I-shaped GFRP-I-shaped steel connector structure, splicing cage for underground diaphragm wall and construction method thereof

An underground diaphragm wall and I-shaped steel technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as inconvenient construction, high initial risk, and difficult maintenance in the later stage, so as to reduce construction risk and difficulty and speed up construction. Construction progress and the effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

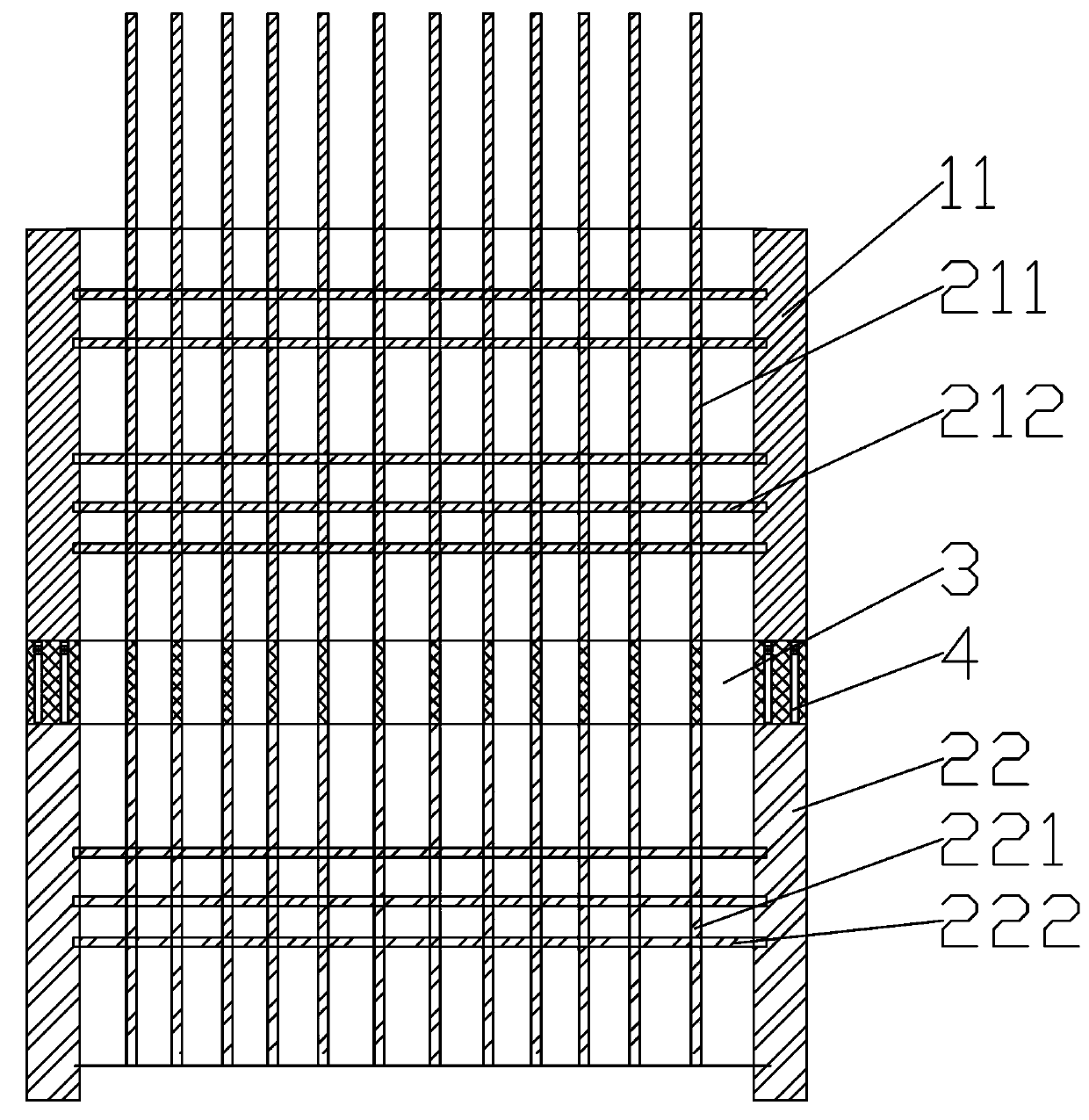

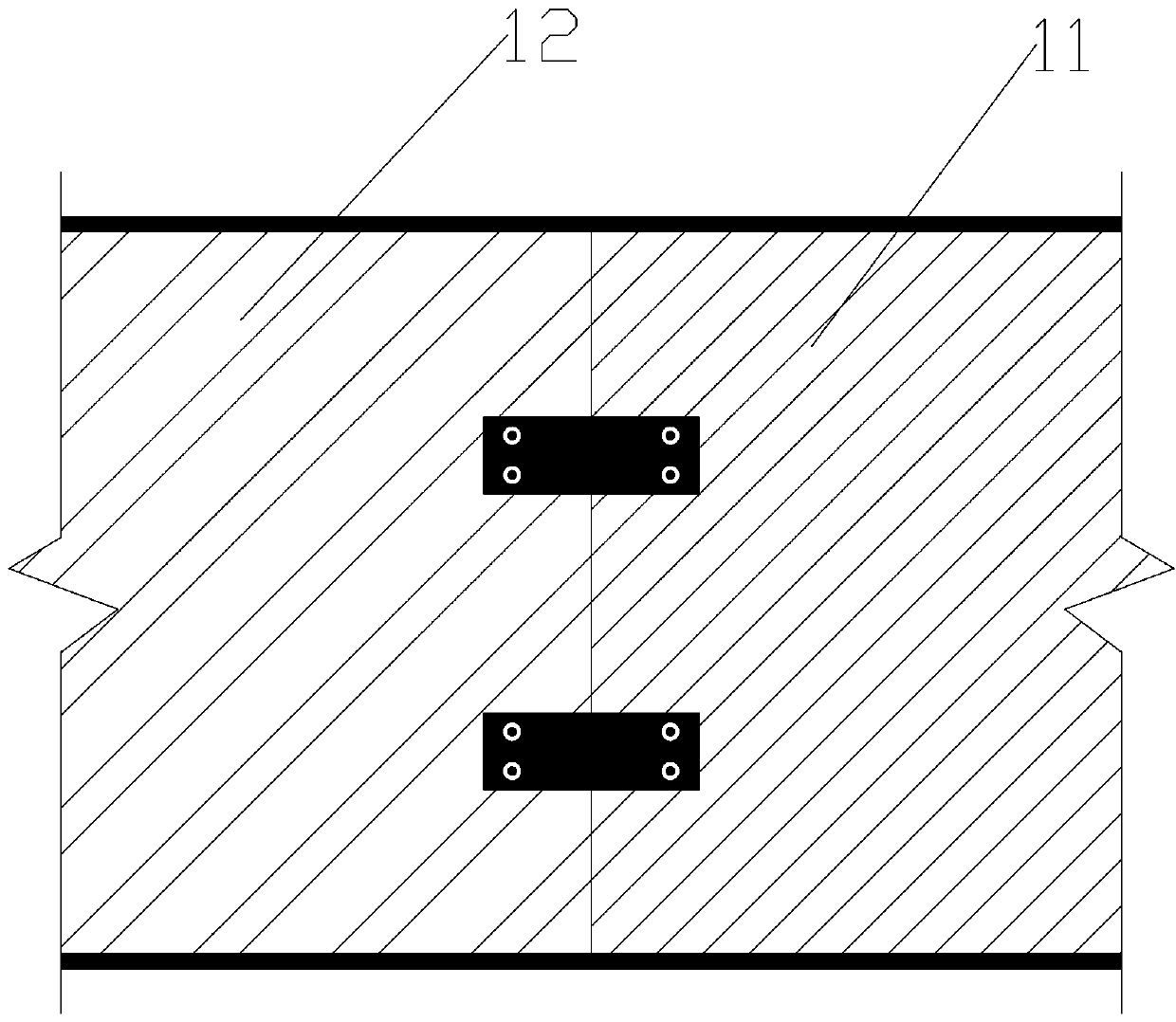

[0036] Embodiment 1: A kind of I-shaped GFRP-I-shaped steel joint structure, see Figure 3-4 , including two spliced I-beams 1, the spliced I-beam 1 includes I-shaped steel 11 and I-shaped GFRP12 seamlessly connected to it through the steel plate 4 and matched in size, wherein the I-shaped steel 11 is welded to the steel plate 4, and the I-shaped steel The type GFRP12 and the steel plate 4 are fixed by punching holes at the corresponding positions of the two and fixing them with screws.

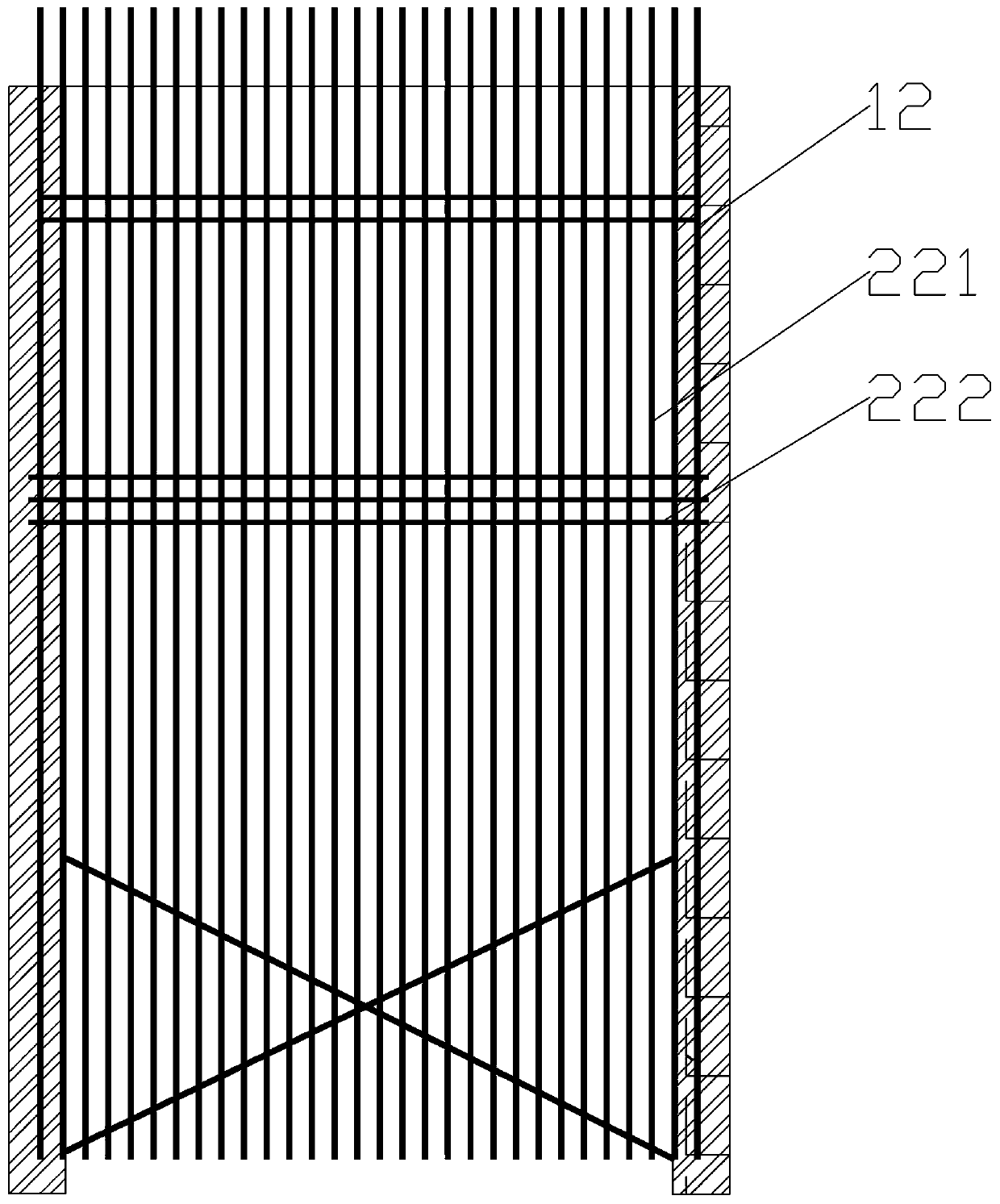

[0037] A splice cage for underground diaphragm walls, see Figure 1-8 The splicing cage includes two above-mentioned splicing I-beams and cage body 2, and the cage body of the I-shaped GFRP12 section is provided with a GFRP reinforcement-steel mixed cage body 22 formed by main reinforcement, distribution reinforcement, truss reinforcement, and scissors reinforcement, wherein the I-shaped The flanges of the GFRP12 section are connected with distribution bars made of 4mm steel wires. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com