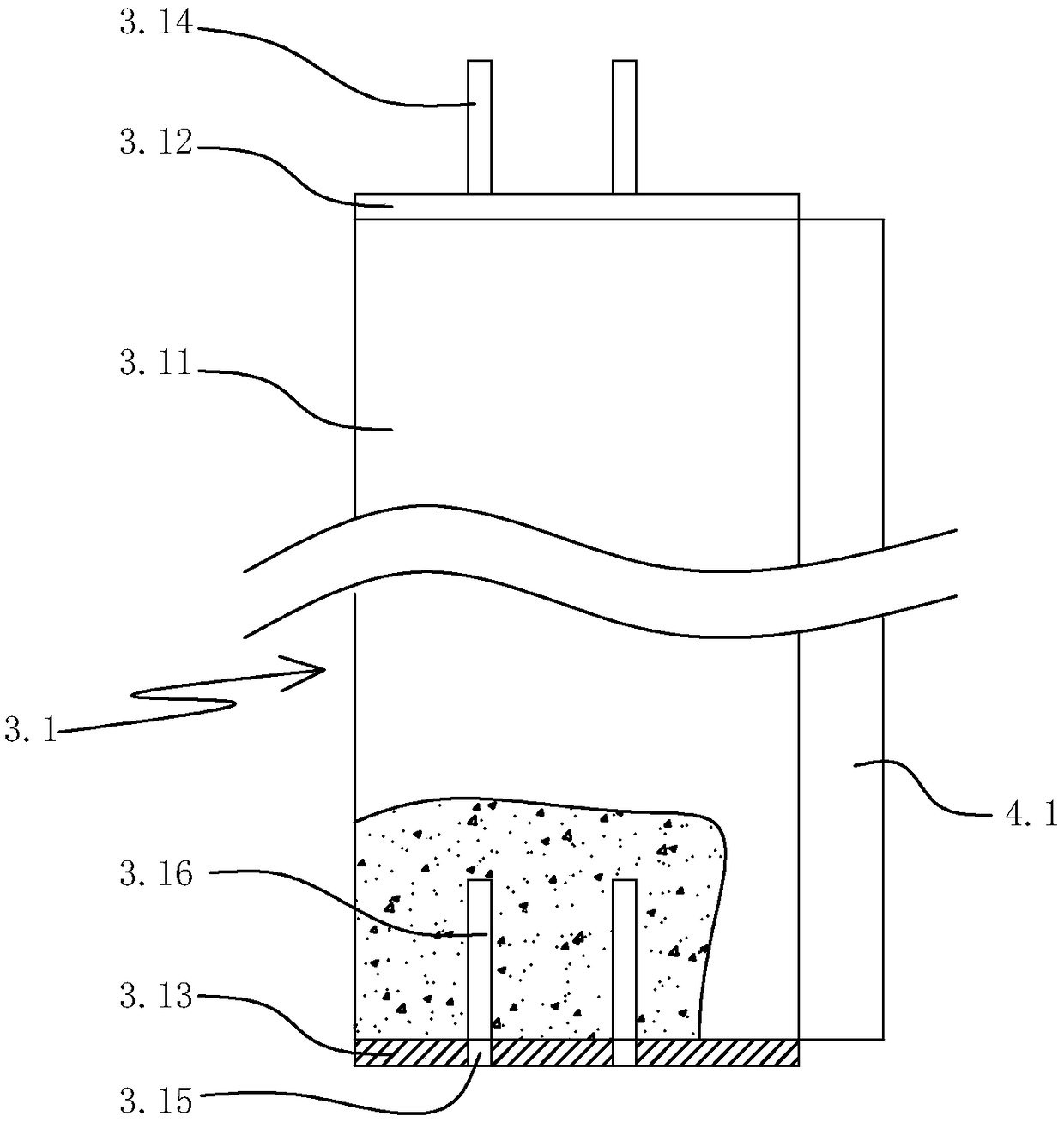

[0109] Such as Figure 5 , Figure 6 As shown, the vertical tenon is composed of several vertical steel pipes 4.11 distributed sequentially from bottom to top. The outer surface of the vertical steel pipe is provided with a number of grout holes 4.12 distributed sequentially from bottom to top, and the grout holes communicate with the inner chamber of the vertical steel pipe.

[0110] The vertical steel pipe is a round pipe. The upper and lower ends of the vertical steel pipe are open. The lower end of the vertical steel pipe is provided with a vertical insertion pipe 4.13. The outer diameter of the vertical insertion pipe is less than or equal to the inner diameter of the vertical steel pipe. Among the two adjacent vertical steel pipes, the vertical insertion pipe on the upper vertical steel pipe is inserted into the upper port of the lower vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com