Rotary milling type deep stirring water sealing curtain construction method

A water-stop curtain and deep mixing technology, which is applied in the fields of engineering and building engineering, can solve the problems of difficult ultra-deep water-stop curtain construction requirements, limited cutting depth of soil layer, and difficult construction completion, etc., so as to improve cement utilization rate and environmental protection. Small impact, the effect of increasing the cement utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

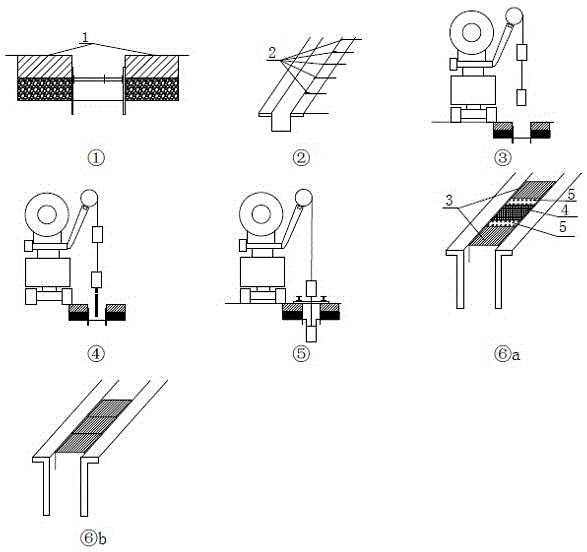

[0016] Such as figure 1 As shown, a rotary milling type deep mixing water-stop curtain construction method includes the following steps:

[0017] 1. Concrete cushion 1 construction ( figure 1 middle ①) to ensure the stability of the construction work surface;

[0018] 2. Mark the location of the construction work, and carry out on-site laying-out according to the design requirements ( figure 1 Middle ②), including milling mixer pay-off 2;

[0019] 3. Milling mixer center positioning ( figure 1 Middle ③), ready to cut in place;

[0020] 4. Jet cement grout ( figure 1 Middle ④), when drilling down, spray the mixture of bentonite and water on the top of the milling to increase the millability of the soil layer, and spray the mixture of cement, bentonite and water on the top of the milling to form a cementitious material;

[0021] 5. cutting mud ( figure 1 Middle ⑤), the milling mixer can fully cut the soil in the horizontal direction, ensure the full mixing between ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com